Blogs

Sputtering Targets Types Explained: 7 Powerful Applications Driving Thin Film Technology | DOMADIA™

Sputtering Targets Types: Why This Hidden Component Decides Coating Success

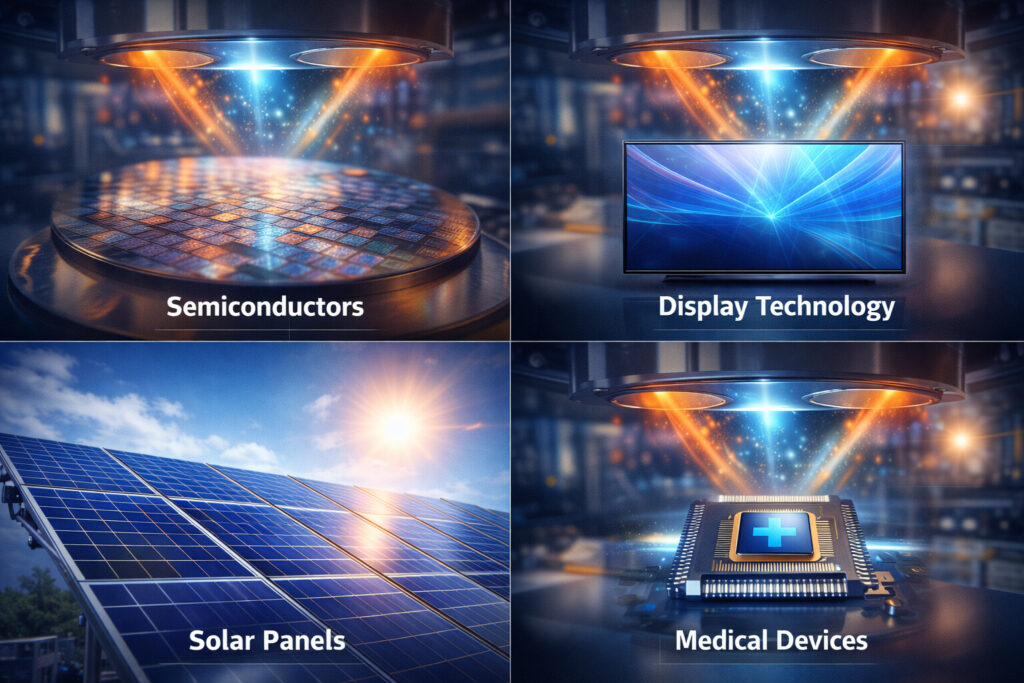

In a semiconductor fab, a display manufacturing line, or a solar panel plant, billions of dollars depend on something most people never see—the sputtering Targets.

When coatings fail, adhesion drops, or electrical performance degrades, the root cause is often not the machine…

It’s the wrong type of sputtering Targets.

Understanding Sputtering Targets Types is no longer optional. It is a reliability decision.

At DOMADIA™, we work closely with coating engineers who have learned this the hard way—after downtime, scrap losses, and requalification delays.

This guide breaks it down clearly, practically, and without fluff.

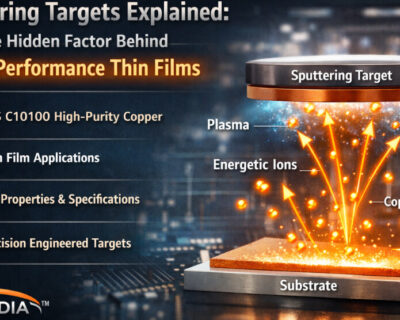

What Is a Sputtering Targets ? (Quick Explanation)

A sputtering Targets is a high-purity material source used in Physical Vapor Deposition (PVD).

When bombarded by energetic ions (usually argon plasma), atoms eject from the Targets and deposit as a thin, uniform film on a substrate.

The type of sputtering Targets directly affects:

- Film purity

- Deposition rate

- Electrical and optical properties

- Coating lifespan

- Process stability

That’s why Sputtering Targets Types matter far more than price alone.

Key Types of Sputtering Targets and Their Applications

1. Metal Sputtering Targets

Examples:

Aluminum, Copper, Titanium, Chromium, Nickel, Molybdenum

Why they’re used:

Metal Targets provide excellent electrical conductivity and uniform deposition.

Applications:

- Semiconductor interconnects

- Display electrodes

- EMI shielding coatings

- Wear-resistant layers

DOMADIA™ Insight:

Even small impurity levels in metal Targets can cause micro-arcing and yield loss.

2. Alloy Sputtering Targets

Examples:

Al-Si, Ni-Cr, Ti-Al, Cu-Sn, Co-Cr

Why they’re used:

Alloy Targets allow property tuning—conductivity, hardness, corrosion resistance—within a single coating.

Applications:

- Thin-film resistors

- Automotive sensors

- Precision electronics

- Decorative functional coatings

Lifecycle Advantage:

Alloy sputtering Targets reduce multilayer complexity and improve process repeatability.

3. Ceramic Sputtering Targets

Examples:

Al₂O₃, ZnO, TiO₂, Si₃N₄, ITO

Why they’re used:

Ceramic Targets deliver dielectric, optical, and insulating properties.

Applications:

- Touch screens and displays

- Optical coatings

- Anti-reflective layers

- Gas and chemical sensors

Key Challenge:

Ceramics require controlled bonding and density to avoid cracking—an area where DOMADIA™ focuses heavily.

4. Compound Sputtering Targets

Examples:

Indium Tin Oxide (ITO), Zinc Aluminum Oxide (AZO), Silicon Carbide

Why they’re used:

Compounds enable multi-functional films—conductive yet transparent, hard yet lightweight.

Applications:

- Solar cells

- Flat panel displays

- Transparent electrodes

- Smart glass

Industry Trend:

As renewable energy grows; compound sputtering Targets are seeing the fastest adoption.

5. Precious Metal Sputtering Targets

Examples:

Gold, Silver, Platinum, Palladium

Why they’re used:

Exceptional conductivity, chemical stability, and catalytic behavior.

Applications:

- MEMS devices

- Medical electronics

- High-end sensors

- Specialty optics

Cost Reality:

Though expensive, longer Targets life and superior film performance justify the investment.

Key Properties That Differentiate Sputtering Targets Types

| Property | Why It Matters |

| Purity (99.9%–99.999%) | Controls film defects |

| Density | Affects sputtering efficiency |

| Grain Structure | Impacts arcing and uniformity |

| Bonding Quality | Prevents delamination |

| Thermal Conductivity | Stabilizes plasma behavior |

DOMADIA™ engineers optimize all five—not just purity.

Standards Followed for Sputtering Targets

- ASTM material specifications

- SEMI standards for semiconductor use

- ISO quality and traceability norms

- Customer-specific qualification protocols

Compliance ensures repeatability across global fabs.

Technical Specifications (Typical Range)

- Purity: 99.9% to 99.999%

- Density: ≥ 99% theoretical

- Thickness: 3 mm to 25 mm

- Diameter / Length: Custom-engineered

- Bonding: Indium / Elastomer / Direct bonding

Shapes Available

- Circular sputtering Targets

- Rectangular planar Targets

- Rotary sputtering Targets

- Custom geometry as per chamber design

DOMADIA™ supports both standard and non-standard shapes.

Mindset Shift: Stop Buying Targets Start Managing Coating Risk

Many teams optimize Targets price per kg.

High-performing teams optimize cost per hour.

The difference shows up in:

- Fewer shutdowns

- Lower scrap rates

- Stable deposition profiles

- Faster scale-up

That’s where the right Sputtering Targets Types pay back.

Why Engineers Choose DOMADIA™

- Material selection support, not just supply

- Consistent batch-to-batch performance

- Application-driven recommendations

- Long-term lifecycle thinking

Conclusion: Sputtering Targets Types Define Thin Film Reliability

Choosing the correct Sputtering Targets Types determines film quality, process stability, and total lifecycle cost.

From metals to ceramics and advanced compounds, DOMADIA™ delivers Targets engineered for real-world performance—not just specifications.

If coating reliability matters, Targets selection must come first.

Choose the Right Sputtering Targets . Protect Your Coating Performance.

Talk to DOMADIA™ specialists to match sputtering Targets types with your deposition process, chamber design, and production goals.

For application-specific sputtering Targets solutions and consistent performance, Contact Us to explore DOMADIA™’s product range and support.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#SputteringTargetsTypes #ThinFilmTechnology #PVDCoatings #SemiconductorMaterials #DOMADIA #AdvancedMaterials #CoatingEngineering

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.