Blogs

Top 7 Properties of Beryllium Bronze Electrical Resistivity for Precision Measurement Devices

Introduction

In the realm of precision measurement, the choice of materials can significantly influence the performance and reliability of devices across various industries, including aerospace, defense, and telecommunications. Beryllium bronze, particularly in its beryllium copper form, stands out due to its exceptional mechanical properties, such as high strength, corrosion resistance, and thermal stability. These characteristics not only enhance the durability of measurement instruments but also ensure their accuracy in dynamic environments.

As procurement professionals navigate the complexities of sourcing materials, understanding the nuances of beryllium bronze’s properties—ranging from electrical resistivity to ductility—becomes crucial.

This article delves into the essential attributes of beryllium bronze, highlighting its role in optimizing precision measurement applications while addressing the strategic considerations that guide effective procurement decisions.

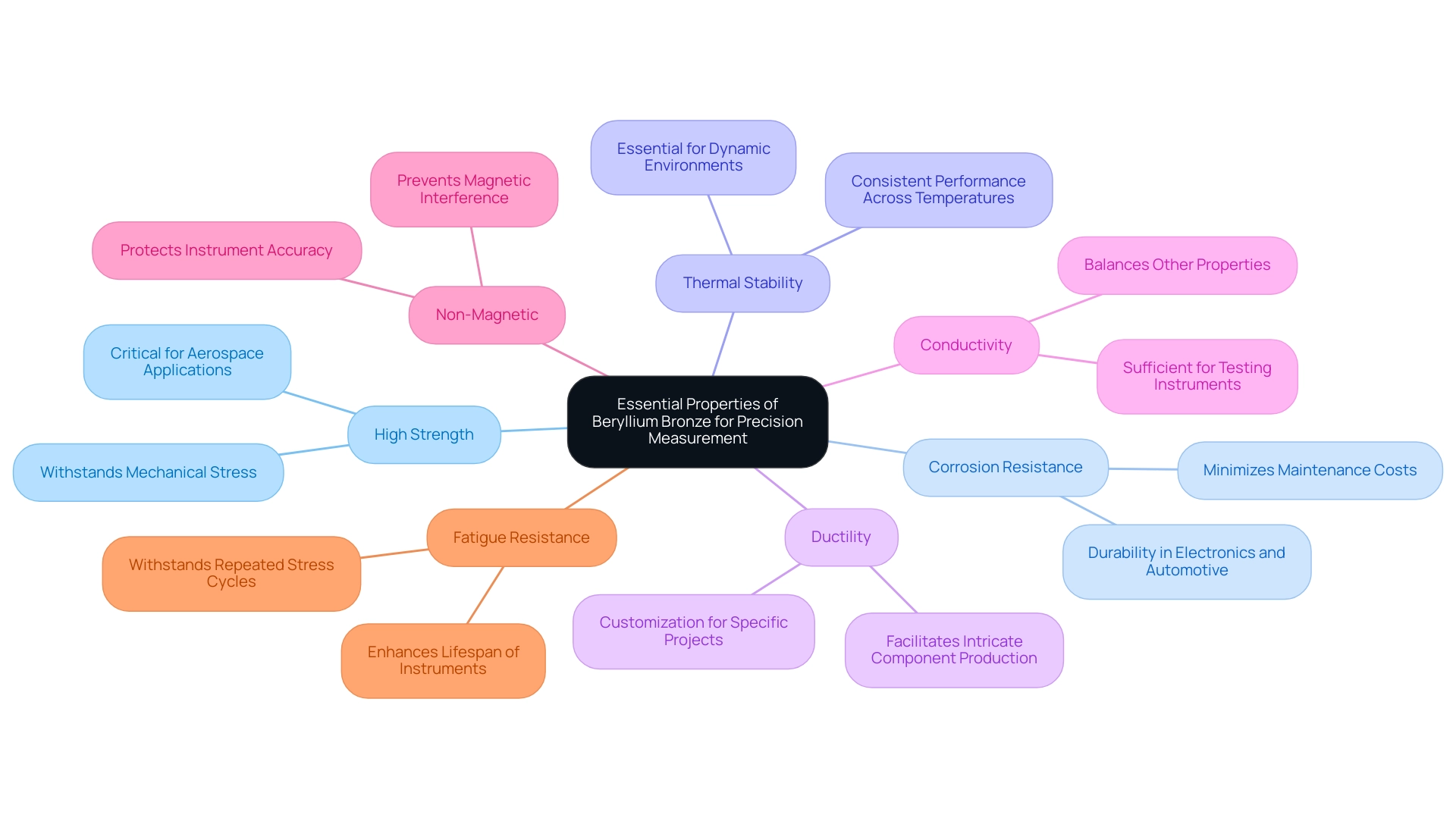

Essential Properties of Beryllium Bronze for Precision Measurement

Bronze and copper are highly regarded for their exceptional properties, particularly their beryllium bronze electrical resistivity for precision measurement devices, making them suitable for various high-performance sectors such as aerospace, defense, and telecommunications. At Domadia, we are dedicated to quality and customer satisfaction, ensuring that our Copper Plates meet the highest standards. The key characteristics include:

High Strength: Beryllium copper boasts remarkable tensile strength, enabling it to withstand significant mechanical stress without deformation. This feature is crucial for maintaining the integrity of precision instruments under challenging conditions, particularly in aerospace applications where reliability is paramount.

Corrosion Resistance: Known for its excellent resistance to corrosion, beryllium copper ensures longevity and reliability across various environments, minimizing maintenance costs—a critical consideration for procurement managers seeking durable materials for electronics and automotive applications.

Thermal Stability: The alloy maintains consistent performance across a broad temperature spectrum, making it ideal for equipment subjected to varying operating conditions. This stability is essential for ensuring precise evaluations over time in dynamic environments.

Ductility: Beryllium copper is easily formable and machinable, facilitating the production of intricate components essential for accurate instruments. This property not only enhances manufacturability but also allows for customization in design to meet specific project needs.

Conductivity: Although its electrical conductivity is not as elevated as that of pure copper, beryllium copper offers sufficient conductivity for numerous applications, ensuring effective performance in testing instruments without compromising other properties.

Non-Magnetic: This trait is especially significant in exacting applications, as it prevents magnetic interference that could distort readings, thereby protecting the accuracy of the instruments.

Fatigue Resistance: Capable of withstanding repeated stress cycles, beryllium copper is well-suited for dynamic applications, enhancing the reliability and lifespan of instruments used in accurate monitoring systems.

Moreover, the significance of Non-Sparking Tools, particularly those made from beryllium copper, cannot be overstated in explosive environments. These tools offer an essential safety feature, stopping sparks that might result in dangerous situations.

Recent advancements, including low frequency electro-magnetic stirring techniques, have improved the mechanical properties of beryllium alloys, further broadening their application range in engineering. Expert Xiaoyan Ma highlights the relevance of beryllium bronze in practical applications, demonstrating its effectiveness through case studies such as ‘Multibody Analysis of the Force in Deploying Booms.’ These exemplary characteristics collectively enhance the performance and dependability of accurate instrumentation, making beryllium bronze electrical resistivity for precision measurement devices a favored option across various industries.

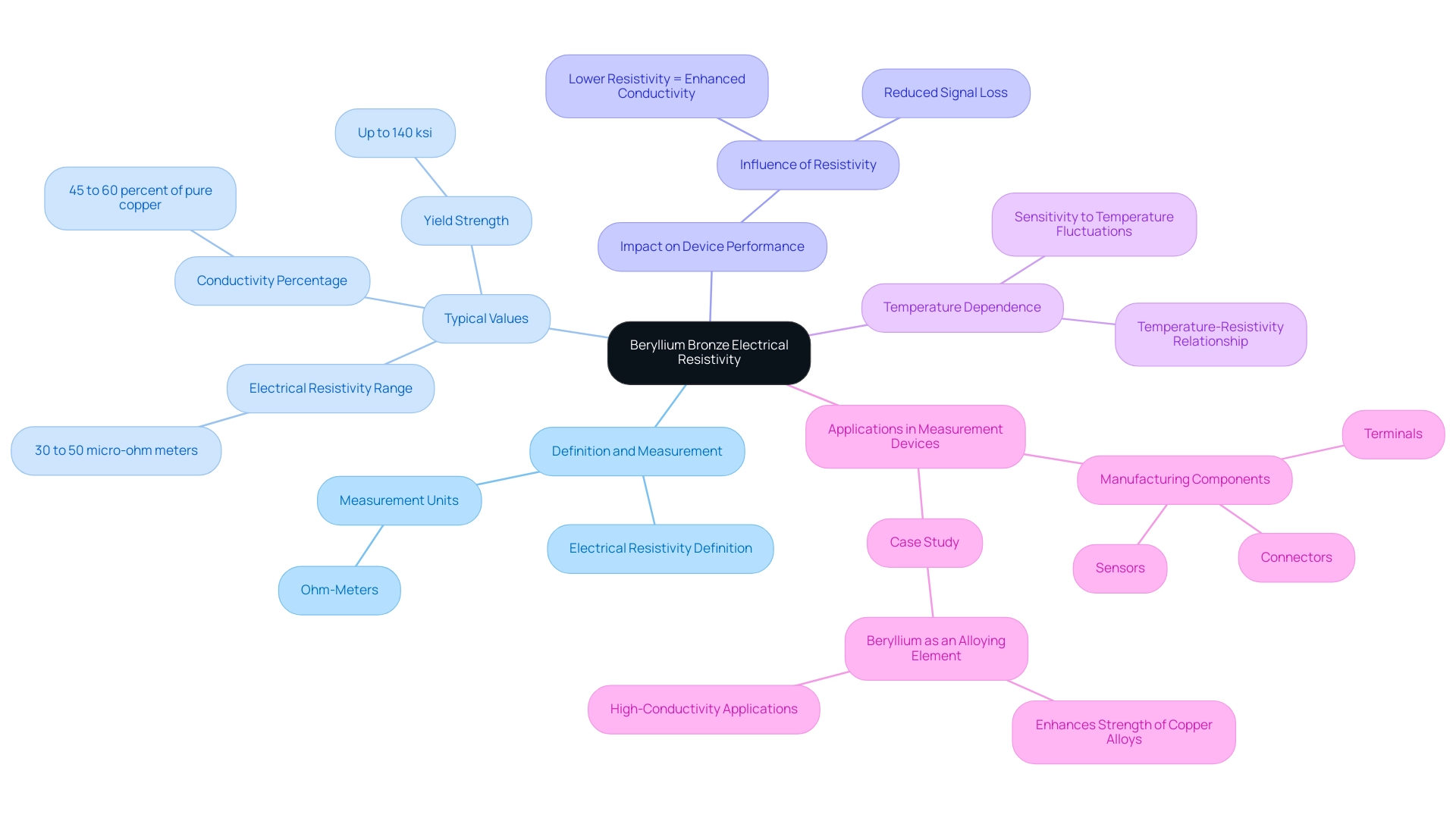

Understanding Electrical Resistivity in Beryllium Bronze

The beryllium bronze electrical resistivity for precision measurement devices is a fundamental characteristic of this bronze alloy, playing a crucial role in its efficacy. At Domadia, your reliable partner for Copper solutions, we recognize the significance of this property in ensuring high performance across various applications in aerospace, defense, and telecommunications. Here are the key aspects to consider:

Definition and Measurement: Electrical resistivity is defined as the degree to which a material resists the flow of electric current, typically quantified in ohm-meters. This property is pivotal for applications demanding precise electrical measurements, particularly in relation to beryllium bronze electrical resistivity for precision measurement devices.

Typical Values: The electrical resistivity of bronze generally falls between 30 to 50 micro-ohm meters, contingent on its specific alloy composition. This range facilitates effective electrical conductivity while providing the necessary resistance to ensure measurement accuracy. Significantly, the beryllium bronze electrical resistivity for precision measurement devices demonstrates electrical and thermal conductivity ranging from 45 to 60 percent of pure copper, which is essential for optimal performance in electronic applications.

Yield Strength: Alloys of bronze containing beryllium, such as Alloys 3 and 10, provide moderate yield strength up to 140 ksi. This strength is essential for maintaining the integrity of components under various operational stresses, making it a reliable choice for demanding applications.Impact on Device Performance: Variations in beryllium bronze electrical resistivity for precision measurement devices directly influence the performance and reliability of testing devices. Lower resistivity translates to enhanced conductivity, which is vital for reducing signal loss in electronic applications.

Temperature Dependence: The beryllium bronze electrical resistivity for precision measurement devices is sensitive to temperature fluctuations, which is a critical factor in precision measurements. Understanding this temperature-resistivity relationship aids procurement managers in selecting materials suited for specific operational environments.

Applications in Measurement Devices: A type of bronze is extensively used in the manufacture of connectors, terminals, and sensors, where dependable electrical performance is essential. The distinctive resistivity properties of beryllium bronze electrical resistivity for precision measurement devices ensure that these instruments maintain accuracy and reliability throughout their lifecycle.

Case Study: This element is an effective alloying agent that enhances the strength of copper-based alloys, even in small proportions. This property makes beryllium valuable in various high-conductivity applications, enhancing the performance of metal alloys utilized in measurement instruments.

A comprehensive understanding of beryllium bronze electrical resistivity for precision measurement devices enables procurement professionals to make informed sourcing choices for materials used in these tools, thereby optimizing performance and adhering to stringent industry standards. Moreover, recent discoveries suggest that bronze alloys, including Brush 60®, show a specific heat increase from 0.080 to 0.091 Btu/(lb•F) across different temperatures; comprehending this variation is vital for procurement choices and can greatly influence equipment performance. At Domadia, we offer a diverse range of products, including foils, sheets, rods, and wires, all customizable to meet your specific requirements. Our dedication to providing high-quality Copper solutions guarantees that you have the appropriate materials for your applications.

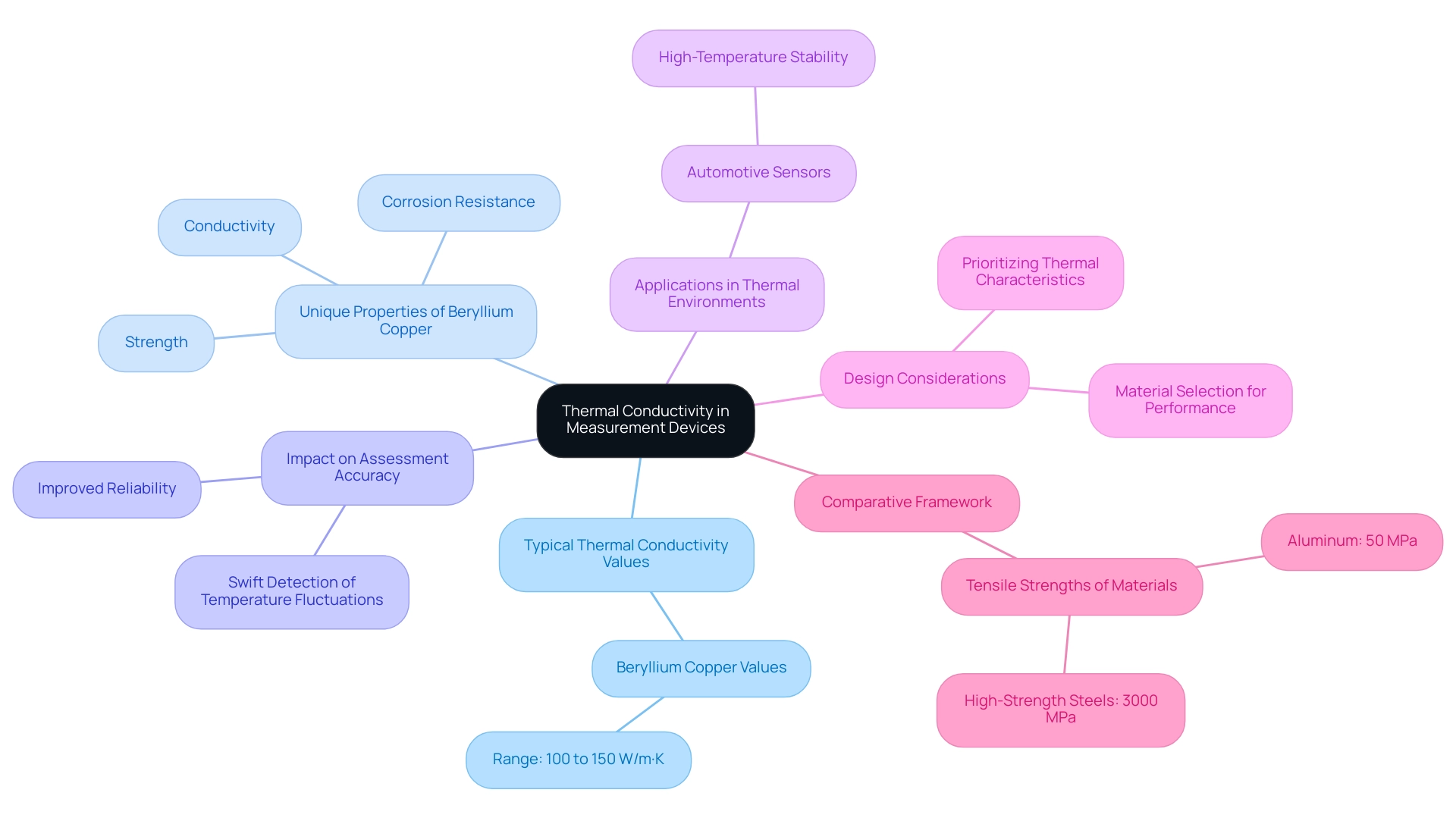

Thermal Conductivity and Its Relevance to Measurement Devices

Thermal conductivity is a critical property that defines a material’s ability to conduct heat, which is essential for precision measurement devices that may encounter fluctuating temperatures. At Domadia, a leader in supplying and manufacturing Beryllium Copper Plates, several key considerations highlight the importance of this property:

- Typical Thermal Conductivity Values: A bronze alloy from Domadia displays thermal conductivity values ranging from 100 to 150 W/m·K. This characteristic facilitates effective heat dissipation, which is vital for maintaining the accuracy of exact instruments in aerospace, defense, and telecommunications.

- Unique Properties: Beryllium Copper is renowned for its unique combination of strength, conductivity, and corrosion resistance, making it the strongest copper alloy available and ideal for demanding applications.

- Impact on Assessment Accuracy: High thermal conductivity is essential as it guarantees that any temperature fluctuations are swiftly detected by the apparatus, thus improving assessment accuracy and reliability—vital in exact applications.

- Applications in Thermal Environments: Devices that operate in high-temperature settings, such as automotive sensors, significantly benefit from the thermal stability afforded by beryllium bronze. This stability minimizes the risk of inaccuracies in assessment, ensuring consistent performance related to beryllium bronze electrical resistivity for precision measurement devices.

- Design Considerations: Engineers creating accurate assessment instruments must prioritize the thermal characteristics of materials to ensure optimal performance under expected operating conditions. Selecting materials with appropriate thermal conductivity is fundamental to achieving desired performance outcomes.

- Comparative Framework: Comprehending the ultimate tensile strengths of different materials, like the spectrum from 50 MPa for aluminum to 3000 MPa for exceptionally high-strength steels, can offer context for the mechanical properties of beryllium bronze and its appropriateness for accurate application.

As Tim Bradow from Rigaku observes, ‘CT instruments can alter battery analysis workflows,’ highlighting the importance of thermal properties in testing tools. By referencing the case study on UNS C172 copper alloys, which outlines their uses in exact components, we can further illustrate the importance of thermal conductivity in various industrial contexts.

By thoroughly understanding thermal conductivity and its implications, procurement professionals can more effectively assess the suitability of beryllium bronze electrical resistivity for precision measurement devices in specific applications. This knowledge guarantees that tools for gauging sustain precision across a diverse range of temperatures. Additionally, as you explore solutions with Domadia, consider our range of Mica Tapes for high-temperature electrical insulation needs, complementing your procurement strategy with top-tier materials.

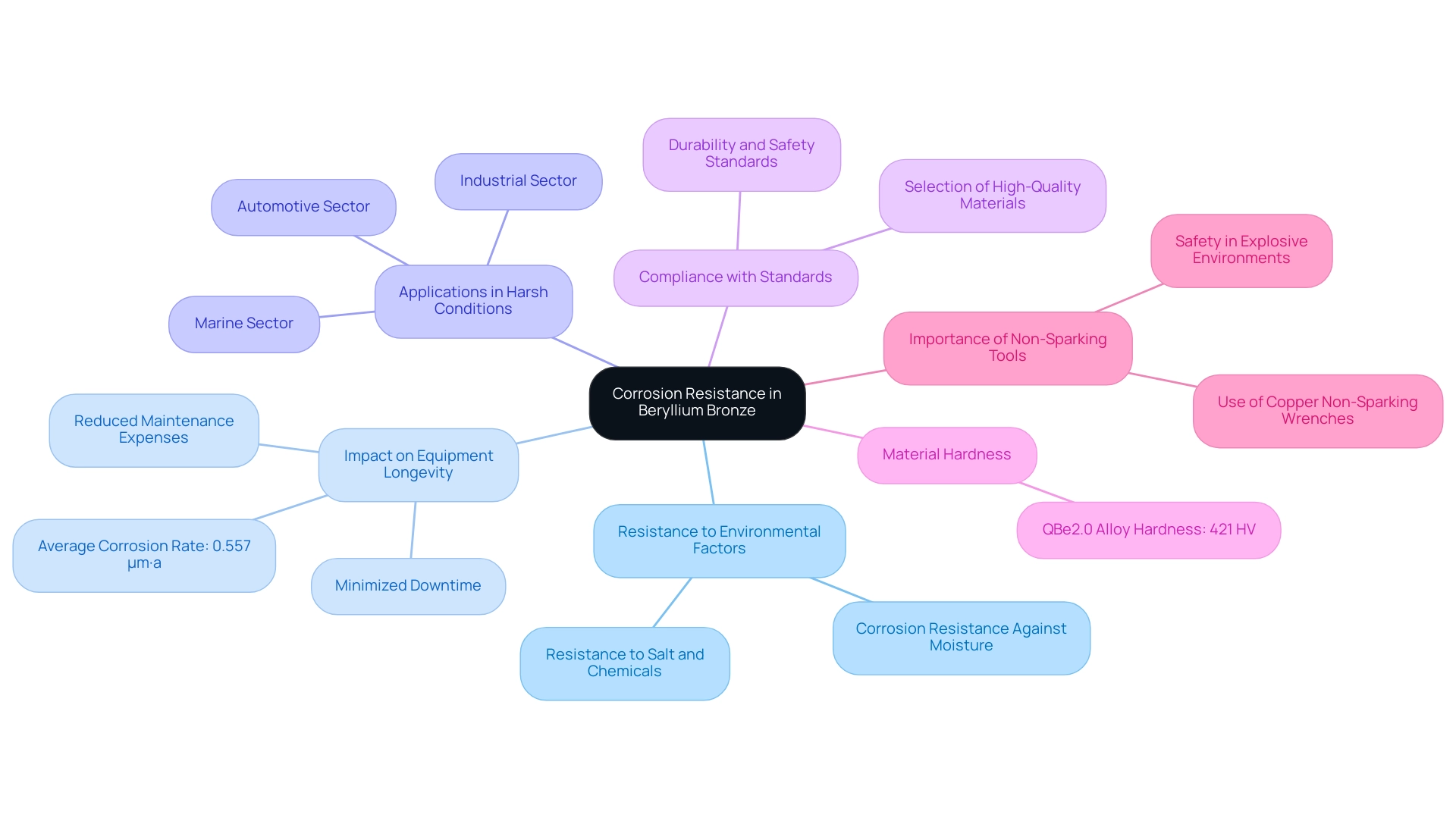

The Role of Corrosion Resistance in Device Longevity

The beryllium bronze electrical resistivity for precision measurement devices is a vital characteristic that provides corrosion resistance, crucial for preserving the functionality of precision instruments throughout their operational lifespan. Key insights include:

- Resistance to Environmental Factors: Beryllium bronze exhibits remarkable corrosion resistance against moisture, salt, and a variety of chemicals, rendering it suitable for operation in diverse and challenging environments.

- Impact on Equipment Longevity: The capability of beryllium bronze to inhibit corrosion greatly improves the longevity of instruments, effectively reducing maintenance expenses and minimizing downtime. Studies indicate that the average corrosion rate of beryllium bronze in industrial atmospheres is merely 0.557 μm·a over 29 years, showcasing its durability.

- Applications in Harsh Conditions: Precision instruments utilized in marine, automotive, and industrial sectors greatly benefit from the beryllium bronze electrical resistivity for precision measurement devices, ensuring consistent and reliable performance even in demanding conditions.

- Compliance with Standards: A thorough understanding of corrosion resistance not only aids procurement managers in selecting high-quality materials but also ensures compliance with industry-specific standards for durability and safety.

- Material Hardness: Additionally, the QBe2.0 alloy demonstrates a hardness of 421 HV after aging for 2 hours at 300 °C, further illustrating its robust mechanical properties, which are vital for high-performance applications.

- Importance of Non-Sparking Tools: In explosive environments, the use of non-sparking tools is critical. Copper non-sparking wrenches, for example, offer a secure option for managing delicate equipment, reducing the chance of igniting combustible materials.

Safety Features and Applications: These non-sparking wrenches are designed to withstand high-stress applications while ensuring safety in hazardous conditions. Their corrosion resistance further boosts their dependability, rendering them appropriate for aerospace, defense, and telecommunications industries.

By emphasizing corrosion resistance and the use of non-sparking tools, procurement professionals can improve the reliability and durability of exacting instruments, ensuring optimal performance in demanding environments. As Z.W. highlighted,

The density of the γ’ phase in the C17200 alloy was greater, while the amounts of the brittle β phase were smaller than those of the QBe2.0 alloy, emphasizing the material’s superior structural integrity.

Furthermore, the innovative findings from recent research utilizing Density Functional Theory (DFT) shed light on the patina formation on beryllium bronze, further reinforcing its protective qualities. Notably, the case study titled ‘Corrosion Behavior of Bronze‘ revealed that the skyward patina layer consists mainly of CuO, Cu(OH), and CuSO4, which plays a critical role in corrosion resistance, demonstrating the material’s long-term viability in harsh environments. Moreover, Guojie Huang’s and Lijun Peng’s association with this research underscores the credibility of these findings.

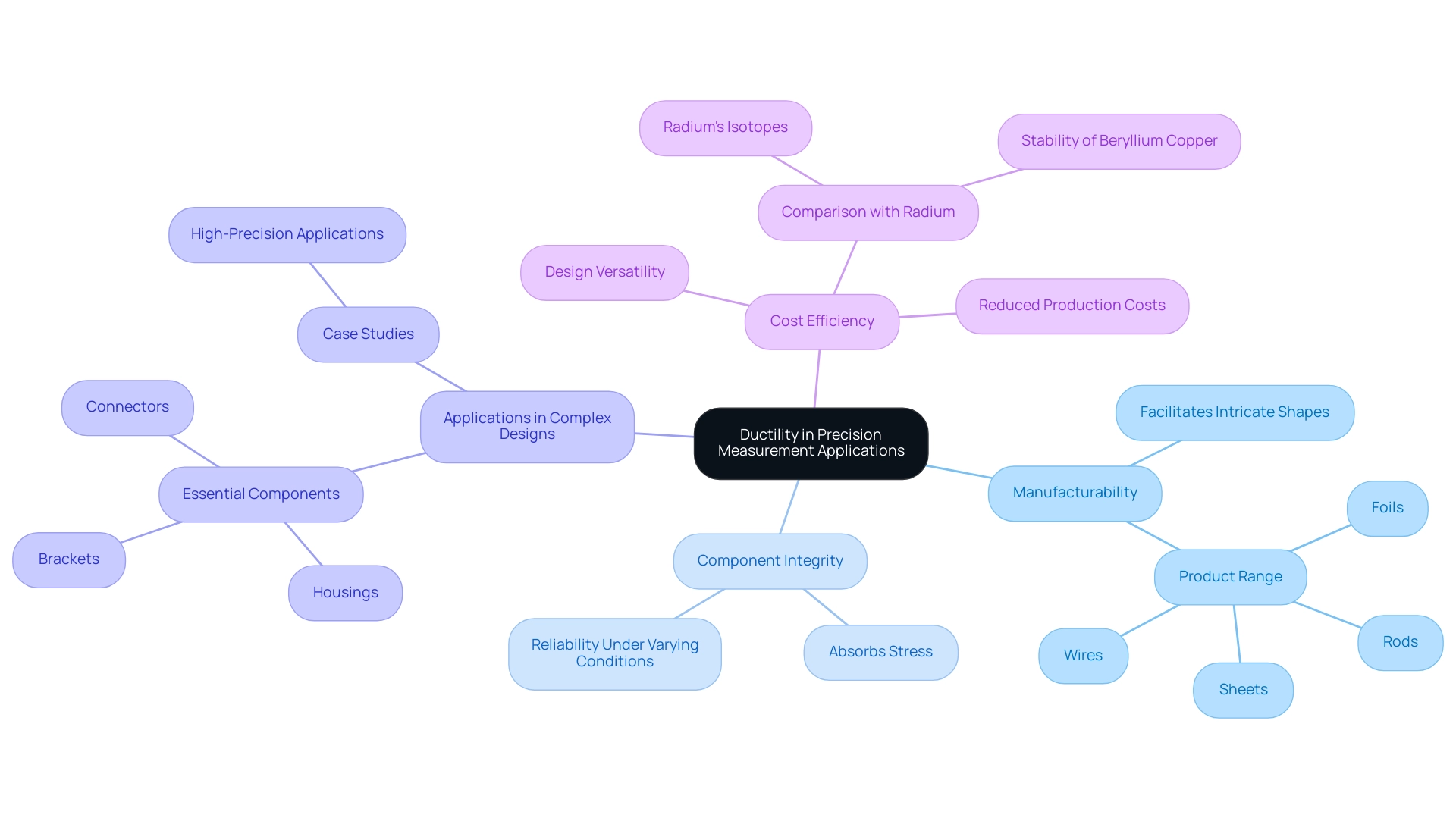

The Importance of Ductility in Precision Measurement Applications

Ductility, characterized as a material’s capacity to endure substantial deformation under tensile stress without breaking, is crucial in accurate application scenarios, particularly when using Copper. Key considerations include:

Manufacturability: The inherent ductility of this alloy facilitates the formation of intricate shapes essential for precision instruments, streamlining the manufacturing process and enhancing production efficiency.

Domadia’s extensive product range, including foils, sheets, rods, and wires, allows for tailored solutions that meet specific design needs.Impact on Component Integrity: High ductility is crucial for ensuring that components can effectively absorb stress without fracturing. This characteristic significantly enhances the reliability of measurement devices, particularly under varying operational conditions.

As noted by Joseph, while some metals produce reactive oxygen species (ROS) resulting in oxidative stress and carcinogenesis, this particular element does not show the same level of risk, emphasizing its safety in applications. Additionally, Copper Alloy is known for its strength, conductivity, and corrosion resistance, making it an ideal choice for demanding environments.

Applications in Complex Designs: In exacting assessment apparatus requiring advanced geometries, Copper alloy’s ductility positions it as the material of choice for essential components such as housings, brackets, and connectors.

Case studies have demonstrated its effectiveness in high-precision applications, ensuring durability and performance. Domadia excels in providing and producing Copper Plates, rendering them essential in these industries.

Cost Efficiency: The capability to manufacture components from ductile materials not only supports design versatility but also contributes to reduced production costs and improved supply chain efficiency.

Furthermore, comparing this to radium, which has 33 different isotopes and is known for its instability, highlights the advantages of using stable and ductile materials like Beryllium Copper, particularly when considering beryllium bronze electrical resistivity for precision measurement devices. By recognizing the importance of ductility and Domadia’s role in providing high-performance Beryllium Copper solutions, procurement professionals can make strategic decisions when sourcing materials, ensuring optimal performance, manufacturability, and overall component integrity.

Conclusion

The exceptional properties of beryllium bronze, particularly in its beryllium copper form, establish it as a pivotal material in the realm of precision measurement devices. Its high strength and fatigue resistance ensure that instruments maintain integrity under significant mechanical stress, which is especially critical in high-performance sectors such as aerospace and defense. Moreover, the alloy’s corrosion resistance significantly enhances the longevity of devices, minimizing maintenance costs and ensuring reliability in various challenging environments.

Understanding the nuances of electrical resistivity and thermal conductivity further underscores the strategic advantages of beryllium bronze in precision applications. With its optimal conductivity and thermal stability, this material facilitates accurate measurements across a range of temperatures, while its ductility supports the manufacturability of intricate components without sacrificing performance. Additionally, the non-magnetic nature of beryllium bronze prevents interference in sensitive measurements, reinforcing its suitability for precision instrumentation.

In conclusion, procurement professionals are encouraged to prioritize beryllium bronze for its multifaceted benefits in precision measurement applications. By leveraging its superior mechanical properties, organizations can enhance the performance and reliability of their devices, ultimately leading to greater efficiency and cost-effectiveness in their operations. As industries continue to evolve, the strategic sourcing of high-quality materials like beryllium bronze will remain essential for sustaining competitive advantage in precision engineering.