Blogs

Understanding Monel Gate Valves: An In-Depth Tutorial for Engineers

Overview

Monel gate valves are characterized by their exceptional corrosion resistance, durability, and ability to operate effectively under high-pressure and extreme temperature conditions, making them ideal for various industrial applications. The article emphasizes these valves’ advantages in sectors such as oil and gas, chemical processing, and marine environments, highlighting their cost-saving potential and long-term reliability due to reduced maintenance needs.

Introduction

In the realm of industrial applications, Monel gate valves stand out as a critical component, renowned for their exceptional durability and resistance to corrosion. Composed primarily of a nickel-copper alloy, these valves are engineered to perform reliably in the most demanding environments, from the depths of marine applications to the high-pressure conditions of oil and gas facilities.

As industries increasingly rely on advanced materials to ensure operational efficiency and safety, understanding the key characteristics, applications, and maintenance considerations of Monel gate valves becomes essential.

This article delves into the specifications that make Monel valves a preferred choice, their versatility across various sectors, and the regulatory standards that govern their use, providing procurement managers with valuable insights for informed decision-making in their supply chains.

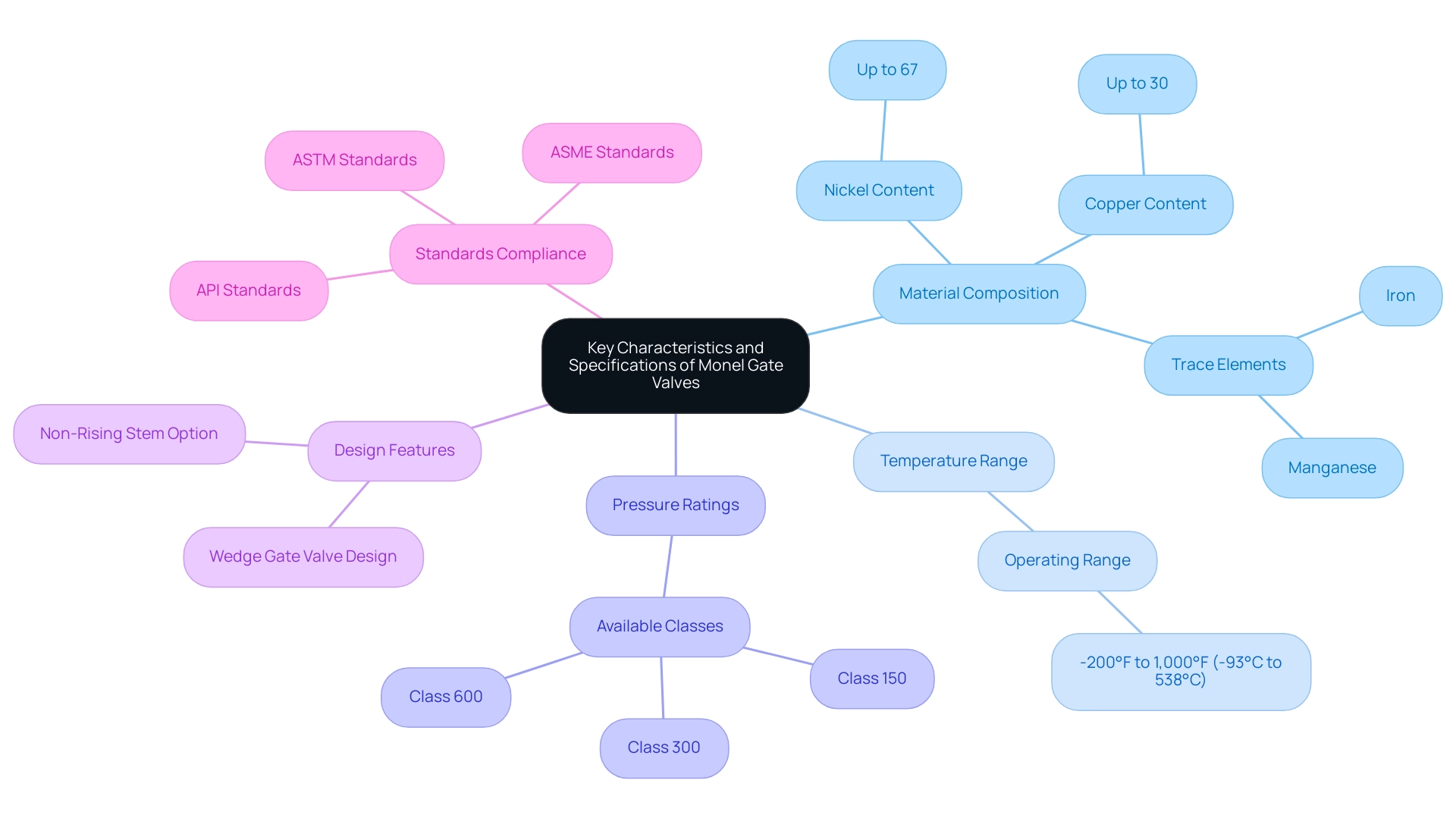

Key Characteristics and Specifications of Monel Gate Valves

Monel gate valves are recognized for their outstanding corrosion resistance, particularly in both acidic and alkaline environments. Constructed from a nickel-copper alloy with a composition primarily comprising nickel (up to 67%) and copper (up to 30%), complemented by trace amounts of iron and manganese, these devices exhibit exceptional strength and durability, making them ideal for high-pressure applications. Shane observes, “Their robust construction ensures minimal maintenance and long-term reliability, even under extreme conditions,” reinforcing the dependability of these devices in demanding environments.

Additionally, the high thermal and electrical conductivity of these alloys further enhances their suitability for various applications.

The following key specifications characterize Monel gate valves:

- Material Composition: Nickel and copper alloy with superior corrosion resistance, excellent mechanical properties, and high-temperature stability.

- Temperature Range: Capable of operating effectively across a broad temperature spectrum, from -200°F to 1,000°F (-93°C to 538°C), ensuring reliability in extreme conditions.

- Pressure Ratings: Available in multiple classes, including Class 150, 300, and 600, accommodating various pressure requirements in industrial applications.

- Design Features: Typically designed as wedge gate valves, they often include a non-rising stem option, advantageous in space-limited installations.

- Standards Compliance: Frequently produced in alignment with ASME, API, and ASTM standards, ensuring their quality and reliability in operation.

A case study titled “Advantages of Specialty Valves” emphasizes that the Monel gate valve provides remarkable corrosion resistance, high-pressure performance, and durability, rendering it suitable for harsh environments like marine, automotive, and electrical sectors. These attributes render these fittings a favored option in challenging environments where durability and resistance to corrosion are essential. Moreover, although needle controls, which cost between $10 and $30, are referenced for comparison, it is crucial to emphasize the greater value of investing in premium shut-off devices for high-pressure and industrial uses.

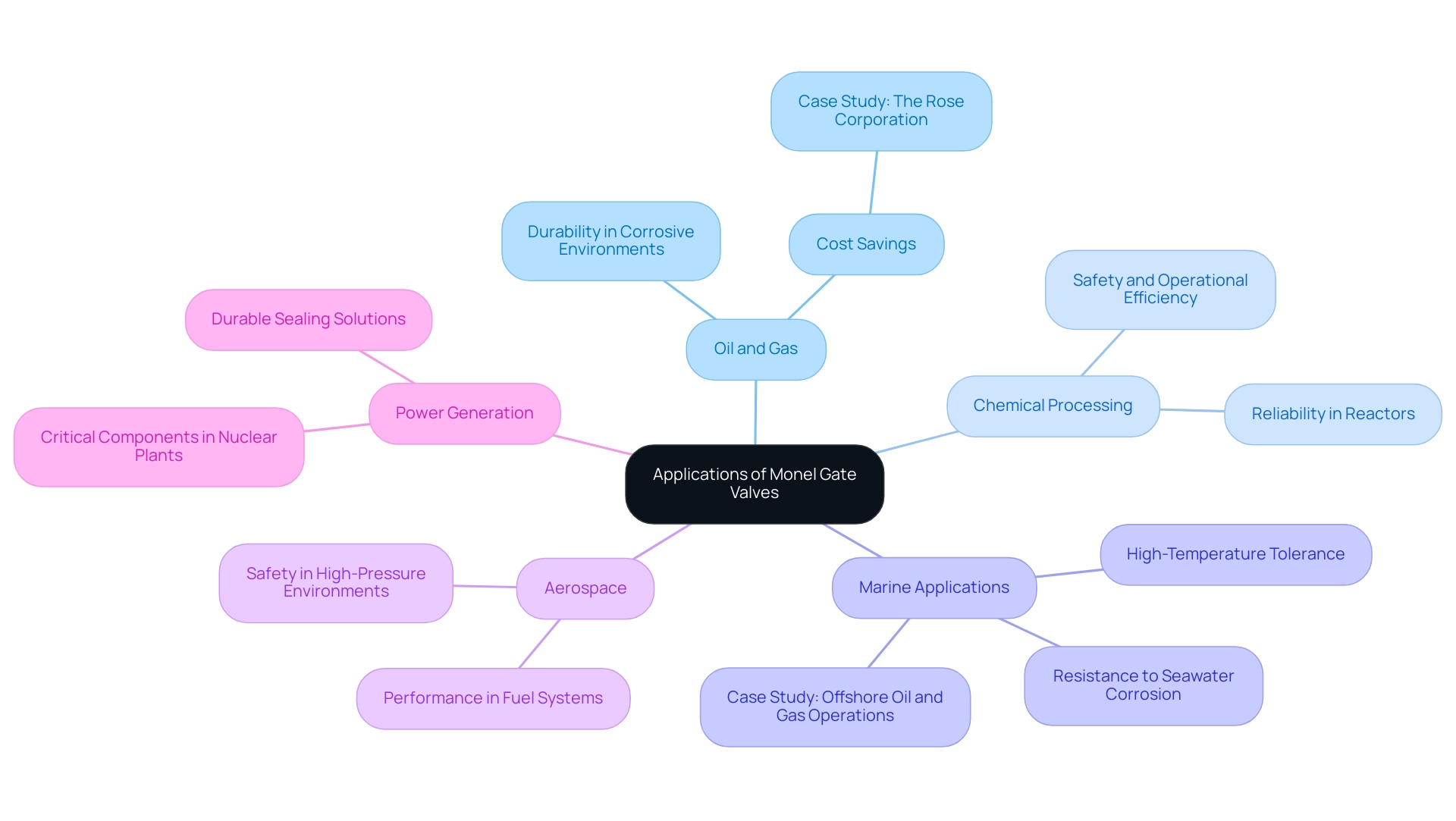

Applications of Monel Gate Valves in Industry

Gate devices made of a specific alloy are essential in numerous sectors because of their remarkable characteristics and performance benchmarks. Key applications include:

- Oil and Gas: In both upstream and downstream processes, Monel valves excel at managing corrosive fluids such as sour gas and brine, ensuring reliability even in the most challenging environments. Their durability helps to reduce maintenance costs and downtime, crucial factors in the competitive oil and gas sector. A case study from The Rose Corporation illustrates this point, showing how a customer saved $36,000 by switching to standard metal hardware, demonstrating the effective cost-saving potential of these devices.

- Chemical Processing: The durability of this alloy to corrosive substances renders these fittings perfect for application in reactors, distillation columns, and other essential apparatus within chemical facilities. Their reliability in maintaining system integrity is paramount for operational efficiency and safety.

- Marine Applications: With outstanding resistance to seawater corrosion, these valves are a preferred choice in shipbuilding and offshore oil rigs. This property guarantees long-lasting functionality in marine environments, where conventional materials may fail. The case study titled ‘The Crucial Role of Valves in Offshore Oil and Gas Operations’ emphasizes their durability and high-temperature tolerance, rendering them essential in reducing maintenance and ensuring dependable operation.

- Aerospace: In aerospace applications, monel gate valves are employed within fuel systems and hydraulic circuits, where they must withstand extreme temperatures and pressures. Their performance is vital for safety and reliability in high-stakes situations.

- Power Generation: Alloy fittings play a critical role in both nuclear and thermal power plants, serving as essential components in systems that require durable and reliable sealing solutions under challenging conditions.

As mentioned by a project manager at The Rose Corporation, “By working with the customer to transition to standard hardware made of the same material, we were able to save the customer $36,000 without sacrificing safety or quality.” This adaptability of these components across these sectors demonstrates their essential role in engineering and procurement strategies. By ensuring safety, efficiency, and adherence to industry standards, procurement managers can significantly improve operational effectiveness by incorporating this material into their supply chains.

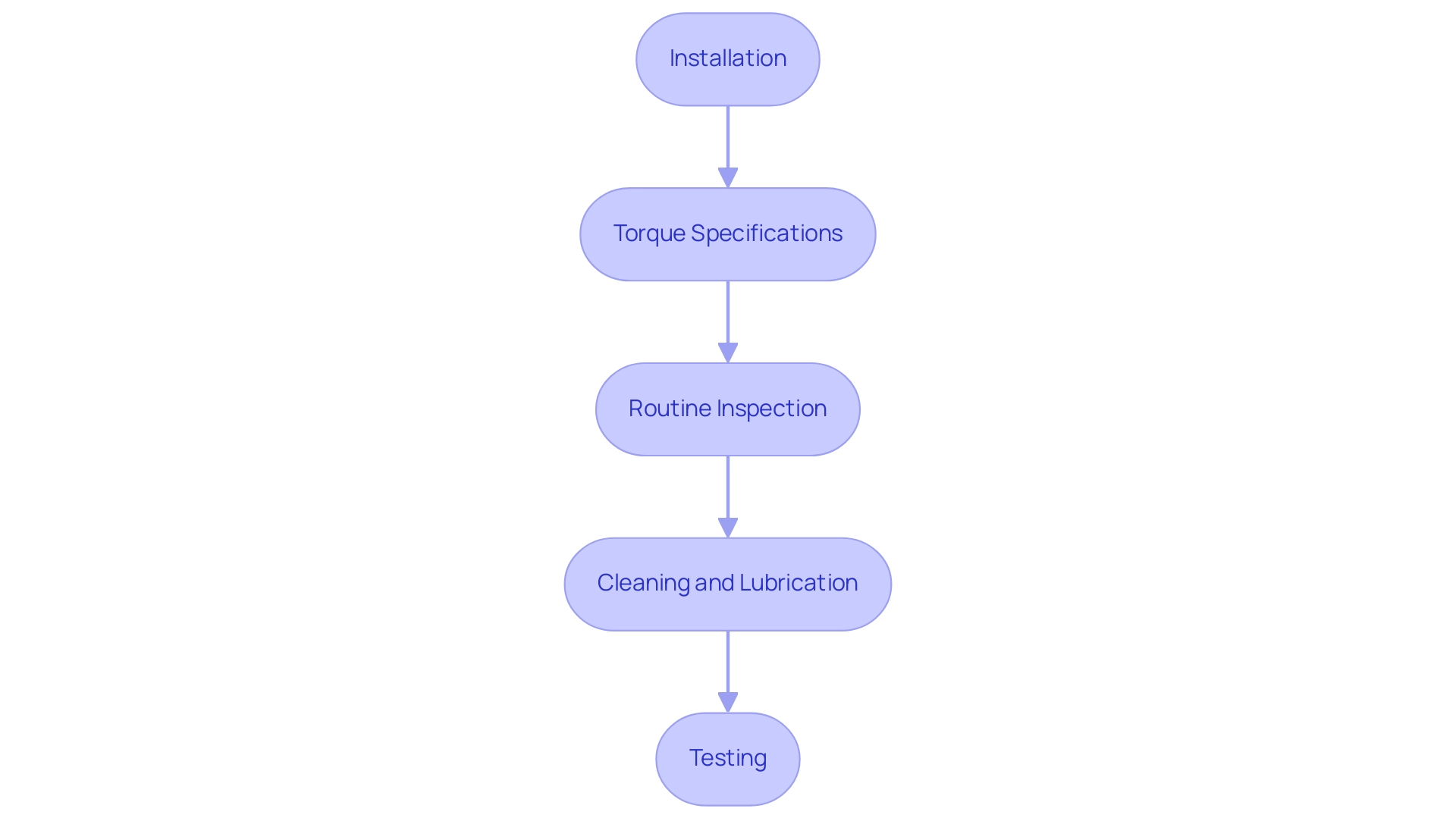

Installation and Maintenance Considerations

The correct installation and upkeep of the monel gate valve fittings are essential for guaranteeing dependable operation across multiple applications, especially in HVAC systems where specifications for meters and gauges are crucial for functionality. Key considerations include:

- Installation: Position the component in the correct orientation, typically horizontal, to prevent flow complications. It is essential to use suitable gaskets and seals that maintain integrity and prevent leaks. Before installation, confirm the component’s compatibility with existing piping systems to ensure optimal functionality, especially concerning HVAC specifications detailed in Section 230519.

- Torque Specifications: Follow the manufacturer’s torque specifications closely during fastening to secure a tight fit without jeopardizing the integrity of the component body.

- Routine Inspection: Establish a regular inspection schedule to detect any signs of wear, corrosion, or leakage. This process should involve checking the stem operation to ensure that the mechanism opens and closes smoothly without resistance.

- Cleaning and Lubrication: Regularly clean the surfaces and apply lubrication to moving parts in accordance with the manufacturer’s recommendations. This practice improves functionality and reduces resistance, thereby prolonging the lifespan of the device.

- Testing: Conduct functional testing immediately after installation and periodically thereafter to verify that the device operates effectively within specified pressure and temperature ranges. For example, ensure that the flow range for orifice flowmeters corresponds with the operational range of the equipment or system served.

Moreover, recognizing that there is an option to cancel the service at any time can offer a more comprehensive perspective of the operational context in which these devices are utilized. Following these guidelines will greatly enhance the integrity and efficiency of these components, ultimately guaranteeing their dependable performance in challenging applications.

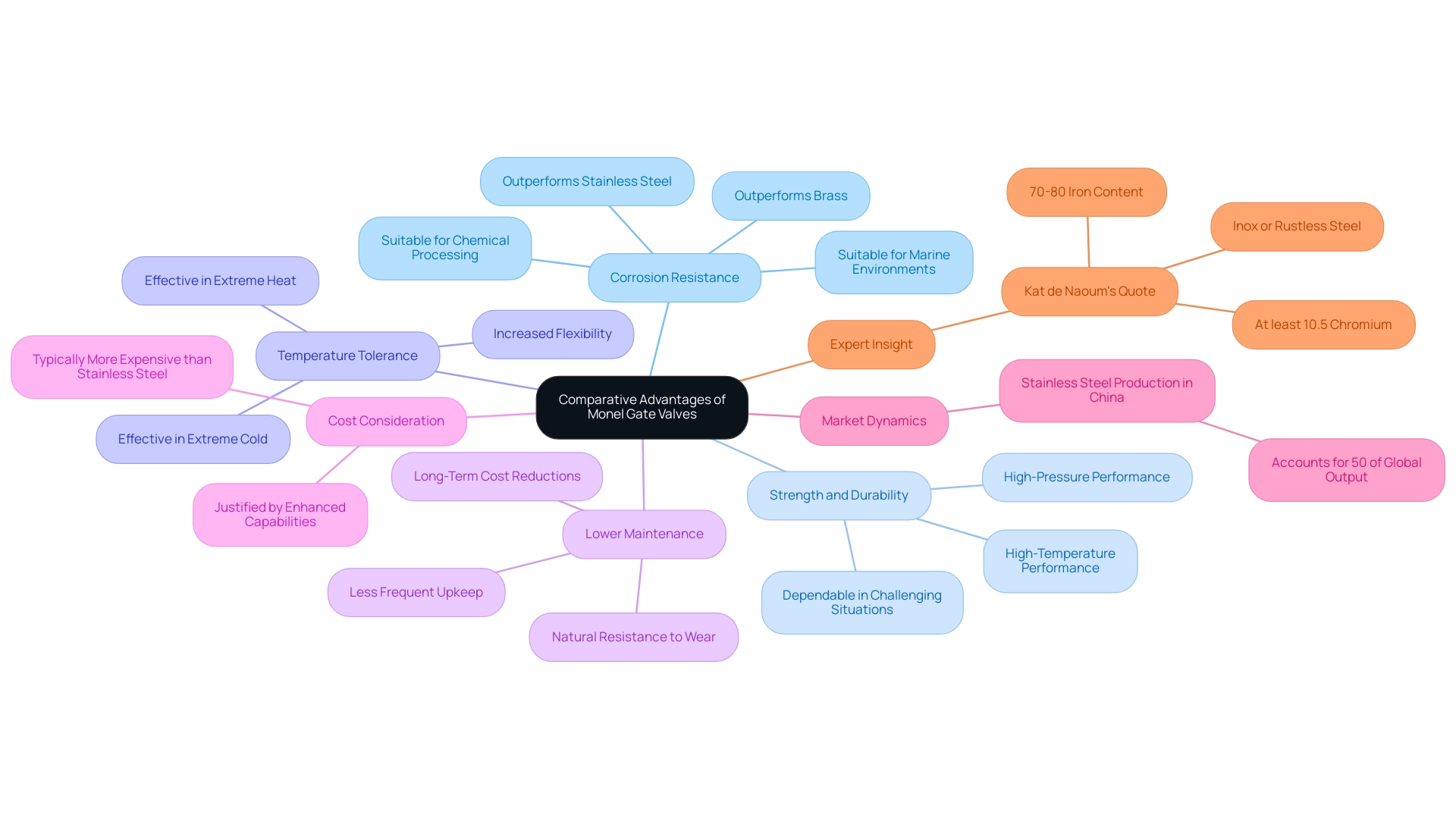

Comparative Advantages of Monel Gate Valves Over Other Materials

Gate fixtures made of this alloy offer several compelling benefits compared to other materials, especially in corrosive settings. Key comparative points include:

Corrosion Resistance: This alloy boasts exceptional resistance to a diverse range of corrosive media, outperforming both stainless steel and brass. This characteristic renders the alloy particularly appropriate for uses in chemical processing and marine environments, where contact with harsh substances is frequent.

Strength and Durability: These fittings maintain their strength and integrity even under high-pressure and high-temperature conditions, often surpassing the performance of alternative materials. This durability guarantees dependability in challenging operational situations.

Temperature Tolerance: With the ability to function across a broad temperature range, these components are effective in both extreme heat and cold, providing increased flexibility for various applications.

Lower Maintenance: Due to their natural resistance to corrosion and wear, these gate mechanisms require less frequent upkeep and replacement. This durability results in considerable long-term cost reductions for sectors dependent on strong fitting solutions.

Cost Consideration: It is important to note that this material is typically more expensive than stainless steel, a factor that procurement managers must consider when evaluating options based on budget constraints. This higher cost is often justified by the enhanced capabilities and longevity of the alloy in corrosive environments.

Market Dynamics: With stainless steel production in China accounting for more than 50% of global annual output, understanding the market dynamics is crucial for making informed material selections.

Expert Insight: As noted by Kat de Naoum, ‘It’s sometimes called ‘inox’ or rustless steel and is made of around 70–80% iron, with at least 10.5% chromium for the protective oxide layer bonus.’ This emphasizes the intrinsic benefits of substances like the monel gate valve, which provides improved corrosion resistance in difficult settings.

These benefits position the monel gate valve as an exceptional option for control devices in industries that require dependable and durable performance, especially in areas characterized by corrosive difficulties.

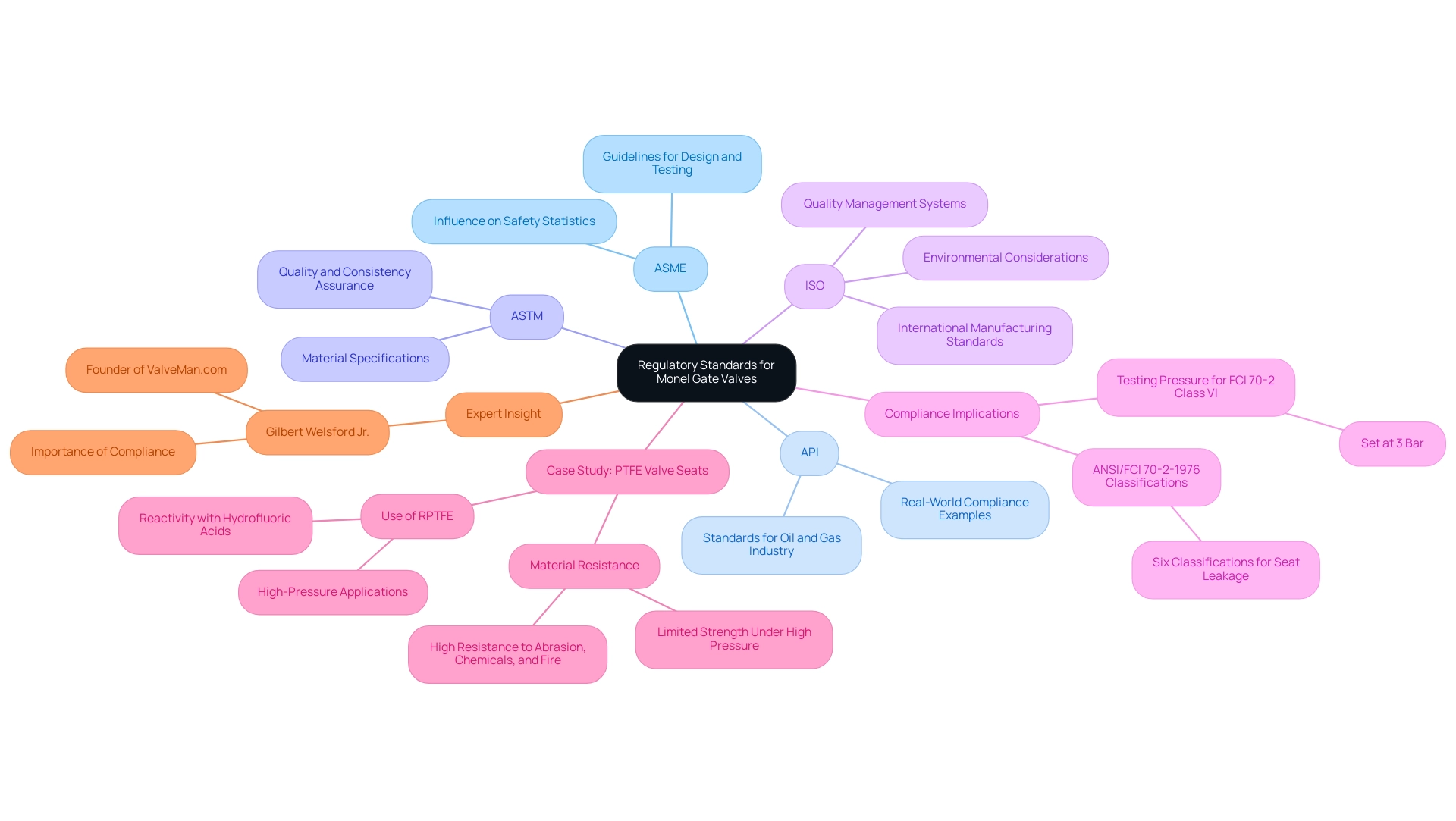

Regulatory Standards and Compliance for Monel Gate Valves

Adherence to regulatory standards is crucial for the safety and reliability of the monel gate valve mechanisms across various applications. Notable standards include:

ASME (American Society of Mechanical Engineers): This organization provides crucial guidelines for the design and testing of devices, ensuring that they perform safely under pressure conditions. The influence of ASME standards on safety statistics for fittings cannot be overstated, as they form the backbone of operational integrity.

API (American Petroleum Institute): API establishes rigorous standards specifically for devices employed in the oil and gas industry, which are designed to endure extreme operating conditions. Real-world examples of API compliance illustrate its critical role in the functionality of the monel gate valve within these harsh environments.

ASTM (American Society for Testing and Materials): ASTM sets forth essential material specifications that guarantee quality and consistency in manufactured products. Adherence to these specifications is vital to maintaining the integrity of components in demanding applications.

ISO (International Organization for Standardization): ISO provides international standards that govern manufacturing processes, incorporating quality management systems and environmental considerations that are increasingly important in today’s market.

In practical terms, compliance can be exemplified by the testing pressure for FCI 70-2 Class VI components, which is set at 3 bar, illustrating the stringent requirements that must be met. Additionally, the ANSI/FCI 70-2-1976 standard establishes six classifications for seat leakage, each designed for specific types and test conditions, further emphasizing the importance of regulatory compliance.

Moreover, the case study on PTFE seat components highlights the challenges associated with these materials. While PTFE is known for its high resistance to abrasion, chemicals, and fire, it has limited strength under high pressure and temperature variations. In high-pressure applications, a variant like RPTFE can be used, although it reacts negatively with hydrofluoric acids, showcasing the need for careful material selection and compliance with standards.

Understanding and ensuring compliance with these standards enhances product reliability, streamlines the procurement process, and significantly reduces legal risks.

As noted by Gilbert Welsford Jr., founder of ValveMan.com, > Compliance is not just about meeting regulations; it is about ensuring our products can withstand the test of time and usage in demanding conditions. Such insights emphasize the importance of strict compliance with regulatory standards in the production of control devices that utilize a monel gate valve.

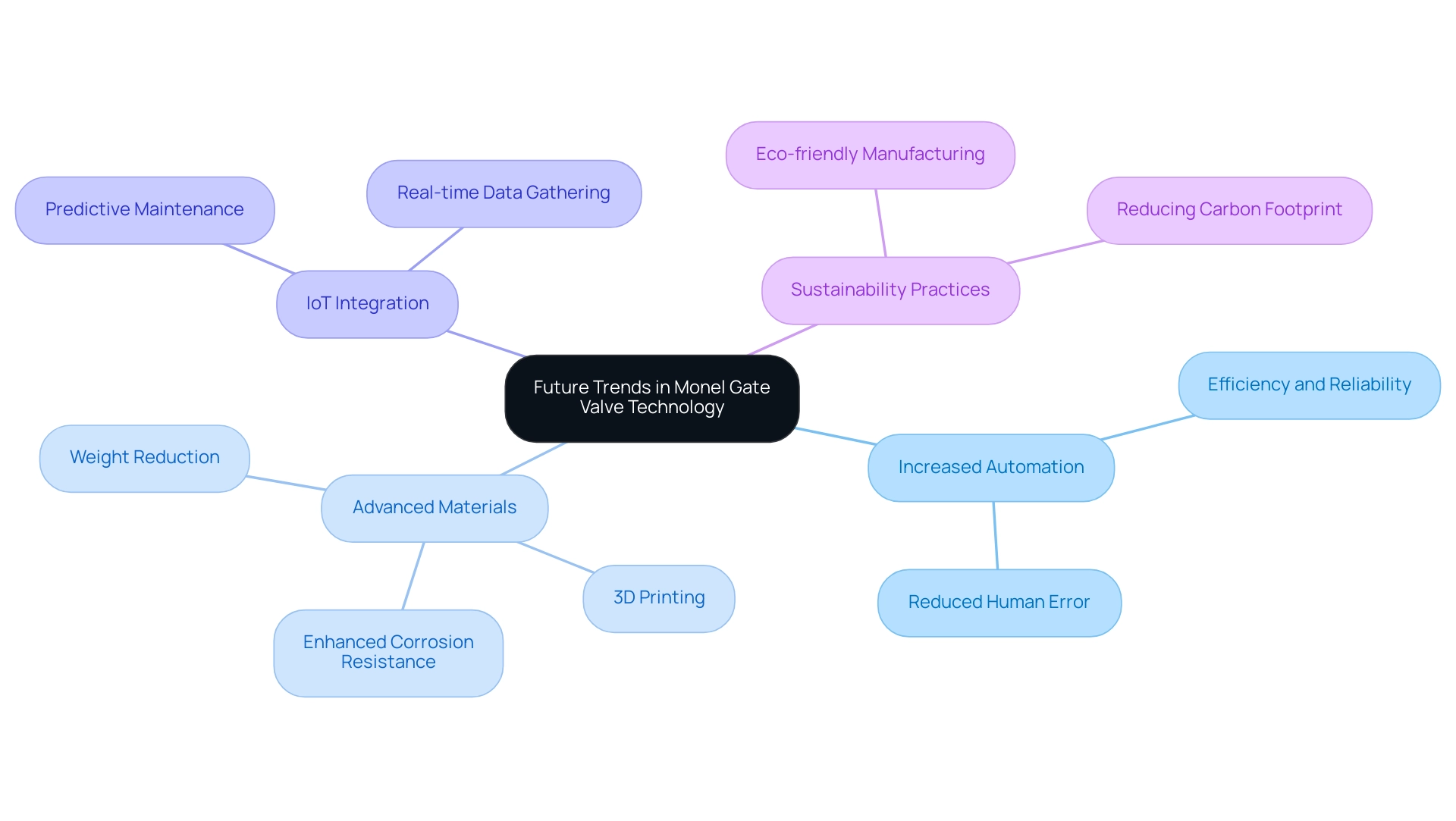

Future Trends in Monel Gate Valve Technology

As industries continue to evolve, several significant trends are emerging in the technology surrounding Monel gate valves:

- Increased Automation: The integration of automation in valve operations is set to enhance both efficiency and reliability, minimizing the need for manual intervention during operation and maintenance. This trend is particularly relevant given the growing emphasis on optimizing operational workflows. As noted by industry experts, “Automation not only streamlines processes but also significantly reduces the risk of human error in critical applications.”

- Advanced Materials: Ongoing research into advanced composite materials is likely to yield enhanced versions of Monel gate valve alloys. These innovations may lead to improvements in performance characteristics, such as weight reduction and enhanced corrosion resistance, which are crucial for extending the lifespan of fittings in demanding environments. Additionally, the advent of 3D printing technology enhances prototyping, allowing for rapid design, production, and testing of new models, thereby speeding up the development cycle.

- IoT Integration: The Internet of Things (IoT) is set to transform monitoring and control systems for fittings. By permitting real-time data gathering on performance and conditions, IoT technology promotes improved predictive maintenance strategies. This capability is increasingly vital in sectors like oil and gas, where equipment failures can lead to significant operational and environmental costs. The trend towards AI maintenance is especially important in this industry, as it supports proactive measures to mitigate risks linked to operations.

- Sustainability Practices: The increasing demand for eco-friendly materials and methods is anticipated to affect the manufacturing of these components. Focused efforts on reducing the carbon footprint during manufacturing will not only align with global sustainability goals but also resonate with procurement strategies that prioritize eco-friendly practices.

These trends will significantly shape the future landscape of the Monel gate valve, impacting its design, application, and procurement strategies within various industries.

Conclusion

Monel gate valves emerge as a vital component in industrial applications, showcasing exceptional durability and corrosion resistance. Their unique nickel-copper alloy composition allows them to thrive in extreme environments, making them indispensable in sectors such as:

- Oil and gas

- Chemical processing

- Marine applications

- Aerospace

By understanding their key characteristics, including temperature and pressure ratings, procurement managers can make informed decisions that enhance operational efficiency and safety.

The versatility of Monel gate valves is underscored by their compliance with stringent regulatory standards, such as:

- ASME

- API

- ASTM

These standards ensure reliability and performance, which are critical in high-stakes environments. Furthermore, the comparative advantages of Monel over other materials highlight its superior resistance to corrosion, strength, and lower maintenance requirements, ultimately translating into long-term cost savings for industries reliant on robust valve solutions.

As the industry evolves, trends such as increased automation, advanced materials development, IoT integration, and sustainability practices are set to redefine the future of Monel gate valves. By embracing these advancements, procurement managers can not only enhance their supply chain strategies but also contribute to safer, more efficient operations in their respective sectors. Investing in Monel gate valves is not merely a decision for immediate needs; it’s a strategic choice that positions organizations for success in an increasingly demanding industrial landscape.