Blogs

DOMADIA™ Beryllium Copper -UNS C17500 Alloy: The Performance Powerhouse in Rods and Bars

Introduction: Why C17500 Is the Hidden Hero of High-Performance Engineering

Visualize this: you’re designing a high-performance system where the margin for failure is zero. The heat is intense. The electrical load is massive. And your material needs to be both resilient and highly conductive. You’ve tried copper. You’ve considered bronze. But nothing quite fits.

There’s one alloy—often overlooked, rarely understood—that quietly powers aerospace controls, subsea tools, and precision molds around the globe. It doesn’t scream for attention, but when performance is critical, it’s always there, doing what ordinary metals can’t.

This is DOMADIA™ Beryllium Copper C17500.

From ultra-precise injection mold cavities to high-voltage connectors, this material blends strength, conductivity, and thermal reliability like no other. When failure isn’t an option, C17500 isn’t just a choice—it’s the only choice.

Chemical Composition of C17500

| Element | Content (%) |

| Copper (Cu) | Balance |

| Beryllium (Be) | 0.4 – 0.7 |

| Cobalt + Nickel | 1.4 – 2.2 |

| Others | ≤ 0.5 |

This alloy belongs to the high-conductivity class of beryllium coppers, offering an ideal combination of moderate strength and high thermal/electrical conductivity.

Key Properties

| Property | Typical Value |

| Electrical Conductivity | 45 – 60% IACS |

| Thermal Conductivity | ~165 W/m·K |

| Ultimate Tensile Strength (UTS) | Up to 120 ksi (827 MPa) |

| Yield Strength | ~60–100 ksi (414–690 MPa) |

| Hardness (HRB) | 85 – 100 |

| Density | 8.75 g/cm³ |

| Corrosion Resistance | Excellent |

Note: These values can vary based on temper and heat treatment conditions.

Standards and Other Designations

- UNS C17500

- ASTM B441

- ASTM B534

- MIL C-81021

- SAE J461

- SAE J463

This alloy is standardized under multiple international frameworks, ensuring global compatibility for OEMs and industrial designers.

Applications of DOMADIA™ Beryllium Copper C17500

- Electrical and Electronic Components:

- Connectors:

The high electrical conductivity and strength of C17500 make it ideal for connectors, switch components, and relay parts.

- Springs:

Its ability to maintain spring action at high temperatures makes it suitable for current-carrying springs and contacts in various electrical and electronic devices.

- Other Electronic Components:

It’s used in cable shielding, heating elements, and other applications where high strength is needed with good conductivity.

- Machined Parts and Precision Components:

- Precision Screw Machined Parts:

C17500 is well-suited for high-precision machining due to its strength and machinability.

- Bearing Applications:

Its wear resistance and strength make it suitable for bearings in various industrial and automotive applications.

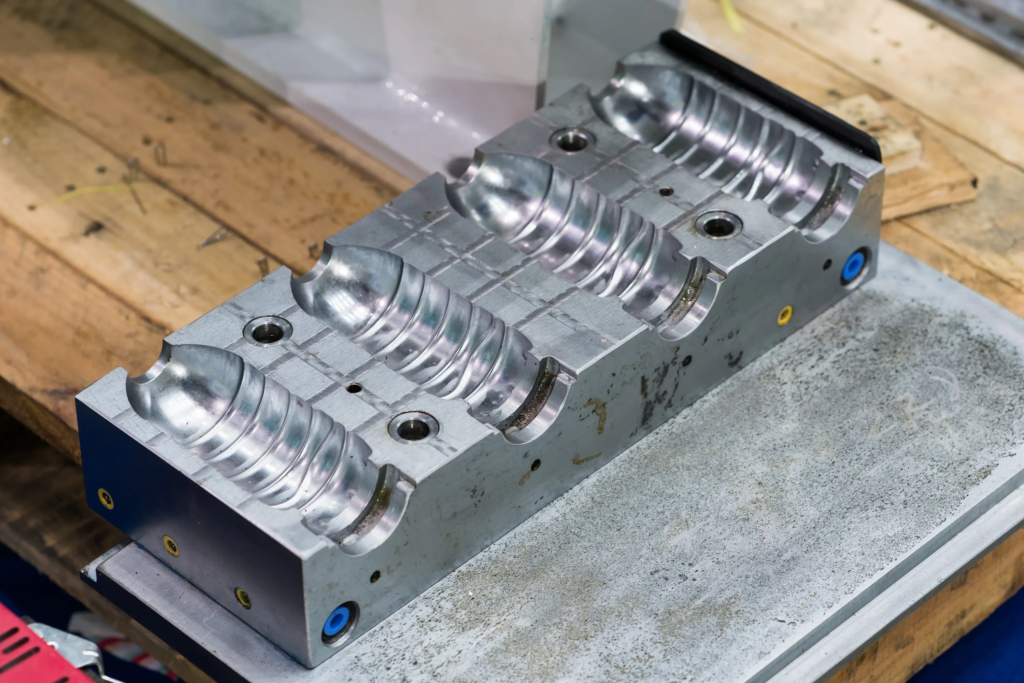

- Plastic Molds:

C17500’s hardness and strength enable it to withstand the high pressures and temperatures involved in plastic molding.

- Corrosion-Resistant Components: Its resistance to corrosion in various environments makes it suitable for applications like marine equipment, chemical processing equipment, and other harsh environments.

- Other Applications:

- Welding Electrodes:

The high conductivity and strength of C17500 make it suitable for welding electrodes.

- Automotive and Aerospace:

It’s used in high-performance automotive components and aerospace applications where strength and durability are crucial.

- Other Industrial Components:

It can be found in housings for magnetic sensing devices, fuse clips, fasteners, and other industrial components.

Technical Specifications

· Machinability: Excellent, especially when using carbide cutting tools.

· Welding ability: Fair. Brazing is preferred over traditional welding methods.

· Workability:

- Hot Work: Good – suitable for high-temperature forming.

- Cold Work: Limited – not ideal for cold forming operations.

· Heat Treatment: Required to achieve full mechanical strength and desired properties.

· Magnetic Properties: Completely non-magnetic, suitable for electronic and precision environments.

Available Forms

DOMADIA™ C17500 is currently available in the following shapes:

Custom sizes and tempers are available upon request for specialized applications.

Why Choose DOMADIA™ C17500?

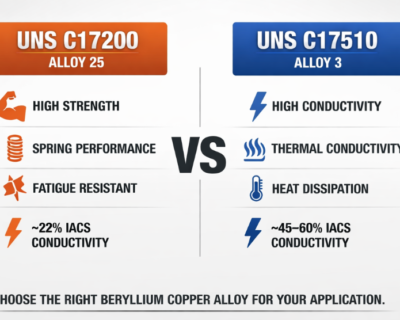

- Balanced Performance: Unlike C17200 which emphasizes strength, C17500 offers a balance of conductivity and mechanical strength.

- Reliable Quality: DOMADIA™ ensures consistency in metallurgical quality and dimensional tolerances.

- Ready-to-Ship Shapes: Our rods and bars are stocked for fast dispatch, ensuring minimum lead time for your critical operations.

Conclusion: DOMADIA™ Beryllium Copper C17500—Engineered for Extreme Expectations

In environments where heat, current, and stress collide, DOMADIA™ Beryllium Copper C17500 stands tall. With its unique capability to blend conductivity with strength, it’s no wonder top engineers are making the shift from traditional alloys to C17500 for next-generation performance.

Need a high-conductivity, high-strength solution for your application? Choose DOMADIA™. Choose performance.

Request a quote now and experience the DOMADIA™ advantage with high-performance Beryllium Copper C17500.

Visit our website on https://domadia.net/

Talk to our experts: Kairav Domadia | Aadil Domadia | Er.Pankaj Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia