Blogs

Chemical Properties Cerium Oxide (CeO₂): 7 Powerful Factors Making It Industrially Essential | DOMADIA™

Chemical Properties Cerium Oxide That Quietly Power Modern Industry

In industrial chemistry, some materials shout with strength.

Others whisper through reliability.

Chemical Properties Cerium Oxide belong firmly in the second category.

Cerium Oxide doesn’t fail dramatically. It doesn’t corrode aggressively. It doesn’t collapse under stress. Instead, it performs—day after day—inside catalytic converters, polishing slurries, solid oxide fuel cells, and precision glass systems where failure would be unacceptable.

At DOMADIA™, Cerium Oxide is treated not as a commodity powder, but as a chemical workhorse whose properties directly shape efficiency, yield, and lifecycle cost.

The Real-World Scenario Engineers Recognize

A glass polishing line keeps producing micro-scratches.

A catalytic converter loses efficiency faster than expected.

A fuel cell degrades before its projected service life.

On paper, the material selection was correct.

In reality, the chemical behavior under operating conditions was misunderstood.

This is where Chemical Properties Cerium Oxide separate it from nearly every other oxide used in industry.

What Makes Cerium Oxide Chemically Unique?

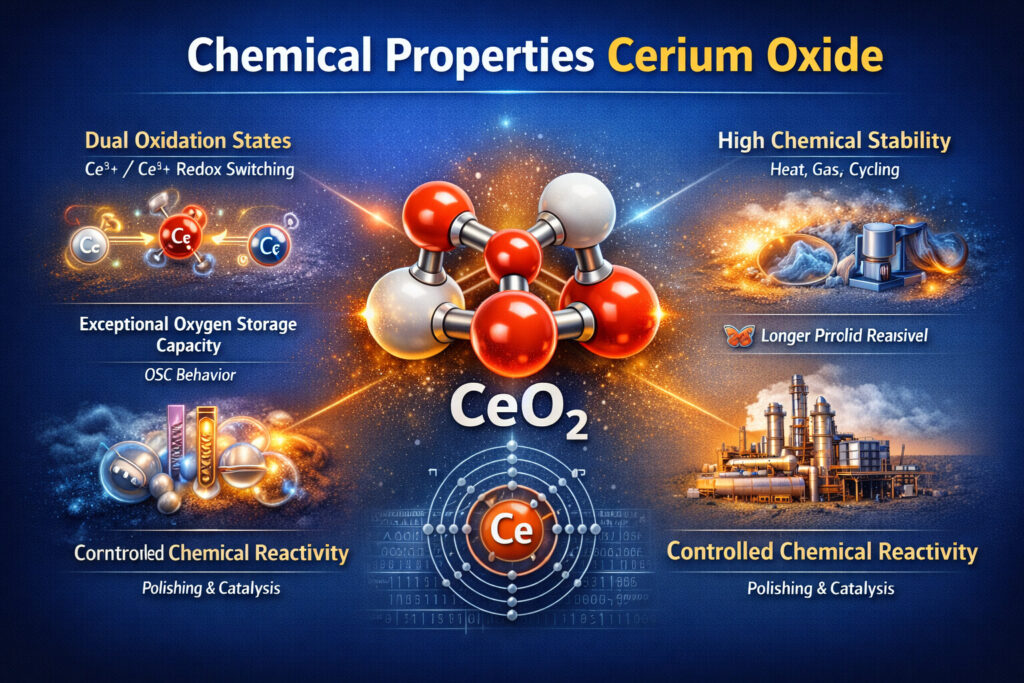

1. Dual Oxidation States (Ce³⁺ / Ce⁴⁺ Redox Switching)

The most defining aspect of Chemical Properties Cerium Oxide is its ability to reversibly switch oxidation states.

- Cerium easily transitions between Ce³⁺ and Ce⁴⁺

- This creates oxygen vacancies within the crystal lattice

- Oxygen can be released and reabsorbed repeatedly

Why it matters:

This redox flexibility allows Cerium Oxide to act as an oxygen buffer, stabilizing reactions instead of exhausting itself.

2. Exceptional Oxygen Storage Capacity (OSC)

Among rare earth oxides, Chemical Properties Cerium Oxide deliver unmatched oxygen storage behavior.

- Absorbs oxygen under oxidizing conditions

- Releases oxygen under reducing conditions

- Maintains lattice integrity during cycling

Industrial impact:

- Cleaner exhaust emissions

- Stable catalytic efficiency

- Reduced catalyst poisoning

This is why Cerium Oxide is indispensable in automotive catalytic converters and energy systems.

3. High Chemical Stability Across Extreme Environments

Many oxides perform well in isolation but degrade when exposed to:

- High temperatures

- Reactive gases

- Continuous thermal cycling

Chemical Properties Cerium Oxide resist:

- Chemical decomposition

- Phase instability

- Reactive corrosion

This stability allows long-term use in:

- High-temperature polishing

- Furnace environments

- Solid oxide fuel cells

4. Controlled Chemical Reactivity (Not Too Aggressive)

Cerium Oxide reacts when needed—but never excessively.

- Strong enough to participate in redox chemistry

- Mild enough to avoid surface damage

- Chemically selective in reaction pathways

This balance explains why Chemical Properties Cerium Oxide dominate precision glass and optics polishing, where surface integrity is critical.

5. Surface Chemistry That Enhances Polishing Efficiency

At the microscopic level, Chemical Properties Cerium Oxide allow it to:

- Form temporary chemical bonds with silica-based surfaces

- Promote material removal without deep abrasion

- Deliver ultra-low surface roughness

Result:

- Higher optical clarity

- Faster polishing cycles

- Reduced reject rates

No other oxide consistently matches Cerium Oxide in chemical-mechanical polishing behavior.

6. Resistance to Chemical Poisoning

Many industrial catalysts degrade because reactive impurities permanently block active sites.

Chemical Properties Cerium Oxide reduce this risk by:

- Absorbing contaminants temporarily

- Preventing irreversible surface poisoning

- Regenerating active oxygen sites

This translates into:

- Longer catalyst life

- Lower replacement frequency

- Reduced downtime

7. Compatibility With Other Industrial Materials

Cerium Oxide blends seamlessly with:

- Zirconia

- Alumina

- Precious metal catalysts

- Polymer matrices

Its chemical neutrality ensures it enhances systems without destabilizing them, a key reason DOMADIA™ supplies it for multi-material industrial assemblies.

Chemical Composition of Cerium Oxide

| Element | Composition |

| Cerium (Ce) | ~81.4% |

| Oxygen (O) | ~18.6% |

| Chemical Formula | CeO₂ |

| Crystal Structure | Fluorite (Cubic) |

This structure is central to the Chemical Properties Cerium Oxide, enabling oxygen mobility and redox reversibility.

Key Industrial Applications Driven by Chemical Properties Cerium Oxide

Automotive Catalytic Converters

The chemical properties of Cerium Oxide enable rapid oxygen storage and release, stabilizing exhaust gas reactions and significantly improving emission control efficiency under fluctuating engine conditions.

Glass & Optical Polishing

Chemical properties of Cerium Oxide allow controlled chemical–mechanical interaction with silica surfaces, delivering superior surface finish, minimal subsurface damage, and high optical clarity.

Solid Oxide Fuel Cells (SOFCs)

Thanks to its redox flexibility and oxygen ion mobility, the chemical properties of Cerium Oxide support stable ionic conductivity and long-term electrochemical performance at elevated temperatures.

Petroleum Refining Catalysts

Chemical properties of Cerium Oxide enhance catalyst redox behavior, improve resistance to poisoning, and maintain reaction efficiency during continuous high-temperature refining operations.

Electronics & Semiconductors

In CMP slurries and surface conditioning, chemical properties of Cerium Oxide ensure precise material removal, uniform planarization, and defect-free semiconductor surfaces.

Across these sectors, Chemical Properties Cerium Oxide directly reduce lifecycle cost and improve reliability.

Standards & Industrial Grades

Cerium Oxide supplied by DOMADIA™ aligns with:

- ASTM chemical purity standards

- ISO industrial material specifications

- Controlled particle-size distribution requirements

- Application-specific surface chemistry criteria

Physical & Chemical Properties Snapshot

| Property | Typical Value |

| Molecular Weight | 172.11 g/mol |

| Melting Point | ~2,600°C |

| Density | ~7.2 g/cm³ |

| Solubility | Insoluble in water |

| Chemical Behavior | Reversible redox |

Shapes & Forms Available at DOMADIA™

- Fine powders

- Polishing-grade micronized particles

- Nano-grade dispersions

- Customized blends for catalytic systems

The Mindset Shift Industries Must Make

Cerium Oxide is not chosen for its price.

It is chosen for its chemical predictability.

The Chemical Properties Cerium Oxide quietly eliminate inefficiencies that would otherwise surface as downtime, defects, and environmental waste.

The Tangible Fix

Select Cerium Oxide not by grade name alone—but by:

- Redox behavior

- Particle chemistry

- Surface reactivity

- Long-term stability under operating conditions

At DOMADIA™, this chemical matching is standard—not optional.

Conclusion: Why Chemical Properties Cerium Oxide Remain Irreplaceable

Materials that last are not always the strongest.

They are the most chemically intelligent.

Chemical Properties Cerium Oxide allow it to adapt, regenerate, and perform under industrial stress without degradation—making it indispensable across modern manufacturing, energy, and environmental systems. When reliability matters more than short-term savings, Cerium Oxide delivers quietly—and consistently.

Looking to leverage the chemical properties of Cerium Oxide for long-term industrial performance?

DOMADIA™ supplies Cerium Oxide engineered for stability, consistency, and real-world operating conditions.

Contact Us to explore Cerium Oxide solutions engineered for industrial reliability by DOMADIA™.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#ChemicalPropertiesCeriumOxide #CeriumOxide #RareEarthMaterials #IndustrialChemistry #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.