Blogs

Understanding Monel K500 Round Bar: A Complete Tutorial on Properties and Applications

Introduction

Monel K500 stands out in the realm of nickel-copper alloys, celebrated for its remarkable strength and corrosion resistance that make it indispensable across various industries. Comprising a unique blend of nickel, copper, aluminum, and titanium, this alloy not only surpasses its predecessor, Monel 400, in mechanical properties but also excels in extreme environments, particularly marine applications.

With its ability to withstand harsh conditions, Monel K500 is increasingly favored for critical components such as:

- Pump shafts

- Valves

These components are utilized in sectors ranging from aerospace to oil and gas. As procurement managers seek reliable and high-performance materials, understanding the specifications, applications, and customization options of Monel K500 becomes essential in making informed decisions that drive operational success.

This article delves into the intricacies of Monel K500, exploring its composition, mechanical properties, and the vital role it plays in modern industry.

Overview of Monel K500: Composition and Classification

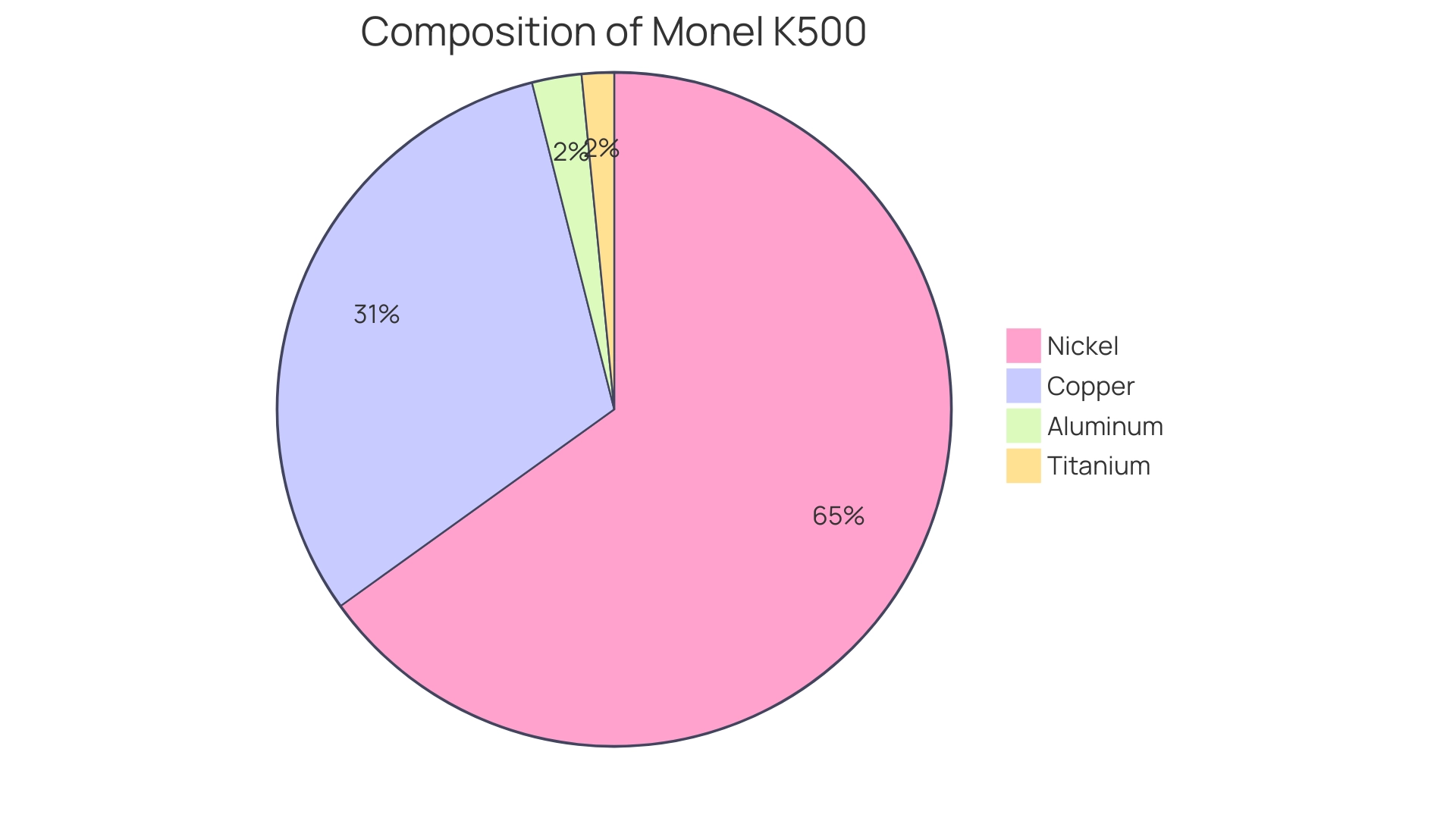

Monel K500 round bar is a nickel-copper mixture celebrated for its remarkable durability and excellent corrosion resistance, making it a favored option in numerous challenging applications. This alloy is primarily composed of:

- Nickel (63%)

- Copper (30%)

- Aluminum (2.3%)

- Titanium (1.5%)

These components significantly enhance its mechanical properties. It boasts approximately three times the yield strength and double the tensile strength compared to Alloy 400, making it particularly noteworthy for its ability to maintain strength at elevated temperatures.

Alloy N05500 is categorized under the UNS N05500 standard and demonstrates remarkable resistance to seawater and other harsh conditions, an essential aspect in marine engineering applications. Recent developments highlight its performance in stagnant seawater, where it exhibited a maximum pit depth of only 0.864 mm after three years of exposure. Additionally, this alloy experiences a slight permanent contraction during aging, but minimal warpage is anticipated due to low temperatures and slow cooling rates.

This exceptional corrosion resistance, combined with its robust mechanical properties, positions the Monel K500 round bar as a superior choice for critical applications such as:

- Pump shafts

- Impellers

- Various electronic components across multiple industries

Its versatility is comparable to the diverse range of copper nickel mixtures provided by Domadia, which serve similar purposes in marine, automotive, and electrical sectors. For procurement managers, Domadia’s extensive product catalog provides numerous options tailored to specific project needs.

Additionally, in settings with explosive risk, utilizing non-sparking tools along with certain metals can improve safety and operational efficiency. The alloy merges the outstanding corrosion resistance of Alloy 400 with enhanced durability and hardness, attained through the incorporation of aluminum and titanium along with regulated heating methods.

Key Physical and Mechanical Properties of Monel K500

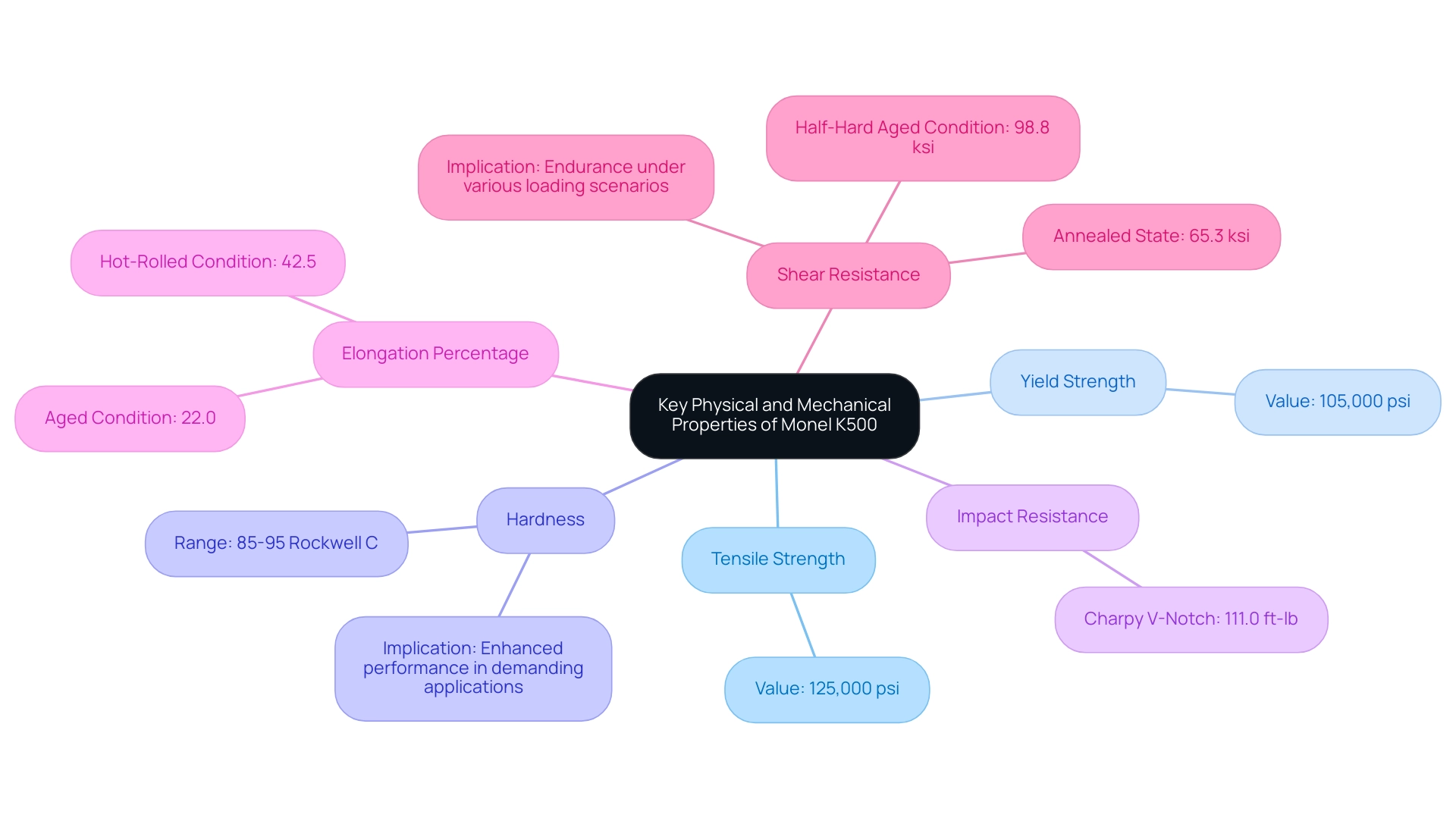

This alloy is noted for its outstanding mechanical characteristics, featuring a tensile resilience of approximately 125,000 psi (862 MPa) and a yield resilience of around 105,000 psi (724 MPa). In contrast to the alloy 400, which displays a lower tensile durability, the other variant demonstrates superior hardness, varying from 85 to 95 Rockwell C. This higher hardness enhances its performance in demanding applications, especially in marine settings where resistance to pitting, stress corrosion cracking, and oxidation is essential. Notably, Monel K500 retains its mechanical integrity at elevated temperatures, maintaining effectiveness in environments reaching up to 1000°F (538°C).

The Charpy V-Notch impact resistance for a one-inch diameter specimen is noted at 111.0 ft-lb, highlighting the material’s robustness under dynamic loading conditions. Furthermore, recent studies indicate a significant decrease in elongation percentage from 42.5% in its hot-rolled condition to 22.0% when aged, highlighting the alloy’s adaptability under various thermal treatments. Furthermore, a case analysis on the shear resistance of the alloy revealed maximum shear values ranging from 65.3 ksi for the annealed state to 98.8 ksi for the half-hard aged condition, demonstrating the material’s ability to endure various loading scenarios.

These characteristics render the Monel K500 round bar an ideal choice for applications that require high strength and resistance to harsh conditions. Firms such as Nickel Systems offer premium exotic grade materials, including Monel K500 round bar, which is a specific nickel-copper alloy appropriate for extreme temperatures and corrosive settings, mirroring present market offerings and trends.

Applications of Monel K500 Round Bars in Industry

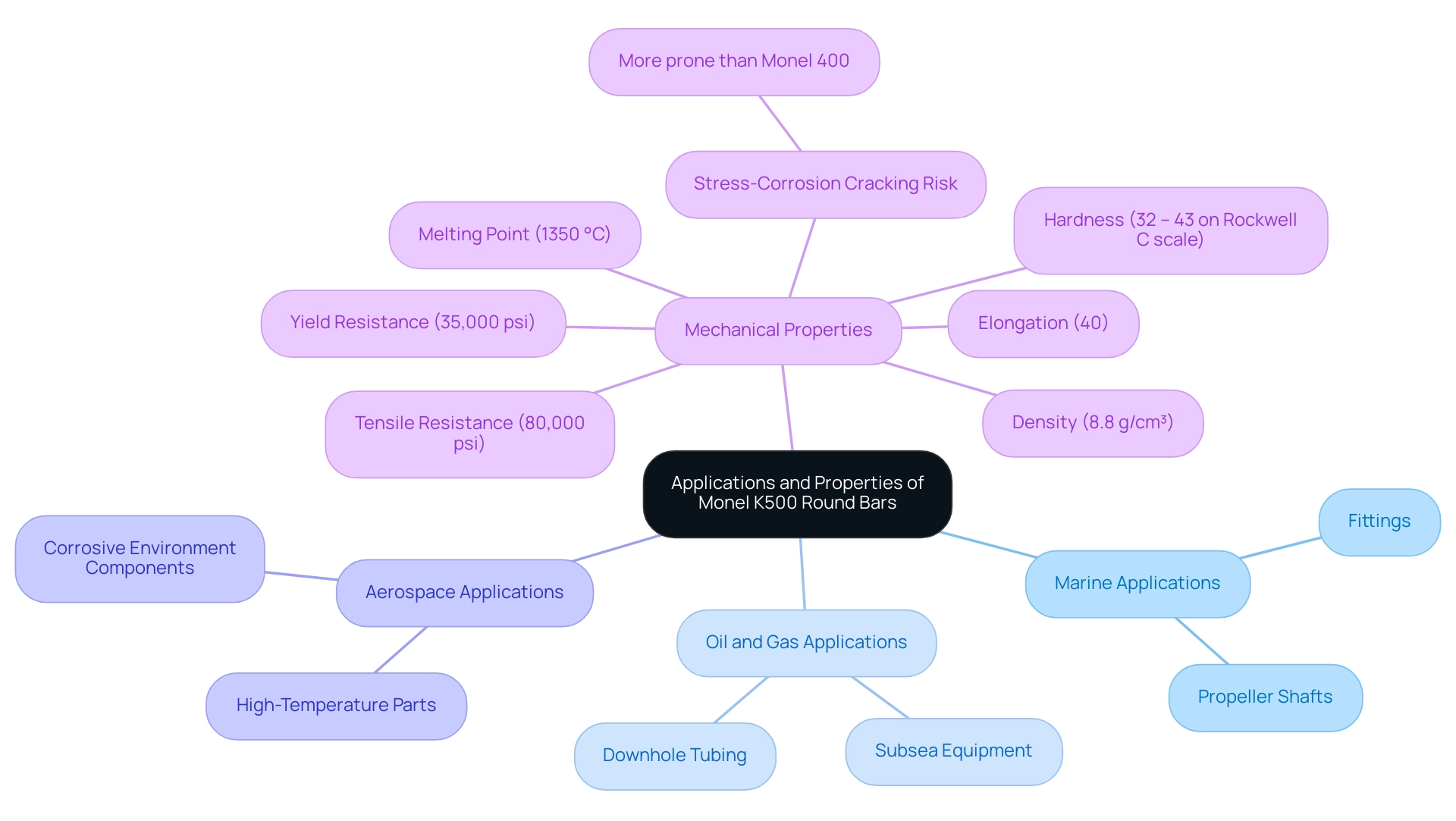

Monel k500 round bar is widely acknowledged for its outstanding performance across various industries, especially in marine, oil and gas, and aerospace applications. These bars are engineered to meet the demands of components such as pumps, valves, and shafts, where high strength and resistance to corrosion are paramount. In the marine sector, the alloy is the preferred material for propeller shafts and fittings, due to its exceptional capacity to resist the corrosive effects of seawater.

The oil and gas sector employs a nickel-copper alloy for critical applications, including subsea equipment and downhole tubing, where durability and reliability are essential. Additionally, in aerospace, an alloy is utilized in parts that must withstand elevated temperatures and corrosive conditions, demonstrating its versatility and durability. Significantly, this alloy demonstrates remarkable mechanical characteristics, featuring:

- A hardness of 32 – 43 on the Rockwell C scale

- A density of 8.8 g/cm³

- A melting point of 1350 °C

- Tensile resistance of 80,000 psi

- Yield resistance of 35,000 psi

- An elongation of 40%

However, it is important to note that age-hardened alloy K is more prone to stress-corrosion cracking compared to alloy 400. These characteristics affirm its status as a preferred choice for heavy-duty applications, making it a vital material in the procurement landscape. The case study titled ‘Mechanical Properties of Monel K500 Round Bar’ further supports its reliability and strength, underscoring its significance in various industrial applications.

Standards and Specifications for Monel K500 Round Bars

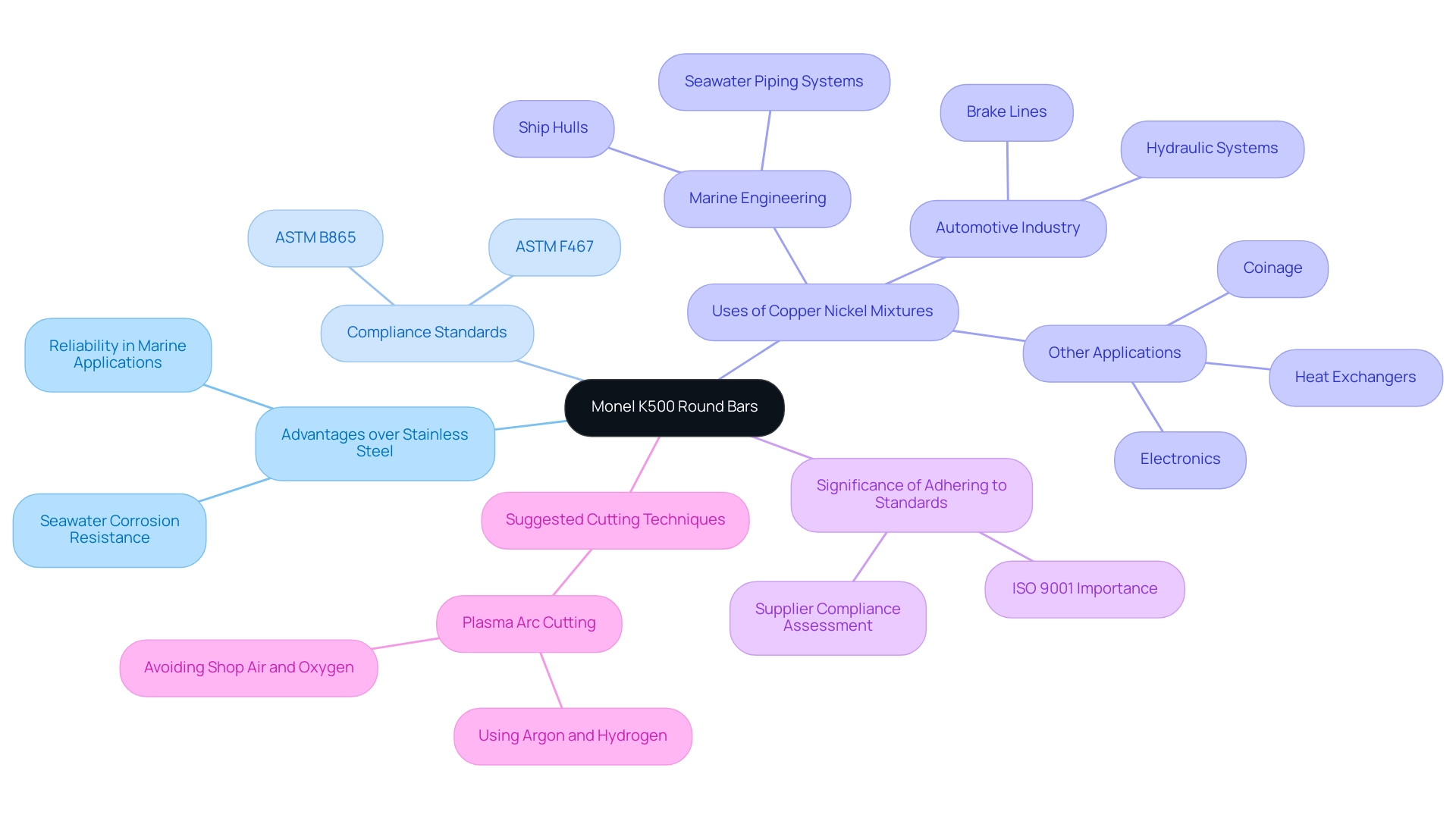

Q1. What are the advantages of copper nickel mixtures over stainless steel in marine environments?

Copper nickel mixtures provide exceptional resistance to seawater corrosion, which is essential for parts like ship hulls and offshore platforms.

In contrast, stainless steel may suffer from pitting and crevice corrosion in similar conditions. This makes copper nickel mixtures a more reliable choice for marine applications.

What are the compliance standards for the alloy K500?

Monel K500 round bar meets strict standards, notably ASTM B865 for nickel-copper materials and ASTM F467 for corrosion-resistant materials. These specifications ensure that the material meets essential performance benchmarks, including mechanical properties such as tensile strength and corrosion resistance.

Q3. What are the uses of copper nickel mixtures?

Copper nickel mixtures are widely utilized in marine engineering for components such as ship hulls and seawater piping systems. They are also utilized in the automotive industry for brake lines and hydraulic systems due to their excellent corrosion resistance. Additionally, copper nickel mixtures find applications in electronics, heat exchangers, and coinage, showcasing their versatility and effectiveness.

What is the significance of adhering to international standards?

Adherence to international standards like ISO 9001 for quality management systems is imperative for manufacturers, ensuring consistency and reliability throughout the production process. This is crucial for procurement managers to assess suppliers’ compliance and guarantee the sourcing of high-quality materials.

Q5. What cutting techniques are suggested for this alloy?

Effective plasma arc cutting of alloys using argon and hydrogen gases is recommended, while shop air and oxygen-bearing gases should be avoided to maintain quality. Insights from case studies reveal that this alloy exhibits specific mechanical properties, making it suitable for heavy-duty applications across various industries.

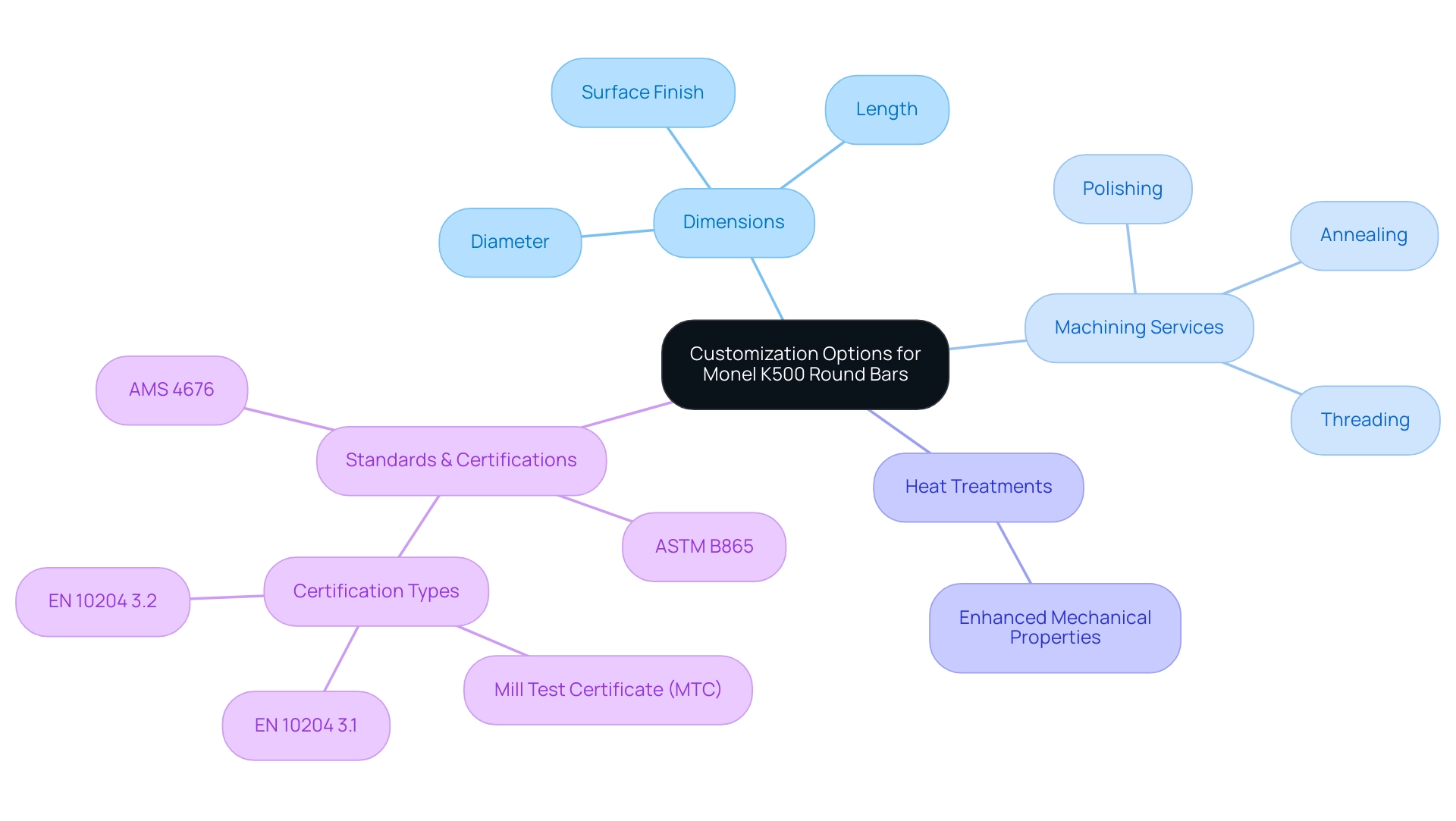

Customization Options for Monel K500 Round Bars

Customization of monel k500 round bars is a critical factor for procurement managers seeking to optimize material performance in their projects. Variations in diameter, length, and surface finish are readily available to meet specific application requirements. Suppliers frequently provide machining services that include essential processes such as:

- Threading

- Polishing

- Annealing

These processes are vital for achieving precise design specifications.

Furthermore, heat treatment processes can be applied to enhance specific mechanical properties, tailoring the material to the unique demands of various applications. The modulus of elasticity for the alloy is 103 ksi, which is an essential factor in material selection. As noted by Robust Special Metals, our monel k500 round bar conforms to various international standards, including:

- ASTM B865

- AMS 4676

They also provide certifications such as:

- Mill Test Certificate (MTC)

- EN 10204 3.1

- EN 10204 3.2

Additionally, best-selling products in this category include:

- Pipes

- Tubes

- Buttweld and forged pipe fittings

- Flanges

- Fasteners

This highlights the relevance of these materials in various applications. Engaging with suppliers to explore these customization capabilities is essential in ensuring that the sourced materials not only meet but exceed the intended performance criteria.

Conclusion

Monel K500 is a standout nickel-copper alloy known for its exceptional strength and corrosion resistance, making it ideal for demanding environments, particularly in marine applications. Its unique composition of nickel, copper, aluminum, and titanium allows it to significantly surpass Monel 400 in mechanical properties, ensuring reliability in critical components across industries.

The alloy’s versatility is evident in its applications within aerospace, oil and gas, and marine engineering, where it is used in pump shafts, valves, and other essential parts. Its impressive mechanical properties, combined with compliance to standards like ASTM B865, provide procurement managers with confidence in its performance.

Customization options enhance Monel K500’s appeal, allowing for tailored solutions that meet specific project requirements. Variations in diameter, length, and surface finish, along with machining services, enable industries to optimize material performance effectively.

In conclusion, Monel K500 represents a significant advancement in alloy technology, offering a strategic advantage for businesses seeking high-performance materials. Its robust characteristics and adaptability make it a vital component in modern industry, supporting success and safety in challenging environments. For procurement managers, understanding the capabilities of Monel K500 is essential for fostering innovation and achieving project excellence.