Blogs

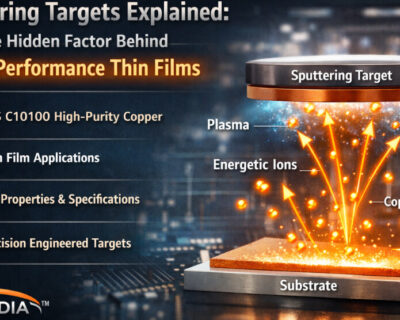

Copper vs Aluminum Sputtering Targets (UNS C11000 vs UNS A91100): The Smart Choice That Improves Yield and Conductivity | DOMADIA™

When Yield Drops, the Problem Isn’t Always the Process

A semiconductor line runs flawlessly for weeks.

Then suddenly—sheet resistance drifts, adhesion weakens, and yield slips by a few percentage points.

The chamber looks fine.

The parameters haven’t changed.

Yet performance keeps declining.

In many fabs, the overlooked reason is simple: the sputtering target material.

This is where Copper vs Aluminum Sputtering becomes more than a material comparison—it becomes a yield decision.

Copper vs Aluminum Sputtering: Rethinking the Default Choice

Aluminum sputtering targets have been the industry’s comfort zone for decades. They are lightweight, familiar, and cost-effective.

Copper sputtering targets, on the other hand, enter the conversation when fabs start prioritizing:

- Higher electrical conductivity

- Lower resistivity films

- Stable performance across advanced nodes

The real shift happens when manufacturers stop asking “Which target is cheaper?”

and start asking “Which target protects yield per wafer?”

Key Properties That Define Thin-Film Performance

Electrical Conductivity

Copper offers ~59 MS/m conductivity, while aluminum delivers ~37 MS/m.

That difference alone explains why Copper vs Aluminum Sputtering directly impacts:

- Interconnect efficiency

- Signal integrity

- Power loss across micro-scale circuits

Film Density and Uniformity

Copper sputtered films are denser and more uniform, resulting in:

- Lower resistivity

- Better adhesion

- Reduced void formation

Aluminum films are lighter but more prone to micro-defects as geometries shrink.

Thermal Stability and Reliability

Copper withstands higher current densities with lower electromigration risk.

Aluminum shows fatigue earlier under thermal cycling and high-load conditions.

In high-performance fabs, this reliability gap becomes impossible to ignore.

Applications Where Copper Clearly Outperforms

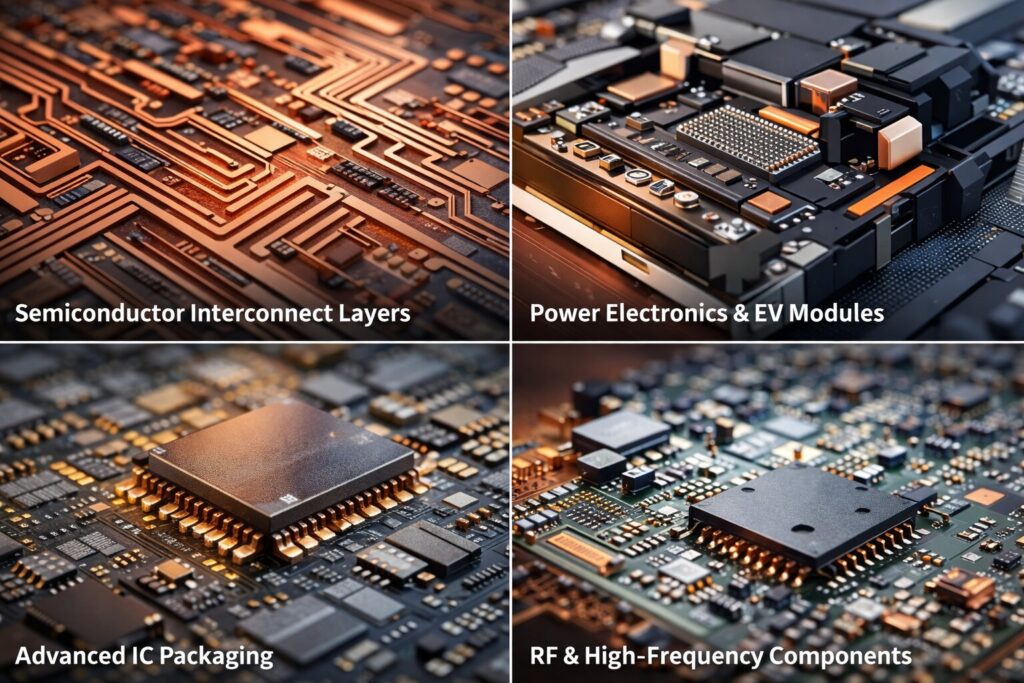

Semiconductor Interconnect Layers

Copper sputtering targets deliver low-resistivity films that support faster signal transmission and reduced power loss. They are essential for advanced-node semiconductor devices where interconnect reliability directly impacts yield.

Power Electronics & EV Modules

In high-current and high-thermal-load environments, Copper vs Aluminum Sputtering becomes a critical comparison for manufacturers. While aluminum performs adequately in moderate conditions, copper films handle greater current density with significantly lower electromigration risk. Therefore, when evaluating Copper vs Aluminum Sputtering, copper sputtering targets clearly offer superior performance for power modules, inverters, and electric vehicle electronics. As a result, industries focused on efficiency, durability, and thermal stability often prioritize copper in the Copper vs Aluminum Sputtering decision-making process.

Advanced IC Packaging

Copper enables dense, uniform metallization in advanced packaging technologies such as flip-chip, wafer-level packaging, and 3D ICs. Its superior conductivity improves electrical performance while maintaining long-term reliability.

RF & High-Frequency Components

Copper sputtered films minimize signal attenuation and resistive losses in RF circuits. This ensures stable performance in 5G devices, communication systems, and high-frequency semiconductor applications.

Precision Microelectronics

For devices requiring ultra-low resistance and consistent electrical performance, copper sputtering targets provide highly uniform films. They are widely used in sensors, MEMS devices, and precision microelectronic components.

Applications Where Aluminum Remains Suitable

Cost-Sensitive Legacy Semiconductor Processes

Aluminum sputtering targets continue to perform reliably in mature process nodes where ultra-low resistivity is not a primary requirement. They offer stable deposition behavior and acceptable electrical performance at a lower initial material cost.

Low-Current Metallization Layers

For applications involving minimal current flow, aluminum films provide sufficient conductivity and adhesion. These targets are commonly used where electrical load, heat generation, and electromigration risk remain low.

Display Panel and Flat Panel Electronics

Aluminum sputtered films are widely used in display technologies such as LCD and basic OLED backplanes. In these applications, conductivity demands are moderate, and aluminum offers a cost-effective metallization solution.

Protective and Reflective Thin-Film Coatings

When evaluating Copper vs Aluminum Sputtering, aluminum sputtering targets remain a practical choice for reflective and protective thin-film applications. In optical components and decorative coatings, surface coverage and reflectivity are prioritized over extremely high electrical conductivity. Therefore, in the broader discussion of Copper vs Aluminum Sputtering, aluminum continues to offer a cost-effective and reliable solution where visual performance and coating uniformity matter more than maximum current-carrying capability.

Standards and Quality Expectations

DOMADIA™ sputtering targets are manufactured to meet:

- ASTM B170 (Copper)

- ASTM B209 (Aluminum)

- SEMI purity expectations

- Controlled grain structures for stable erosion profiles

Quality consistency is what separates stable deposition from unpredictable yield loss.

Lifecycle Cost: Where the Real Difference Appears

At first glance, aluminum sputtering targets seem economical.

But over time, the hidden costs surface.

Aluminum targets typically require:

- More frequent replacement

- Higher scrap rates

- Increased chamber downtime

Copper targets, by contrast:

- Deliver longer service life

- Maintain consistent deposition rates

- Reduce unplanned process interruptions

In Copper vs Aluminum Sputtering, copper often wins on total cost of ownership, not purchase price.

Environmental Impact: Performance with Responsibility

Every target change means:

- Energy-intensive recycling

- Material waste

- Production downtime

Because copper sputtering targets last longer, they:

- Reduce recycling frequency

- Minimize scrap generation

- Lower environmental impact

For DOMADIA™, longer lifecycle materials are both a performance and sustainability choice.

Technical Specifications (Typical Range)

- Purity: Up to 5N (99.999%)

- Density: Copper ≈ 8.96 g/cm³ | Aluminum ≈ 2.7 g/cm³

- Grain structure: Customized for uniform erosion

- Bonding options: Indium or elastomer bonded backing plates

Shapes Available

DOMADIA™ supplies sputtering targets in:

- Circular disc targets

- Rectangular planar targets

- Custom OEM geometries

- Bonded and unbonded configurations

The Smart Takeaway

When conductivity, yield stability, and lifecycle cost matter,

Copper vs Aluminum Sputtering stops being a debate.

The most successful fabs don’t choose based on price alone.

They choose materials that keep production stable, predictable, and scalable.

Contact us to select the right sputtering target—Copper or Aluminum—engineered for performance, reliability, and long-term value by DOMADIA™.

Choosing the right sputtering target directly impacts yield, conductivity, and long-term process stability

Contact Us to evaluate copper vs aluminum sputtering targets or Get a Quote for application-specific solutions from DOMADIA™.

The right target material makes the difference between stable yield and hidden losses—Contact Us to choose the right sputtering target with DOMADIA™.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CopperVsAluminumSputtering #SputteringTargets #ThinFilmTech #SemiconductorManufacturing #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.