Blogs

Cerium Oxide Polishing vs Zirconia Abrasives: The Hidden Cost of Slower Performance | DOMADIA™

Introduction: Cerium Oxide Polishing Is Where Time Quietly Starts Bleeding Money

Cerium Oxide Polishing decisions are often made on habit, not performance.

In many glass, optics, semiconductor, and precision finishing plants, abrasive selection hasn’t changed in years. Operators continue using zirconia abrasives because they’re familiar, widely available, and seem economical on paper.

But production managers see a different reality every day:

- Polishing cycles stretch longer

- Rework increases

- Machines stay occupied beyond planned takt time

The cost doesn’t show up on the abrasive invoice.

It shows up in lost throughput, energy usage, and delayed deliveries.

That’s where Cerium Oxide Polishing quietly changes the economics.

At DOMADIA™, this comparison comes up repeatedly—and the results are rarely intuitive.

The Real-World Scenario: Same Line, Same Machine, Different Outcome

Two optical glass manufacturers ran identical polishing lines:

- Same machines

- Same glass grade

- Same workforce

The only difference was abrasive choice.

Plant A used zirconia abrasives.

Plant B switched to Cerium Oxide Polishing compounds supplied by DOMADIA™.

Within 60 days:

- Plant B reduced polishing time per batch by 28%

- Surface defect rejection dropped by nearly half

- Energy consumption per finished unit declined noticeably

Plant A didn’t fail.

It just moved slower—silently paying a premium for time.

Mindset Shift: Abrasives Are Productivity Tools, Not Consumables

Zirconia abrasives are usually justified as:

“They’re cheaper per kilogram.”

But Cerium Oxide Polishing reframes the question entirely:

“How fast can we reach spec—consistently?”

Polishing is not about abrasion alone.

It’s about chemical–mechanical interaction.

Cerium oxide doesn’t just grind—it reacts with glass surfaces at a molecular level, accelerating material removal without aggressive pressure.

That difference defines lifecycle cost.

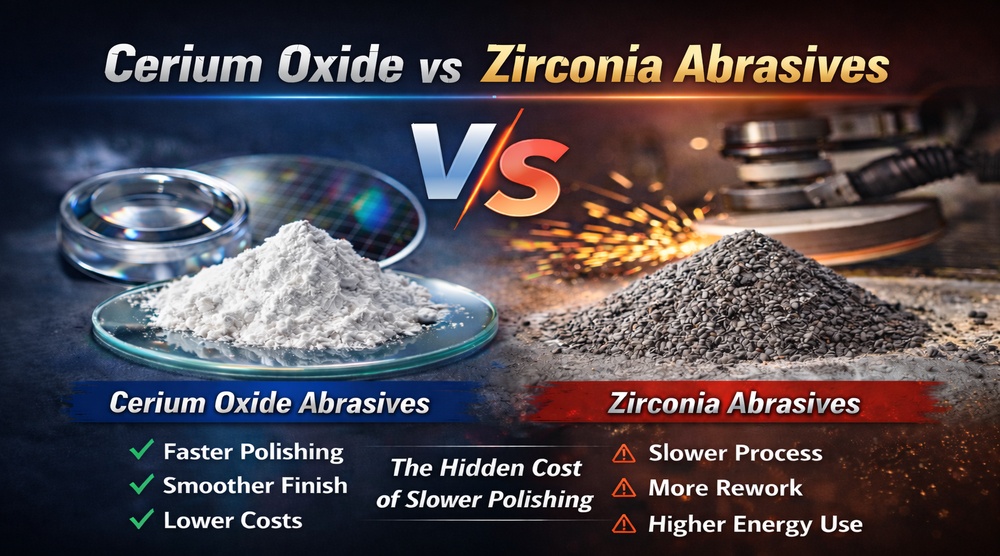

Chemical Composition Comparison

Cerium Oxide Polishing Abrasives

- Primary component: CeO₂

- Rare earth oxide with chemical affinity to silica

- Enables chemical-mechanical polishing (CMP)

- Self-sharpening behavior during polishing

Zirconia Abrasives

- Primary component: ZrO₂

- Hard, inert ceramic oxide

- Relies purely on mechanical abrasion

- No chemical interaction with glass surfaces

This single difference explains why Cerium Oxide Polishing achieves faster, smoother, and more repeatable results.

Properties: Where Performance Diverges

| Property | Cerium Oxide Polishing | Zirconia Abrasives |

| Polishing Speed | High | Moderate |

| Surface Finish | Ultra-smooth | Acceptable |

| Heat Generation | Low | Higher |

| Tool Wear | Reduced | Higher |

| Consistency | Excellent | Variable |

Zirconia removes material.

Cerium Oxide Polishing refines surfaces.

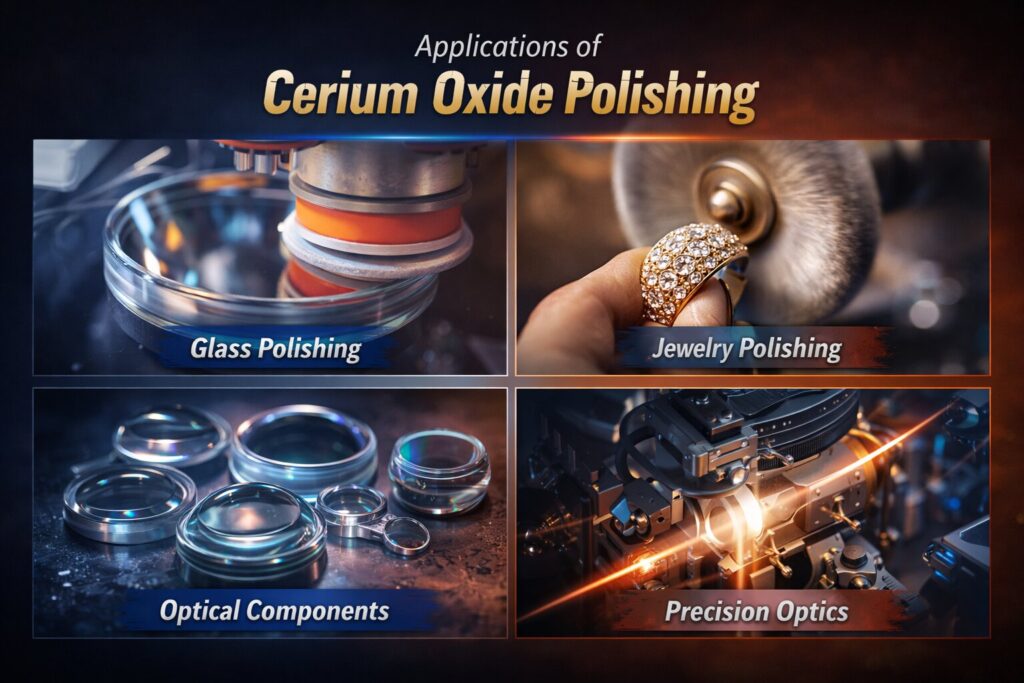

Applications: Where Slower Polishing Becomes Expensive

Glass & Optical Components

Cerium Oxide Polishing delivers faster clarity development and reduces micro-scratches that lead to rejection.

Display & Architectural Glass

Higher throughput with fewer passes improves line efficiency and lowers energy costs.

Semiconductor Wafers

Controlled removal rates and surface integrity are critical—Cerium Oxide Polishing minimizes downstream failures.

Precision Ceramics

Lower pressure polishing reduces chipping and edge damage.

Across these sectors, Cerium Oxide Polishing consistently shortens cycle time while improving yield.

Lifecycle Cost Comparison: The Hidden Math

Zirconia abrasives may appear economical upfront, but over time:

- Longer machine occupation increases overhead

- More frequent abrasive replacement adds downtime

- Higher rework rates inflate scrap costs

Cerium Oxide Polishing, though higher in initial price, offers:

- Faster cycle completion

- Fewer consumable changes

- Reduced labor and energy per unit

When measured per finished component—not per kilogram—Cerium Oxide Polishing often costs less.

Environmental Impact: Performance Is Sustainability

Here’s the overlooked truth:

The more often you replace abrasives, the more material you scrap and recycle.

Zirconia abrasives wear faster, requiring frequent replacement and disposal.

Cerium Oxide Polishing lasts longer, meaning:

- Less frequent recycling

- Lower waste generation

- Reduced environmental footprint

At DOMADIA™, promoting longer-life materials isn’t marketing—it’s a practical contribution to sustainable manufacturing.

Standards & Quality Control

DOMADIA™ Cerium Oxide Polishing materials are supplied with:

- Controlled particle size distribution

- Batch-level consistency

- Application-specific grading for glass, optics, and electronics

This ensures predictable polishing behavior across long production runs.

Technical Specifications (Typical)

- Purity: High CeO₂ content

- Particle size: Fine to ultra-fine grades

- Bulk density: Optimized for slurry stability

- Reactivity: Tuned for silica-based surfaces

(Custom specifications available from DOMADIA™ based on application needs.)

Shapes & Supply Forms Available

DOMADIA™ supplies Cerium Oxide Polishing materials in:

- Powder form

- Slurry-ready grades

- Customized particle distributions

This flexibility ensures compatibility with existing polishing systems—no process overhaul required.

Conclusion: Cerium Oxide Polishing Is a Time Advantage

Cerium Oxide Polishing is not chosen because it is premium-priced.

It is chosen because time is expensive.

Slower polishing:

- Ties up machines

- Increases energy use

- Quietly inflates cost per unit

Faster polishing unlocks capacity you already own.

At DOMADIA™, we help manufacturers stop paying for lost time—and start investing in controlled performance.

Upgrade Your Polishing Performance with Confidence

Stop paying the hidden cost of slower polishing cycles. Switch to performance-driven Cerium Oxide Polishing solutions engineered for speed, precision, and long-term efficiency.

Connect with DOMADIA™ today and optimize your polishing process for measurable results.

Ready to improve your polishing efficiency? Click Contact Us and take the next step toward optimized surface finishing.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

Directly whatsapp us for an Enquiry: https://wa.link/kairav

#CeriumOxidePolishing #CeriumOxideAbrasives #ZirconiaAbrasives #GlassPolishing #OpticalManufacturing #PrecisionFinishing #IndustrialAbrasives #SurfaceEngineering #ManufacturingEfficiency #DOMADIA™

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.