Blogs

What Are LS3 Inconel Exhaust Valves? Understanding Their Role in Engine Performance

Overview:

LS3 Inconel exhaust valves are critical components in LS3 engines, known for their exceptional heat resistance and strength, which enhance engine performance by controlling exhaust flow and improving vehicle efficiency. The article underscores their significance by detailing how these valves withstand extreme temperatures and pressures, outperforming traditional materials like stainless steel, thus ensuring durability and optimal performance in high-stress automotive applications.

Introduction

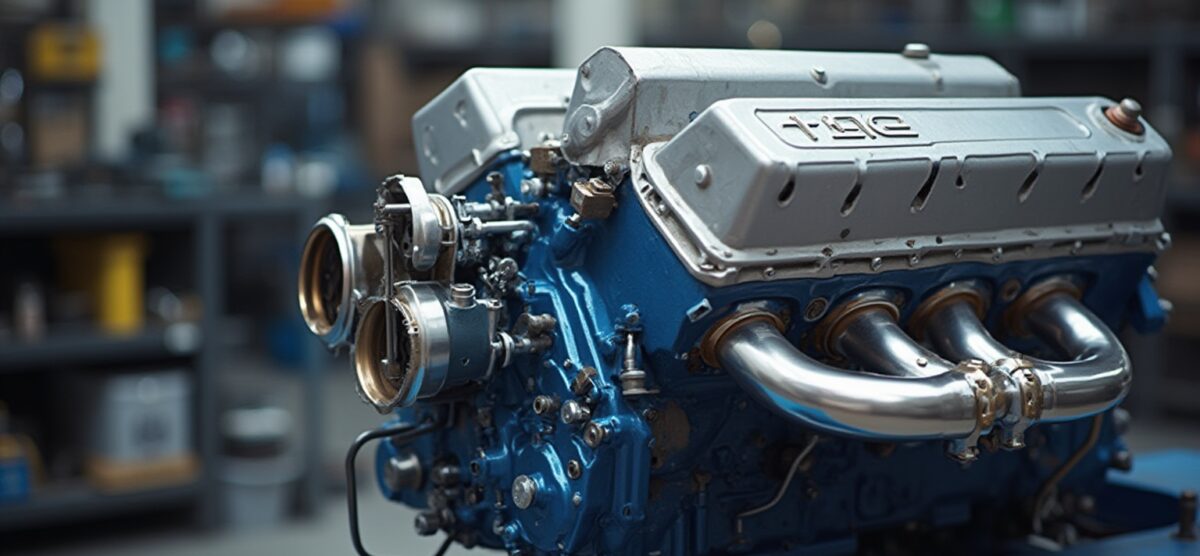

In the realm of high-performance automotive engineering, the choice of materials can make all the difference between success and failure on the track. Among these, LS3 Inconel exhaust valves stand out as critical components that enhance engine efficiency and durability under extreme conditions. Crafted from a nickel-chromium superalloy, Inconel exhibits unparalleled heat resistance and strength, essential for withstanding the intense thermal and mechanical stresses inherent in high-performance applications.

This article delves into the significance of Inconel valves, exploring their performance benefits, comparative advantages over traditional materials, and diverse applications in automotive engineering. As the demand for optimized engine performance grows, understanding the role of these advanced materials becomes crucial for procurement managers and engineers alike, ensuring they remain at the forefront of innovation in the automotive industry.

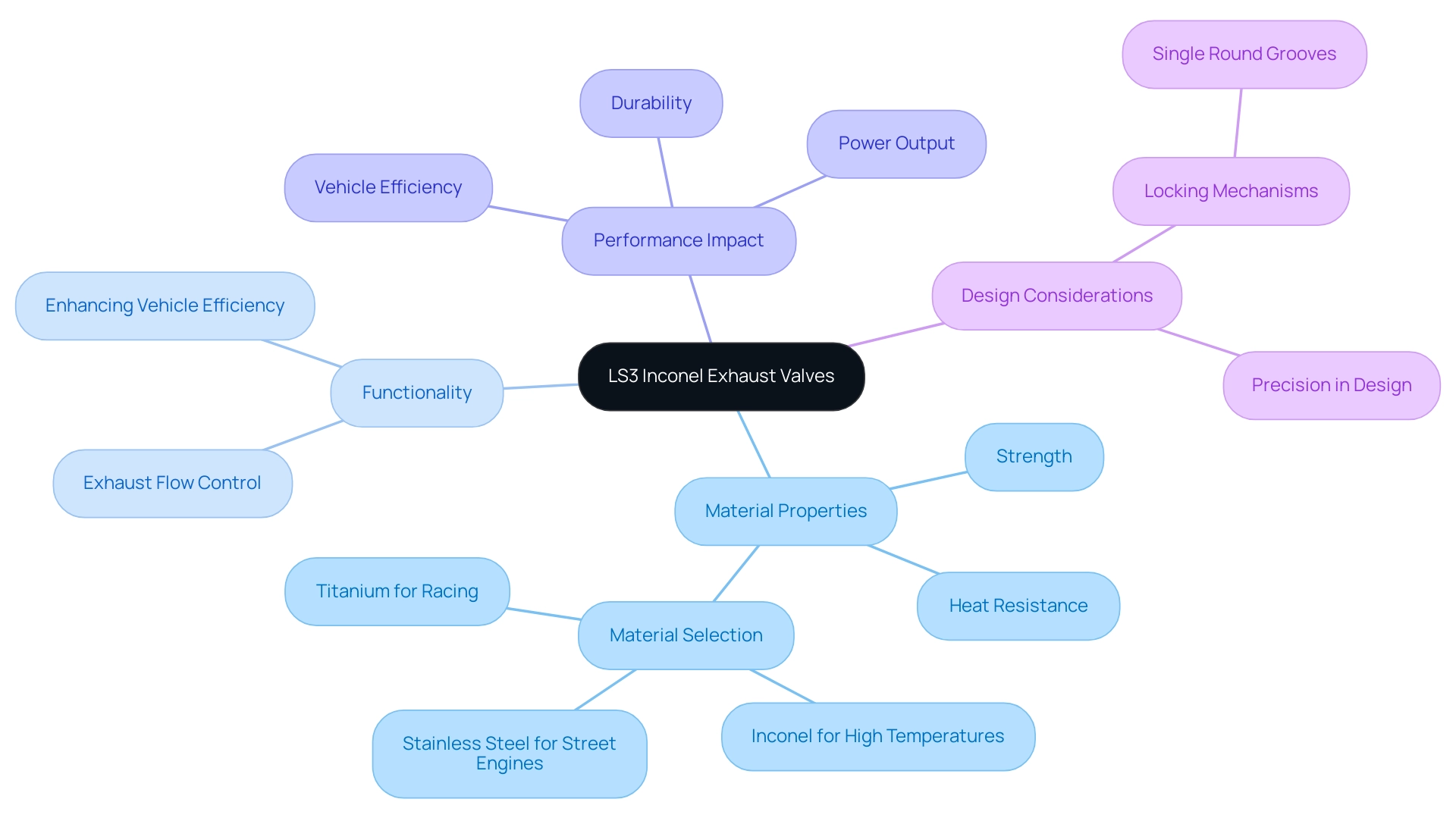

Introduction to LS3 Inconel Exhaust Valves: Definition and Importance

LS3 inconel exhaust valves are essential components in LS3 motors, which are widely acknowledged for their capabilities in high-performance automotive uses. Inconel, a nickel-chromium superalloy, boasts remarkable heat resistance and strength, making it particularly suitable for exhaust components subjected to intense thermal and mechanical stress. These components are crucial for controlling exhaust flow and enhancing vehicle efficiency—a vital element for attaining optimal results in both competitive settings and everyday driving situations.

Their importance goes beyond simple functionality; they directly affect durability, power output, and overall vehicle efficiency. As emphasized by a prominent industry specialist, plavutka, ‘The selection of substance is crucial; these components can endure the significant pressures faced during rapid acceleration and deceleration, especially in marine machinery.’ This highlights the importance of choosing the appropriate materials for particular uses, emphasizing the role of LS3 inconel exhaust valves in enhancing LS3 machinery effectiveness and efficiency.

Moreover, the design of locking mechanisms can minimize stress, with single round grooves being preferable in high-end racing, further emphasizing the importance of precision in design.

Performance Benefits of Inconel Exhaust Valves in LS3 Engines

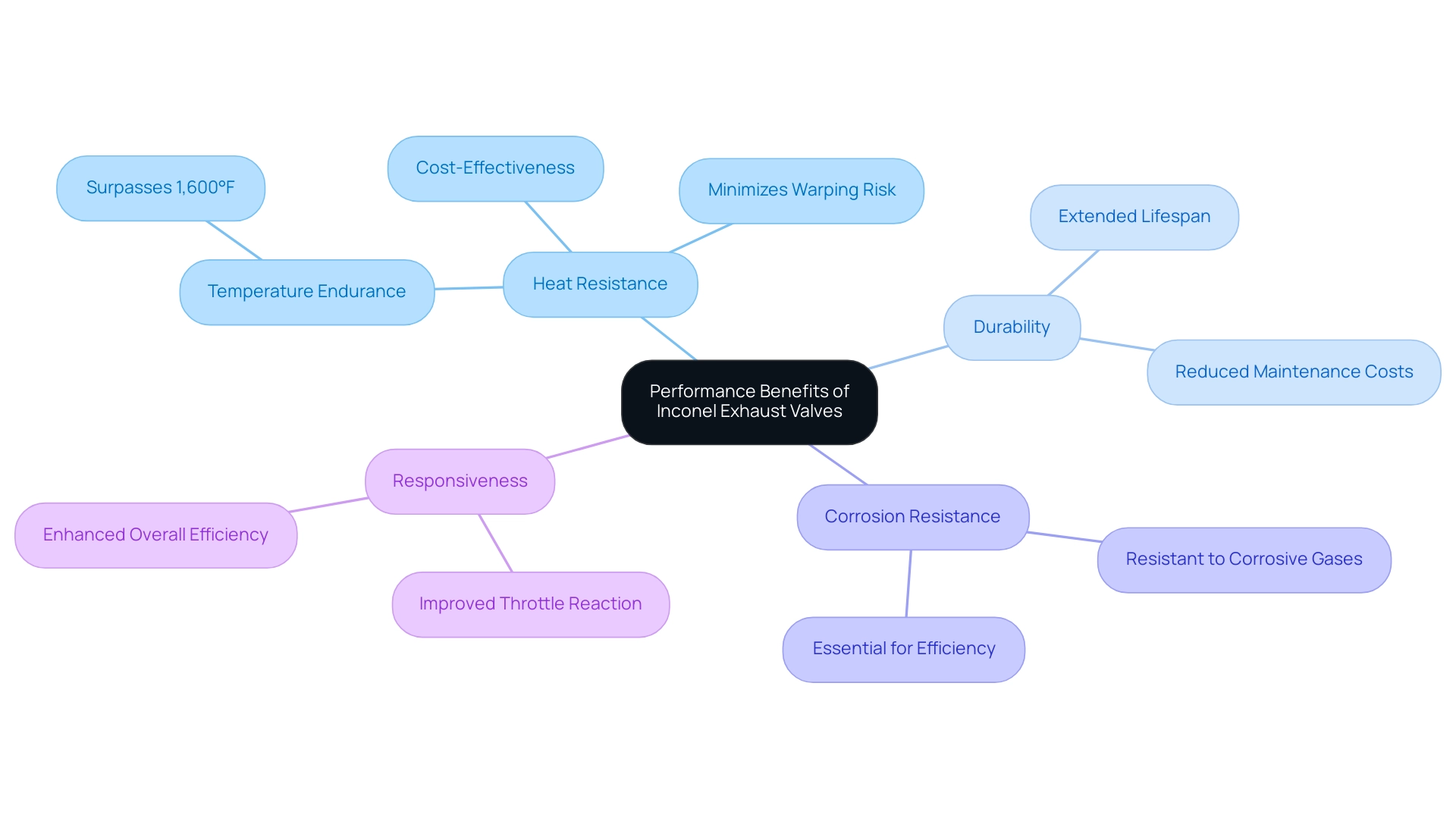

Alloy exhaust components, including LS3 Inconel exhaust valves, offer various important performance benefits for LS3 power units. Notably, their exceptional heat resistance enables them to endure the extreme temperatures encountered during combustion, effectively minimizing the risk of warping or failure. Based on industry data, these components can endure temperatures surpassing 1,600°F, which is essential for preserving machinery integrity under high-performance conditions.

This inherent durability not only extends the lifespan of the components but also renders them a cost-effective option over time. Moreover, these fittings demonstrate exceptional resistance to corrosion, essential for maintaining machinery efficiency, particularly in settings marked by extremely corrosive exhaust gases. Case studies emphasize the restricted supply of certain products, with manufacturers such as Weidouli expanding their offerings to satisfy increasing demand, thus ensuring improved access for high-performance applications.

Combined with their lightweight characteristics, these components improve responsiveness, enabling faster throttle reaction and enhanced overall efficiency. As mentioned by 94AWDcoupe, a participant in the performance community, “the factory component is the way forward… To at Port Flow Design is acquiring them for me at $25 each,” highlighting the competitive pricing and quality of the materials. These characteristics make LS3 Inconel exhaust valves an ideal choice for high-performance exhaust components, where careful attention to detail is essential for attaining peak engine efficiency.

Comparative Analysis: Inconel vs. Traditional Valve Materials

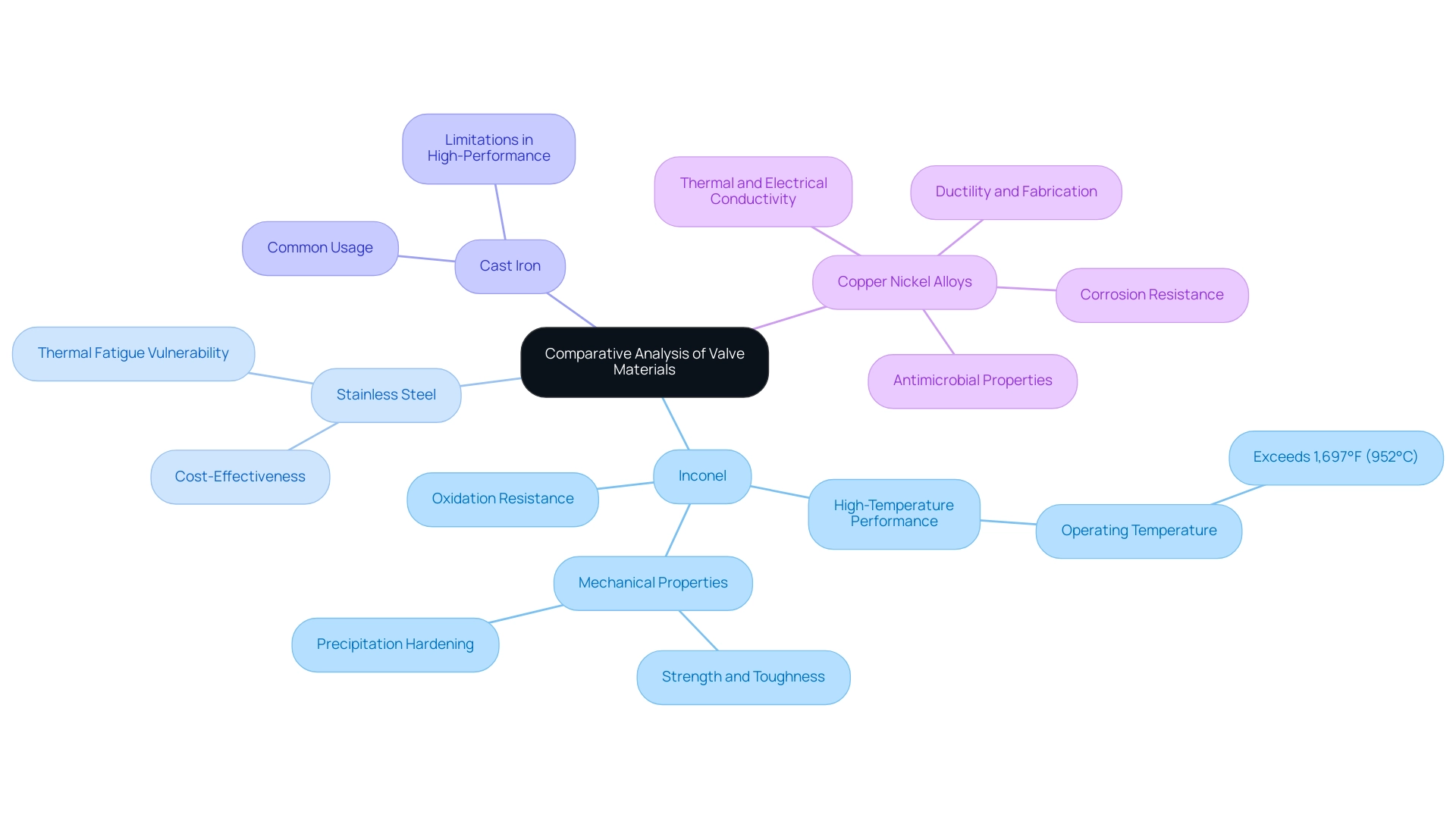

A thorough comparison of specific components, such as ls3 inconel exhaust valves, against conventional materials like stainless steel and cast iron uncovers notable benefits, especially in high-performance uses. While stainless steel valves are prevalent for their cost-effectiveness and satisfactory functioning, they exhibit vulnerabilities under extreme conditions, notably thermal fatigue, which can lead to warping at elevated temperatures. In contrast, the ls3 inconel exhaust valves demonstrate exceptional structural integrity, maintaining performance even beyond the operating temperature of 304 stainless steel, which reaches 1,697°F (952°C).

This resilience is attributed to the unique microstructure of this alloy, a product of its nickel and chromium composition, which undergoes precipitation hardening through heat treatment, thereby enhancing its mechanical properties such as strength and toughness. Furthermore, the superior resistance to oxidation and corrosion of ls3 inconel exhaust valves ensures extended longevity and reliability in demanding environments, fulfilling the rigorous requirements of high-stress applications. Expert opinions emphasize that ls3 inconel exhaust valves have evaluation metrics that are unparalleled when compared to traditional materials, especially in high-temperature scenarios.

Conversely, copper nickel alloys present notable advantages, particularly in marine environments. Their high resistance to corrosion and excellent thermal and electrical conductivity make them ideal for applications requiring durability and reliability. Additionally, their good ductility and ease of fabrication add to their appeal, while their antimicrobial properties render them suitable for hygiene-sensitive applications.

Specifically, copper nickel alloys are known for their outstanding corrosion resistance in marine environments, excellent thermal and electrical conductivity, good ductility, ease of fabrication, and antimicrobial properties, making them a strong choice for high-performance applications. This comparative analysis emphasizes the critical significance of material selection, including ls3 inconel exhaust valves, for optimal engine efficiency, particularly in competitive contexts where capability and durability are paramount. Recent studies utilizing analytical techniques like Energy-Dispersive X-ray Spectroscopy (EDS) and X-ray Diffraction (XRD) have confirmed the advantages of both nickel-chromium alloys and copper nickel alloys over traditional materials, making them preferred choices for manufacturers aiming to enhance their products’ performance metrics.

Additionally, advancements in functionally graded materials, as reported in recent news, further underscore the ongoing evolution in material science, positioning both nickel-chromium alloy and copper nickel alloys as leading options in the industry.

Applications of LS3 Inconel Exhaust Valves in Automotive Engineering

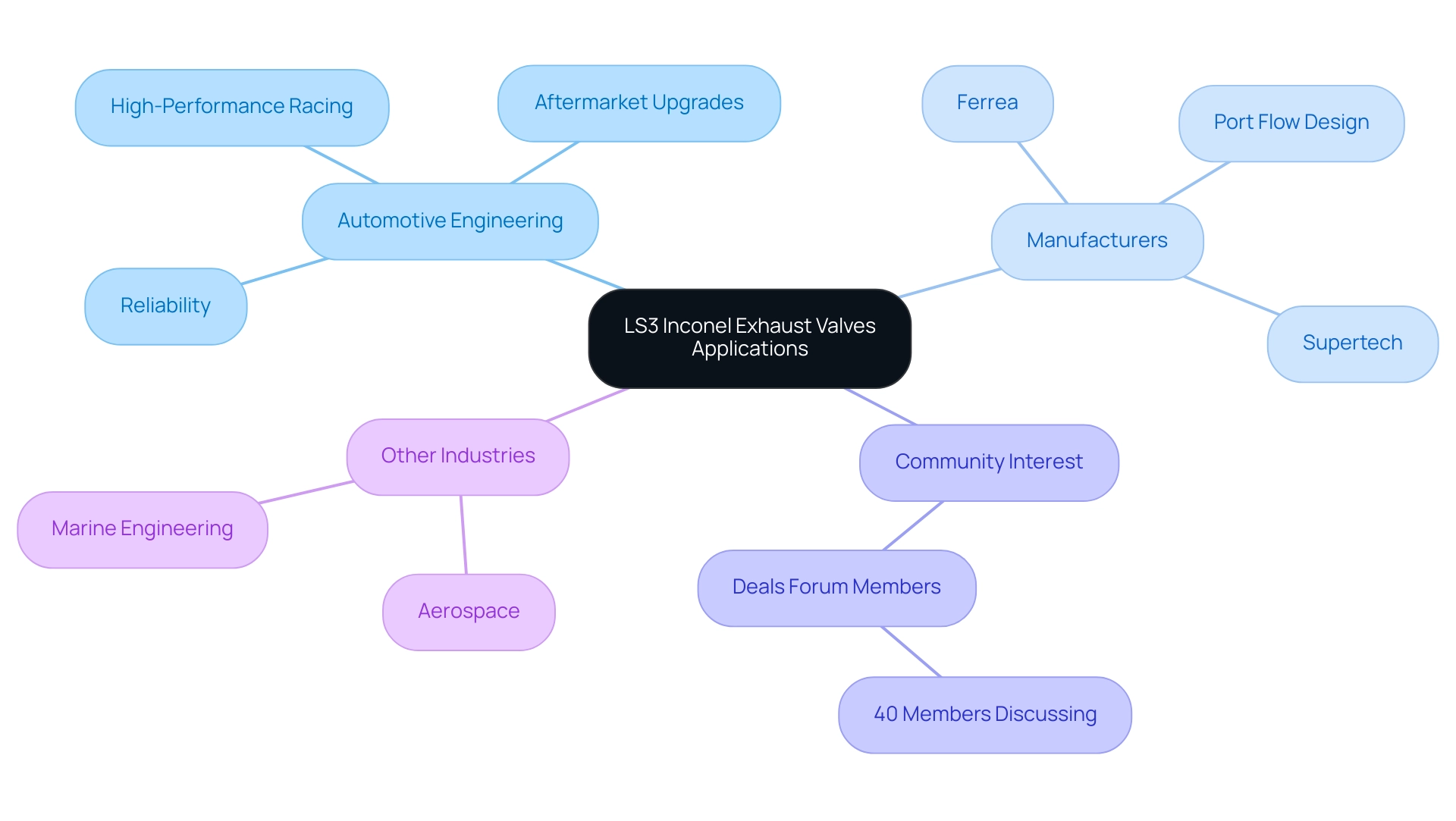

LS3 Inconel exhaust valves are crucial for high-performance automotive applications, especially in the racing and modified vehicle sectors. Their exceptional ability to endure extreme temperatures and pressures makes them the optimal choice for engines that operate at elevated RPMs. Enthusiasts often turn to these components for aftermarket upgrades, seeking enhanced performance and reliability.

Significantly, with 40 members in the Deals Forum discussing these components, there is a clear community interest in alloy fittings. Leading manufacturers, including Ferrea, Supertech, and Port Flow Design, endorse specialized components like LS3 Inconel exhaust valves for effectively managing elevated exhaust gas temperatures (EGTs), reinforcing their importance in high-performance applications. Beyond racing, nickel-chromium alloy exhaust valves find crucial applications in sectors where longevity is paramount, such as aerospace and marine engineering.

A case study on Inconel’s applications illustrates its versatility in extreme environments, further highlighting its importance in modern engine design and the necessity for advanced materials in the evolving landscape of automotive engineering.

Conclusion

The exploration of LS3 Inconel exhaust valves underscores their critical role in high-performance automotive engineering. These valves, crafted from a nickel-chromium superalloy, exhibit exceptional heat resistance and strength, enabling them to withstand the extreme conditions encountered in racing and modified vehicles. Their ability to regulate exhaust flow effectively enhances engine efficiency, durability, and overall performance, making them invaluable components for both everyday driving and competitive racing scenarios.

In comparing Inconel to traditional materials such as stainless steel and cast iron, it becomes evident that Inconel’s superior structural integrity and corrosion resistance provide distinct advantages. While traditional materials may falter under high thermal stress, Inconel maintains its performance, thereby extending valve lifespan and reducing long-term costs. This comparative analysis highlights the importance of selecting the right materials for specific applications, reinforcing the necessity of advanced materials like Inconel in optimizing engine performance.

The diverse applications of LS3 Inconel exhaust valves in automotive engineering, particularly in racing and high-stress environments, demonstrate their versatility and significance. As the demand for optimized engine performance continues to grow, understanding the benefits and applications of these advanced materials is essential for procurement managers and engineers. Embracing Inconel valves not only enhances vehicle performance but also positions manufacturers at the forefront of innovation in the automotive industry. The strategic choice of materials is paramount for achieving excellence in high-performance applications, ensuring that the future of automotive engineering remains robust and competitive.