Blogs

Beryllium Copper Selection: UNS C17200 vs C17510 for Electrical Performance

Beryllium Copper Selection often looks like a material checkbox on a drawing—but in reality, it decides whether an electrical system runs cool, stable, and reliable… or slowly fails under real-world conditions.

A control-panel manufacturer once faced repeated contact failures. The springs looked perfect. The plating was correct. Assembly was flawless. Yet overheating and contact degradation kept returning.

The issue wasn’t workmanship.

The issue was Beryllium Copper Selection.

They had chosen a high-strength alloy where higher conductivity was required.

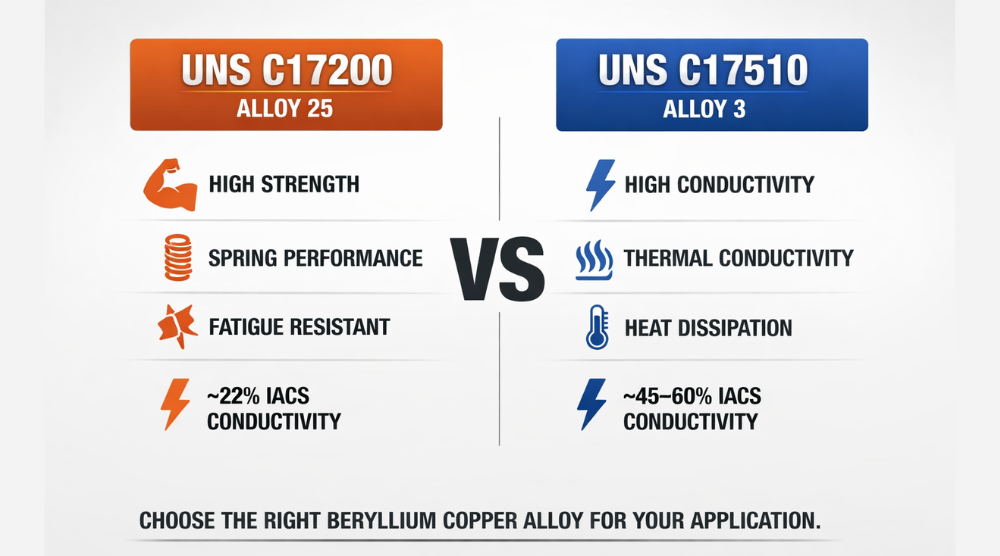

This exact scenario is why engineers frequently compare UNS C17200 vs UNS C17510. Both are premium beryllium copper alloys—but they are designed to solve different electrical problems.

At DOMADIA™, we help customers move beyond “which alloy is better” to the smarter question:

Which alloy performs better for this electrical duty cycle?

Understanding the Core Difference

When discussing Beryllium Copper Selection, the distinction is simple:

- UNS C17200 (Alloy 25) focuses on maximum strength, fatigue resistance, and spring stability

- UNS C17510 (Alloy 3) focuses on higher electrical and thermal conductivity with good mechanical strength

Both are excellent. Choosing incorrectly is expensive.

Chemical Composition Overview

UNS C17200 – High-Strength Beryllium Copper

C17200 contains a higher percentage of beryllium compared to conductivity-focused grades. This chemistry allows it to achieve very high mechanical strength after heat treatment while maintaining useful electrical conductivity.

The composition is optimized for:

- Spring performance

- Fatigue resistance

- Stress relaxation resistance

UNS C17510 – High-Conductivity Beryllium Copper

C17510 uses a chemistry balanced toward conductivity. With controlled additions of nickel and cobalt, it delivers significantly higher electrical and thermal conductivity than C17200, while still retaining good strength.

The composition is optimized for:

- Heat dissipation

- Electrical efficiency

- Stable performance in current-heavy applications

This chemical difference drives the entire Beryllium Copper Selection decision.

Electrical & Mechanical Properties Comparison

Electrical Conductivity

- C17200: Moderate conductivity, typically around 20–25% IACS

- C17510: High conductivity, typically 45–60% IACS

If heat buildup is limiting component life, Beryllium Copper Selection should favor C17510.

Strength & Spring Performance

- C17200: Exceptional tensile strength, yield strength, and fatigue life

- C17510: Moderate strength, not intended for high-stress spring applications

If contact force stability is critical, Beryllium Copper Selection should favor C17200.

Thermal Conductivity

- C17510 transfers heat away faster, reducing thermal degradation

- C17200 retains heat longer due to lower conductivity

Thermal behavior often decides Beryllium Copper Selection in electrical systems.

Technical Specifications (Typical Reference)

| Property | UNS C17200 | UNS C17510 |

| Electrical Conductivity | ~22% IACS | ~45–60% IACS |

| Strength Capability | Very High | Moderate |

| Thermal Conductivity | Moderate | High |

| Fatigue Resistance | Excellent | Good |

| Stress Relaxation | Excellent | Moderate |

| Typical Role | Spring-driven contacts | Current & heat handling |

These values vary by temper and form but clearly illustrate Beryllium Copper Selection logic.

Standards & Material Control

Both alloys are produced under internationally recognized copper alloy standards. Correct specification ensures:

- Consistent chemistry

- Predictable heat treatment response

- Reliable mechanical and electrical performance

At DOMADIA™, we supply both C17200 and C17510 in controlled tempers to ensure design intent is met without surprises.

Applications: Where Each Alloy Clearly Wins

UNS C17200 Applications

Choose C17200 when spring force and durability dominate the requirement:

- Electrical connectors and terminals

- Relay and switch springs

- Precision contact springs

- Components exposed to vibration or cyclic loading

Here, Beryllium Copper Selection prioritizes force retention over conductivity.

UNS C17510 Applications

Choose C17510 when heat and current flow define success:

- Resistance welding electrodes

- High-current electrical contacts

- Heat-sensitive electrical components

- Conductive structural parts

Here, Beryllium Copper Selection prioritizes thermal and electrical efficiency.

Lifecycle Cost: The Real Comparison

At first glance, both alloys appear premium. But lifecycle economics reveal the truth.

- Using C17200 where conductivity is insufficient leads to overheating and early failure.

- Using C17510 where spring force is required leads to loss of contact pressure.

Correct Beryllium Copper Selection reduces:

- Replacement frequency

- Downtime costs

- Warranty claims

- Emergency maintenance

Longer service life almost always offsets material cost differences.

Environmental Impact: Performance Reduces Waste

Every premature replacement adds:

- Scrap generation

- Energy consumption

- Recycling emissions

Because C17200 and C17510 are chosen for long service life when properly applied, correct Beryllium Copper Selection directly reduces environmental impact.

At DOMADIA™, we see material longevity as an engineering-led contribution to sustainability.

Shapes Available from DOMADIA™

DOMADIA™ supplies both UNS C17200 and UNS C17510 in multiple forms:

- Strip & Coil

- Sheet & Plate

- Rod & Bar

- Wire

- Custom-cut blanks

- Precision profiles (as per drawing)

Material form is part of Beryllium Copper Selection, not an afterthought.

A Simple Selection Checklist

Choose UNS C17200 if your design requires:

- High spring force

- Fatigue resistance

- Stable contact pressure

- Long-term mechanical reliability

Choose UNS C17510 if your design requires:

- High electrical conductivity

- Better heat dissipation

- Reduced thermal wear

- Efficient current handling

This checklist solves 90% of Beryllium Copper Selection challenges.

Conclusion

Beryllium Copper Selection is not about picking the strongest or most conductive alloy—it’s about choosing the alloy that prevents failure in your application.

- UNS C17200 protects spring-driven electrical systems.

- UNS C17510 protects current-driven electrical systems.

At DOMADIA™, we don’t just supply beryllium copper—we help engineers select alloys that last longer, fail less, and reduce total cost of ownership.

Choosing between UNS C17200 and UNS C17510 shouldn’t be a guess.

Connect with DOMADIA™to finalize the right beryllium copper alloy for your electrical performance, lifecycle, and form-factor requirements.

Contact Us to make confident beryllium copper alloy decisions for reliable electrical performance.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#BerylliumCopperSelection #UNSC17200 #UNSC17510 #Alloy25 #Alloy3 #ElectricalPerformance #CopperAlloys #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.