Blogs

Understanding Monel Mesh: An In-Depth Tutorial on Properties and Uses

Introduction

In the realm of industrial materials, Monel mesh emerges as a standout choice, particularly in environments where durability and corrosion resistance are paramount. Composed primarily of nickel and copper, this versatile alloy not only offers exceptional mechanical properties but also excels in demanding applications across various sectors, including:

- Marine

- Oil and gas

- HVAC

Recent advancements in research highlight the alloy’s impressive yield and ultimate strength, reinforcing its suitability for critical components. As procurement managers navigate the complexities of material selection, understanding the unique advantages of Monel mesh becomes essential. This article delves into the properties, applications, and comparative advantages of Monel mesh, providing valuable insights for informed decision-making in procurement strategies.

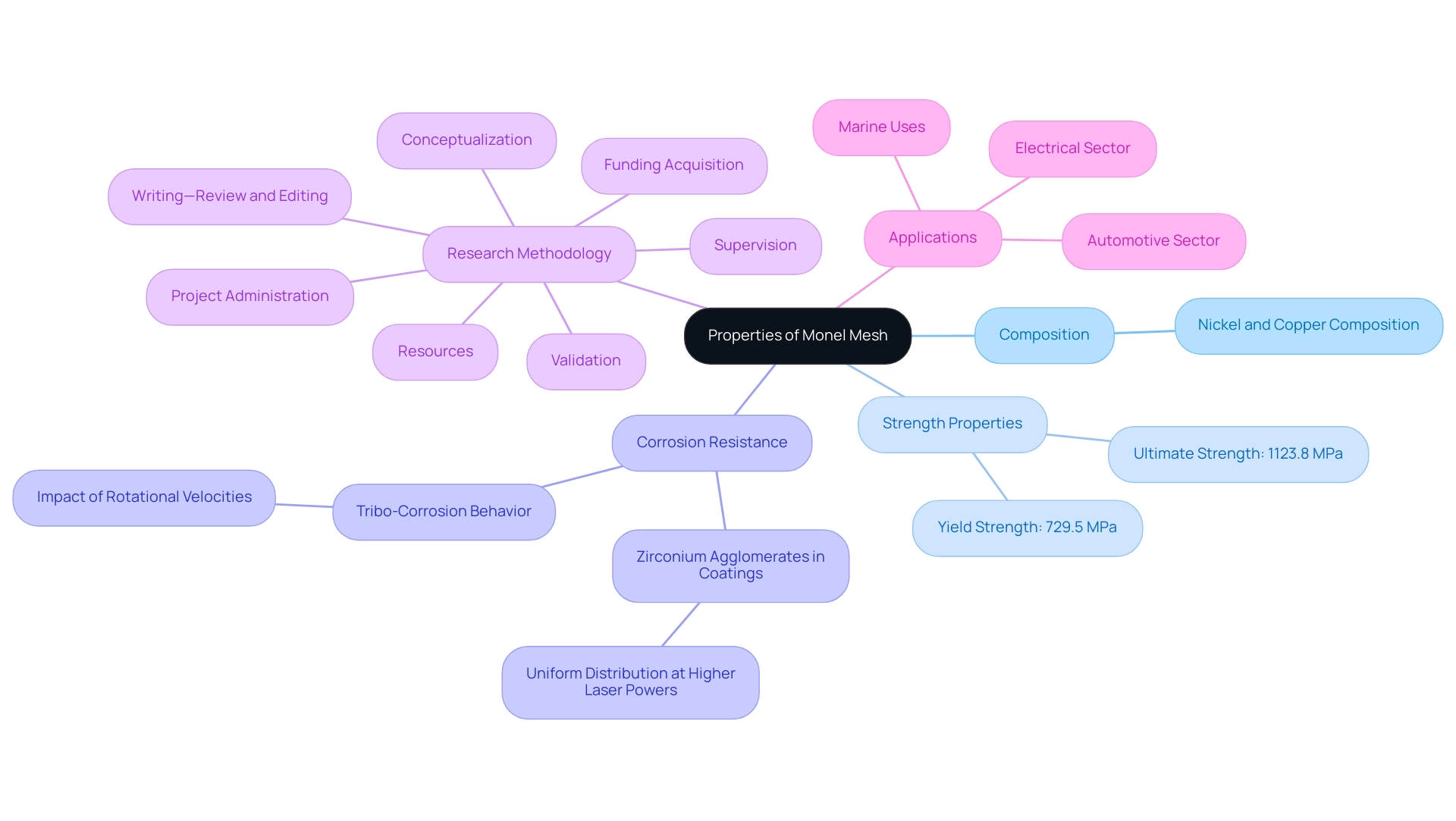

Exploring the Properties of Monel Mesh

This type of mesh, known as monel mesh, is primarily composed of nickel and copper and is renowned for its exceptional properties that make it a preferred choice in demanding environments. At Domadia, we provide a varied selection of copper nickel alloys, including a specific type that is especially beneficial in marine uses because of their exceptional ability to withstand corrosion and oxidation. Recent research highlights that the alloy 400 exhibits a yield strength of 729.5 MPa and an ultimate strength of 1123.8 MPa, underscoring its superior structural integrity under stress.

Furthermore, a study titled ‘Tribo-Corrosion Behavior of Alloy 400’ investigates its performance in marine settings, revealing that varying rotational velocities significantly impact its wear and corrosion resistance. These findings enhance comprehension of the alloy’s durability, which is vital for procurement managers evaluating material appropriateness in particular uses. As Katrin Jahns noted, the comprehensive research involved:

- Conceptualization

- Funding acquisition

- Project administration

- Resources

- Supervision

- Validation

- Writing—review and editing

highlighting the thoroughness of the study.

Furthermore, recent EDS tests confirmed the presence of agglomerates enriched with zirconium in the coatings, with a more uniform distribution of Zr at higher laser powers, indicating advancements in material properties that may further enhance nickel-copper alloy applications. Along with its strength, this metal grid provides excellent thermal and electrical conductivity, rendering it adaptable in numerous industrial fields, such as automotive and electrical sectors. The blend of these characteristics makes monel mesh a strategic option for those evaluating materials that can endure the challenges of marine settings, guaranteeing long-term dependability and effectiveness.

We encourage procurement managers to explore our extensive product catalog for specific copper nickel alloy solutions tailored to their project needs, with easy access to product information and customer support available to assist in the selection process.

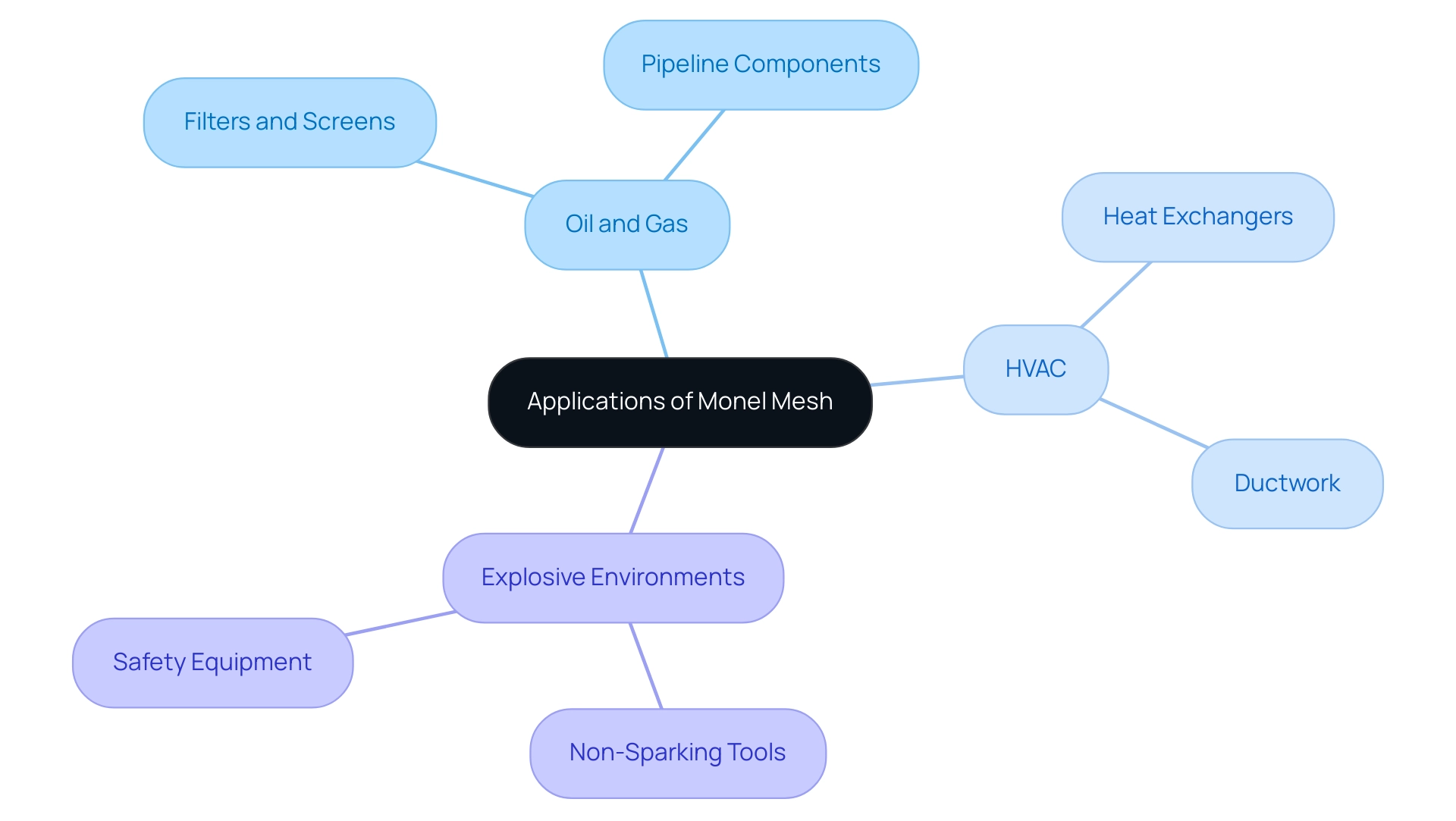

Applications of Monel Mesh in Various Industries

This alloy, while showcasing remarkable adaptability across various sectors, especially in oil and gas and HVAC uses, can also function as an option in situations where non-sparking tools are vital. In the oil and gas sector, alloy mesh is integral to the design of filters and screens, delivering longevity and reliability even in the most corrosive environments. This material’s built-in corrosion durability makes it an ideal choice for critical components, thereby lowering maintenance costs and enhancing operational efficiency.

Notably, statistics indicate that alloy 500, with its heightened resistance to abrasion and erosion, is particularly effective in applications such as pipeline filters and separators, where durability is crucial to maintaining system integrity.

In explosive environments, Non-Sparking Tools constructed from materials such as nickel-copper alloy can prevent ignition risks, making them essential for safety. In the HVAC sector, a nickel-copper alloy netting has its role in heat exchangers and ductwork where durability is essential. Its capability to endure elevated temperatures without jeopardizing mechanical attributes is clearly illustrated in the case study of alloy 400 wire fabric, which has been considered appropriate for high-temperature uses involving steam and hot water.

This adaptability ensures efficient filtration, allowing the specific material to effectively remove particulates from liquids and gases, thereby maintaining optimal system performance.

As industry leaders emphasize, understanding material capabilities is crucial for procurement strategies, particularly when selecting non-sparking tools for hazardous environments. This highlights the strategic significance of this material in procurement approaches, as it not only fulfills the stringent requirements of various sectors but also aids in sustainable operational practices while ensuring safety in explosive environments.

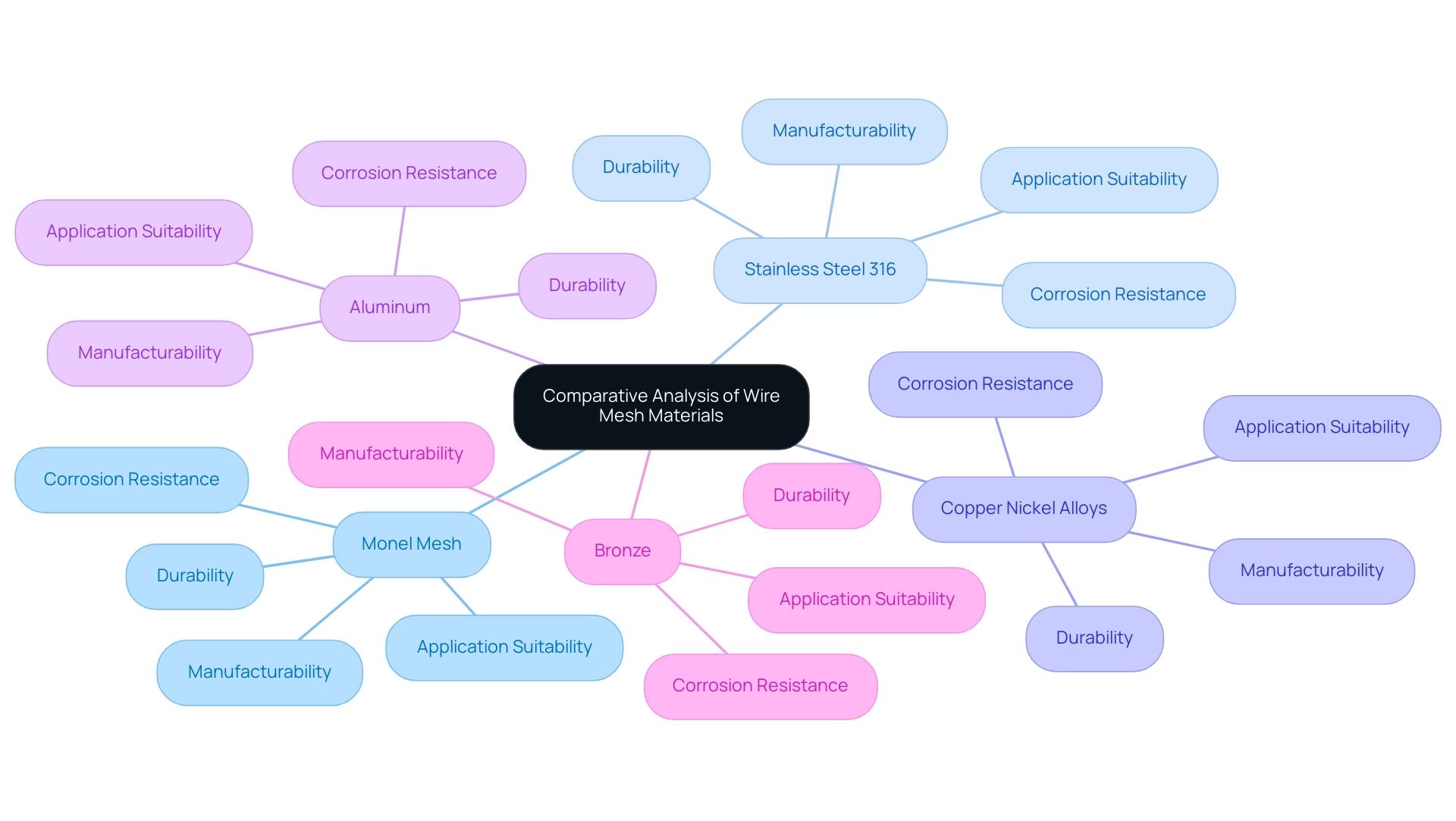

Comparative Analysis: Monel Mesh vs. Other Wire Mesh Materials

The mesh made from this alloy stands out in comparisons with materials such as stainless steel, aluminum, and bronze due to its exceptional properties. For instance, in the case study titled ‘Monel 400 vs 316 Stainless Steel,’ this alloy excels in marine and chemical settings, demonstrating its advantage over stainless steel 316, which, although acknowledged for its effective corrosion protection, cannot match its performance in highly acidic and alkaline conditions. Furthermore, copper nickel alloys, akin to a specific metal, provide considerable benefits in these situations, such as:

- High durability against corrosion

- Outstanding thermal and electrical conductivity

- Good ductility

- Antimicrobial characteristics

These properties render them perfect for electrical uses and environments that require hygiene sensitivity.

Although stainless steel 316 displays improved durability in specific corrosive environments, the hardness of copper nickel alloys exceeds that of many stainless steel varieties, strengthening their status as ideal selections for harsh conditions. Moreover, copper nickel alloys are simpler to manufacture, increasing their attractiveness for diverse uses. In contrast, aluminum is lighter but lacks the necessary strength and durability that copper nickel alloys offer, making them less suitable for critical applications.

Although bronze netting is recognized for its durability, it still falls short of the performance of copper nickel alloys when subjected to extreme environmental factors. Ultimately, as emphasized by the quote, ‘the best material depends on your specific requirements, such as the level of corrosion durability, strength, cost considerations, and the operating environment.’ Therefore, in situations that demand high resistance to both corrosion and mechanical stress, nickel-copper alloys emerge as preferred materials, ensuring reliability and longevity in critical applications.

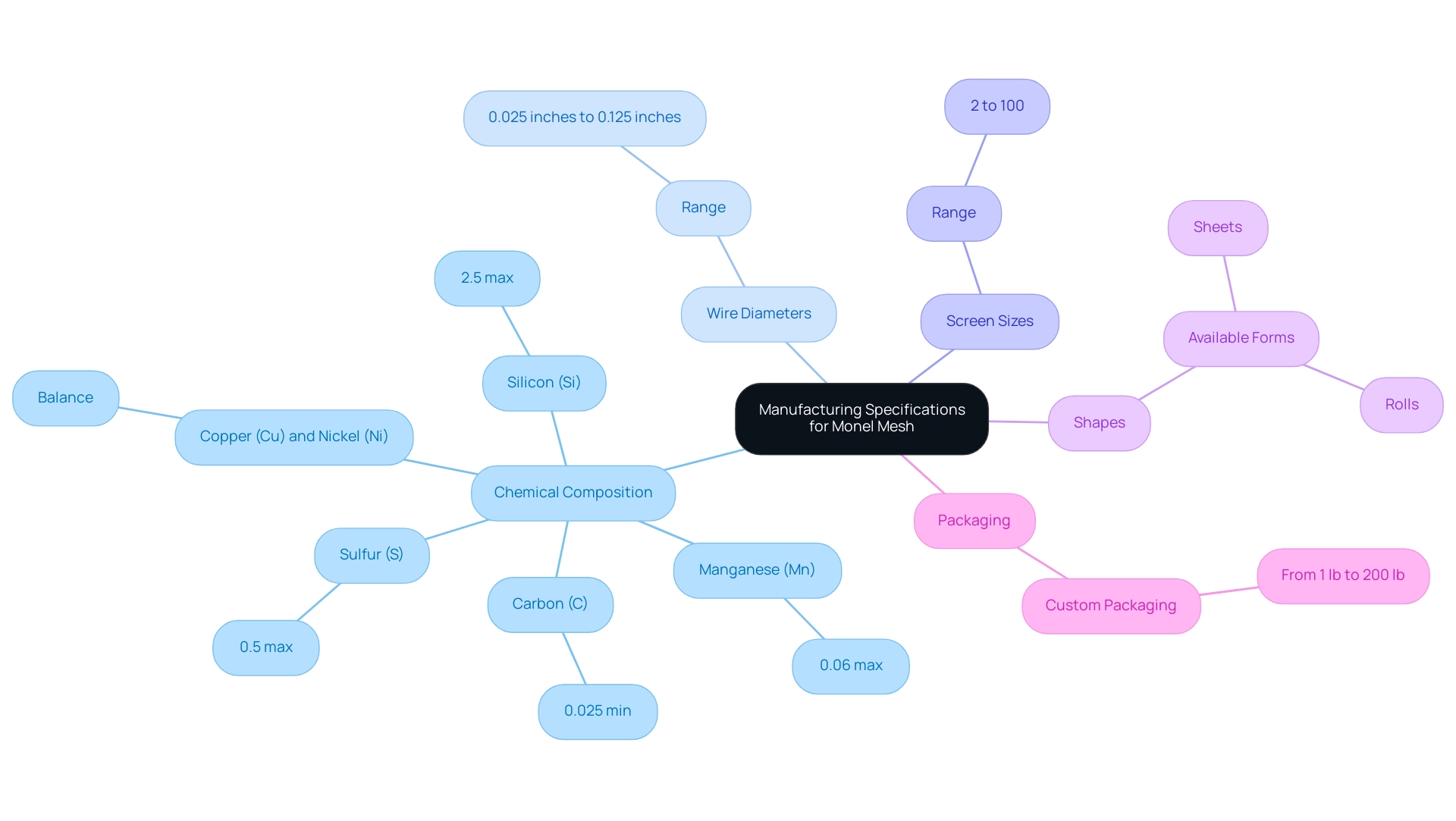

Manufacturing Specifications and Standards for Monel Mesh

The alloy fabric is produced in accordance with stringent industry standards, particularly ASTM B164, which outlines the specifications for wire and fabric products. The chemical composition limits for alloy 400 as specified in QQ-N-281 include:

- Carbon (C) 0.025 min

- Manganese (MN) 0.06 max

- Sulfur (S) 0.5 max

- Silicon (Si) 2.5 max

- Copper (Cu) and Nickel (Ni) being the balance.

Common wire diameters for nickel-copper alloy screens typically range from 0.025 inches to 0.125 inches, while screen sizes can vary significantly, spanning from 2 to 100.

According to particular usage requirements, this mesh can be produced in various shapes, including sheets and rolls. Additionally, custom packaging for Alloy 400 Wire is available from as low as 1 lb to 200 lb, providing flexibility for procurement managers. Following these specifications is crucial for guaranteeing that the final products comply with international quality standards, thus improving their performance in end-use scenarios.

As highlighted by Seamac Piping Solutions Inc., our company is providing a comprehensive selection of 400 Rod, Bars, Wire, and Monel mesh Wire Mesh at very reasonable rates to our domestic as well as global clients. This dedication to quality and adherence to ASTM B164, combined with their well-developed warehouse and storage capabilities, strengthens the reliability and efficiency of this alloy in various industrial applications, ensuring that urgent customer requirements are met.

Maintaining and Caring for Monel Mesh Products

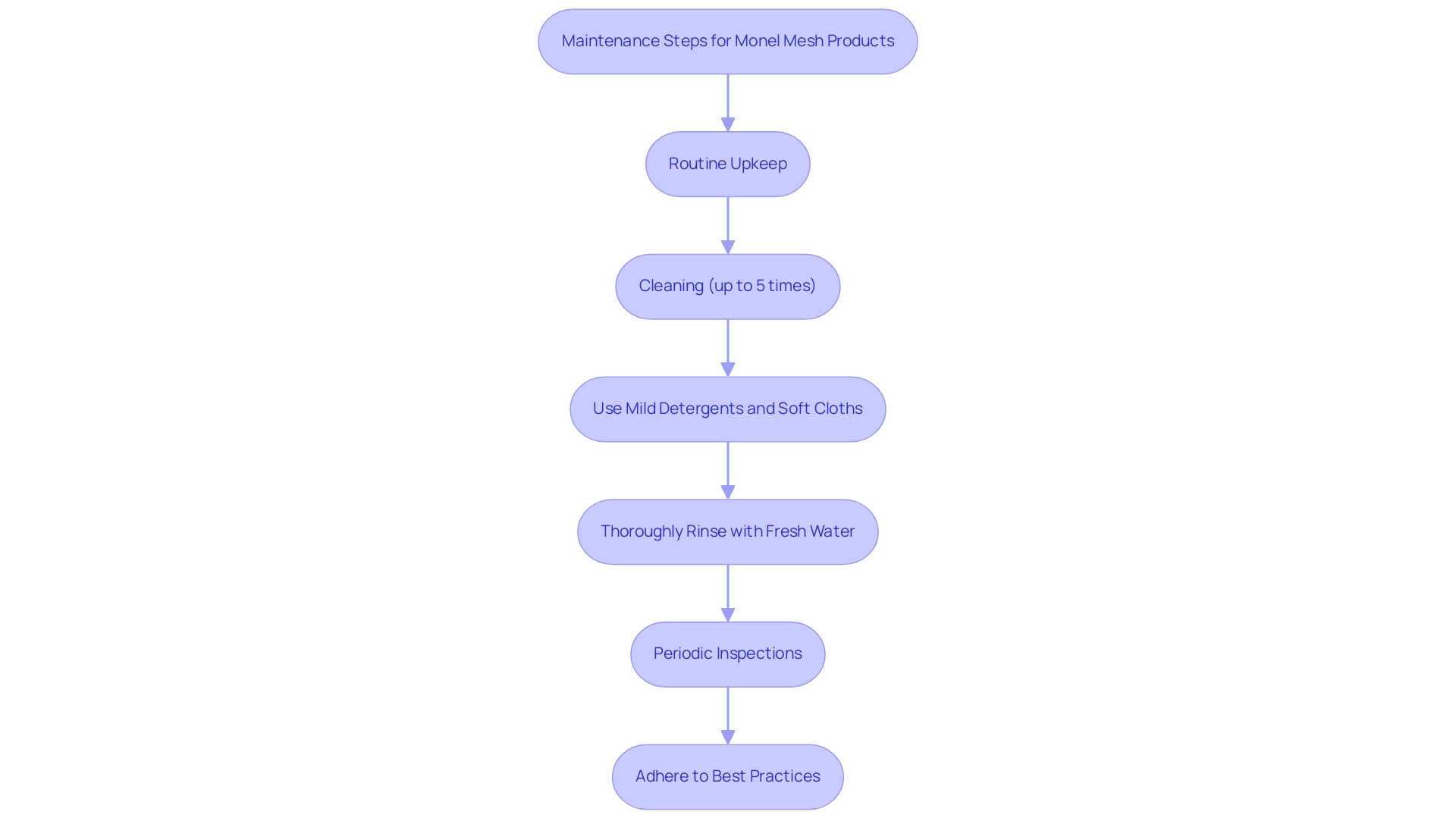

Routine upkeep of nickel-copper alloy products is essential to avoid contaminant accumulation that can hasten corrosion. It is noteworthy that these filter cartridges can be cleaned up to 5 times before needing replacement, highlighting the effectiveness of proper maintenance practices. Employing mild detergents and soft cloths during cleaning is essential, as abrasive materials can scratch and compromise the integrity of the surface.

In industrial environments where the alloy grid is often subjected to harsh chemicals, it is recommended to thoroughly rinse the grid with fresh water to neutralize corrosive effects. Additionally, conducting periodic inspections for signs of wear and tear will help identify potential issues early, allowing for timely interventions that ensure optimal performance. The characteristics of Alloy 400, which is recognized for its exceptional resistance to corrosion and wear, highlight the significance of these maintenance practices.

By adhering to these best practices, procurement managers can significantly enhance the longevity and reliability of monel mesh products, ultimately contributing to more efficient operations. As Filson states, ‘All the products will be packed and delivered directly from our factory to save time,’ ensuring a reliable supply of quality materials.

Conclusion

Monel mesh represents a crucial material choice for industries requiring exceptional durability and corrosion resistance. Its unique composition, primarily of nickel and copper, equips it with outstanding mechanical properties that are essential in demanding environments such as marine, oil and gas, and HVAC applications. The findings from recent research underscore Monel’s impressive strength and resilience, making it a strategic option for critical components where reliability is paramount.

The versatility of Monel mesh extends beyond its mechanical advantages; it serves vital roles in various applications, including:

- Non-sparking tools for hazardous environments

- Effective filtration systems in oil and gas

Its ability to withstand extreme conditions while maintaining performance not only reduces maintenance costs but also enhances operational efficiency. Furthermore, comparative analyses reveal that Monel consistently outperforms alternatives like stainless steel and aluminum, solidifying its position as a preferred choice for procurement managers.

Understanding the manufacturing specifications and maintenance requirements of Monel mesh ensures that procurement strategies are grounded in quality and longevity. By adhering to industry standards and implementing proper care practices, organizations can maximize the lifespan and performance of Monel products. As industries continue to evolve, the strategic selection of Monel mesh will undoubtedly contribute to sustainable operational practices and enhanced safety measures across various sectors.