Blogs

Understanding Beryllium Copper Tensile Strength: An In-Depth Tutorial

Introduction

In the realm of advanced materials, beryllium copper stands out as a crucial alloy that combines exceptional strength, conductivity, and corrosion resistance. Comprising primarily copper and beryllium, this alloy is not just a choice but a necessity for industries where performance under pressure is paramount. As the demand for high-quality components continues to surge, procurement managers are increasingly recognizing the significance of beryllium copper in applications ranging from aerospace to electronics.

This article delves into the following aspects of beryllium copper:

- Composition

- Mechanical properties

- Heat treatment processes that enhance tensile strength

- Diverse applications

- Critical safety practices required for handling this powerful material

Understanding these facets will equip procurement professionals with the insights needed to make informed sourcing decisions in a rapidly evolving market.

Introduction to Beryllium Copper: Composition and Significance

Beryllium bronze is a mixture mainly made of metal and another element, usually comprising between 0.5% and 3% of the latter. This unique formulation results in exceptional material properties, including beryllium copper tensile strength, high tensile strength, excellent electrical and thermal conductivity, and remarkable corrosion resistance. Notably, DOMADIA Beryllium Copper complies with international standards UNS and ASTM, ensuring quality and reliability for procurement managers.

Recent discussions on March 10, 2024, highlighted the use of a master alloy, emphasizing its increasing importance in various sectors, particularly in non-sparking instruments essential for safety in hazardous environments. The product range encompasses various forms such as rods, sheets, and custom components, making it suitable for a variety of uses. These traits make this alloy essential across industries like aerospace, automotive, electronics, and telecommunications, where performance under stress is crucial.

Its durable and reliable nature makes it ideal for critical components such as connectors, springs, and tools. The beryllium copper tensile strength of the alloy is crucial as it not only guarantees the durability of these components but also enhances their performance, making it essential for procurement managers to consider when sourcing materials for high-stakes applications. Moreover, significant participants in the alloy sector, such as Materion and NGK, are set to take advantage of the rising demand and usage variety, further highlighting the significance of this substance in modern production.

For the latest insights, refer to our blog updates, which offer ongoing discussions about innovations and uses in the beryllium metal sector.

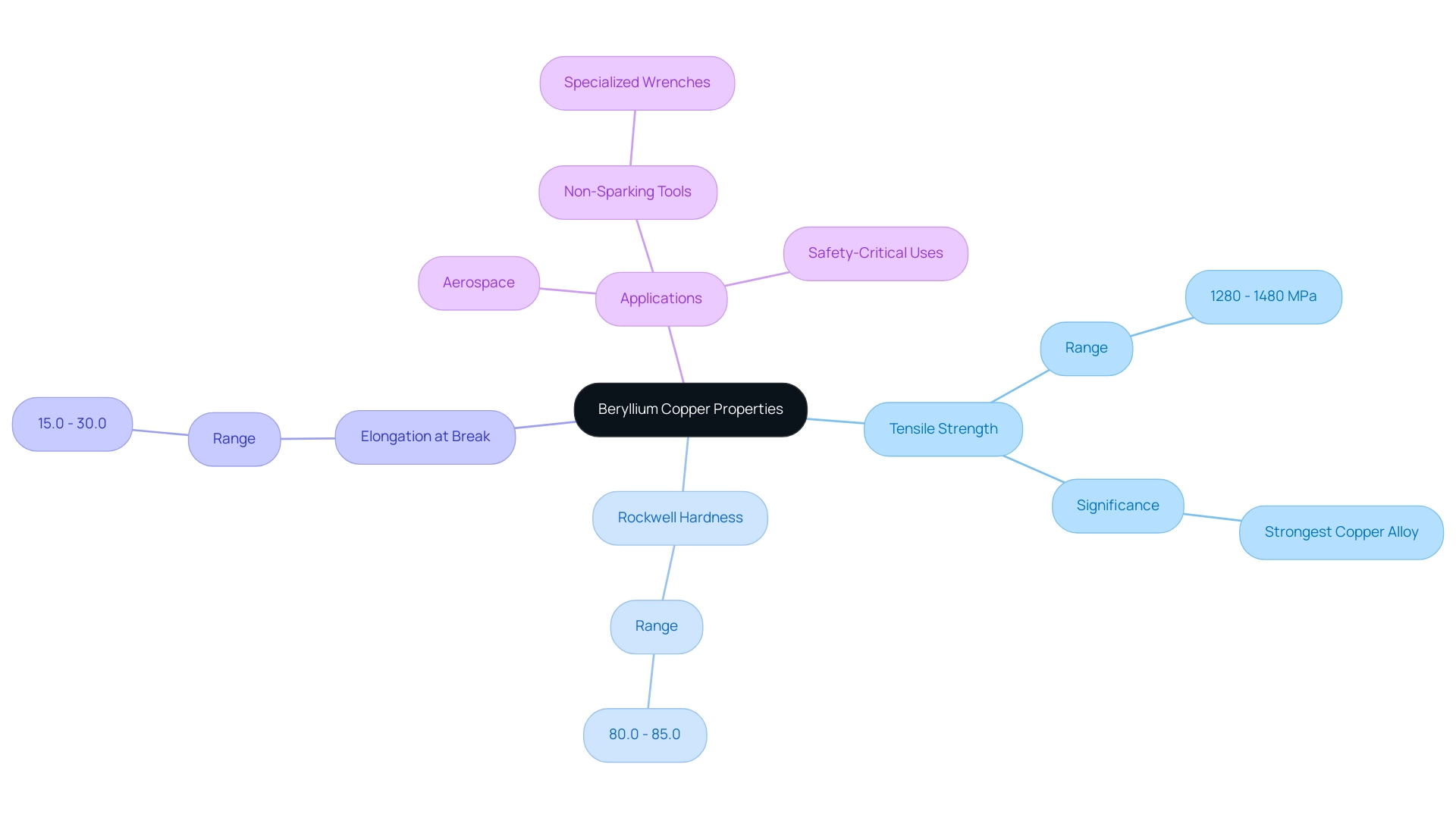

Understanding the Mechanical Properties: Tensile Strength of Beryllium Copper

Tensile strength is defined as the maximum tensile stress a substance can endure before it fails. In the realm of Beryllium Copper, particularly with the UNS C17200 alloy, the beryllium copper tensile strength exhibits considerable variability based on alloy composition and heat treatment processes, ranging from 1280 to 1480 MPa. The beryllium copper tensile strength, combined with the material’s ability to deform without catastrophic failure, establishes Beryllium Copper as the strongest copper alloy, making it an ideal selection for challenging uses in aerospace and precision settings.

Procurement managers should acknowledge the exceptional strength, conductivity, and durability of Domadia’s Beryllium Copper Plates, as they are designed for dependable performance in various industrial uses. Domadia is committed to quality and customer satisfaction, ensuring that our products meet the highest standards. Recent case studies have highlighted the UNS C17200’s Rockwell hardness between 80.0 – 85.0 and an impressive elongation at break of 15.0 – 30.0%, underscoring its appropriateness for safety-critical uses.

Furthermore, the introduction of non-sparking Beryllium Copper tools, including our specialized non-sparking wrenches, enhances safety in hazardous environments, making them indispensable for professionals in the field. As Prof. Bo Chen aptly noted, ‘additive manufacturing is revolutionizing structural integrity in safety-critical industries,’ reflecting the ongoing advancements in understanding and utilizing Beryllium Copper alloys. For detailed pricing and inventory information on our Beryllium Copper Strips, please contact us directly.

Heat Treatment Processes and Their Impact on Tensile Strength

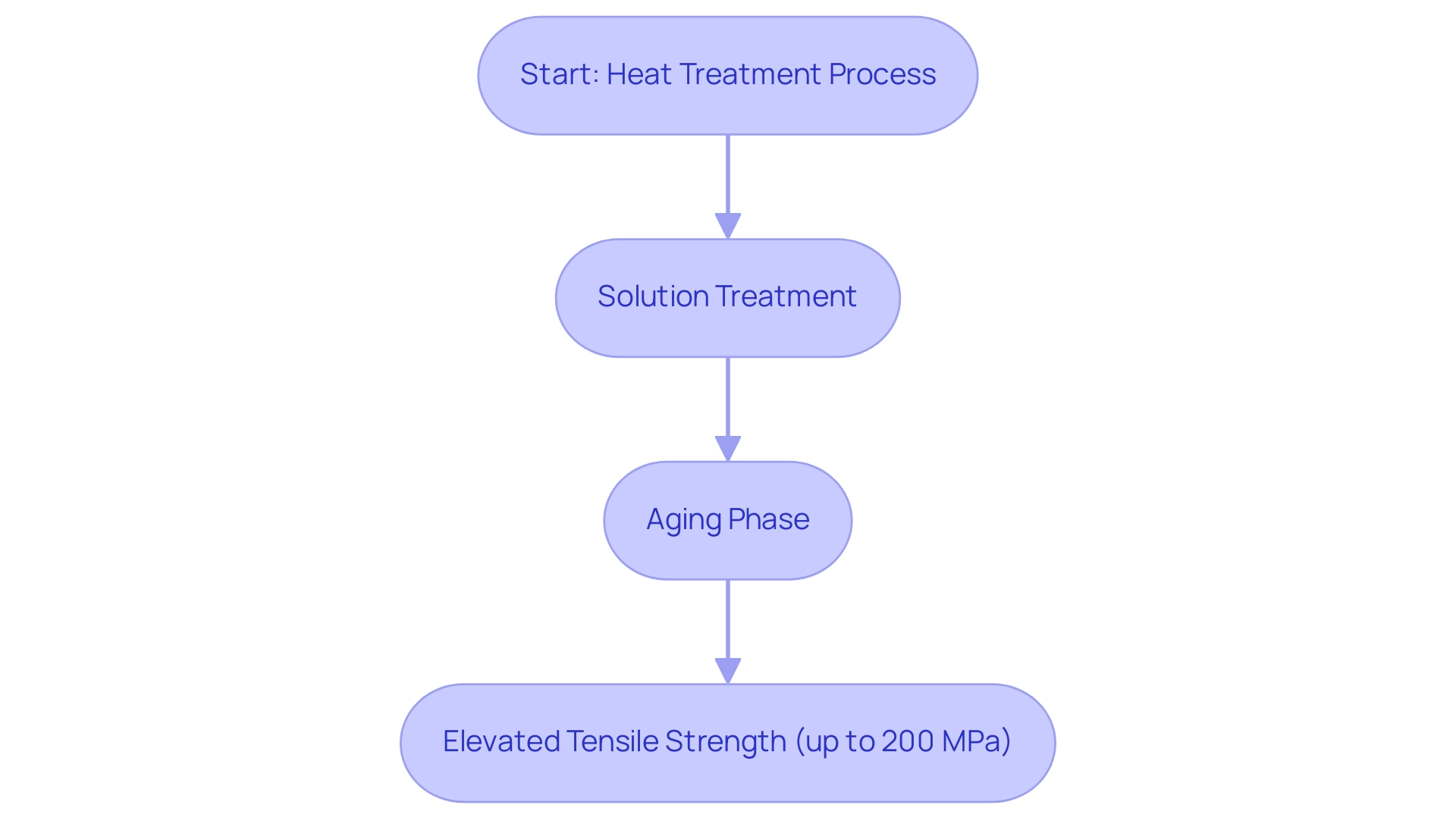

Heat treatment methods, especially aging and solution treatment, are essential in improving the beryllium copper tensile strength of an alloy, which is an important component in various applications. During the solution treatment, the alloy undergoes elevated temperatures, allowing for the dissolution of beryllium within the copper matrix before rapid cooling, which is crucial for preserving dissolved elements in a solid solution. The subsequent aging phase involves reheating the alloy at lower temperatures, leading to the formation of precipitates that significantly enhance strength.

Research indicates that these treatments can elevate the tensile strength of beryllium copper by as much as 200 MPa compared to untreated alloys. A case study titled ‘Influence of Ageing Process on Sound Velocity in C17200 Copper-Beryllium Alloy’ reveals how the aging process impacts sound velocity, identifying distinct mechanisms governing changes at different temperatures. These insights underscore the complex mechanisms at play during thermal treatments.

Additionally, measuring the coefficient of thermal expansion and thermal conductivity on aged samples provides a comprehensive view of aging effects on properties. As Sivakumar D. states, ‘C17200 exhibits the highest beryllium copper tensile strength among all beryllium based alloys.’ Comprehending these processes allows procurement experts to make informed choices concerning the selection of heat treatments customized for specific applications, ensuring optimal performance in challenging environments.

At Domadia, we are committed to being your trusted partner for Beryllium Copper solutions, offering an extensive product range that includes:

- Foils

- Sheets

- Rods

- Wires

- Custom fabrication options to meet your specific requirements.

Our Beryllium Copper strips are competitively priced, with inventory readily available to support your procurement needs.

Applications of Beryllium Copper: Leveraging Tensile Strength in Industry

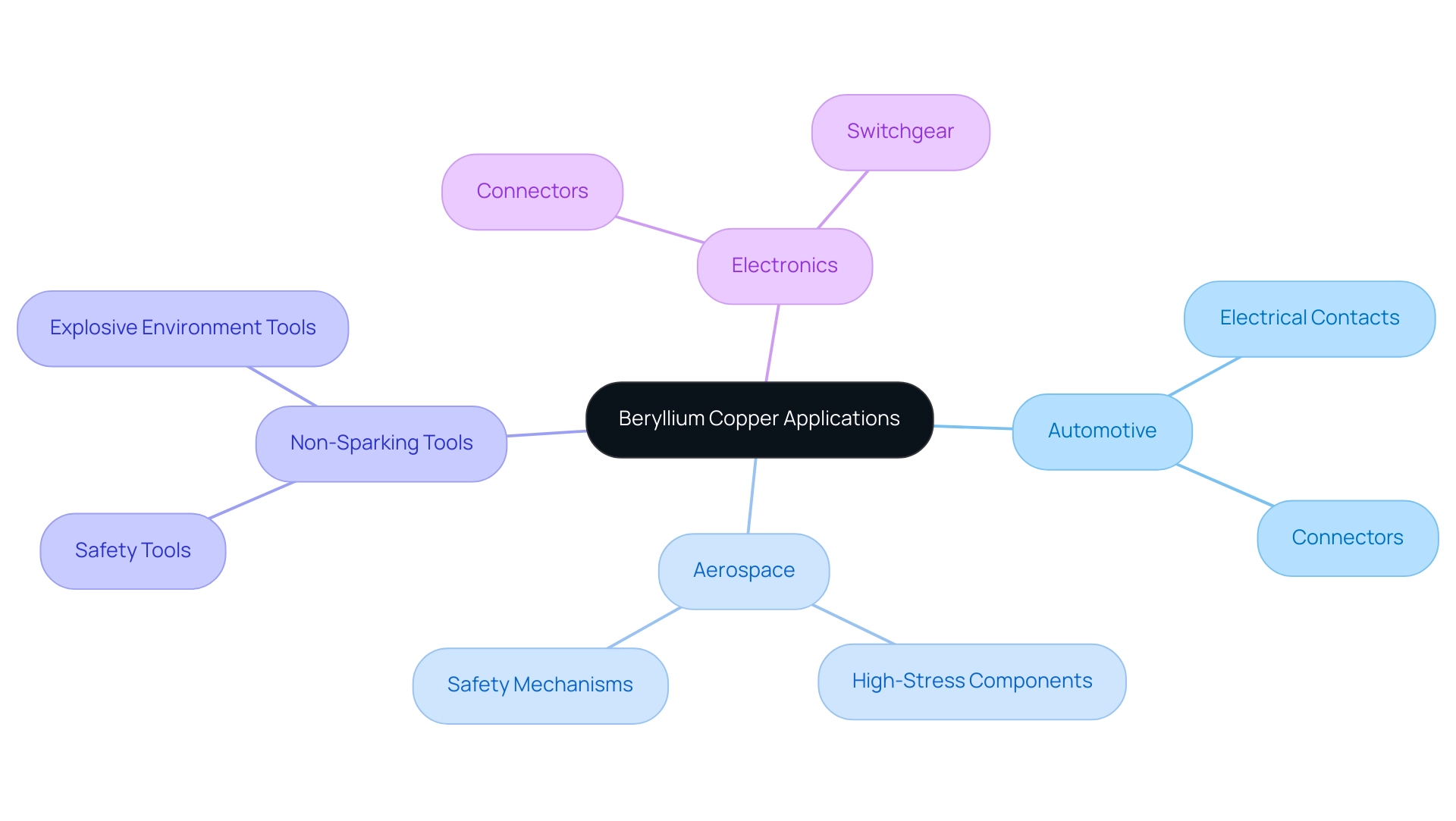

Beryllium copper tensile strength is a notable characteristic of this versatile material, recognized for its exceptional mechanical properties, making it indispensable across several industries. In the automotive industry, a specific alloy is mainly used in electrical contacts and connectors intended to operate dependably under substantial mechanical stress. Its robust nature ensures that these components maintain functionality and safety, even in demanding conditions.

Likewise, the aerospace sector utilizes a specific alloy for components exposed to high-stress settings, where performance is essential for operational safety. Additionally, non-sparking tools made from beryllium copper tensile strength are essential in explosive environments, providing a safe alternative for various applications. These tools are specifically designed to prevent sparks that could ignite flammable substances, ensuring safety during operations in hazardous locations.

Notably, its role in electronics, particularly in connectors and switchgear, highlights the substance’s ability to deliver superior electrical conductivity and durability. With industry forecasts indicating that by 2027, the worth of China’s sector may attain RMB10 billion, procurement managers must proactively identify sourcing opportunities for alloy components. This growing market not only signifies an increase in demand for high-performance materials but also emphasizes the necessity for procurement strategies that prioritize transparency and ownership of issues with clients.

The pricing of a specific alloy scrap is influenced by several factors, including market demand, purity, and current metal prices. Domadia addresses these dynamics by offering fair and competitive pricing, informed by ongoing market analysis and strong supplier relationships that ensure they remain responsive to changes in the industry. For instance, effective teamwork in Business Intelligence (BI) collaborations is crucial for ensuring smooth sourcing processes.

By comprehending these uses and the significance of teamwork, procurement managers can make knowledgeable strategic sourcing choices that take advantage of the changing environment of specialized alloys in industry-specific uses.

Safety and Handling Practices for Beryllium Copper

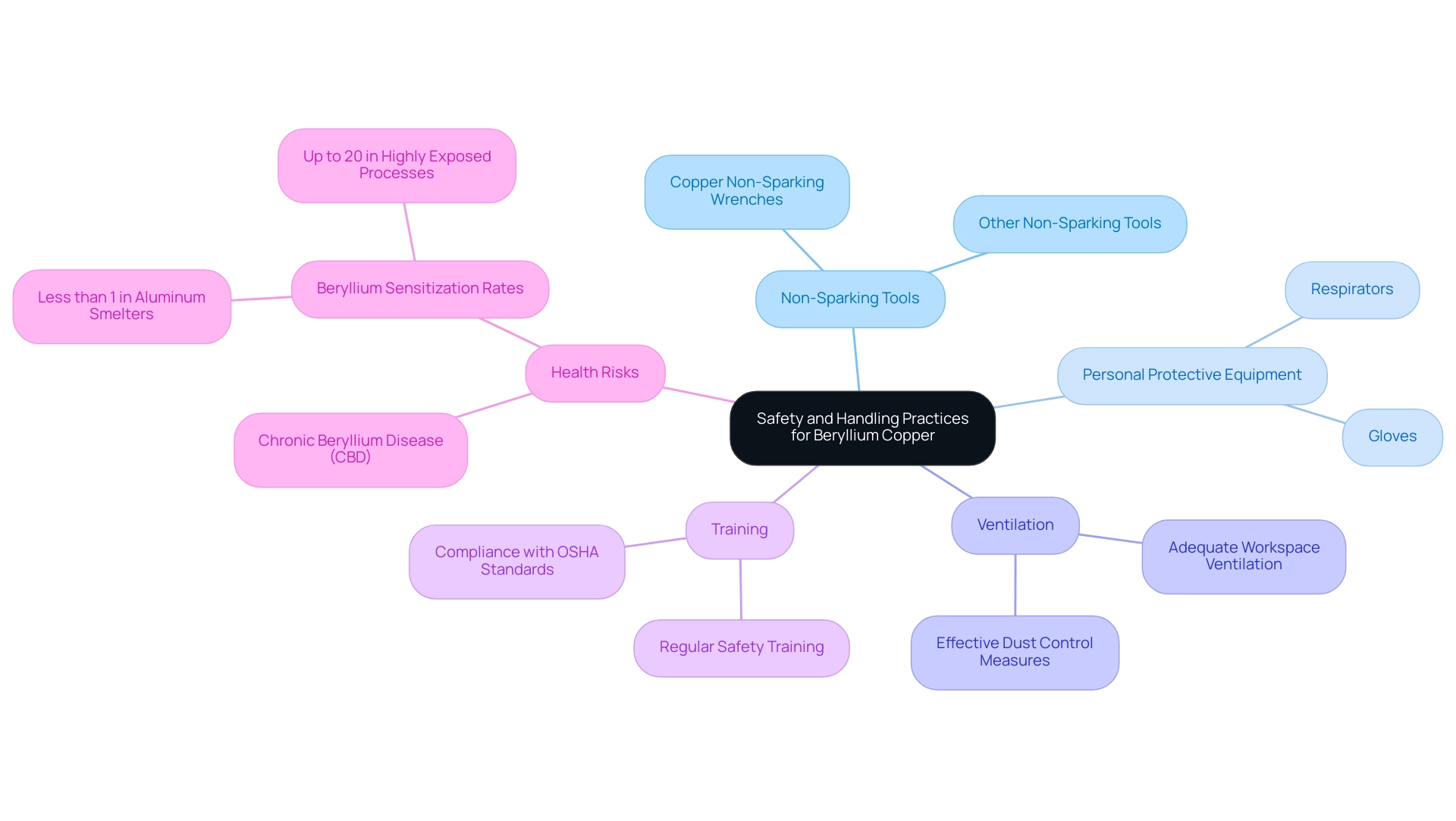

Managing this alloy requires strict compliance with safety protocols to reduce significant health hazards, especially in settings where explosive risks are present. Non-sparking tools, particularly copper non-sparking wrenches, are the best alternative for such applications due to their inherent safety features that prevent ignition in volatile settings. These tools are specifically designed to eliminate the risk of sparks that could ignite flammable materials, making them essential for safe operations.

Exposure to dust from the element can lead to chronic disease (CBD), a debilitating lung condition that significantly affects those impacted. Studies indicate that sensitization rates among exposed workers vary by industry, highlighting the pressing need for vigilance and the critical importance of using non-sparking tools in these scenarios. Therefore, employing appropriate personal protective equipment (PPE) such as respirators and gloves is non-negotiable during machining or handling of this alloy.

Furthermore, ensuring that workspaces are adequately ventilated and equipped with effective dust control measures remains vital. Regular safety training and compliance with OSHA standards are critical components of a comprehensive safety strategy. As noted by Natalia Pawlas and Cezary M. Pałczyński in the Handbook on the Toxicology of Metals, sensitization to this element is an adverse effect that warrants ongoing medical follow-up.

A case study titled ‘Chronic Beryllium Disease in Occupational Settings’ illustrates the risks of exposure and emphasizes the importance of monitoring affected workers. By prioritizing these best practices and utilizing non-sparking tools, procurement managers can create a safer working environment for all personnel involved in processes that utilize beryllium copper, while also leveraging the advantages of these tools to enhance safety in explosive environments, particularly regarding beryllium copper tensile strength.

Conclusion

Beryllium copper is undeniably a vital alloy that combines exceptional mechanical properties, making it indispensable across various high-performance industries. Its unique composition of copper and beryllium not only provides remarkable tensile strength but also ensures excellent electrical and thermal conductivity. Understanding the intricate heat treatment processes that enhance these properties further equips procurement managers with the knowledge necessary for selecting the optimal materials tailored to specific applications.

The diverse applications of beryllium copper, ranging from aerospace to automotive, showcase its versatility and reliability under significant mechanical stress. The alloy’s role in producing non-sparking tools highlights its critical safety applications, particularly in hazardous environments. As industries increasingly recognize the importance of sourcing high-quality components, the demand for beryllium copper is projected to grow, necessitating strategic procurement practices that prioritize transparency and informed decision-making.

Moreover, the safety considerations surrounding the handling of beryllium copper cannot be overstated. Adhering to best practices and employing appropriate personal protective equipment are essential to mitigate health risks associated with exposure. By fostering a culture of safety and compliance, procurement professionals can not only enhance workplace safety but also maximize the benefits of integrating beryllium copper into their operations.

In conclusion, the strategic sourcing and application of beryllium copper are essential for meeting the demands of modern industries. By prioritizing this alloy, procurement managers can ensure the longevity and performance of critical components, ultimately contributing to operational success across sectors that depend on high-quality materials.