Blogs

What is Invar? Understanding Its Properties and Uses

Introduction

In the ever-evolving landscape of modern engineering, the demand for materials that offer precision and stability is paramount. Invar, a nickel-iron alloy renowned for its exceptionally low thermal expansion coefficient, emerges as a cornerstone in applications where accuracy is non-negotiable.

With a composition that typically includes:

– 36% nickel

– 64% iron

Invar not only maintains its dimensional integrity across varying temperatures but also plays a critical role in sectors ranging from aerospace to electronics. As industries increasingly seek reliable solutions to combat temperature fluctuations, the significance of Invar and its advanced variants, such as Super Invar, becomes even more pronounced.

This article delves into the unique properties, diverse applications, and the transformative potential of Invar, highlighting its indispensable role in the advancement of precision engineering and technology.

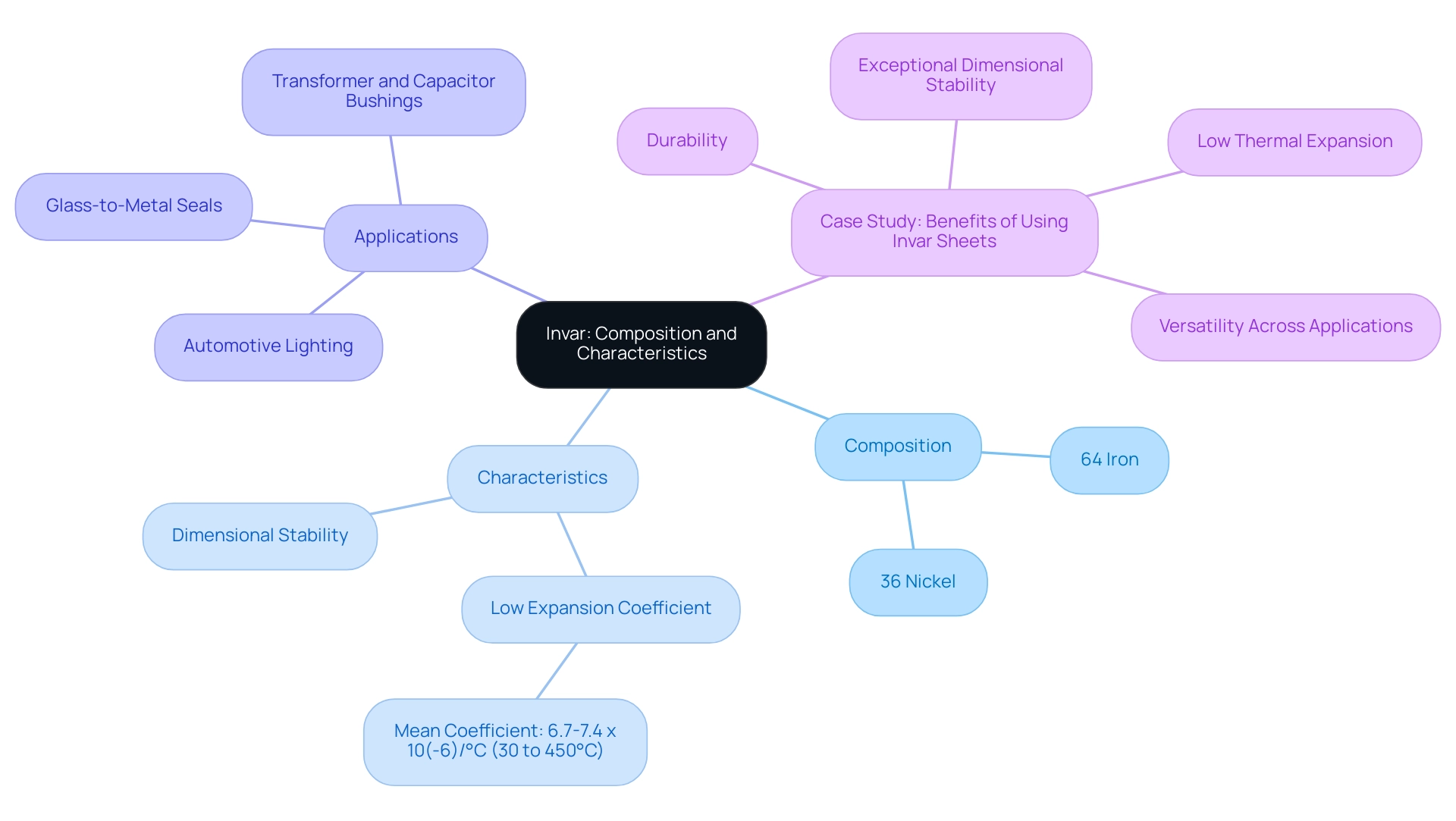

Defining Invar: Composition and Characteristics

This nickel-iron alloy is characterized by its exceptionally low expansion coefficient, generally varying between 6.7 to 7.4 x 10(-6)/°C within the temperature range of 30 to 450°C. This unique property allows the alloy, which we define invar as being composed of approximately 36% nickel and 64% iron, to maintain exceptional dimensional stability under varying thermal conditions. Such stability is essential in high-precision fields, rendering the alloy indispensable in areas where accuracy is vital.

Initially created in the early 20th century, this alloy has transformed into a cornerstone for various uses, including:

– Glass-to-metal seals in electronic tubes

– Automotive lighting

– Transformer and capacitor bushings

A significant case study titled ‘Benefits of Using Specific Sheets’ emphasizes how these sheets offer remarkable dimensional stability, low heat expansion, versatility across applications, and durability, making them perfect for high-precision uses in various industries. Additionally, Serife Korkmaz emphasizes the importance of combining particle size, zeta potential, and shelf-life analysis in research, which can further transform our understanding of these materials’ properties.

Its versatility and durability continue to solidify its role across various industries, reaffirming the alloy’s importance in advancing modern technology.

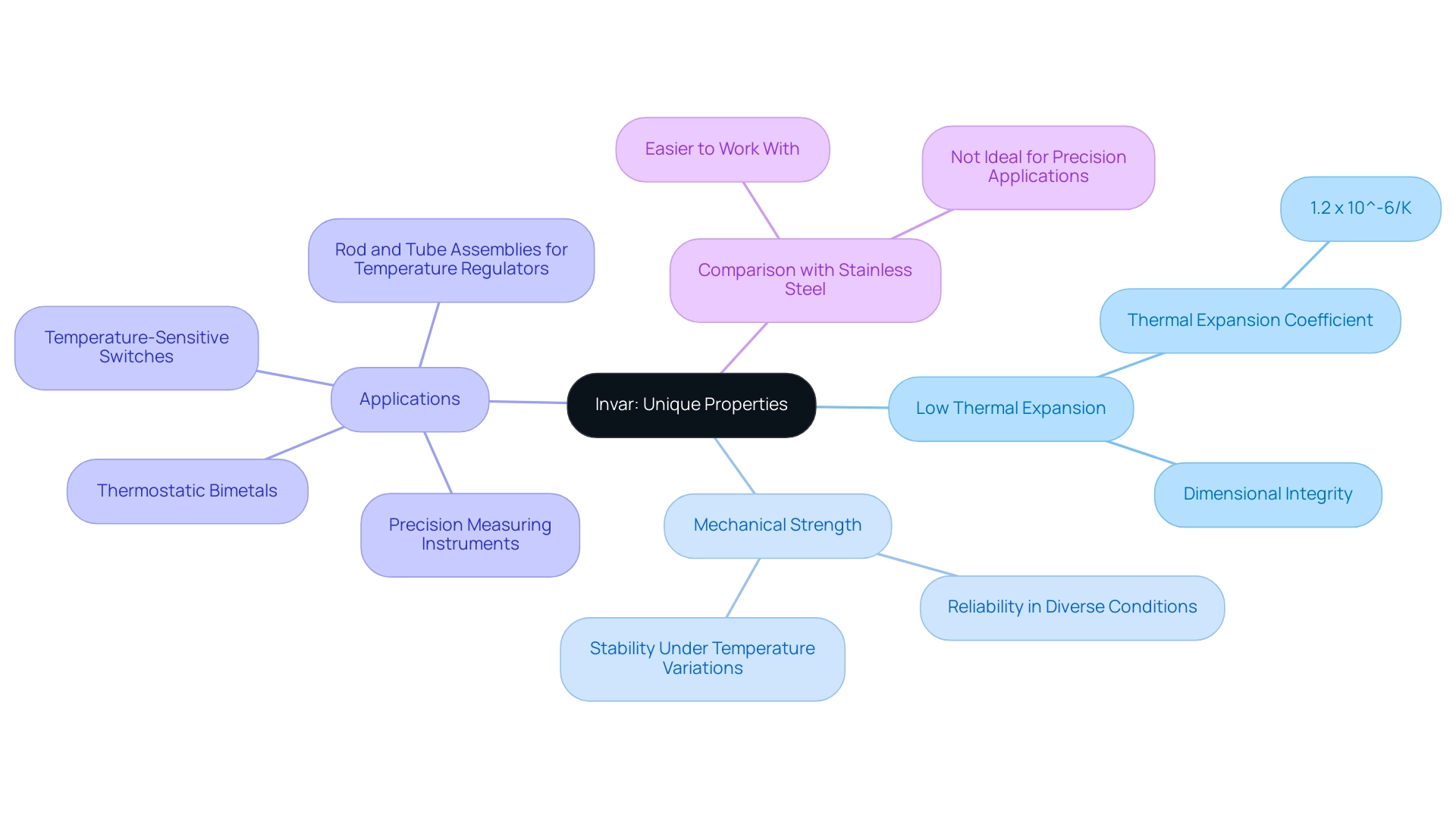

Unique Properties of Invar: Low Thermal Expansion and Strength

This alloy stands out in the realm of materials due to its remarkably low thermal expansion coefficient, approximately 1.2 x 10^-6/K. This characteristic enables components made from a specific alloy to maintain their dimensional integrity across a broad temperature spectrum, positioning it as an ideal choice for precision measuring instruments and scientific equipment. Alongside thermostatic bimetals—engineering marvels that respond to temperature changes with remarkable precision—one can define Invar 36 as being employed in uses requiring motion with temperature variations, such as in bimetallic thermostats, rod and tube assemblies for temperature regulators, and temperature-sensitive switches.

In settings where temperature variations are prevalent, this alloy’s low expansion ensures that crucial measurements stay precise, a characteristic unmatched by most other metals and mixtures. Compared to stainless steel, which is easier to work with due to its malleability, this alloy’s unique properties, including its stability and mechanical strength, make it the preferred material for precision uses. Beyond its thermal performance, this alloy also demonstrates notable mechanical strength and stability, further reinforcing its function in scenarios that require reliability under diverse conditions.

A case study titled ‘Properties and Applications of the Alloy’ highlights that this material, composed mostly of iron and 36% nickel, prevents shape changes when exposed to temperature variations, making it particularly useful in scientific measuring devices. As James A. Monroe, Founder & CEO of ALLVAR, emphasizes, ‘The ALLVAR team has been working hard in 2023 and is ready.’ This dedication to excellence demonstrates an increasing acknowledgment of the company’s potential in high-precision uses, highlighting its superiority when contrasted with traditional substances.

The combination of a specific alloy with thermostatic bimetals improves the overall performance of temperature-responsive systems, enabling greater accuracy and dependability in crucial uses.

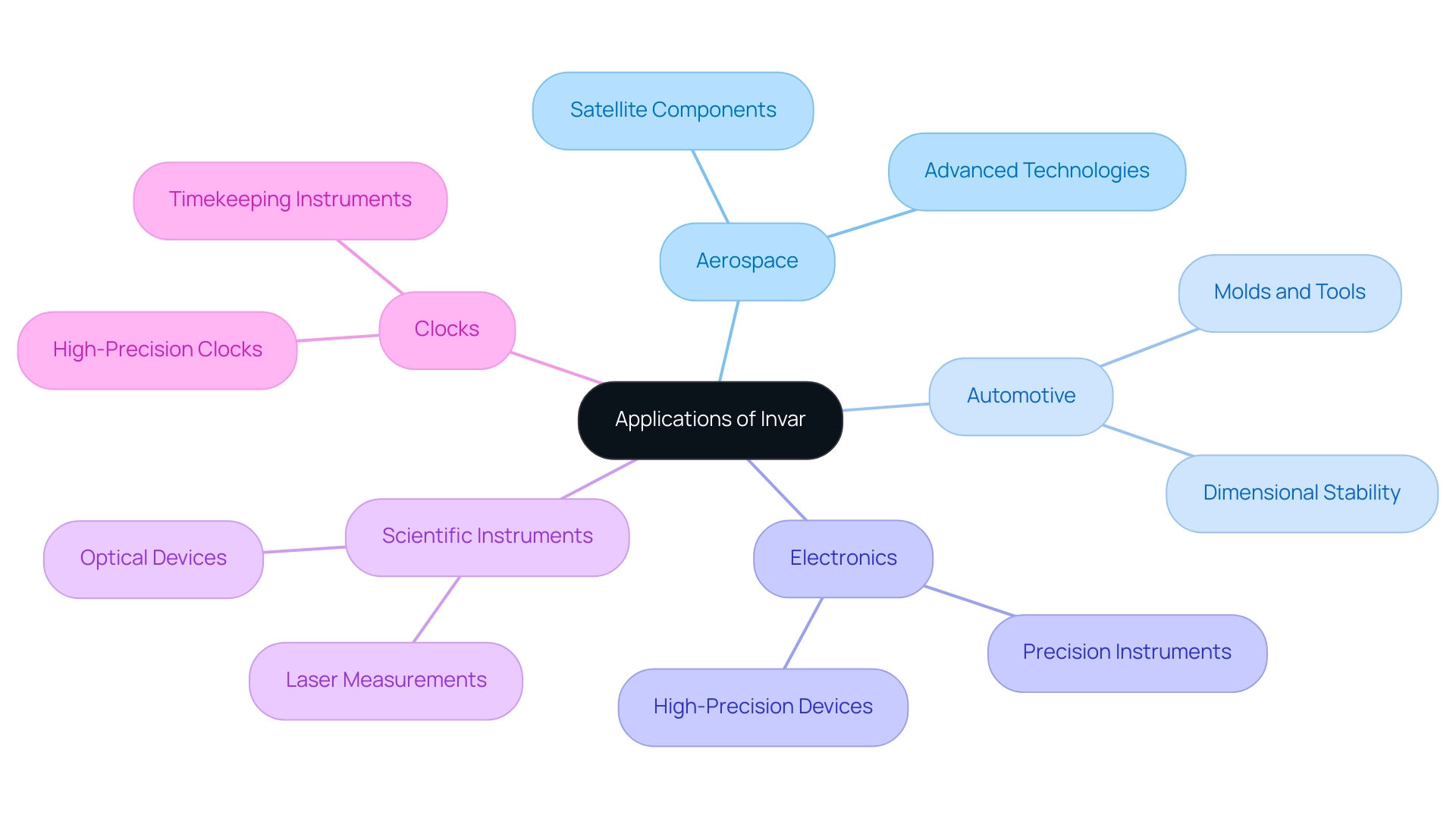

Applications of Invar: Where Precision Matters

This alloy is a critical material in applications demanding exceptional precision, notably in the manufacturing of clocks, scientific instruments, and aerospace components. Its intrinsic property of low thermal expansion makes it an optimal choice for sensitive laser measurements and high-precision optical devices. In the aerospace sector, this alloy is integral to the production of satellite components and other advanced technologies, reflecting its essential role in contemporary engineering.

Moreover, its applications extend to the automotive and electronics industries, where it is utilized in molds and tools that require stringent dimensional stability throughout the manufacturing process. The growing need for high-quality, eco-friendly products further enhances the significance of this material across these sectors. The Application Segment Analysis of the market, which spans over 250 pages, details year-on-year growth rates and the factors influencing market dynamics, making it a comprehensive resource for procurement managers.

As Manoj Phagare mentions, ‘We also offer the data support where you can engage with the team of analysts who contributed to the report,’ highlighting the importance of expert insights in comprehending the changing environment of these technologies.

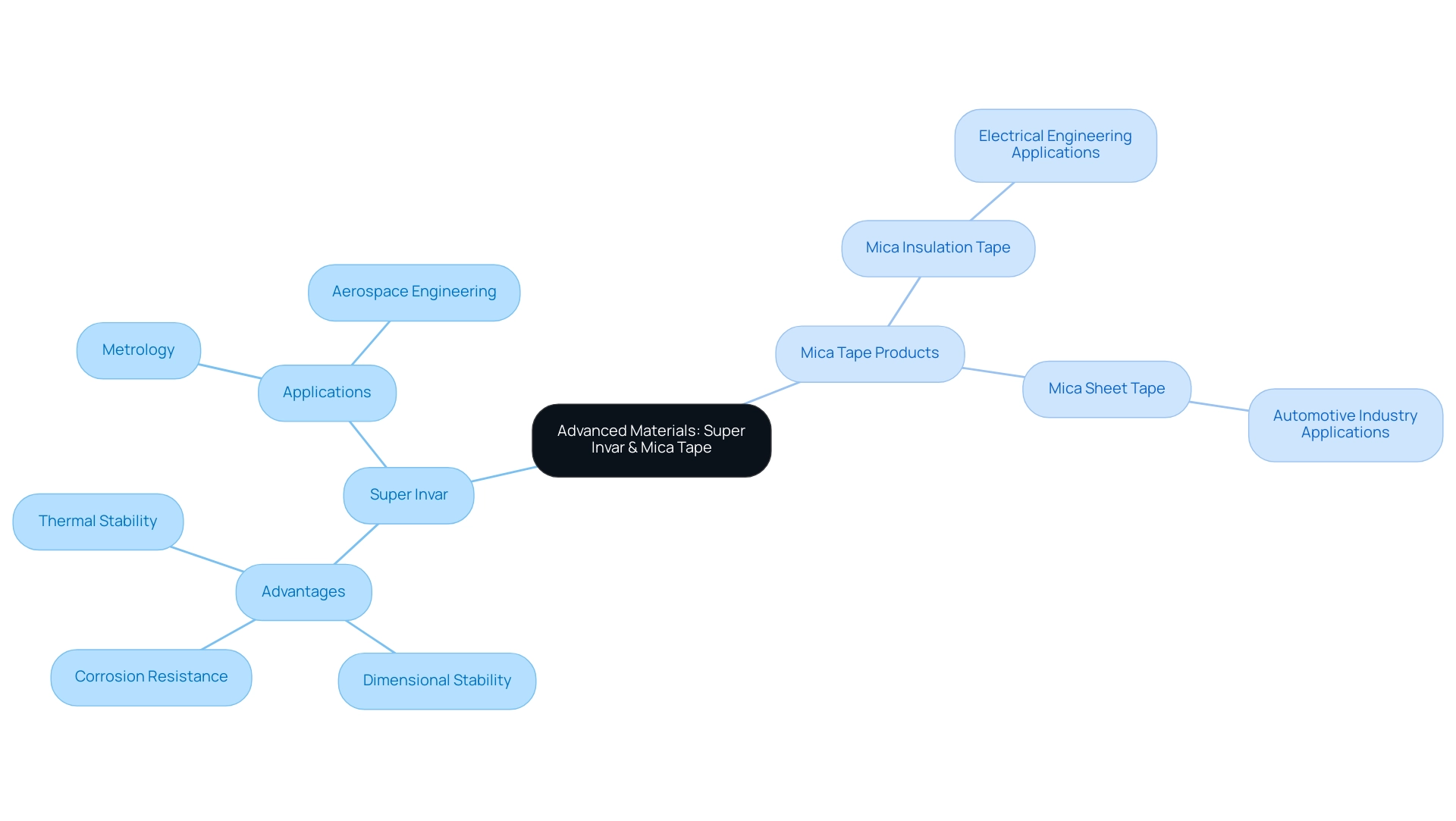

Exploring Variants: Super Invar and Its Advantages

Super Invar, a sophisticated variant of this material, incorporates elements such as cobalt, which significantly enhances its thermal stability while further minimizing its thermal expansion coefficient. This extraordinary material makes Super Invar particularly beneficial for contexts that require outstanding accuracy and stability during temperature variations. While both Invar and Super Invar serve similar functions, the latter is frequently favored in high-tech settings where extreme accuracy is paramount, which helps to define Invar’s role in advanced metrology and aerospace engineering.

Furthermore, Mica Tape products, created for high-temperature resistance and electrical insulation, enhance these uses by offering dependable insulation solutions across diverse environments. For instance:

– Mica Insulation Tape is ideal for critical electrical engineering applications due to its superior insulation properties.

– Mica Sheet Tape offers robust solutions for insulating large flat surfaces in aerospace and automotive industries.

The ongoing development of such materials reflects the dynamic advancements in material science, continually striving to fulfill the rigorous requirements of modern technology.

Recent insights indicate that the enhanced structural uniformity and dimensional stability afforded by thermal treatments, such as annealing and stress relieving, are crucial for optimizing performance in fabricated components. As highlighted in a recent case study, Super Invar maintains performance across a broader range of operating temperatures and exhibits superior corrosion resistance compared to a different material, which often requires protective coatings. This solidifies Super Invar’s position as a crucial component in cutting-edge applications, fulfilling and often surpassing expectations for precision engineering.

Notably, the integration of Mica Tape products into electrical insulation systems further underscores the importance of selecting high-quality materials for safety and efficiency. As noted, ‘ALLVAR Alloy 30 is all the VAR that standard alloy isn’t,’ emphasizing the competitive advantage that Super Invar holds in modern engineering. Furthermore, the exceptional flame resistance and dielectric strength of Mica Tape for Electrical ensure added safety in fire hazard-prone applications, making it a vital component in fire-resistant cables and insulation systems.

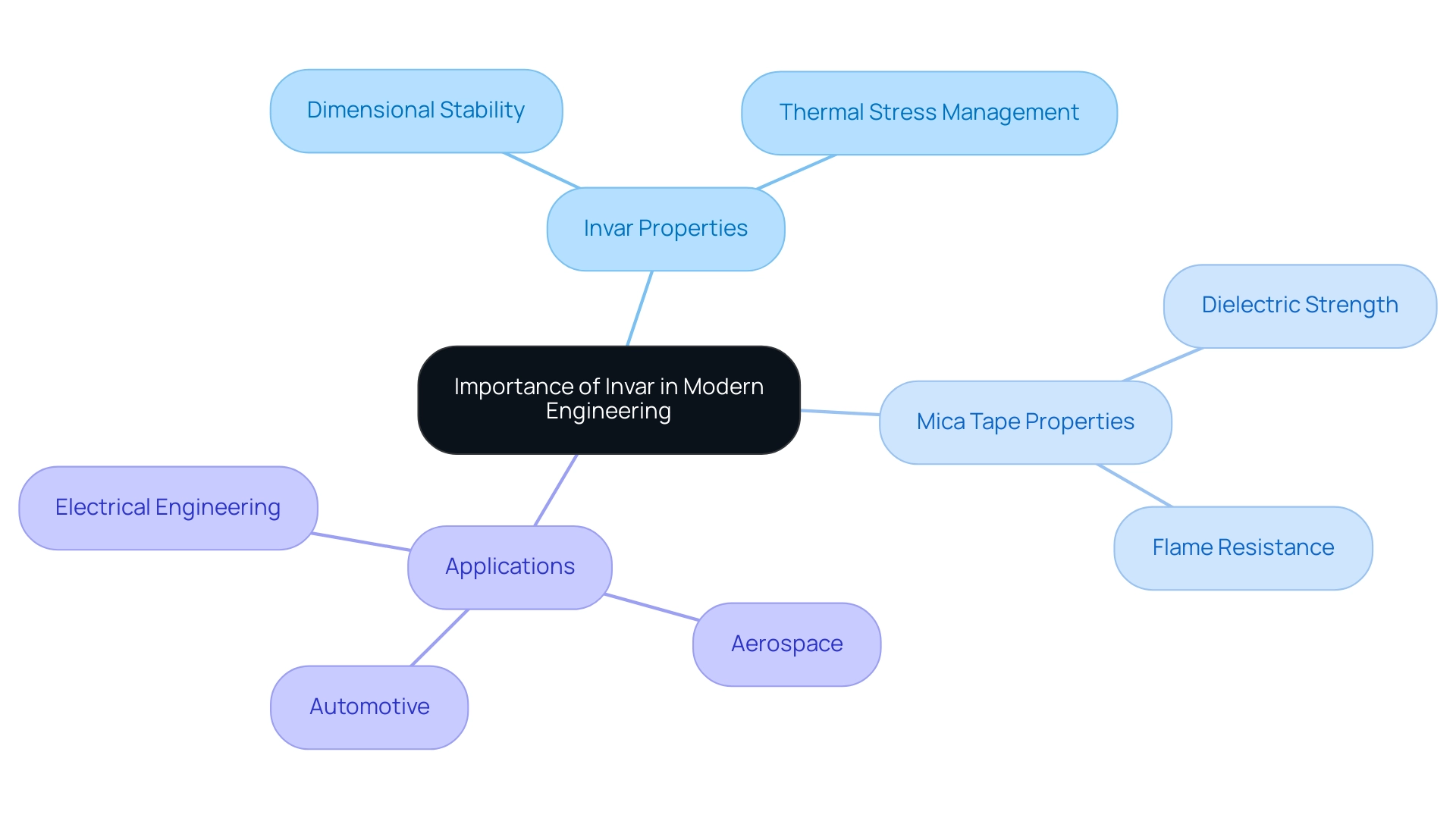

The Importance of Invar in Modern Engineering

The importance of this material in modern engineering is profound, especially as industries face the challenge of temperature variations that can impact precision. This alloy has emerged as an essential material, valued for its unique properties that allow it to maintain dimensional stability under thermal stress. This stability not only enhances the performance of precision instruments but also boosts the efficiency and reliability of manufacturing processes.

To enhance the capabilities of Domadia’s Mica Tape products, including Mica Insulation Tape, Mica Sheet Tape, and Insulating Mica Tapes, emerge as crucial solutions for high-temperature electrical insulation. These tapes are created to endure extreme conditions while providing superior dielectric strength and flame resistance, rendering them essential in critical uses across various sectors, such as aerospace, automotive, and electrical engineering. Recent studies, like the one published in Scientific Reports, article 7043, titled ‘Thermal Expansion Anomaly Regulated by Entropy,’ emphasize ongoing innovations in science aimed at enhancing the characteristics of both advanced alloys and Mica Tape for high-tech applications.

With increasing demand for these capabilities, particularly in cutting-edge sectors, their roles are set to expand. A significant case study, ‘Precise control of negative thermal expansion in stainless invar type alloy,’ helps to define invar’s contribution to advancements in telescope technology by enhancing performance. Experts such as Jingying Zuo have observed,

These findings illustrate the crucial function of Mica Tape products in creating more efficient systems,

which highlights the synergy between advanced substances and Mica Tape in engineering solutions.

Furthermore, Dr. Yong He, a specialist in the preparation and post-processing of nuclear materials, highlights the significance of this alloy in specific uses. As we look toward the future, it is clear that both Invar and Mica Tape will remain integral to the engineering toolkit, which will help to define Invar advancements across various applications.

Conclusion

Invar stands as a pivotal material in modern engineering, characterized by its exceptional low thermal expansion coefficient and remarkable dimensional stability. With a composition primarily of 36% nickel and 64% iron, this nickel-iron alloy has established itself as a critical component across diverse industries, from aerospace to electronics. Its ability to maintain accuracy under temperature variations ensures that precision instruments and high-performance components function reliably, which is vital in applications where even the slightest deviation can lead to significant consequences.

The unique properties of Invar, particularly its mechanical strength and stability, make it a preferred choice for high-precision applications. As demonstrated in various case studies, Invar’s integration into technologies such as thermostatic bimetals and advanced scientific instruments underscores its transformative potential in precision engineering. Furthermore, the emergence of advanced variants like Super Invar enhances the possibilities, offering even greater dimensional stability and thermal resistance, thereby addressing the evolving demands of high-tech applications.

As industries continue to strive for excellence in precision and reliability, the importance of materials like Invar and its derivatives cannot be overstated. The ongoing advancements in material science, including the development of complementary products like Mica Tape, further reinforce the strategic role of Invar in optimizing performance across critical sectors. Looking ahead, embracing these materials will be essential for meeting the challenges posed by modern engineering demands and ensuring sustained innovation in precision technology.