Blogs

Beryllium Copper Non-Sparking Wrench

🔧 Beryllium Copper Non-Sparking Wrenches:

Beryllium Copper (BeCu) is a high-performance alloy composed of approximately 1.8–2% beryllium, with the remainder being copper.This unique composition results in a material that is both exceptionally strong and non-sparking, making it ideal for tools used in environments where flammable substances are present.Non-sparking wrenches made from BeCu are specifically designed to prevent the generation of sparks during use, thereby reducing the risk of igniting volatile materials.

⚙️ Key Properties of Beryllium Copper Wrenches

1. Non-Sparking

The foremost advantage of BeCu wrenches is their non-sparking nature.Unlike traditional steel tools, which can produce sparks upon impact, BeCu tools minimize this risk, making them suitable for use in explosive atmospheres.

2. Non-Magnetic

BeCu is inherently non-magnetic, a crucial property when working near sensitive electronic equipment or in environments where magnetic interference must be avoided.

3. High Strength and Durability

Despite being non-ferrous, BeCu wrenches offer strength comparable to steel tools.They can withstand heavy use without deforming, ensuring longevity and reliability.

4. Corrosion Resistance

BeCu exhibits excellent resistance to corrosion, making these wrenches ideal for use in marine environments or chemical plants where exposure to corrosive substances is common.

🛠️ Applications of Beryllium Copper Non-Sparking Wrenches

BeCu non-sparking wrenches are indispensable in various industries, including:

Oil and Gas:Used on rigs and in refineries where flammable gases are present.

Chemical Plants:Essential for maintenance tasks in environments with volatile chemicals.

Mining:Utilized in underground operations to prevent ignition of combustible gases.

Aerospace:Employed in aircraft maintenance where safety is critical.

Marine:Ideal for shipbuilding and repair, especially in confined spaces with fuel vapors.

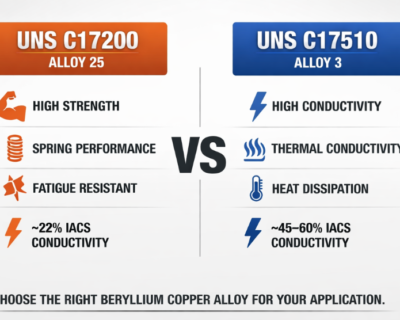

🆚 BeCu vs. Other Non-Sparking Materials

While other materials like Aluminum Bronze are also used for non-sparking tools, BeCu offers superior strength and durability.Aluminum Bronze tools are softer and may wear out faster under heavy use.BeCu’s combination of hardness and corrosion resistance makes it a more reliable choice for demanding applications.

🧼 Maintenance and Safety Considerations

To ensure the longevity and safety of BeCu wrenches:

Regular Inspection:Check for signs of wear or damage before each use.

Proper Cleaning:Clean tools after use to remove any contaminants that could impair their non-sparking properties.

Safe Storage:Store in a dry, clean environment to prevent corrosion.

Avoid Misuse:Use the wrenches only for their intended purposes to maintain their integrity.

🔗 Discover more on our website https://domadia.net/contact/