Blogs

Understanding Permalloy Density: An In-Depth Tutorial on Properties and Applications

Overview

Permalloy density is crucial for its applications in electronics and magnetic shielding, significantly enhancing performance by reducing energy losses and providing effective protection against external interference. The article supports this by detailing how permalloy’s high density and properties, such as temperature adaptability and manufacturing techniques, make it an ideal material for transformers, inductors, and various advanced electronic components.

Introduction

The significance of permalloy in modern technology cannot be overstated, as its unique composition and exceptional magnetic properties make it a cornerstone in various applications, from electronics to advanced magnetic shielding. Comprised primarily of nickel and iron, permalloy exhibits high permeability and low coercivity, which are critical for enhancing performance in devices such as transformers and inductors.

As industries increasingly rely on efficient and reliable materials, understanding the fundamental characteristics of permalloy, including its response to temperature fluctuations and its manufacturing processes, becomes essential for procurement managers.

This article delves into the intricate properties of permalloy, its diverse applications, and the emerging trends that are shaping its future in a rapidly evolving technological landscape.

Fundamental Properties of Permalloy: Composition and Characteristics

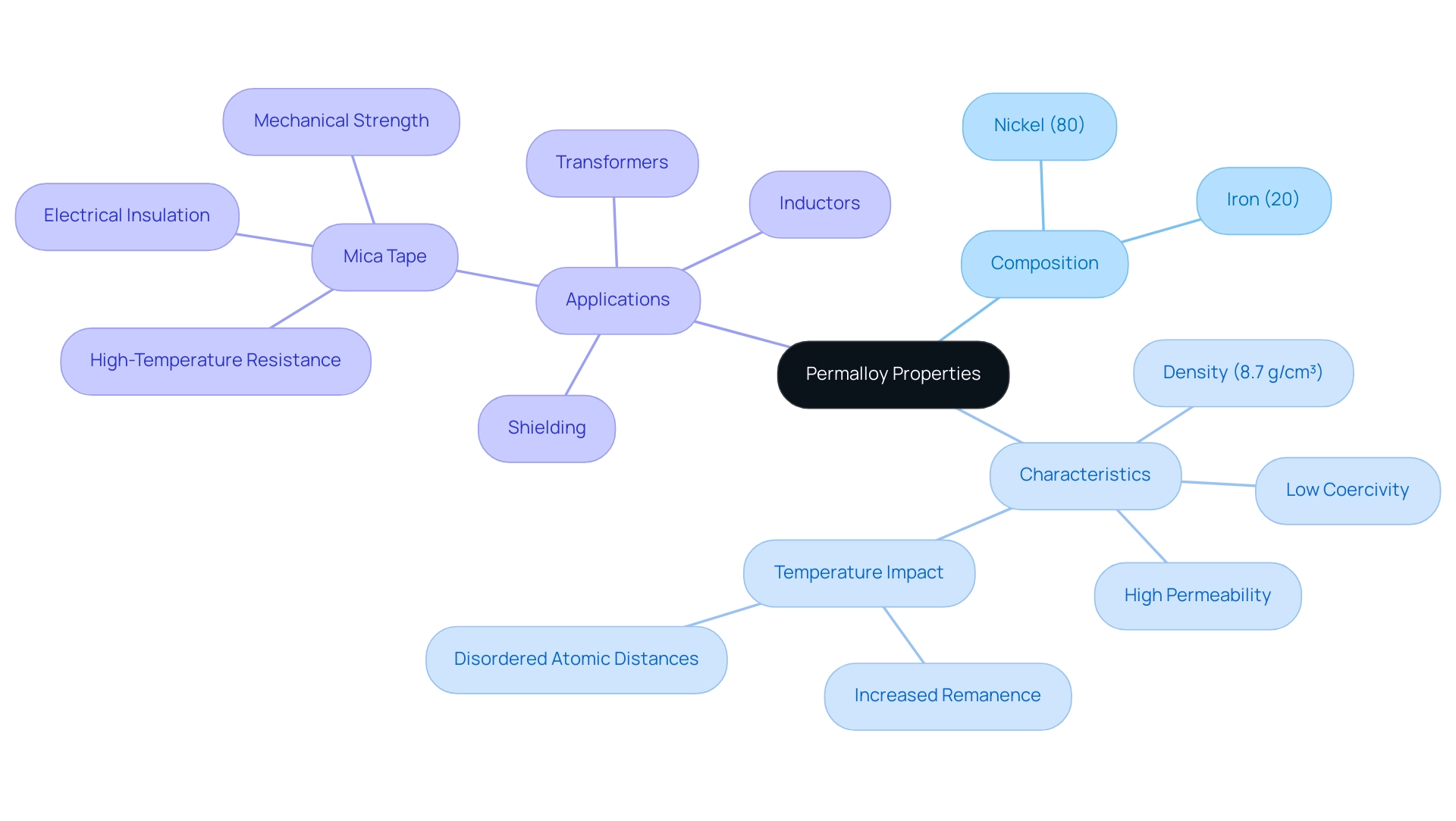

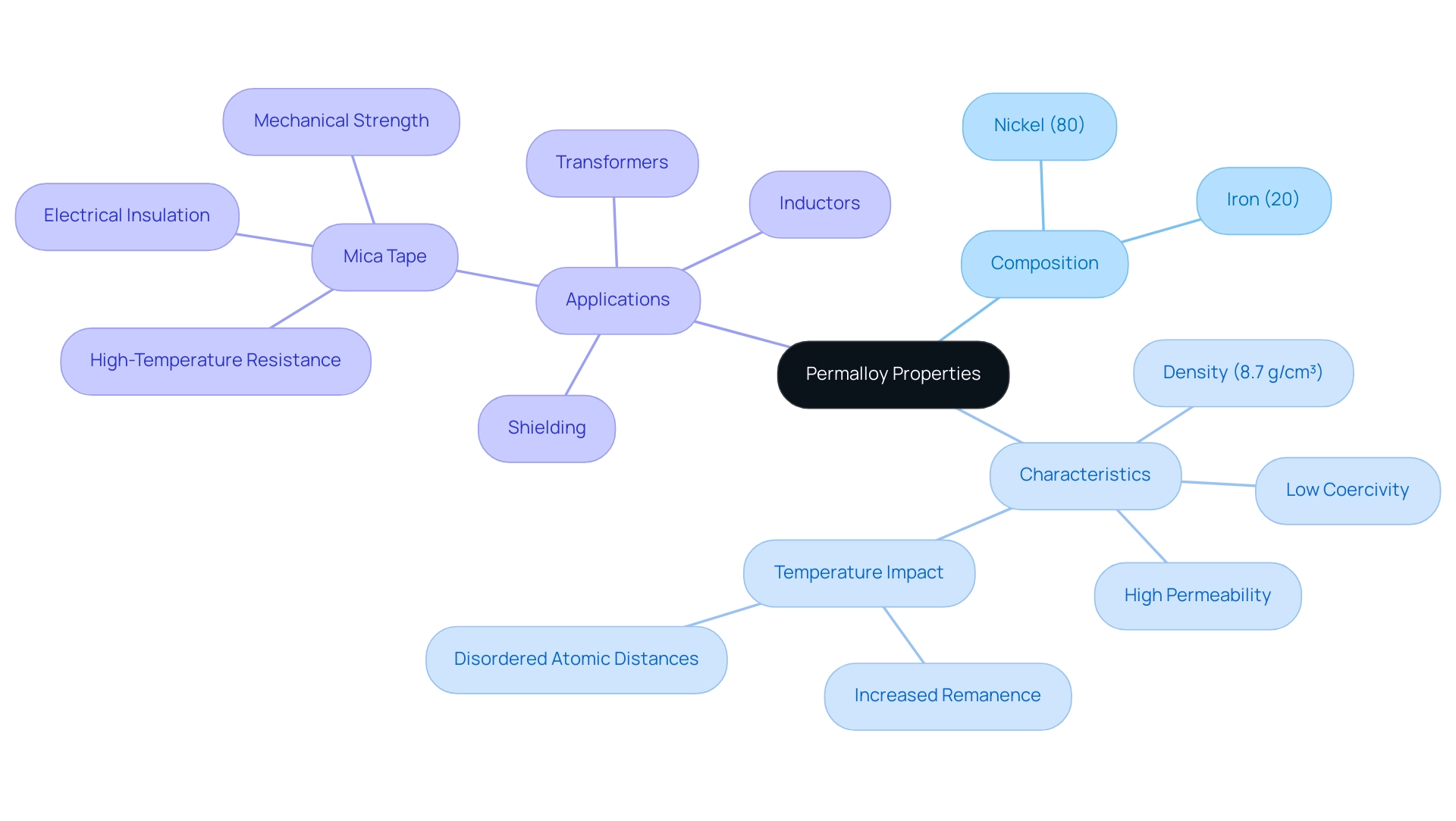

Permalloy, an alloy mainly consisting of about 80% nickel and 20% iron, is famous for its outstanding properties, which include high permeability and low coercivity. With a permalloy density of approximately 8.7 g/cm³, this feature is essential for evaluating its use in different electromagnetic devices. The alloy is especially appreciated for its exceptional shielding capabilities and minimal losses, making it an ideal choice for transformers, inductors, and applications requiring effective shielding.

Notably, as Jinji Sun observes,

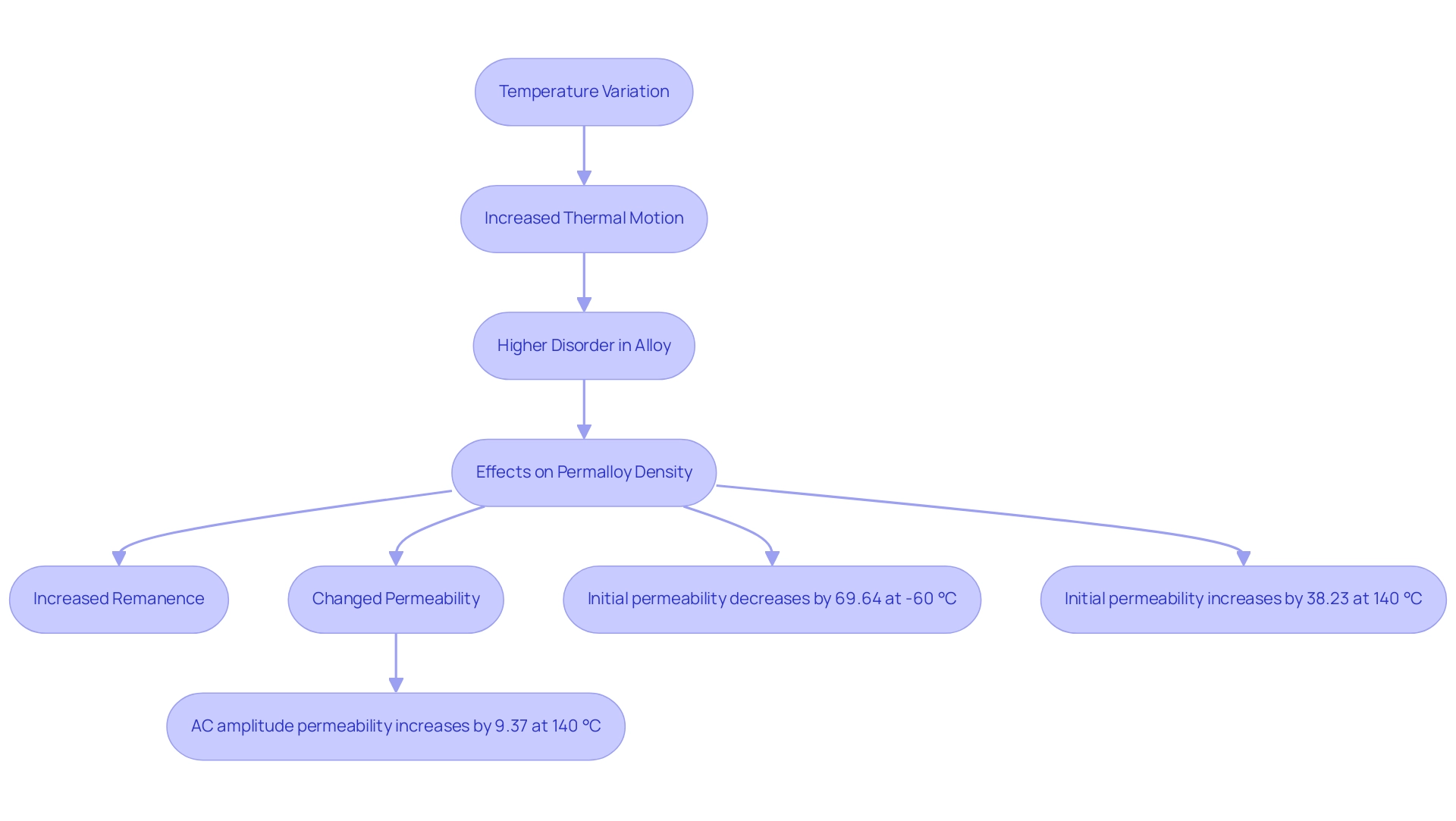

Temperature has a significant impact on the properties of permalloy.

This emphasizes that thermal motion rises with temperature, resulting in disordered atomic distances, which subsequently improves remanence and influences the alloy’s overall functioning. This effect is crucial, especially in real-world applications where temperature fluctuations can complicate magnetic behavior.

Furthermore, the thermal and electrical conductivity of this material are essential for its performance in electronic components, where efficient heat dissipation is vital. Recent research highlights that at elevated temperatures, such as 140 °C, the AC amplitude permeability of this alloy can increase by 9.37% at a frequency of 1 kHz, illustrating its adaptability and effectiveness under varying conditions. In conjunction with other materials, Mica Tape products, known for their high-temperature resistance, excellent electrical insulation properties, mechanical strength, and flame resistance, serve as critical components in applications like transformers and inductors.

These tapes provide reliable thermal and electrical insulation, ensuring safety and performance in demanding environments. The mechanical strength of Mica Tape allows it to withstand harsh conditions, while its dielectric strength protects against electrical breakdown. Additionally, the complexities of real-world materials necessitate simulations before experiments, as indicated by current studies, which emphasize the need to understand how this alloy interacts in practical scenarios.

Insights from the case study on Co on FeMn Exchange Biasing also reveal the intricate behaviors of interactions, showcasing how exchange biasing can lead to asymmetric hysteresis loops and different reversal processes, further highlighting the complexities of permalloy’s properties.

Applications of Permalloy: From Electronics to Magnetic Shielding

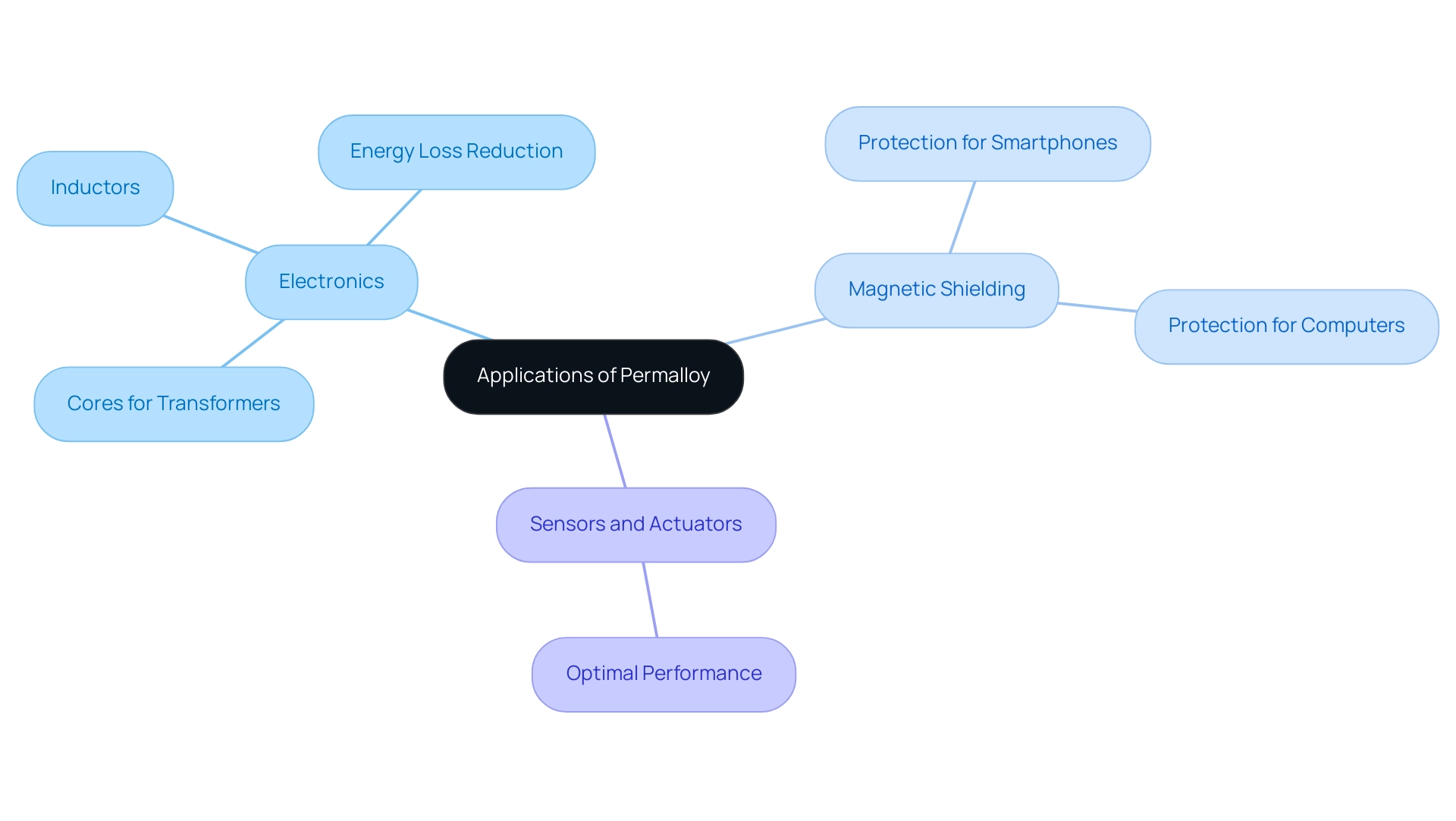

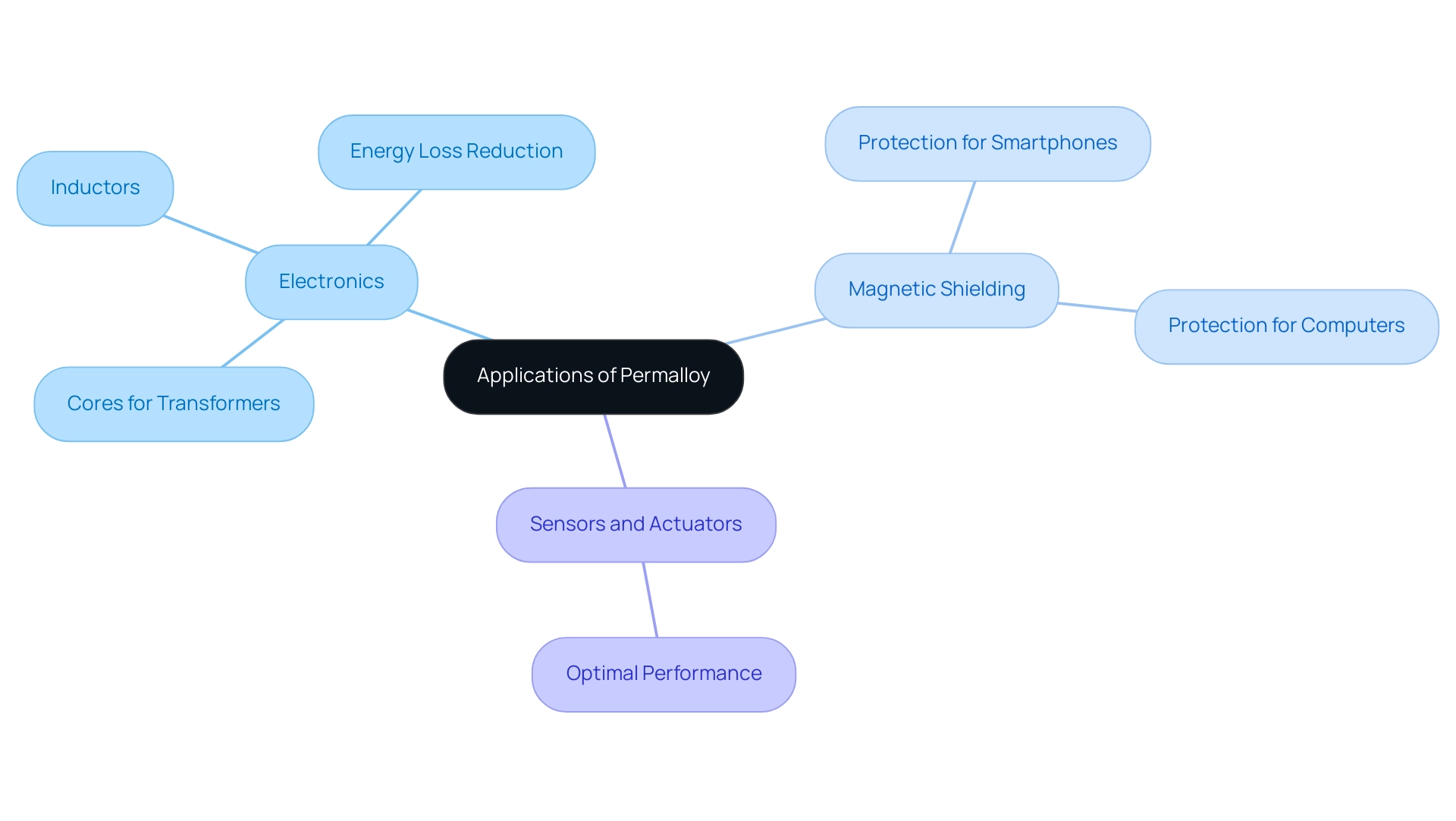

The density of permalloy plays a pivotal role in the electronics sector, particularly in the production of cores for transformers and inductors. The exceptionally high permalloy density significantly enhances performance by reducing energy losses, which is a crucial factor for efficient operation. Indeed, recent data show that this alloy’s utilization in shielding purposes has risen by more than 20% in the past year, highlighting its efficiency in protecting delicate electronic components from interfering external fields.

This protection is vital in modern devices such as smartphones and computers, where even minor interference can result in operational malfunctions. As one electronics expert aptly stated, ‘Just as professionals in Transportation Planning negotiate their worth by showcasing their value and achievements, this material demonstrates its value in achieving high-performance electronic solutions.’ Beyond its uses in electronics, this alloy is also employed in sensors and actuators due to its permalloy density, which is crucial for optimal performance.

The case study titled ‘The Evolving Landscape of Permalloy for Current Sensor Market’ illustrates how the market is transforming due to increasing demand for high-precision current sensing solutions, particularly in renewable energy and electric vehicles. The material’s versatility extends to various manufacturing techniques, including advanced thin film deposition processes, underscoring its significance in cutting-edge technological uses. As the market evolves, the demand for this material in these contexts continues to grow, driven by the increasing need for high-performance electronic solutions.

Impact of Temperature on Permalloy Density

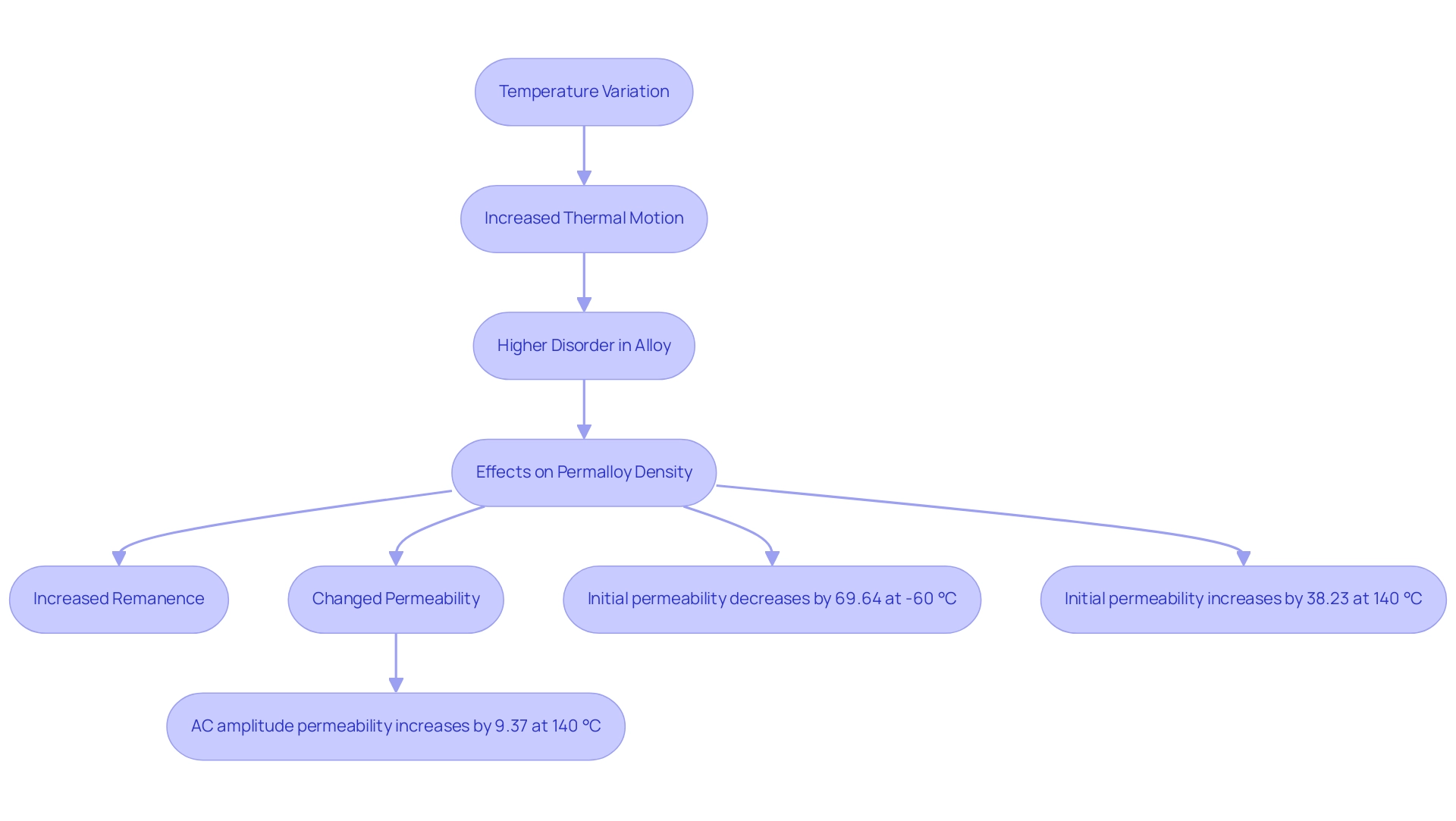

Temperature variations considerably affect the permalloy density and properties of the alloy, impacting its overall effectiveness in diverse applications. As thermal motion increases with temperature, the disorder within the alloy rises, leading to higher remanence and changed permeability. Notably, studies indicate that the permalloy density‘s AC amplitude permeability can increase by 9.37% at 140 °C under a frequency of 1 kHz.

This emphasizes the significance of considering thermal expansion in settings such as transformers and magnetic sensors, where efficiency and stability are crucial. In parallel, Domadia’s Mica Tape products are designed to address challenges posed by high temperatures in electrical insulation. With superior flame resistance, high dielectric strength, and excellent mechanical strength, these tapes are essential for critical applications across various sectors, from household appliances to industrial machinery.

Materials engineers routinely conduct thermal analyses to ensure that alloy components and Mica Tapes perform optimally within designated temperature ranges. For instance, a recent investigation into the magnetic properties of a specific alloy showed that permalloy density affects initial permeability, which decreases by 69.64% at -60 °C but increases by 38.23% at 140 °C, demonstrating the critical influence of temperature on magnetic performance. Similarly, Mica Tapes, which boast high mechanical strength and resistance to extreme temperatures, are invaluable in constructing components that require reliable insulation.

Furthermore, advancements in production techniques such as directed energy deposition (DED) and laser beam melting (LBM) have enabled the creation of specialized alloys with tailored properties, enhancing their applicability in various sectors. F.L. Kong emphasizes the practical uses of these insights, stating,

Owing to these advantages, the glassy alloy-coating technique has been employed on surface glassy alloy layers inside solder-melting vessels in continuous solder casting machines of 50 cm in diameter and 34–40 cm in height.

Additionally, bimetal works by exploiting the different rates of thermal expansion of two bonded metals, acting as a mechanical switch in devices like thermostats, which automatically turn them on or off in response to temperature changes. These findings highlight the importance for procurement managers to take into account temperature impacts and recent production innovations when choosing insulation solutions such as Mica Tape for uses spanning from automotive parts to consumer electronics.

Manufacturing Techniques for Permalloy Components

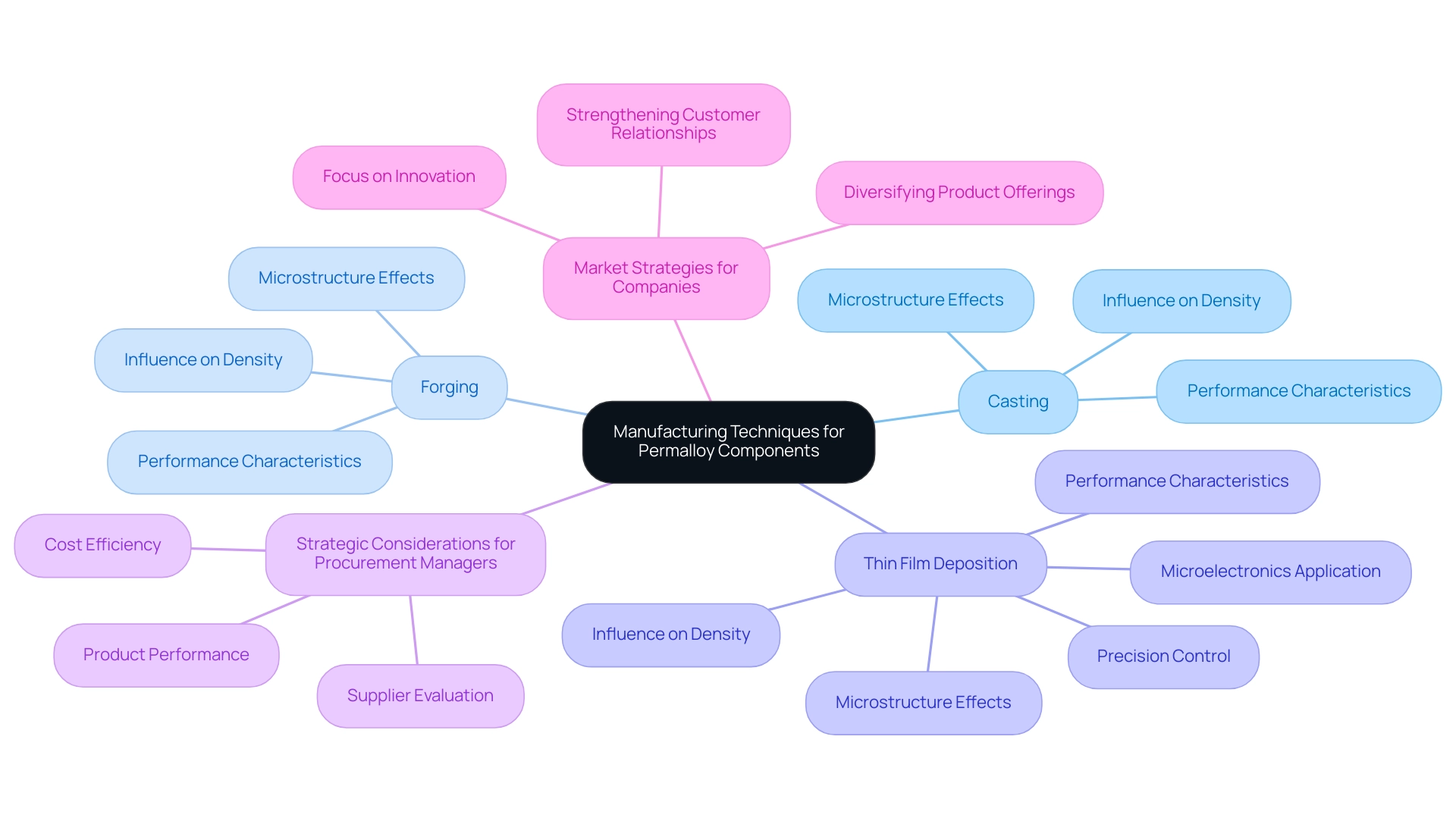

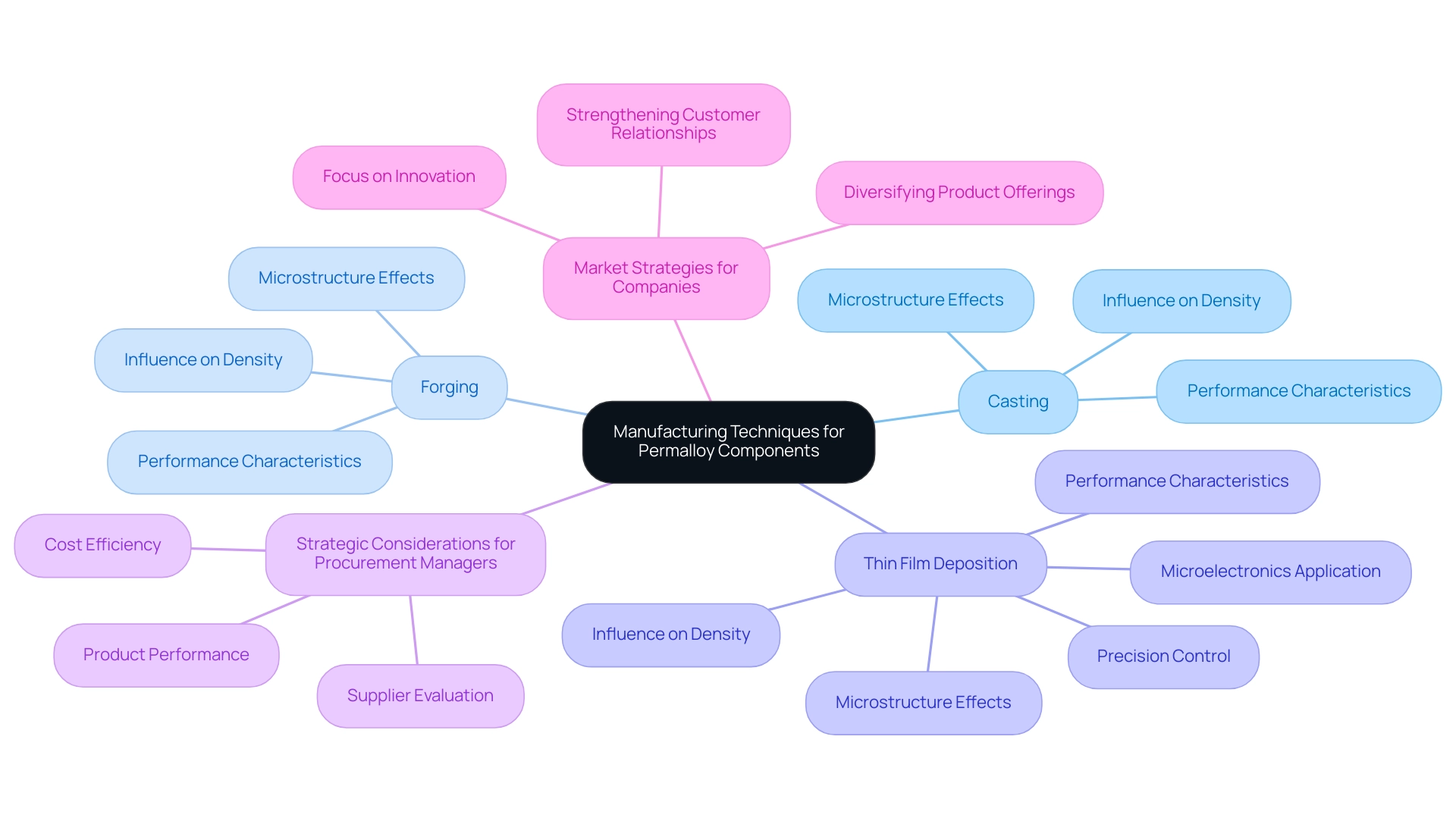

The manufacturing of permalloy components involves a range of techniques, including casting, forging, and thin film deposition, which significantly influence permalloy density, microstructure, and overall properties. Notably, thin film deposition techniques offer exceptional precision in controlling both thickness and composition, which are vital for applications in microelectronics. Recent advancements in this area have led to enhanced performance characteristics, as evidenced by microstructural investigations conducted with an Axiovert 200 MAT optical microscope, revealing critical insights into the forged parts.

As Inoue F.L. Kong states, ‘Owing to these advantages, the glassy alloy-coating technique has been applied to surface glassy alloy layers inside solder-melting vessels in continuous solder casting machines of 50 cm in diameter and 34–40 cm in height.’ This emphasizes the innovative methods in production of the alloy.

Furthermore, procurement managers can benefit from understanding these manufacturing processes, enabling them to evaluate suppliers based on their capabilities to produce high-quality components with optimal permalloy density that adhere to stringent standards. Engaging in discussions about manufacturing techniques not only fosters better supplier relationships but also enhances cost efficiency and product performance. Key features in reflectivity often appear near specific values and may vary in sensitivity depending on the magnetic configuration, which is crucial for optimizing product specifications.

As highlighted in the strategic analysis of the alloys market, companies can strategize for success by focusing on innovation, diversifying product offerings, and strengthening customer relationships through value-added services. These strategies are vital for achieving growth and sustainability in the alloys market. With the AC amplitude permeability notably increasing by 9.37% at 140 °C at a frequency of 1 kHz, the performance of these materials can be significantly optimized through these advanced manufacturing techniques.

Regulatory Standards and Compliance for Permalloy

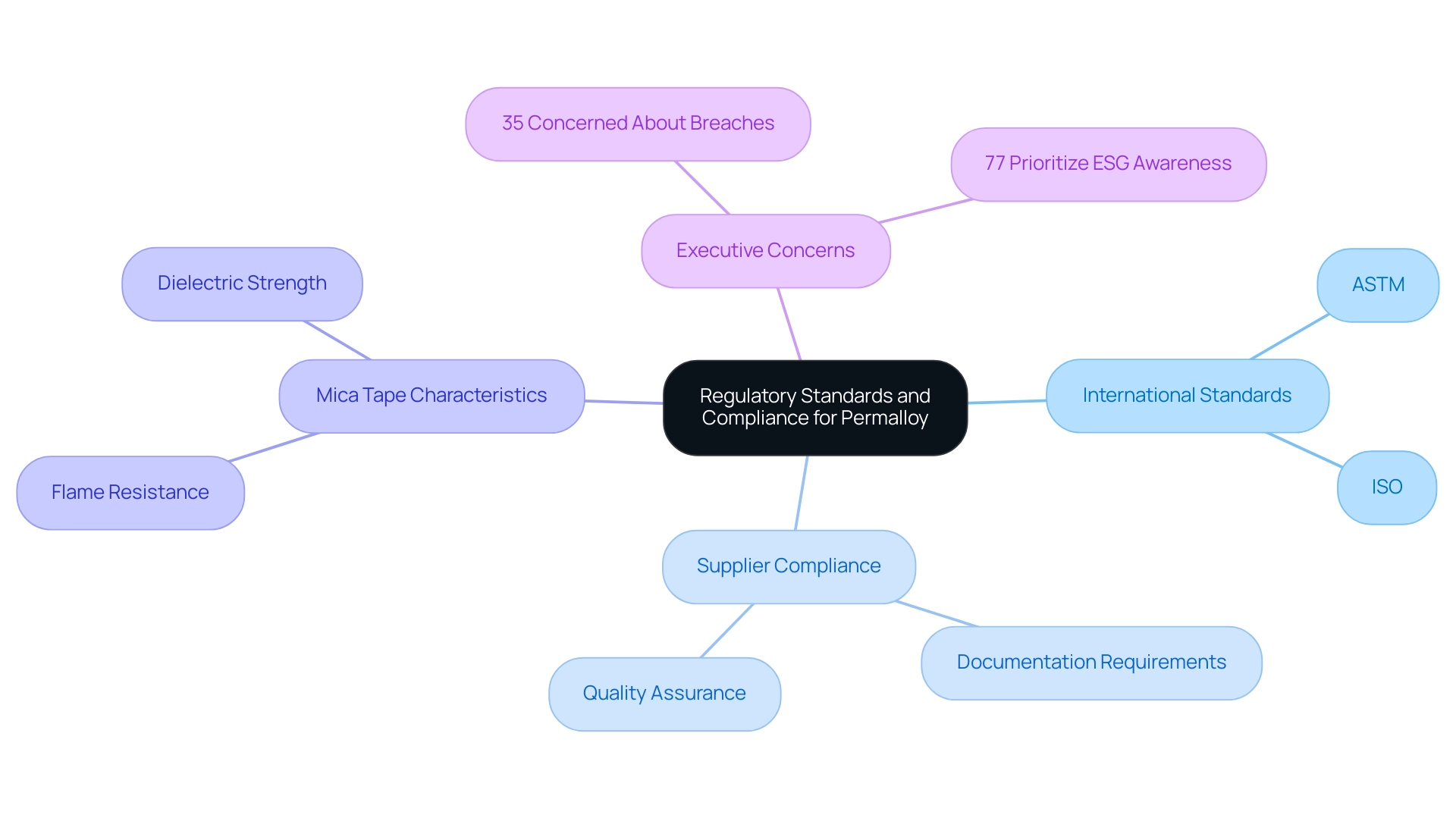

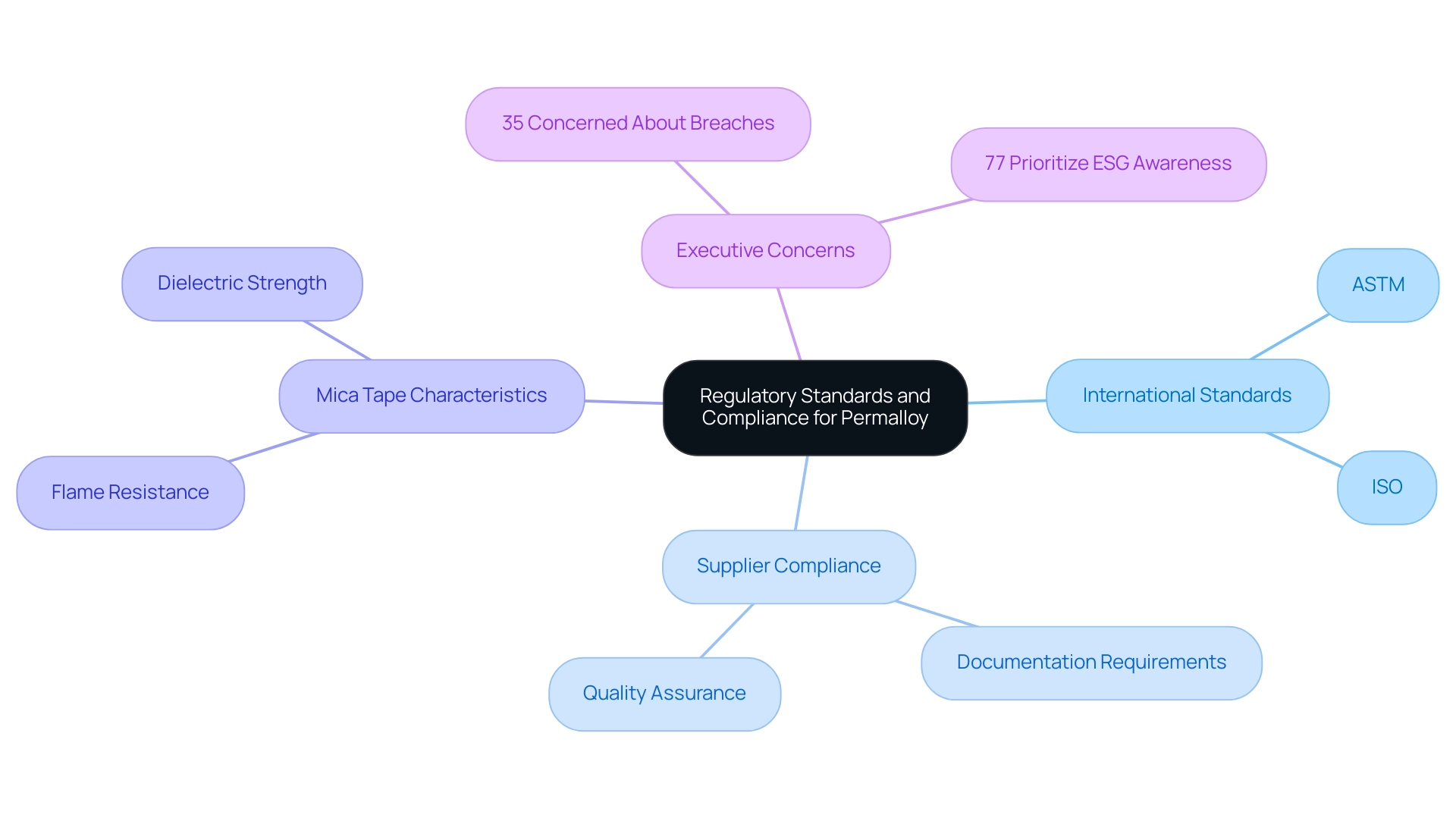

When engaging in permalloy procurement, adherence to international standards such as ASTM and ISO, which also consider permalloy density, is of paramount importance. These standards not only guarantee that the material satisfies stringent quality, safety, and environmental criteria but also play a crucial role in mitigating compliance risks. Procurement managers must ensure that suppliers, including those of mica tape products known for their high-temperature resistance and electrical insulation, can furnish comprehensive documentation that attests to compliance with these regulations.

Mica insulation tape, for example, is known for its outstanding flame resistance and dielectric strength, making it appropriate for essential uses in electrical engineering, such as in the production of fire-resistant cables. This diligence safeguards against potential legal complications and enhances product reliability. In fact, 35% of business and tech executives find third-party breaches to be a concerning cyber threat, underscoring the necessity of supplier compliance.

Furthermore, remaining vigilant about evolving regulatory landscapes is essential for organizations aspiring to uphold compliance and maintain a competitive edge in the marketplace. Collaborating with suppliers who prioritize quality assurance and regulatory adherence, such as those offering mica insulation tapes and related products, can significantly improve procurement outcomes, positioning organizations favorably within the industry. As corporate risk and compliance professionals recognize, staying abreast of ESG-related developments is vital, with 77% emphasizing the criticality of this awareness for strategic decision-making.

For instance, effective lead prioritization, as demonstrated in a recent case study, shows that organizations that implement stringent compliance and documentation practices can enhance procurement outcomes and better manage their sales opportunities. Furthermore, the utilization of mica sheet tape in aerospace contexts demonstrates its mechanical strength and resistance to elevated temperatures, further emphasizing the varied uses of mica tape products in ensuring safety and effectiveness.

Future Trends in Permalloy Applications

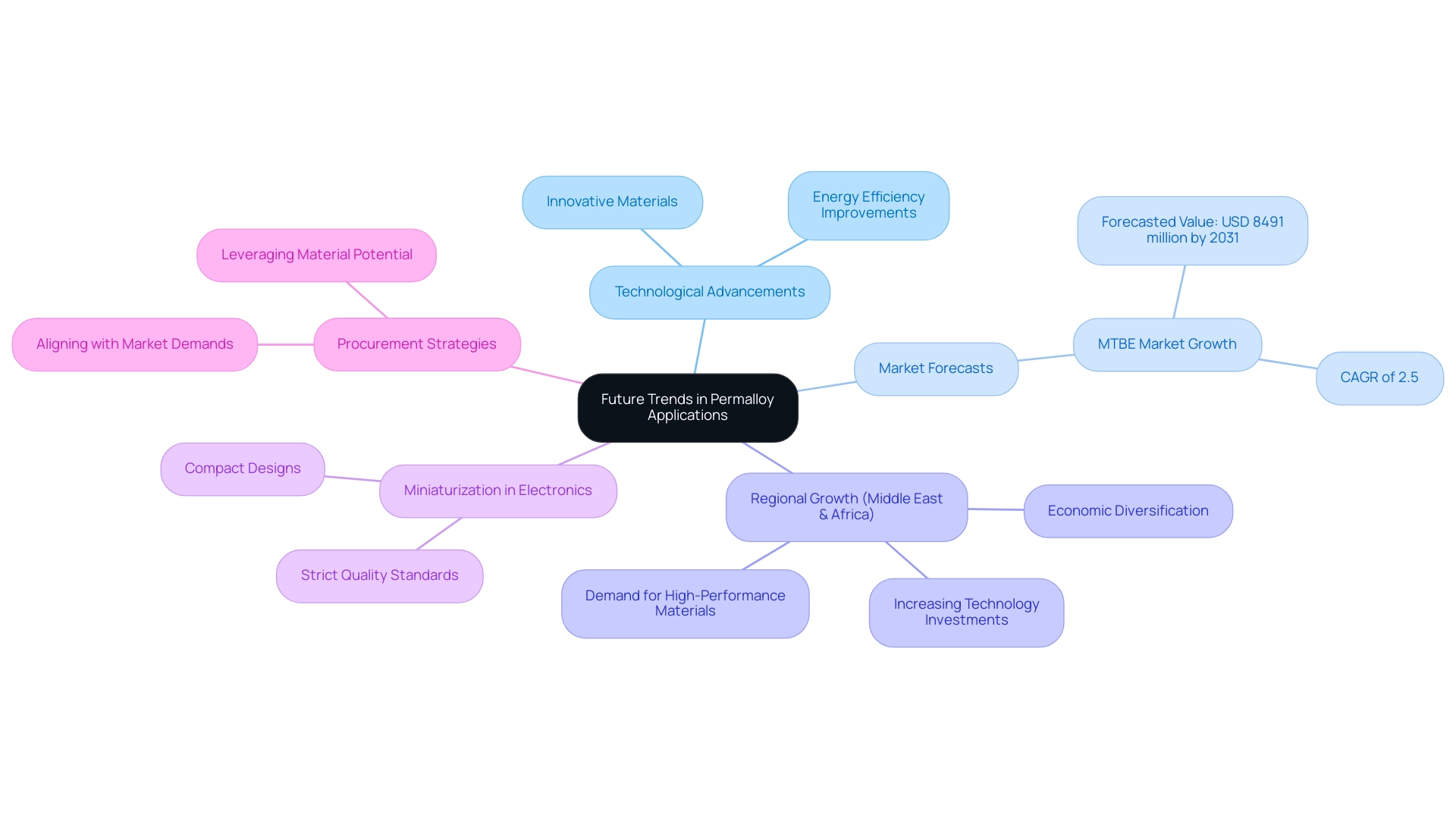

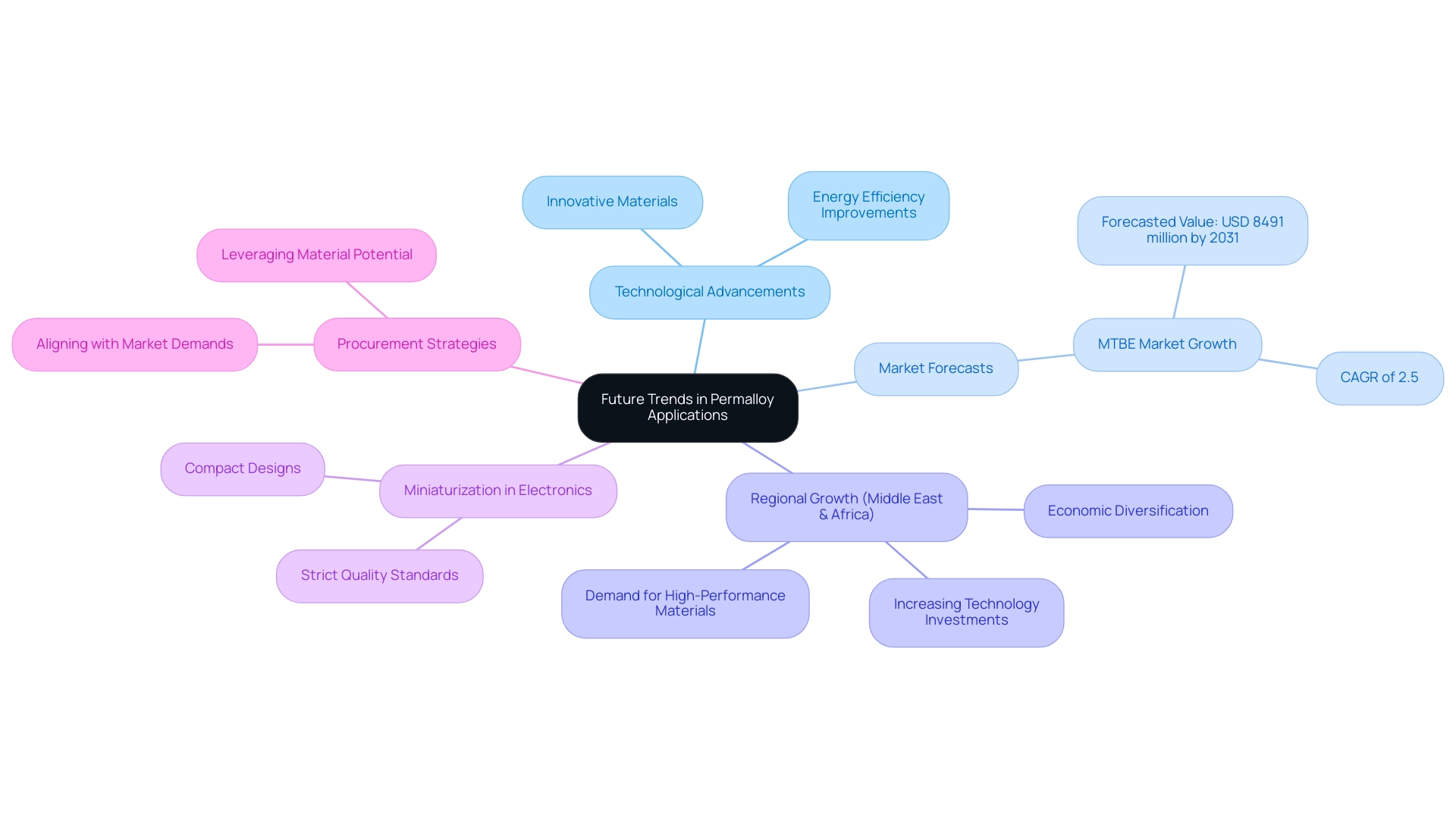

As technological advancements continue to reshape various industries, the uses of this alloy are poised for significant expansion, particularly within the renewable energy and advanced electronics sectors. The global Methyl Tertiary Butyl Ether (MTBE) market, forecasted to reach USD 8491 million by 2031 with a CAGR of 2.5%, reflects a growing trend towards innovative materials that enhance energy efficiency and performance. Advancements in materials, particularly those with permalloy density in soft ferromagnetic alloys, are anticipated to generate new possibilities, especially in electric vehicle components where efficient energy transformation and effective shielding are essential.

Furthermore, the growth in the Middle East & Africa, driven by economic diversification and increasing technology investments, underscores the rising demand for high-performance magnetic materials in these regions. The trend towards miniaturization in electronic devices further amplifies this demand, as a specific alloy can meet strict quality standards in increasingly compact designs. It is essential for procurement managers to remain vigilant about these evolving trends, ensuring that their sourcing strategies are aligned with future market demands and technological innovations.

By doing so, they can leverage the potential of this material to enhance product performance and meet the growing needs of the industry. Additionally, insights from the global Polyester Yarn market case study illustrate the competitive landscape and supply trends that may also apply to the permalloy density market, providing further context for procurement decisions.

Conclusion

The exploration of permalloy’s properties and applications underscores its critical role in modern technology. With a composition primarily of nickel and iron, permalloy’s unique magnetic characteristics, including high permeability and low coercivity, make it indispensable for various applications, particularly in electronics and magnetic shielding. The impact of temperature on its performance further emphasizes the need for procurement managers to consider environmental factors when sourcing materials, ensuring that they select components capable of maintaining efficiency and reliability across diverse conditions.

As the demand for high-performance materials continues to rise, permalloy’s versatility in manufacturing techniques—from casting to advanced thin film deposition—highlights its adaptability to meet the evolving needs of industries. The increasing reliance on permalloy in sensors, actuators, and magnetic cores reflects a growing trend that procurement managers must navigate strategically. By understanding the manufacturing processes and regulatory standards associated with permalloy, organizations can foster better supplier relationships and enhance compliance, ultimately improving product outcomes.

Looking ahead, the future of permalloy is bright, particularly in sectors such as renewable energy and advanced electronics. Technological advancements will likely drive new applications, reinforcing the importance of staying abreast of market trends and innovations. By aligning sourcing strategies with these emerging opportunities, procurement managers can leverage the benefits of permalloy to enhance performance and meet the industry’s increasing demands. Investing in a comprehensive understanding of permalloy will not only support immediate operational needs but also position organizations for sustained growth in a rapidly changing technological landscape.

Introduction

The significance of permalloy in modern technology cannot be overstated, as its unique composition and exceptional magnetic properties make it a cornerstone in various applications, from electronics to advanced magnetic shielding. Comprised primarily of nickel and iron, permalloy exhibits high permeability and low coercivity, which are critical for enhancing performance in devices such as transformers and inductors.

As industries increasingly rely on efficient and reliable materials, understanding the fundamental characteristics of permalloy, including its response to temperature fluctuations and its manufacturing processes, becomes essential for procurement managers.

This article delves into the intricate properties of permalloy, its diverse applications, and the emerging trends that are shaping its future in a rapidly evolving technological landscape.

Fundamental Properties of Permalloy: Composition and Characteristics

Permalloy, an alloy mainly consisting of about 80% nickel and 20% iron, is famous for its outstanding properties, which include high permeability and low coercivity. With a permalloy density of approximately 8.7 g/cm³, this feature is essential for evaluating its use in different electromagnetic devices. The alloy is especially appreciated for its exceptional shielding capabilities and minimal losses, making it an ideal choice for transformers, inductors, and applications requiring effective shielding.

Notably, as Jinji Sun observes,

Temperature has a significant impact on the properties of permalloy.

This emphasizes that thermal motion rises with temperature, resulting in disordered atomic distances, which subsequently improves remanence and influences the alloy’s overall functioning. This effect is crucial, especially in real-world applications where temperature fluctuations can complicate magnetic behavior.

Furthermore, the thermal and electrical conductivity of this material are essential for its performance in electronic components, where efficient heat dissipation is vital. Recent research highlights that at elevated temperatures, such as 140 °C, the AC amplitude permeability of this alloy can increase by 9.37% at a frequency of 1 kHz, illustrating its adaptability and effectiveness under varying conditions. In conjunction with other materials, Mica Tape products, known for their high-temperature resistance, excellent electrical insulation properties, mechanical strength, and flame resistance, serve as critical components in applications like transformers and inductors.

These tapes provide reliable thermal and electrical insulation, ensuring safety and performance in demanding environments. The mechanical strength of Mica Tape allows it to withstand harsh conditions, while its dielectric strength protects against electrical breakdown. Additionally, the complexities of real-world materials necessitate simulations before experiments, as indicated by current studies, which emphasize the need to understand how this alloy interacts in practical scenarios.

Insights from the case study on Co on FeMn Exchange Biasing also reveal the intricate behaviors of interactions, showcasing how exchange biasing can lead to asymmetric hysteresis loops and different reversal processes, further highlighting the complexities of permalloy’s properties.

Applications of Permalloy: From Electronics to Magnetic Shielding

The density of permalloy plays a pivotal role in the electronics sector, particularly in the production of cores for transformers and inductors. The exceptionally high permalloy density significantly enhances performance by reducing energy losses, which is a crucial factor for efficient operation. Indeed, recent data show that this alloy’s utilization in shielding purposes has risen by more than 20% in the past year, highlighting its efficiency in protecting delicate electronic components from interfering external fields.

This protection is vital in modern devices such as smartphones and computers, where even minor interference can result in operational malfunctions. As one electronics expert aptly stated, ‘Just as professionals in Transportation Planning negotiate their worth by showcasing their value and achievements, this material demonstrates its value in achieving high-performance electronic solutions.’ Beyond its uses in electronics, this alloy is also employed in sensors and actuators due to its permalloy density, which is crucial for optimal performance.

The case study titled ‘The Evolving Landscape of Permalloy for Current Sensor Market’ illustrates how the market is transforming due to increasing demand for high-precision current sensing solutions, particularly in renewable energy and electric vehicles. The material’s versatility extends to various manufacturing techniques, including advanced thin film deposition processes, underscoring its significance in cutting-edge technological uses. As the market evolves, the demand for this material in these contexts continues to grow, driven by the increasing need for high-performance electronic solutions.

Impact of Temperature on Permalloy Density

Temperature variations considerably affect the permalloy density and properties of the alloy, impacting its overall effectiveness in diverse applications. As thermal motion increases with temperature, the disorder within the alloy rises, leading to higher remanence and changed permeability. Notably, studies indicate that the permalloy density‘s AC amplitude permeability can increase by 9.37% at 140 °C under a frequency of 1 kHz.

This emphasizes the significance of considering thermal expansion in settings such as transformers and magnetic sensors, where efficiency and stability are crucial. In parallel, Domadia’s Mica Tape products are designed to address challenges posed by high temperatures in electrical insulation. With superior flame resistance, high dielectric strength, and excellent mechanical strength, these tapes are essential for critical applications across various sectors, from household appliances to industrial machinery.

Materials engineers routinely conduct thermal analyses to ensure that alloy components and Mica Tapes perform optimally within designated temperature ranges. For instance, a recent investigation into the magnetic properties of a specific alloy showed that permalloy density affects initial permeability, which decreases by 69.64% at -60 °C but increases by 38.23% at 140 °C, demonstrating the critical influence of temperature on magnetic performance. Similarly, Mica Tapes, which boast high mechanical strength and resistance to extreme temperatures, are invaluable in constructing components that require reliable insulation.

Furthermore, advancements in production techniques such as directed energy deposition (DED) and laser beam melting (LBM) have enabled the creation of specialized alloys with tailored properties, enhancing their applicability in various sectors. F.L. Kong emphasizes the practical uses of these insights, stating,

Owing to these advantages, the glassy alloy-coating technique has been employed on surface glassy alloy layers inside solder-melting vessels in continuous solder casting machines of 50 cm in diameter and 34–40 cm in height.

Additionally, bimetal works by exploiting the different rates of thermal expansion of two bonded metals, acting as a mechanical switch in devices like thermostats, which automatically turn them on or off in response to temperature changes. These findings highlight the importance for procurement managers to take into account temperature impacts and recent production innovations when choosing insulation solutions such as Mica Tape for uses spanning from automotive parts to consumer electronics.

Manufacturing Techniques for Permalloy Components

The manufacturing of permalloy components involves a range of techniques, including casting, forging, and thin film deposition, which significantly influence permalloy density, microstructure, and overall properties. Notably, thin film deposition techniques offer exceptional precision in controlling both thickness and composition, which are vital for applications in microelectronics. Recent advancements in this area have led to enhanced performance characteristics, as evidenced by microstructural investigations conducted with an Axiovert 200 MAT optical microscope, revealing critical insights into the forged parts.

As Inoue F.L. Kong states, ‘Owing to these advantages, the glassy alloy-coating technique has been applied to surface glassy alloy layers inside solder-melting vessels in continuous solder casting machines of 50 cm in diameter and 34–40 cm in height.’ This emphasizes the innovative methods in production of the alloy.

Furthermore, procurement managers can benefit from understanding these manufacturing processes, enabling them to evaluate suppliers based on their capabilities to produce high-quality components with optimal permalloy density that adhere to stringent standards. Engaging in discussions about manufacturing techniques not only fosters better supplier relationships but also enhances cost efficiency and product performance. Key features in reflectivity often appear near specific values and may vary in sensitivity depending on the magnetic configuration, which is crucial for optimizing product specifications.

As highlighted in the strategic analysis of the alloys market, companies can strategize for success by focusing on innovation, diversifying product offerings, and strengthening customer relationships through value-added services. These strategies are vital for achieving growth and sustainability in the alloys market. With the AC amplitude permeability notably increasing by 9.37% at 140 °C at a frequency of 1 kHz, the performance of these materials can be significantly optimized through these advanced manufacturing techniques.

Regulatory Standards and Compliance for Permalloy

When engaging in permalloy procurement, adherence to international standards such as ASTM and ISO, which also consider permalloy density, is of paramount importance. These standards not only guarantee that the material satisfies stringent quality, safety, and environmental criteria but also play a crucial role in mitigating compliance risks. Procurement managers must ensure that suppliers, including those of mica tape products known for their high-temperature resistance and electrical insulation, can furnish comprehensive documentation that attests to compliance with these regulations.

Mica insulation tape, for example, is known for its outstanding flame resistance and dielectric strength, making it appropriate for essential uses in electrical engineering, such as in the production of fire-resistant cables. This diligence safeguards against potential legal complications and enhances product reliability. In fact, 35% of business and tech executives find third-party breaches to be a concerning cyber threat, underscoring the necessity of supplier compliance.

Furthermore, remaining vigilant about evolving regulatory landscapes is essential for organizations aspiring to uphold compliance and maintain a competitive edge in the marketplace. Collaborating with suppliers who prioritize quality assurance and regulatory adherence, such as those offering mica insulation tapes and related products, can significantly improve procurement outcomes, positioning organizations favorably within the industry. As corporate risk and compliance professionals recognize, staying abreast of ESG-related developments is vital, with 77% emphasizing the criticality of this awareness for strategic decision-making.

For instance, effective lead prioritization, as demonstrated in a recent case study, shows that organizations that implement stringent compliance and documentation practices can enhance procurement outcomes and better manage their sales opportunities. Furthermore, the utilization of mica sheet tape in aerospace contexts demonstrates its mechanical strength and resistance to elevated temperatures, further emphasizing the varied uses of mica tape products in ensuring safety and effectiveness.

Future Trends in Permalloy Applications

As technological advancements continue to reshape various industries, the uses of this alloy are poised for significant expansion, particularly within the renewable energy and advanced electronics sectors. The global Methyl Tertiary Butyl Ether (MTBE) market, forecasted to reach USD 8491 million by 2031 with a CAGR of 2.5%, reflects a growing trend towards innovative materials that enhance energy efficiency and performance. Advancements in materials, particularly those with permalloy density in soft ferromagnetic alloys, are anticipated to generate new possibilities, especially in electric vehicle components where efficient energy transformation and effective shielding are essential.

Furthermore, the growth in the Middle East & Africa, driven by economic diversification and increasing technology investments, underscores the rising demand for high-performance magnetic materials in these regions. The trend towards miniaturization in electronic devices further amplifies this demand, as a specific alloy can meet strict quality standards in increasingly compact designs. It is essential for procurement managers to remain vigilant about these evolving trends, ensuring that their sourcing strategies are aligned with future market demands and technological innovations.

By doing so, they can leverage the potential of this material to enhance product performance and meet the growing needs of the industry. Additionally, insights from the global Polyester Yarn market case study illustrate the competitive landscape and supply trends that may also apply to the permalloy density market, providing further context for procurement decisions.

Conclusion

The exploration of permalloy’s properties and applications underscores its critical role in modern technology. With a composition primarily of nickel and iron, permalloy’s unique magnetic characteristics, including high permeability and low coercivity, make it indispensable for various applications, particularly in electronics and magnetic shielding. The impact of temperature on its performance further emphasizes the need for procurement managers to consider environmental factors when sourcing materials, ensuring that they select components capable of maintaining efficiency and reliability across diverse conditions.

As the demand for high-performance materials continues to rise, permalloy’s versatility in manufacturing techniques—from casting to advanced thin film deposition—highlights its adaptability to meet the evolving needs of industries. The increasing reliance on permalloy in sensors, actuators, and magnetic cores reflects a growing trend that procurement managers must navigate strategically. By understanding the manufacturing processes and regulatory standards associated with permalloy, organizations can foster better supplier relationships and enhance compliance, ultimately improving product outcomes.

Looking ahead, the future of permalloy is bright, particularly in sectors such as renewable energy and advanced electronics. Technological advancements will likely drive new applications, reinforcing the importance of staying abreast of market trends and innovations. By aligning sourcing strategies with these emerging opportunities, procurement managers can leverage the benefits of permalloy to enhance performance and meet the industry’s increasing demands. Investing in a comprehensive understanding of permalloy will not only support immediate operational needs but also position organizations for sustained growth in a rapidly changing technological landscape.