Blogs

Cold Roll Cladding: The Smart Way to Bond Metals Without Heat

Introduction

Ever wondered how engineers manage to combine the strength of steel with the conductivity of copper, or the lightweight nature of aluminum with the toughness of steel? The answer lies in a fascinating process known as Cold Roll Cladding. Unlike traditional coating or welding methods, this technology doesn’t just stick metals together—it fuses them into one solid, reliable composite.

In this blog, we’ll explore what cold roll cladding is, why it matters, how it works, and where it’s used across industries like energy, automotive, and electrical engineering.

What is Cold Roll Cladding?

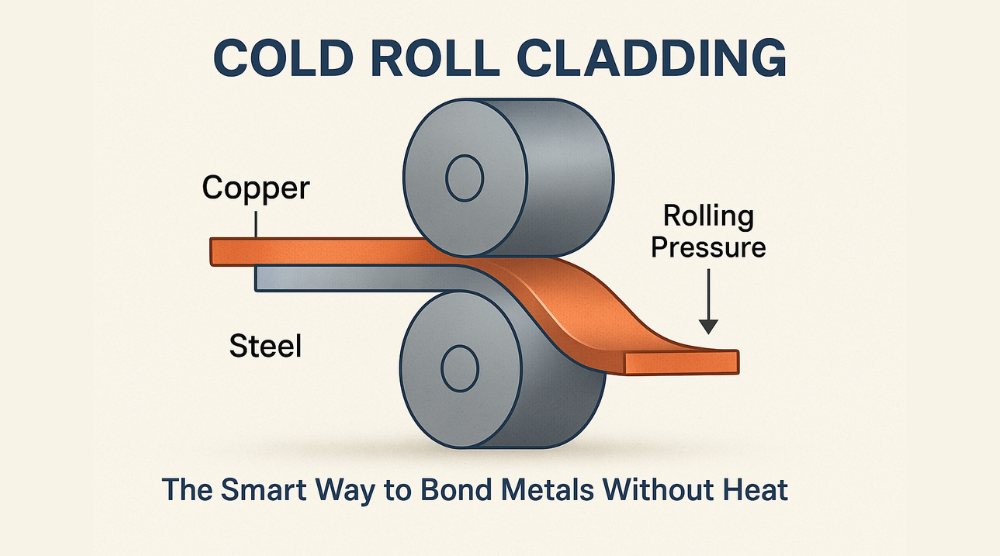

Cold roll cladding is a process for producing multi-layer metal composites. Instead of simply applying a coating, it achieves real metallurgical bonding between two or more different metals. This bond is formed by applying high rolling pressure and deformation during the process.

In simple terms, imagine two different metal sheets being pressed together so tightly that their surfaces merge at the atomic level—creating one strong, layered structure.

Why is it Called “Cold”?

The word cold highlights that no external heat is applied during the bonding process. Unlike hot plating or welding, the bond happens through mechanical force.

Here’s what makes it special:

- Oxides are broken in the rolling gap.

- Fresh, pure metal surfaces are exposed.

- These surfaces are then fused together, almost like a solid-state weld.

This method is especially useful for hard-to-weld combinations like:

- Steel + Copper

- Steel + Aluminum

- Steel + Titanium

Advantages Over Hot Plating

- ✅ Cost-effective – No need for expensive blast furnaces.

- ✅ Better structural control – The bonding happens in a controlled environment.

- ✅ Reduced risk of brittle phases – Avoids unwanted brittle intermetallic layers that often form during hot processes.

In short, cold roll cladding delivers strong, clean, and reliable bonds without the downsides of high heat.

Surface Preparation: The Secret to Success

The surface plays a crucial role in whether the bond will succeed. Before rolling, the metal surfaces are brushed or ground.

This preparation helps in two ways:

- Removes oxides that would otherwise prevent bonding.

- Creates micro-roughness (like tiny ridges) that improve grip and bonding strength.

Think of it as breaking the “eggshell” of the metal surface so the pure metal beneath can fuse properly.

Inside the Rolling Gap

Here’s how the process unfolds inside the rolling mill:

- Reduction: Metals are pressed together with a 60–75% reduction per round. This stage creates what experts call the “Green Bond.”

- Annealing: After rolling, the composite is annealed (heat-treated) to stabilize the bond. This step allows diffusion between layers, resulting in a stable, long-lasting compound.

Key Factors That Influence Cold Roll Cladding

Several technical parameters affect the quality of the bond:

- Reduction ratio – How much the thickness is reduced.

- Coating thickness ratio – Balance between the layers.

- Rolling speed – Faster speeds may reduce bonding effectiveness.

- Friction – Must be controlled to avoid defects.

- Surface cleanliness – Dust, oil, or oxide layers can ruin the bond.

- Annealing parameters – The right heat treatment is critical.

Applications of Cold Roll Cladding

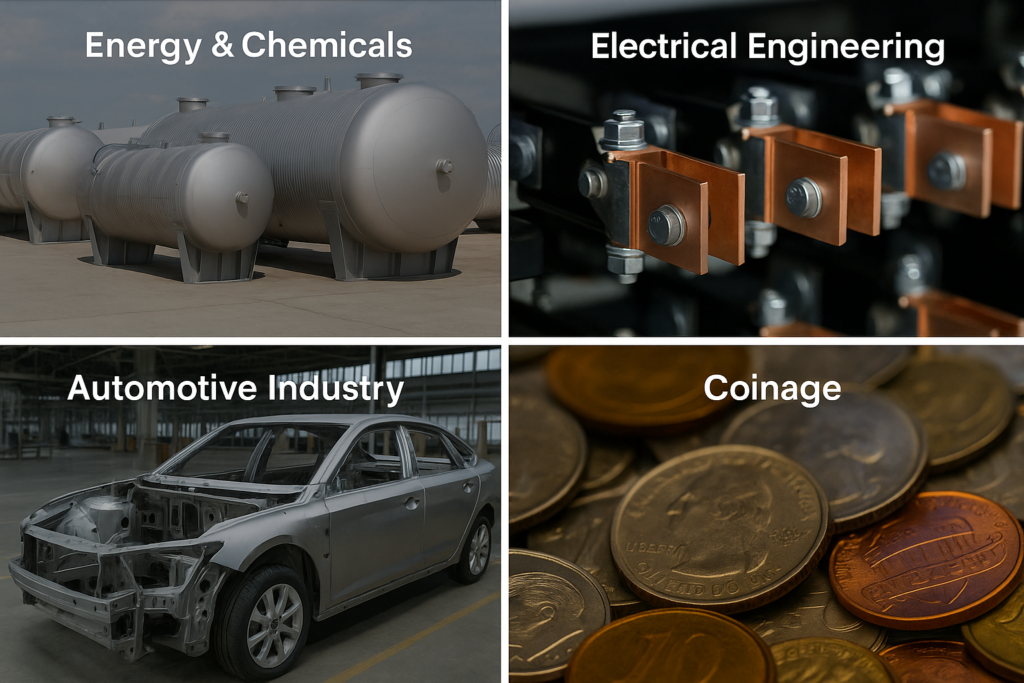

Cold roll cladding isn’t just a laboratory process—it’s used widely across industries:

1. Energy & Chemicals

- Steel + Stainless Steel composites are used for heat exchangers, storage tanks, and chemical containers.

- Benefits: corrosion resistance with cost efficiency.

2. Electrical Engineering

- Steel + Copper combinations are used in rails, battery contacts, and connectors.

- Benefits: conductivity of copper + strength of steel.

3. Automotive Industry

- Steel + Aluminum composites are ideal for lightweight vehicle structures.

- Benefits: fuel efficiency and reduced emissions without sacrificing strength.

4. Coinage

- Everyday coins often use a steel core with a colored top layer.

- Benefits: cost savings with durability and aesthetics.

Conclusion

Cold roll cladding is a modern, sustainable, and cost-effective technique that combines the best properties of multiple metals. By applying rolling pressure instead of heat, it achieves strong, stable, and versatile composites. From energy plants to electric cars and even the coins in your pocket, this process is shaping industries silently but powerfully. It’s a reminder that sometimes, innovation doesn’t need fire—it just needs the right pressure.

Talk to us: Kairav Domadia | Aadil Domadia | Er.Pankaj Domadia | Pragati Sanap | Pooja N N

#ColdRollCladding #MetalComposites #SteelCopper #SteelAluminum #ManufacturingInnovation #EngineeringSolutions #MetalBonding #AutomotiveMaterials #ElectricalEngineering #SustainableManufacturing