Blogs

Crucible Alloy Applications for Extreme Heat – UNS Certified | DOMADIA™

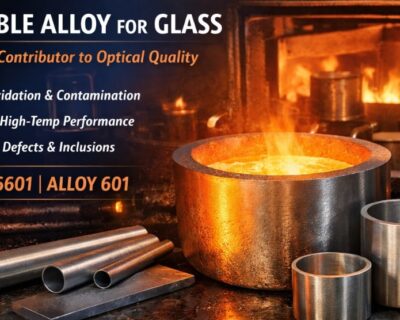

In high-temperature industries, failure is never just a technical issue—it’s a financial loss, a production delay, and sometimes a safety risk. Crucible Alloy Applications operate where molten metals reach extreme temperatures and aggressive chemical environments push materials to their limits, making reliability non-negotiable. In these unforgiving conditions, crucible alloys become the silent guardians of uptime and safety. At this intersection of extreme heat and zero tolerance for failure, DOMADIA™ Crucible Alloys stand proven through performance, consistency, and UNS-certified metallurgy.

This blog explores how Crucible Alloy Applications perform when conditions are severe, why correct material selection matters, and where DOMADIA™ delivers measurable, long-term value.

What Are Crucible Alloys? | Engineering Confidence Under Heat

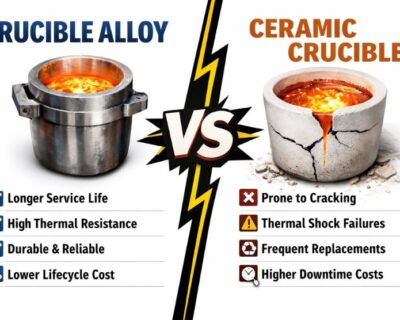

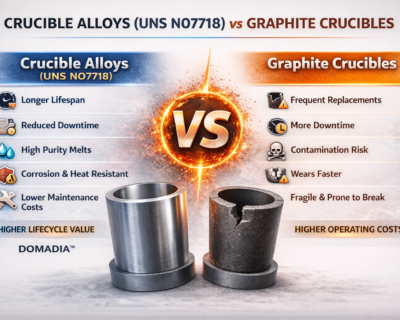

Crucible alloys are specially engineered metallic materials designed to withstand continuous exposure to extreme temperatures, molten metals, thermal shock, and chemical attack. Crucible Alloy Applications demand materials that go beyond conventional ceramics or graphite-only solutions, offering a unique balance of mechanical strength, thermal stability, and chemical resistance.

DOMADIA™ Crucible Alloys are developed for industries where downtime is unacceptable, metal purity is critical, and contamination carries a high operational cost.

Chemical Composition of DOMADIA™ Crucible Alloys

The performance of a crucible begins at the atomic level. DOMADIA™ Crucible Alloys are formulated using carefully balanced elements that ensure long-term stability.

Typical Alloying Elements Include:

- Nickel (Ni): Provides high-temperature strength and oxidation resistance

- Chromium (Cr): Enhances corrosion and scaling resistance

- Molybdenum (Mo): Improves creep resistance at elevated temperatures

- Iron (Fe): Adds structural integrity and thermal endurance

- Carbon & Minor Elements: Controlled additions for hardness and wear resistance

This optimized chemistry allows DOMADIA™ crucible alloys to maintain performance across repeated thermal cycles without cracking or deformation.

Key Properties That Enable Zero Failure

Crucible Alloy Applications Where Extreme Heat Meets Zero Failure depend on a precise set of material properties:

1. Exceptional Thermal Shock Resistance

Rapid heating and cooling cycles are common in foundries and induction melting. DOMADIA™ alloys resist micro-cracking that typically leads to sudden crucible failure.

2. High Melting Point & Structural Stability

Even under prolonged exposure to molten copper, aluminum, or specialty alloys, structural integrity remains intact.

3. Chemical Inertness

Minimal reaction with molten metals ensures:

- No contamination

- Consistent alloy purity

- Improved final product quality

4. Extended Service Life

Longer operational cycles reduce replacement frequency, downtime, and operational costs.

Crucible Alloy Applications Where Extreme Heat Meets Zero Failure

1. Non-Ferrous Metal Melting

In aluminum, copper, brass, and bronze melting operations, crucible performance directly impacts metal quality.

Why DOMADIA™ Works:

- Stable under induction and resistance heating

- No flaking or contamination

- Uniform heat distribution

This consistency improves casting yield and reduces rework.

2. Precious Metal Refining

Gold, silver, platinum, and palladium processing demand absolute purity.

Failure is not an option here.

DOMADIA™ Crucible Alloys provide:

- Chemical neutrality

- High resistance to aggressive fluxes

- Precise thermal control

Refiners trust these alloys to protect both material value and process accuracy.

3. High-Temperature Chemical Processing

Chemical reactors, pilot plants, and specialized furnaces expose crucibles to corrosive environments.

DOMADIA™ Advantage:

- Resistance to oxidation and chemical erosion

- Stable dimensions under prolonged heat

- Reliable performance in aggressive atmospheres

This reliability ensures process continuity and operator safety.

4. Laboratory & R&D Furnaces

In research environments, repeatability matters more than volume.

Crucible alloy applications in R&D require:

- Predictable performance

- Minimal material interaction

- Long service life under varied test conditions

DOMADIA™ Crucible Alloys support innovation without introducing variables.

5. Continuous Production Foundries

In high-output foundries, downtime equals lost revenue.

DOMADIA™ Crucibles deliver:

- Reduced replacement cycles

- Stable performance over continuous runs

- Lower total cost of ownership

Even if initial material costs are higher, lifecycle economics favor crucible alloys.

Technical Specifications (Typical Range)

- Operating Temperature: Up to 1600°C (depending on alloy grade)

- Thermal Conductivity: Optimized for uniform heat transfer

- Oxidation Resistance: Excellent at elevated temperatures

- Mechanical Strength: Maintained under cyclic loading

- Service Life: Significantly longer than ceramic alternatives

(Custom specifications available from DOMADIA™ based on application.)

Shapes Available from DOMADIA™

To suit diverse industrial requirements, DOMADIA™ Crucible Alloys are available in:

- Cylindrical crucibles

- Conical crucibles

- Rectangular & custom profiles

- Thick-wall designs for extended life

- Precision-machined laboratory crucibles

Custom dimensions and tolerances are available on request.

Why DOMADIA™ Crucible Alloys Are Worth the Investment

While ceramic crucibles may appear economical upfront, the hidden costs of failure—scrap loss, downtime, contamination, and safety risks—quickly outweigh initial savings. Crucible Alloy Applications are engineered to eliminate these risks by delivering consistent performance under extreme thermal and chemical stress.

DOMADIA™ Crucible Alloy Applications Where Extreme Heat Meets Zero Failure represent:

- Fewer replacements

- Less waste and recycling

- Lower environmental impact

- Predictable production outcomes

The longer service life of Crucible Alloy Applications also means less frequent scrapping, contributing to reduced environmental damage—a quiet but meaningful sustainability advantage aligned with responsible industrial engineering.

Final Takeaway

Crucible Alloy Applications Where Extreme Heat Meets Zero Failure are not about choosing the cheapest option—they are about choosing certainty.

When your process involves extreme temperatures, valuable materials, and zero margin for error, DOMADIA™ Crucible Alloys deliver performance that lasts.

Extreme heat is unavoidable. Failure is not.

Choose reliability. Choose lifecycle value. Choose DOMADIA™.

When extreme heat leaves no room for failure, your crucible material must deliver proven performance.

DOMADIA™Crucible Alloys are engineered for zero-failure applications under the most demanding thermal and chemical conditions.

Connectwith our experts today to specify the right UNS-certified crucible alloy for your process.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CrucibleAlloyApplications #HighTemperatureAlloys #FoundryTechnology #MetalProcessing #ZeroFailure #IndustrialMaterials #DOMADIA™

Directly whatsapp us for an Enquiry: https://wa.link/kairav

Our reach includes Surat, Vapi, Ankleshwar, Bharuch, and Silvassa across Gujarat, Maharashtra, Dadra & Nagar Haveli, Rajasthan, and MP, with exports to China, Taiwan, Hong Kong, Macau, and Mongolia.