Blogs

Best Practices for Magnetic Shielding in Magnetic Resonance Imaging (MRI): Expert Insights

Overview:

The article focuses on best practices for magnetic shielding in MRI systems, emphasizing the importance of effective shielding to ensure high-quality imaging by blocking external magnetic fields and reducing radiofrequency interference. It supports this by detailing the use of specific materials like DOMADIA Oxygen Free Copper and mica tape, as well as the necessity for thorough site assessments and compliance with safety regulations to enhance MRI performance and patient safety.

Introduction

In the realm of magnetic resonance imaging (MRI), the importance of effective magnetic shielding cannot be overstated. As healthcare facilities strive to deliver high-quality imaging, the challenges posed by external magnetic fields and radiofrequency interference become increasingly apparent.

Understanding the intricacies of magnetic shielding—from the selection of advanced materials like DOMADIA Oxygen Free Copper to the implementation of innovative shielding technologies—is essential for procurement managers tasked with enhancing MRI system performance.

This article delves into the fundamental principles of magnetic shielding, best practices for implementation, the challenges faced, and the latest innovations that promise to elevate safety and imaging quality in MRI environments. By exploring these facets, readers will gain valuable insights into optimizing their MRI facilities while ensuring compliance with regulatory standards.

Fundamentals of Magnetic Shielding in MRI

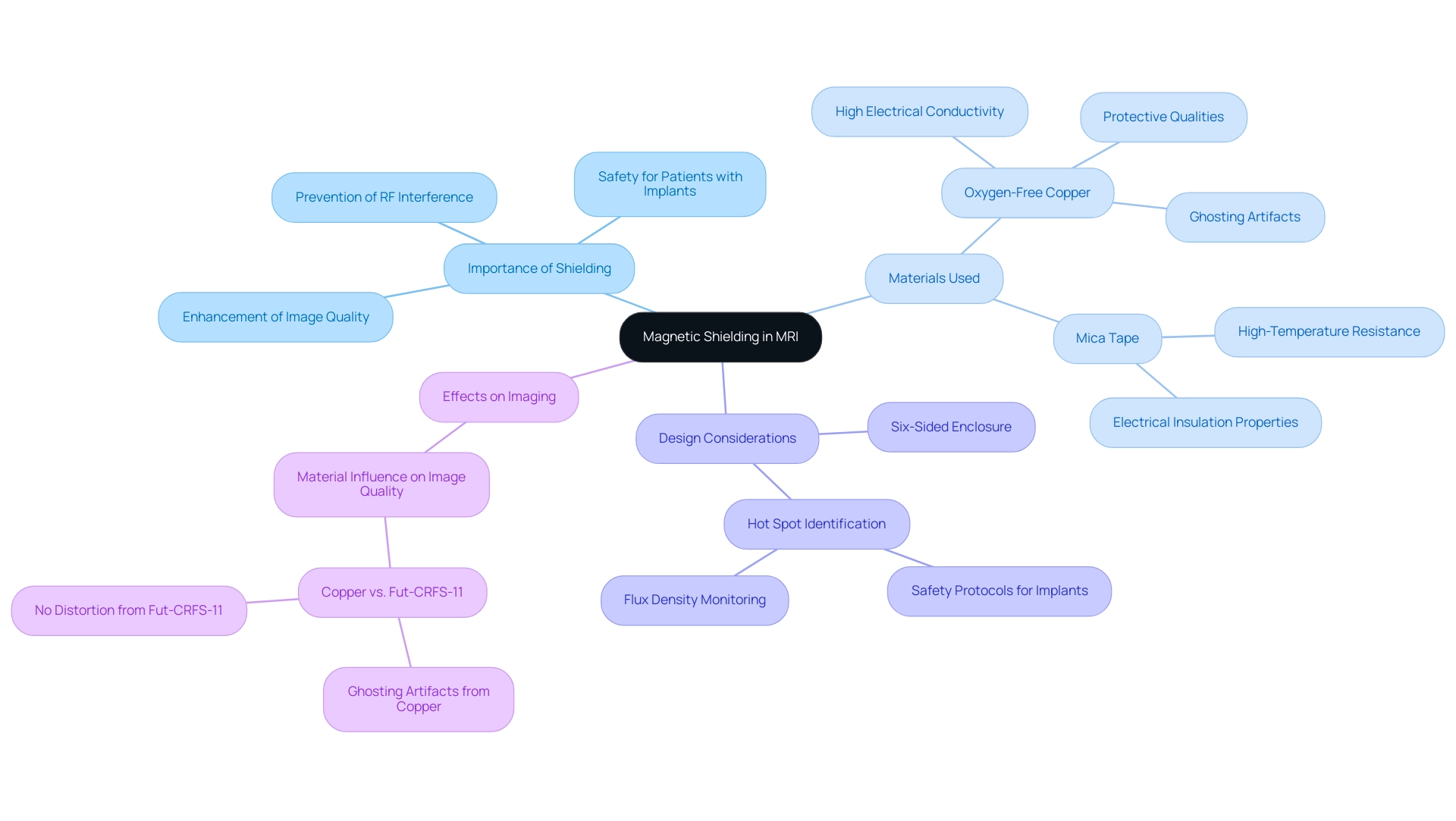

The implementation of magnetic shielding in magnetic resonance imaging (MRI) systems is essential for guaranteeing high-quality imaging by efficiently obstructing external fields and reducing radiofrequency (RF) interference, both of which can considerably diminish image quality. A comprehensive understanding of the sources of magnetic fields—including both external influences and those generated by the MRI machine itself—is essential. Effective RF protection is crucial for maintaining signal integrity during imaging processes, which involves the use of magnetic shielding in magnetic resonance imaging (MRI).

Materials with high electrical conductivity, like DOMADIA Oxygen Free Copper (OFE/OHFC), are frequently used because of their excellent protective qualities and essential roles in medical components. Additionally, mica tape products are significant for their high-temperature resistance and electrical insulation properties, making them suitable for various applications in MRI systems. To optimize overall system performance, the design of the MRI room must incorporate both passive and active protection solutions, particularly magnetic shielding in magnetic resonance imaging (MRI).

Earlier research suggests that magnetic shielding in magnetic resonance imaging (MRI) should ideally comprise a six-sided enclosure without openings, emphasizing the significance of design in protection applications. As Terence Price emphasizes, ‘designers must determine the position of any hot spots in the installation where flux density could exceed 0.5 mT, posing potential risks to individuals with heart pacemakers or other electronic implants.’ A case study assessing the influence of different materials on MR imaging revealed that while copper introduced ghosting artifacts, the Fut-CRFS-11 sample showed no visible distortion, indicating its favorable performance in MR imaging.

Staying informed about developments in protective technologies, including the use of oxygen-free copper and mica tape products, is crucial for procurement managers aiming to enhance MRI system performance and ensure patient safety.

Best Practices for Implementing Magnetic Shielding in MRI Facilities

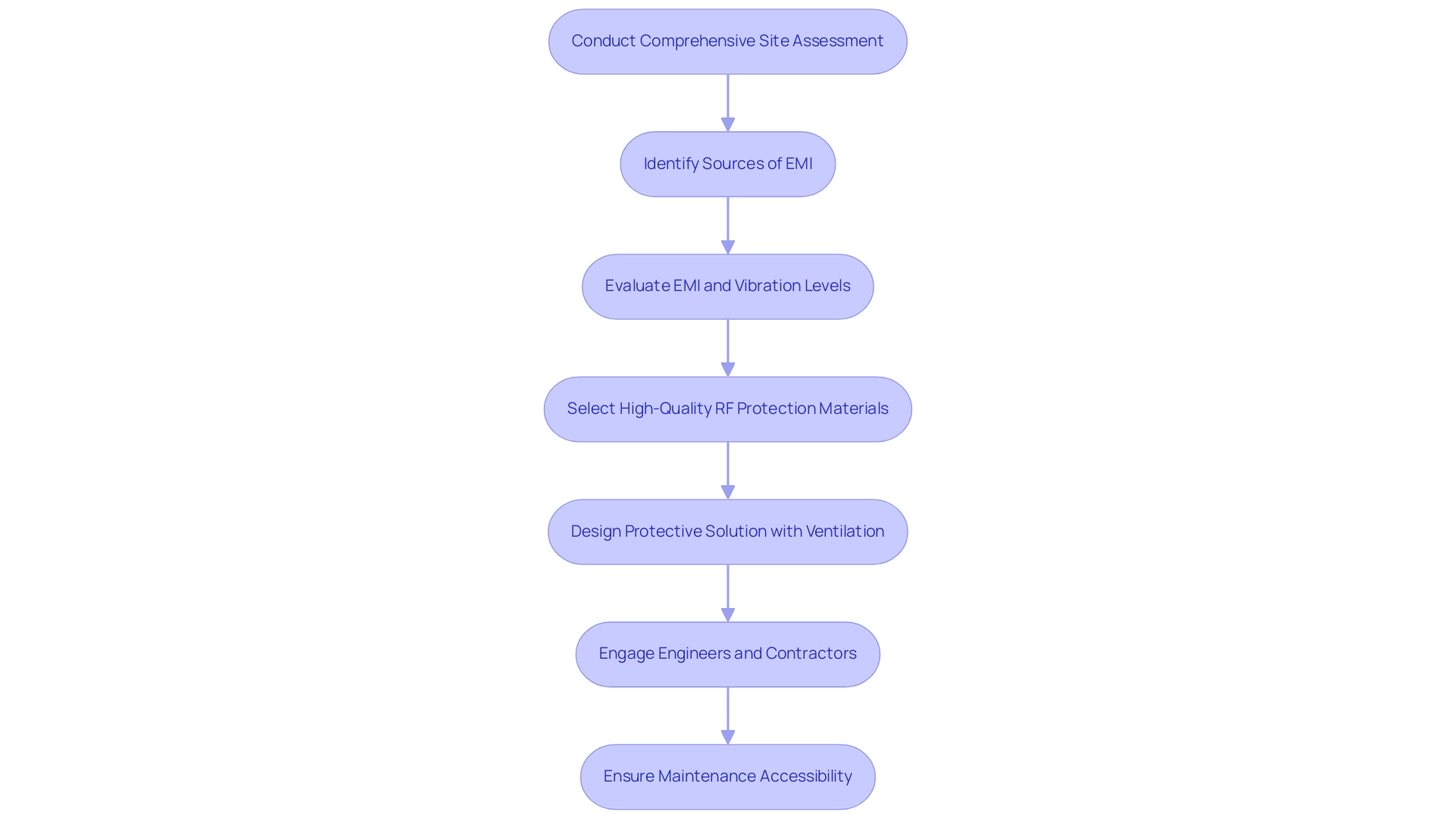

To effectively implement magnetic shielding in magnetic resonance imaging (MRI) facilities, it is paramount to initiate the process with a comprehensive site assessment. This assessment should pinpoint potential sources of electromagnetic interference (EMI) that could compromise imaging quality. For instance, before installing RF protection, evaluating the site’s EMI and vibration levels is crucial, as excessive EMI can hinder the MRI scanner’s performance, ensuring that the MRI system operates effectively post-installation.

Utilizing high-quality RF protection materials—such as:

- DOMADIA Oxygen Free Copper (OFE/OHFC)

- Conductive fabrics

- Specially designed metal sheets

- Mica Tape Products for high-temperature resistance and electrical insulation

ensures robust defense against interference. Significantly, MR images displayed ghosting artifacts with the 12-μm-thick copper sample, whereas the Fut-CRFS-11 sample showed no visible distortion, emphasizing the effectiveness of advanced substances in minimizing imaging artifacts. Ongoing protection through magnetic shielding in magnetic resonance imaging (MRI) is essential; openings in the substance can permit EMI to penetrate and interfere with the magnetic field, leading to distorted images.

Furthermore, it is essential to design the protective solution with adequate ventilation and accessibility in mind, enabling maintenance without jeopardizing the integrity of the protection. Engaging closely with engineers and contractors throughout the installation phase significantly enhances the effectiveness of the enclosure, as these collaborative efforts ensure the optimal selection and application of high-quality materials, maximizing the diagnostic capabilities of MRI systems. As Marcel Straub aptly noted, such teamwork leads to fruitful outcomes.

Challenges and Solutions in MRI Magnetic Shielding

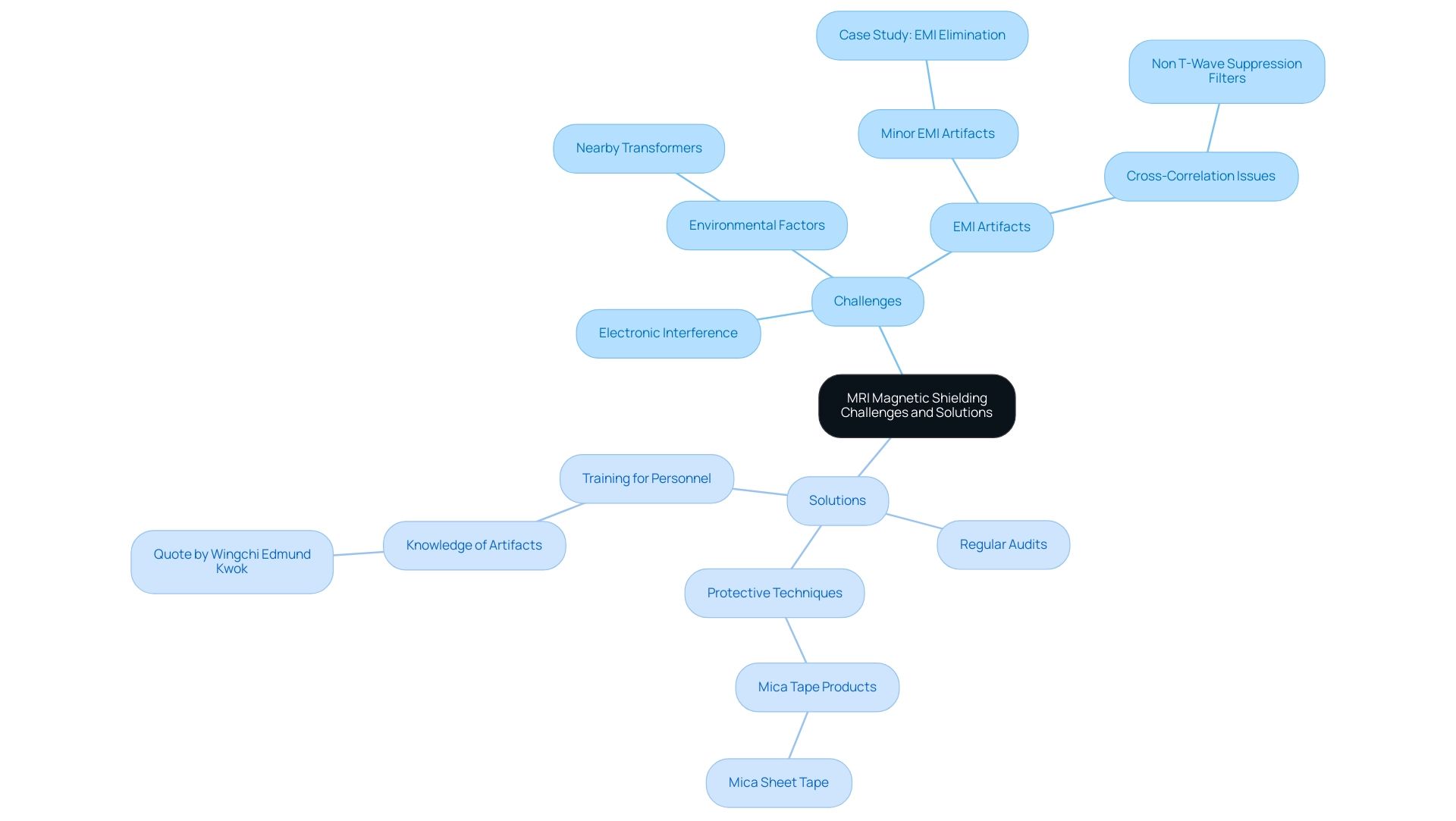

Magnetic shielding in magnetic resonance imaging (MRI) environments is often compromised by electronic interference and environmental factors, such as nearby transformers. These common challenges necessitate a proactive approach to mitigating their impact. Conducting regular audits of the MRI environment is crucial, enabling teams to maintain a comprehensive inventory of potential interference sources.

Effective solutions typically involve a combination of passive and active protection techniques, such as magnetic shielding in magnetic resonance imaging (MRI). For instance, incorporating Mica Tape products, known for their high-temperature resistance and exceptional electrical insulation properties, can enhance the safety and reliability of MRI operations. The inclusion of protective layers, combined with Mica Tape’s excellent flame resistance and dielectric strength, plays a crucial role in enhancing magnetic shielding in magnetic resonance imaging (MRI) by significantly diminishing interference levels.

Notably, the 20Hz harmonic was filtered out by the MR1-MR3 and MR5-MR7 filters, showcasing the effectiveness of these interventions. Furthermore, ongoing training for MRI personnel is vital; as noted by Wingchi Edmund Kwok from the University of Rochester,

- “It is important for MRI personnel to have a good basic knowledge of these artifacts to be able to promptly distinguish them from RF interference artifacts to effectively handle the artifact problem.”

This knowledge not only enhances the overall effectiveness of protection strategies but also ensures that staff can swiftly address and troubleshoot interference issues as they arise, fostering a more reliable MRI environment.

Furthermore, a case study named ‘Preliminary Evaluation of EMI Elimination in a Clinical Setting’ demonstrated that even with magnetic shielding in magnetic resonance imaging (MRI), minor EMI artifacts were present. The suggested approach greatly enhanced image quality and SNRs, demonstrating its possible use in high-field MRI settings, even with partial RF protection. Mica Tape products, particularly Mica Sheet Tape, which is ideal for insulating large flat surfaces, can be instrumental in addressing these challenges, ensuring high-grade insulation to maintain safety and performance.

Furthermore, cross-correlation analyses showed that non t-wave suppression filters did not correlate well with the input ECG signal, emphasizing additional challenges in MRI signal protection.

Innovations in Magnetic Shielding Technologies for MRI

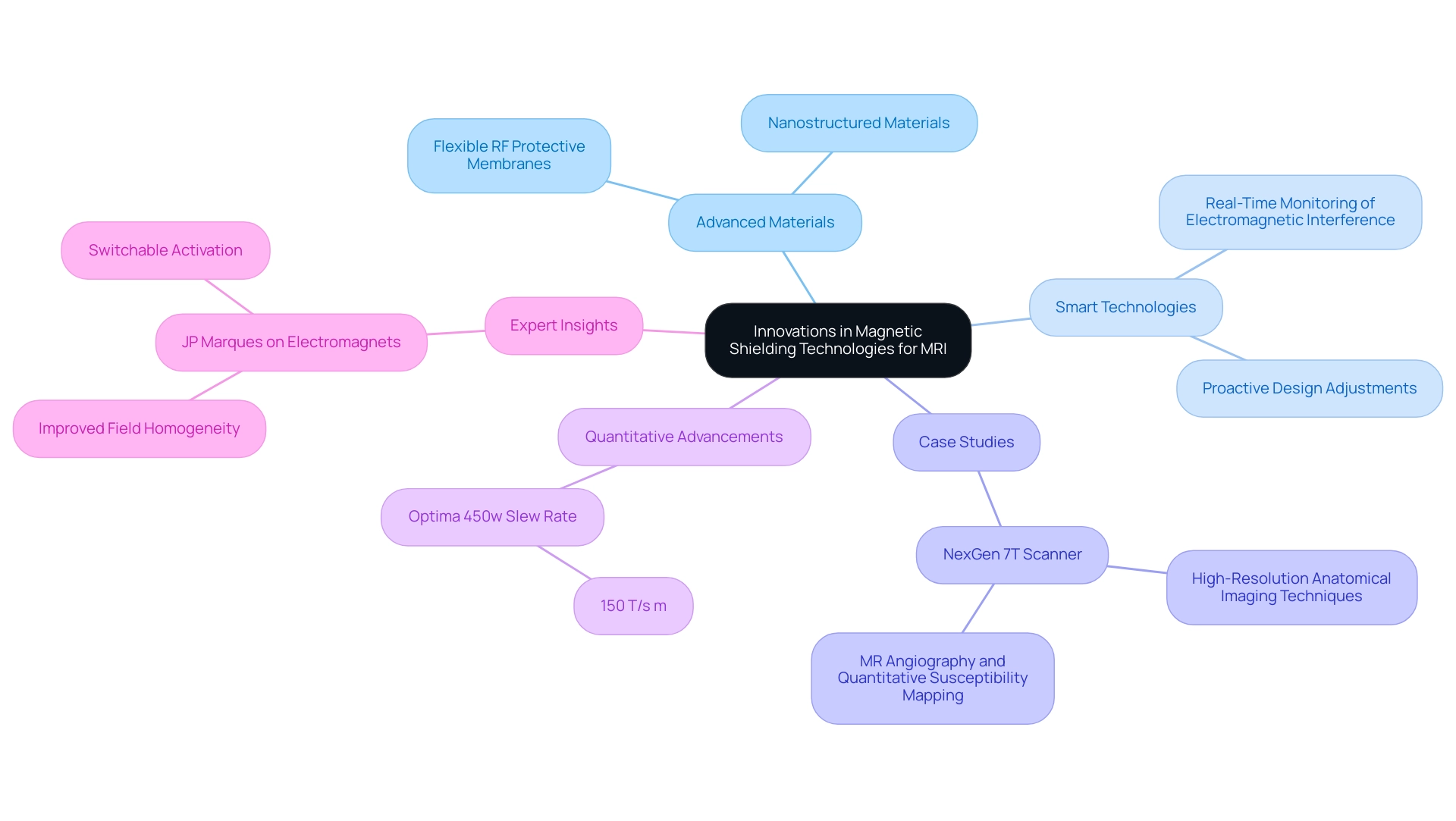

Recent advancements in magnetic shielding in magnetic resonance imaging (MRI) technologies have led to the emergence of innovative composite substances that significantly improve protective effectiveness without adding excessive weight, making installation simpler and more efficient. Among these advancements, flexible RF protective membranes and nanostructured materials are currently under investigation for their ability to provide effective magnetic shielding in magnetic resonance imaging (MRI) within confined spaces, where traditional materials may fall short. Significantly, the Optima 450w features a maximum slew rate (SR) of 150 T/s m, emphasizing the quantitative advancements in protection technologies.

The integration of smart technology into protective solutions further revolutionizes this field by enhancing magnetic shielding in magnetic resonance imaging (MRI), as it enables real-time monitoring of electromagnetic interference levels. Such capabilities facilitate proactive adjustments to protective designs, optimizing performance by implementing magnetic shielding in magnetic resonance imaging (MRI). A case study featuring the NexGen 7T scanner, created through a partnership with UC Berkeley and Siemens Healthineers, demonstrated the scanner’s effectiveness in high-resolution anatomical imaging, which emphasizes the role of magnetic shielding in magnetic resonance imaging (MRI) through these advanced protective elements.

According to JP Marques, “Compared with permanent magnets, electromagnets have enhanced field uniformity and can be activated and deactivated,” which emphasizes the benefits of utilizing advanced protective technologies. Staying informed about these innovations is crucial for facilities aiming to enhance their operational capabilities and remain competitive in an evolving landscape.

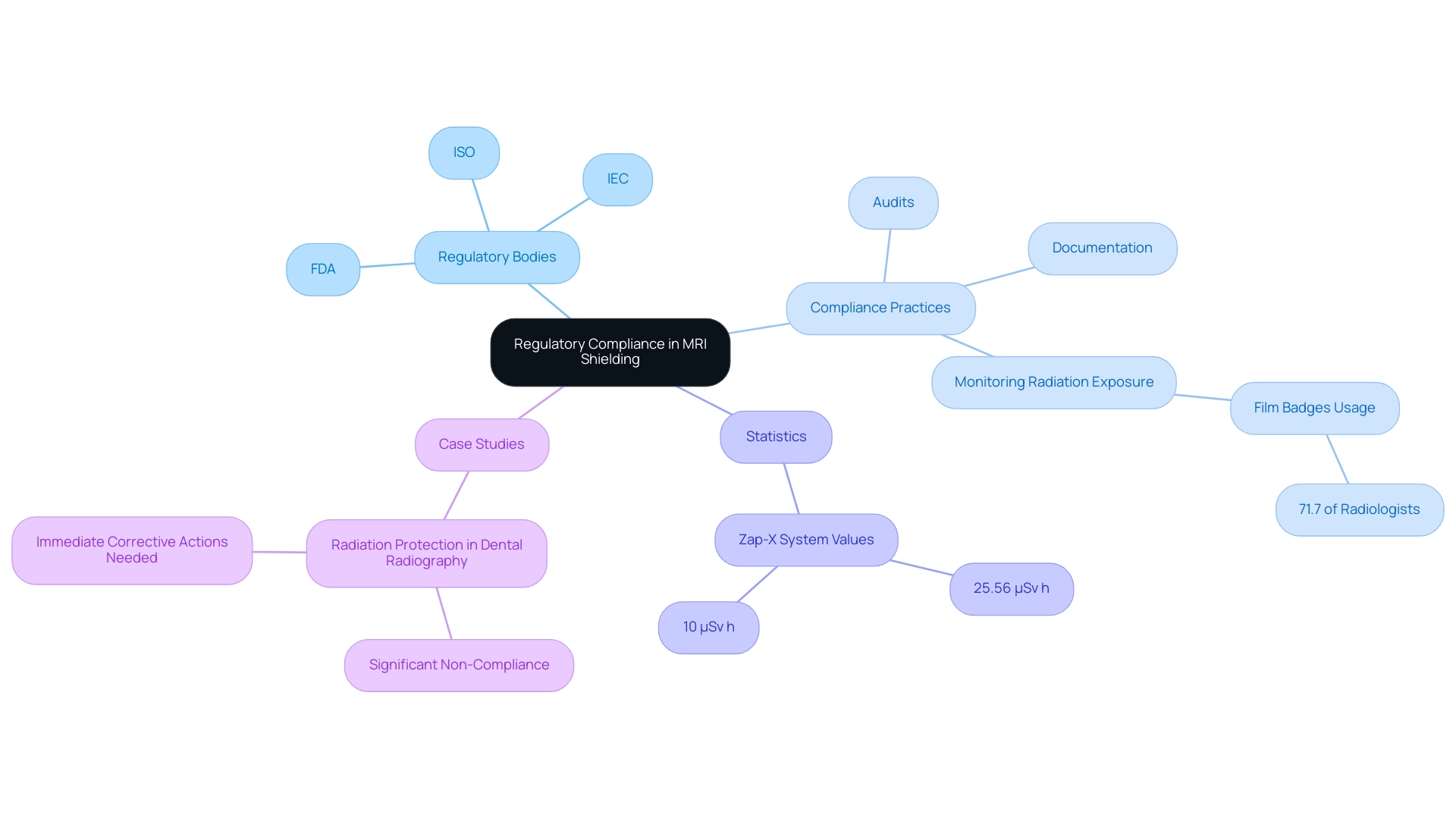

Regulatory Compliance and Safety Standards in MRI Shielding

MRI facilities are required to navigate a complex landscape of regulatory compliance standards, primarily established by the FDA, IEC, and ISO. A comprehensive grasp of these regulations regarding magnetic protection substances and installation methods is essential. For instance, the calculated values of the Zap-X system, which are 25.56 μSv h and 10 μSv h, highlight the significance of adhering to safety standards in radiotherapy technologies.

Regular audits play a pivotal role in ensuring that shielding solutions conform to the latest guidelines, fostering an environment of safety and compliance. Documenting all materials used and the installation processes is vital, as it simplifies compliance reviews and inspections. Furthermore, proactive engagement with regulatory bodies and industry associations offers facilities crucial insights into evolving standards.

As noted by Rostamzadeh, 71.7% of radiologists in Kermanshah, Iran, used film badges daily, underscoring the importance of monitoring radiation exposure in compliance practices. Additionally, a case study evaluating radiation protection principles in dental radiography centers revealed significant non-compliance with radiation protection standards, necessitating immediate corrective actions. This approach not only ensures ongoing compliance but also safeguards the well-being of patients and staff alike, while enhancing overall operational efficacy.

Conclusion

Effective magnetic shielding is an indispensable component in the delivery of high-quality MRI imaging. By understanding the fundamentals of magnetic shielding, including the selection of superior materials like DOMADIA Oxygen Free Copper and Mica Tape, healthcare facilities can significantly mitigate the risks posed by external magnetic fields and radiofrequency interference. Implementing best practices, from thorough site assessments to the integration of both passive and active shielding solutions, ensures that MRI systems operate at peak performance while maintaining patient safety.

The challenges inherent in magnetic shielding, such as electronic interference and environmental factors, require ongoing vigilance and proactive strategies. Regular audits and continuous training for MRI personnel are essential to address these issues effectively and to enhance the overall reliability of MRI operations. Furthermore, embracing innovations in magnetic shielding technologies, such as flexible RF membranes and smart monitoring systems, allows facilities to stay ahead in optimizing their imaging capabilities.

Lastly, maintaining compliance with regulatory standards is crucial for safeguarding the health of patients and staff. By adhering to established safety protocols and engaging actively with regulatory bodies, facilities not only ensure compliance but also foster an environment that prioritizes safety and operational efficiency. As the field of MRI continues to evolve, staying informed and adaptable will be key to enhancing imaging quality and advancing patient care.