Blogs

Analyzing the Interaction Mechanisms of Chromium and Nickel Alloys

Introduction

Nickel-chromium alloys are indispensable in a multitude of high-performance applications, thanks to their exceptional electrical transport properties. The interplay between nickel and chromium within these alloys significantly influences their conductivity and overall performance. This article delves into the intricate electrical transport characteristics of nickel-chromium alloys, examining how their composition and microstructure impact their utility in critical applications such as electronic components and aerospace systems.

With a burgeoning demand in the aerospace and energy sectors, understanding these properties is paramount for engineers and procurement managers aiming to optimize material performance and ensure reliability in extreme conditions. Furthermore, the article explores the corrosion resistance of these alloys, their toxicity and biological effects, and their extensive applications across various industries, providing a comprehensive overview of their current and future significance.

Electrical Transport Properties of Nickel-Chromium Alloys

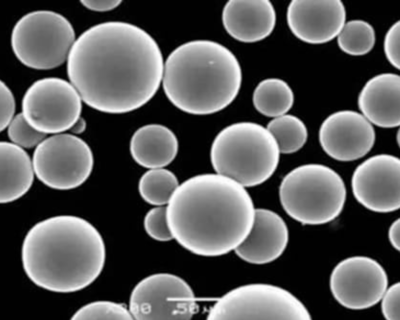

Nickel-chromium mixtures play a pivotal role in various high-performance applications due to their exceptional electrical transport properties. The electrical conductivity of these materials is highly dependent on their specific composition and microstructure. Nickel, known for its excellent conductivity, enhances the overall performance of these alloys. In contrast, chromium’s atomic structure and bonding characteristics can influence electron mobility, impacting the substance’s conductivity. This comprehension is vital for engineers and designers who utilize these substances in essential applications such as electronic components and systems.

In the aerospace sector, the demand for nickel-chromium mixtures is surging, driven by the need for materials that withstand extreme conditions. These metal mixtures are integral in manufacturing aircraft components due to their strength, thermal stability, and resistance to corrosion. The increased demand has led to extended lead times and rising spot prices, particularly in Europe and the United States, as aerospace customers secure high volumes of nickel.

The energy sector also heavily relies on nickel-chromium alloys. In nuclear power stations, these substances are utilized in heat transfer and cooling systems, as well as in reactor vessels and radioactive waste containers. Onshore wind energy employs a specific metal in gearing and generator parts, while fossil fuel power plants take advantage of the corrosion and heat resistance of materials containing that metal, improving the longevity of boilers and heat exchangers.

Furthermore, this metal is a crucial component in lithium-ion batteries for electric vehicles and stationary energy storage systems. Cathodes with a higher proportion of this metal provide greater energy density and extended driving ranges in comparison to those with reduced amounts of it. However, the expense of nickel mixtures remains a challenge, emphasizing the significance of strategic sourcing and supply chain management.

Grasping the complex characteristics of nickel-chromium mixtures and their uses in different sectors is vital for enhancing performance and guaranteeing the dependability of essential systems.

Corrosion Resistance of Nickel-Chromium Alloys

Nickel-chromium materials are celebrated for their remarkable corrosion resistance, which is significantly enhanced by the inclusion of chromium. This addition leads to the formation of a passive oxide layer on the surface, protecting the metal in hostile environments. This characteristic is highly beneficial in sectors like aerospace, chemical processing, and marine industries, where exposure to corrosive elements is prevalent. The durability of nickel-chromium mixtures is further shown in uses such as fossil fuel power plants, where they are chosen for their capacity to withstand high temperatures and pressures, thus enhancing efficiency and decreasing emissions. Likewise, in nuclear power facilities, these materials are essential to both heat transfer systems and reactor vessels, highlighting their dependability and durability. Additionally, their use in LNG facilities and offshore wind turbines highlights their effectiveness in combating seawater corrosion and stress corrosion cracking. Consequently, the intrinsic durability of nickel-chromium alloys guarantees the extended longevity and reliability of parts in numerous challenging uses.

Toxicity and Biological Effects of Nickel and Chromium

Nickel and chromium are indispensable in various industrial applications, yet their toxicity and biological effects cannot be ignored. Extended contact with this metal can lead to allergic responses and additional health issues. Chromium, particularly in its hexavalent form, stands out as a recognized carcinogen. These health concerns are crucial for industries dealing with these materials to understand, ensuring they comply with safety regulations and promote responsible usage. The effect of metal smelting on the environment is clear in Indonesia’s Weda Bay Industrial Park, where pollution has greatly diminished marine life, impacting local fishermen such as Max Sigoro. Furthermore, studies on animals have shown that heavy metals like nickel and chromium can adversely affect cognitive function and behavior, leading to neurotoxicity and neuropsychological disorders. Therefore, it is imperative to adopt proactive approaches to identify and mitigate these environmental and health risks to protect workers and the ecosystem.

Applications and Future Directions of Nickel-Chromium Alloys

Nickel-chromium mixtures are extensively utilized across various sectors due to their exceptional mechanical properties and high resistance to heat and corrosion. These metal mixtures are integral in components for gas turbines, heat exchangers, and medical devices, underscoring their versatility and reliability. The aerospace sector, especially, has experienced a notable rise in demand for these high-performance substances, fueled by the revival of international travel and subsequent requests for new aircraft by major airlines.

The chemical industry’s advancements in chromium catalysts have also spurred demand, with Asia Pacific emerging as a leader in stainless steel production. This region’s rapid economic growth, urbanization, and infrastructure development have significantly influenced the global chromium market. China’s dominance in stainless steel manufacturing further amplifies this trend, highlighting the region’s pivotal role in meeting the growing needs of various industries.

Future research is poised to enhance the properties of nickel-chromium mixtures even further, exploring innovative applications in emerging fields such as renewable energy and advanced manufacturing. The development of new processing facilities, like those planned by Canada Nickel Company, aims to support the transition to greener energy and materials, ensuring a sustainable supply of critical minerals. These initiatives reflect the ongoing efforts to optimize alloy formulations and processing techniques, addressing both current and future industrial demands.

Conclusion

Nickel-chromium alloys are essential in high-performance applications, thanks to their superior electrical transport properties and corrosion resistance. The combination of nickel and chromium enhances conductivity and ensures durability, making these alloys vital in aerospace and energy sectors. As demand for components that withstand extreme conditions grows, understanding their composition and microstructure becomes increasingly important for optimizing performance.

These alloys excel in corrosion resistance, extending the lifespan of components in chemical processing and marine industries, where corrosive exposure is common. Their ability to endure high temperatures and pressures further enhances efficiency and reduces emissions in applications such as fossil fuel power stations and nuclear facilities.

However, the toxicity of nickel and chromium presents health and environmental concerns that must be addressed. Implementing proactive measures is crucial for compliance with safety regulations and for protecting workers and the ecosystem. As industries continue to evolve, effective procurement and management of nickel-chromium alloys will be essential to meet both current and future demands.

In conclusion, advancements in nickel-chromium alloys present significant opportunities for innovation across various sectors. Ongoing research and development will enhance these materials, supporting sustainable practices and meeting the growing needs of the global market. Understanding their properties and implications remains vital for engineers and procurement managers as reliance on these alloys continues to increase.