Blogs

Copper Alloys vs Aluminum Alloys: Electrical Performance Comparison | DOMADIA™

A Suspenseful Start…

A major EV manufacturer approached DOMADIA™ with a persistent problem:

Their battery connectors were overheating — again.

They had switched to an inexpensive aluminum alloy thinking it would reduce component cost. But the hidden cost?

Voltage drops… heat generation… unexpected downtime… and warranty claims creeping up every quarter.

The turning point came when their engineering lead switched to a high-conductivity copper alloy from DOMADIA™.

One simple material change.

And the problem disappeared.

This real industrial scenario opens the bigger debate:

Which performs better electrically — Copper Alloys or Aluminum Alloys?

Let’s dive deep.

Understanding the Chemical Composition

Copper Alloys (Typical UNS Examples: C11000, C17200, C26000)

- Base element: Copper (Cu ≥ 60–99.9%)

- Common alloying additions: Be, Sn, Zn, Ni, Co, Si

- Purpose: Enhances strength, fatigue resistance & conductivity retention.

Aluminum Alloys (Typical UNS Examples: A91000, A92024, A96061)

- Base element: Aluminum (Al ≥ 85–99%)

- Alloying additions: Mg, Si, Mn, Cu, Zn

- Purpose: Reduces weight, improves corrosion resistance & machinability.

Electrical Performance Comparison

1. Electrical Conductivity

(Reference: IACS – International Annealed Copper Standard)

Copper Alloys

- High-conductivity grades (C11000): 100% IACS

- Beryllium copper: 20–60% IACS

- Brass / Bronze: 15–40% IACS

Aluminum Alloys

- Pure aluminum: 61% IACS

- Commercial aluminum alloys: 30–50% IACS

Conclusion:

Copper alloys offer higher conductivity → lower losses → lower heat generation.

2. Resistivity & Heat Buildup

- Copper alloys: Low resistivity → minimal heat rise

- Aluminum alloys: Higher resistivity → more heat under high current

For high-power EVs, switchgear, and busbars, this difference becomes massive.

3. Strength vs Conductivity Balance Copper alloys maintain conductivity even under stress, forming less oxide.

Aluminum alloys form insulating oxide layers, increasing contact resistance over time.

Mechanical & Thermal Properties

| Property | Copper Alloys | Aluminum Alloys |

| Density | High | Low (lightweight) |

| Thermal Conductivity | Excellent | Good |

| Oxidation | Low | High |

| Creep Resistance | High | Low |

| Fatigue Strength | Very High | Moderate |

| Weldability | Excellent (specific grades) | Excellent |

| Cost | Higher | Lower |

Industry Standards

Copper Alloy Standards

- ASTM B194 (BeCu)

- ASTM B422 (Phosphor Bronze)

- ASTM B152 (Copper Sheet)

- ASTM B601 (Contact Materials)

Aluminum Alloy Standards

- ASTM B209 (Aluminum Plate)

- ASTM B221 (Aluminum Extrusions)

- ASTM B211 (Aluminum Rod & Bar)

DOMADIA™ supplies materials aligned with ASTM, AMS, MIL, JIS, DIN & ISO standards.

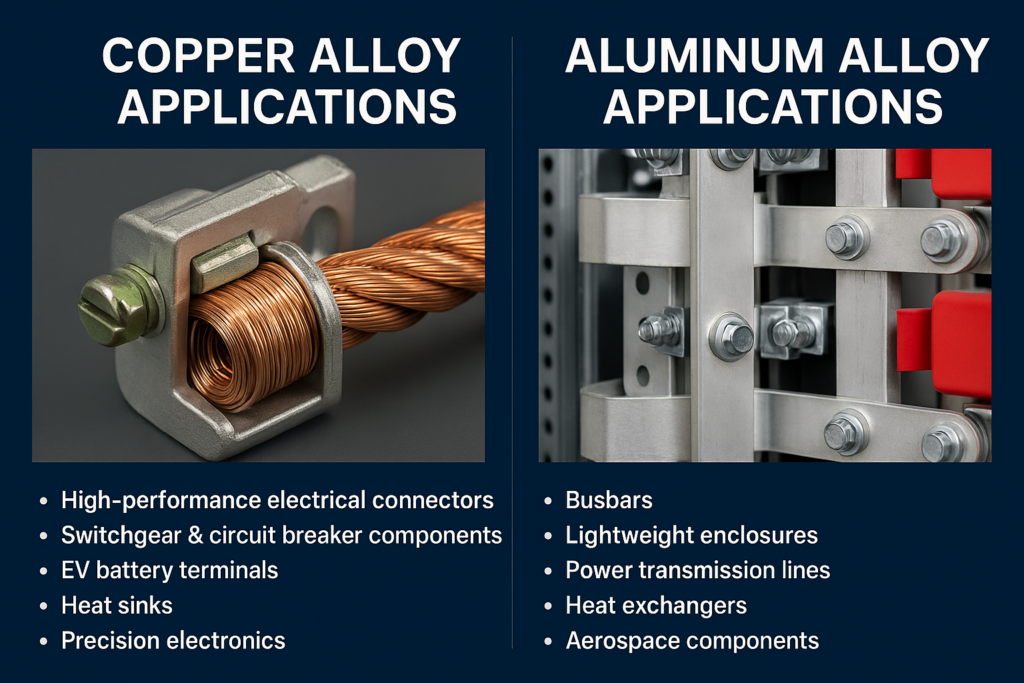

Applications: Copper vs Aluminum

Copper Alloy Applications

- High-performance electrical connectors

- Switchgear & circuit breaker components

- EV battery terminals

- Heat sinks

- Precision electronics

Aluminum Alloy Applications

- Busbars

- Lightweight enclosures

- Power transmission lines

- Heat exchangers

- Aerospace components

Shapes Available at DOMADIA™

Copper Alloys

- Sheets & Plates

- Rods, Bars & Strips

- Foils & Clad Materials

- Wires & Tubes

- Custom CNC components

Aluminum Alloys

- Plates & Sheets

- Extruded Profiles

- Bars & Rods

- Coils & Foils

- Machined Parts

Key Technical Specifications Checklist

Copper Alloys

- Conductivity: 20–100% IACS

- Tensile Strength: 300–1400 MPa

- Operating Temp: Up to 300°C

Aluminum Alloys

- Conductivity: 30–61% IACS

- Tensile Strength: 100–570 MPa

- Operating Temp: Up to 200°C

Environmental Impact

Copper alloys require less replacement, meaning:

- Lower production emissions

- Reduced mining

- Reduced waste

- Higher recyclability

Longer lifecycle = less environmental burden.

Final Verdict: Which Performs Better Electrically?

The phrase Copper Alloys vs Aluminum Alloys Electrical Performance comes down to one truth:

• Copper alloys are the preferred choice for high-current systems, precision performance, and applications where long-term reliability is essential.

• Aluminum alloys offer strong value for lightweight, budget-friendly, and structurally focused electrical systems where moderate performance is sufficient.

For EVs, power electronics, connectors & high-load electrical systems:

Copper alloys offer unmatched electrical performance, lower heat loss, longer life, and higher reliability.

DOMADIA™ recommends copper alloys where failure is not an option.

See Which Alloy Fits Your Application — Get a Free Material Assessment

Make the Right Alloy Choice for Peak Electrical Performance

Contact DOMADIA™ for Specifications & Pricing

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CopperAlloys #AluminumAlloys #ElectricalConductivity #EngineeringMaterials #DOMADIA #MetalsComparison #EVMaterials #ConductiveMetals

Directly whatsapp us for an Enquiry: https://wa.link/kairav