Blogs

Crucible Alloy Composition & Performance: The Science Behind Extreme Heat Reliability

Crucible Alloy Composition: Where Performance Begins

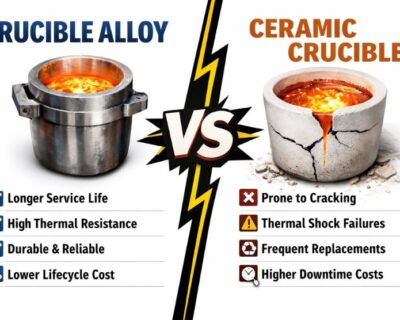

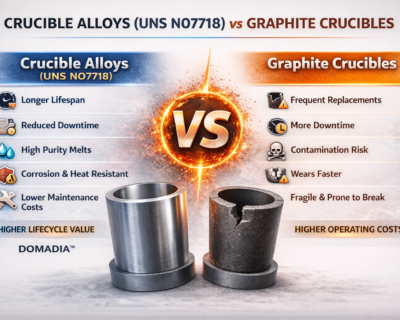

Crucible Alloy Composition is not a background specification—it is the deciding factor between stable melting operations and premature crucible failure.

In foundries, refineries, and advanced metallurgical furnaces, crucibles operate at temperatures where ordinary metals collapse, oxidize, or contaminate melts.

At DOMADIA™, crucible alloys are engineered with composition-first thinking—because in extreme heat environments, chemistry decides survival.

Why Composition Matters More Than Shape in Crucible Alloys

A crucible may look solid from the outside.

But inside, atomic interactions decide:

- Whether it resists oxidation

- Whether it reacts with molten metal

- Whether it cracks under thermal cycling

- Whether it lasts months—or fails in weeks

Crucible Alloy Composition directly controls thermal stability, corrosion resistance, mechanical strength, and chemical inertness.

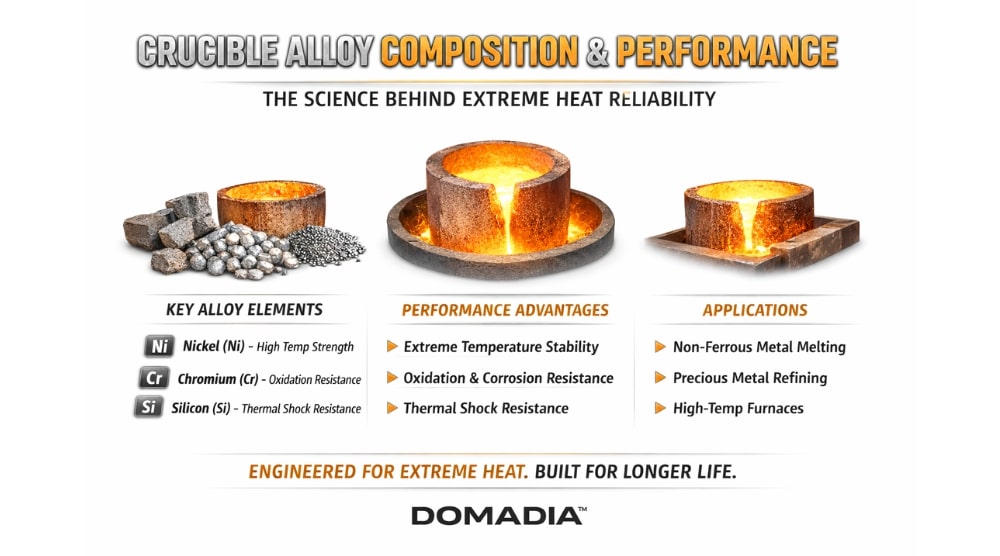

Chemical Composition of Crucible Alloys

Crucible alloys are not single-metal systems. They are carefully balanced multi-element alloys, designed to perform under continuous thermal stress.

Key Alloying Elements & Their Roles

Nickel (Ni)

- Forms the structural backbone of most crucible alloys

- Provides high-temperature strength and oxidation resistance

- Maintains ductility under prolonged heat exposure

Chromium (Cr)

- Creates a stable oxide layer for corrosion resistance

- Essential for resistance to slag, fluxes, and aggressive melts

Iron (Fe)

- Adds mechanical rigidity and cost efficiency

- Balanced carefully to avoid scaling and distortion

Aluminum (Al)

- Promotes alumina scale formation

- Enhances oxidation resistance at extreme temperatures

Silicon (Si)

- Improves thermal shock resistance

- Strengthens oxide layers under cyclic heating

Carbon (C)

- Increases creep resistance

- Must be tightly controlled to prevent embrittlement

At DOMADIA™, crucible alloy composition is optimized to maintain chemical neutrality with molten metals, ensuring clean melts and minimal contamination.

Performance Characteristics of Crucible Alloys

Crucible Alloy Composition directly translates into measurable performance advantages:

1. Extreme Temperature Stability

- Continuous service above 1100–1400°C

- No softening or deformation during long heat cycles

2. Oxidation & Scaling Resistance

- Stable oxide layers prevent material loss

- Consistent wall thickness over extended service life

3. Thermal Shock Resistance

- Withstands rapid heating and cooling

- Reduces cracking during charge changes

4. Mechanical Strength at Heat

- High creep resistance

- Maintains shape even under molten metal load

5. Chemical Inertness

- Minimal reaction with molten aluminum, copper, nickel, or precious metals

- Preserves alloy purity inside the crucible

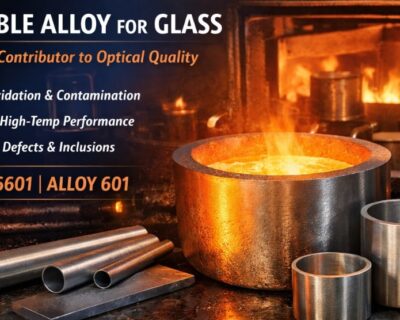

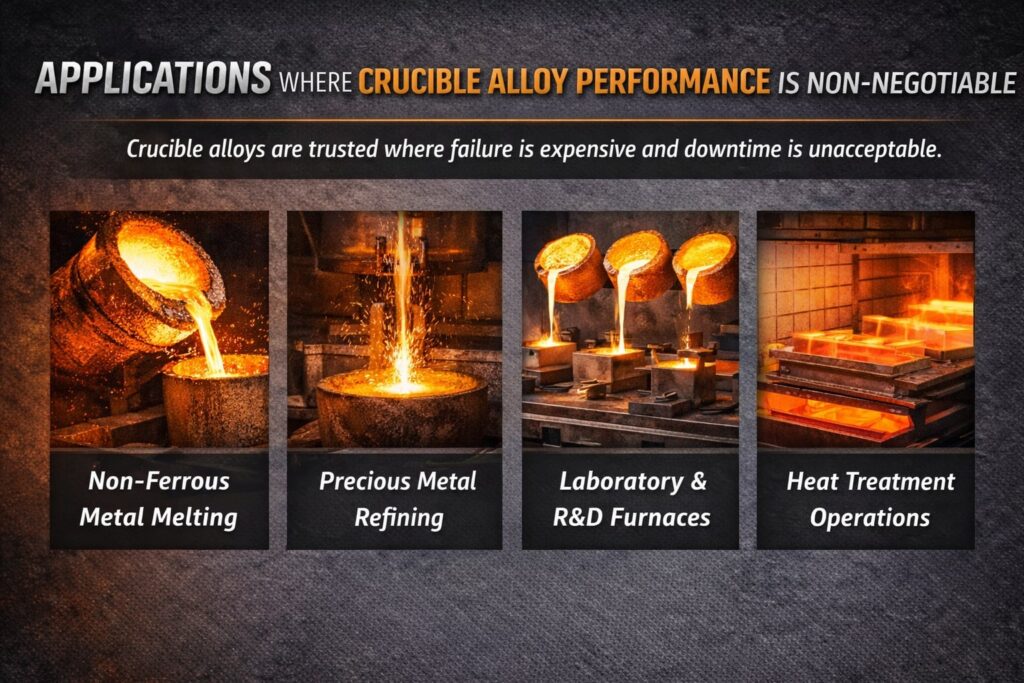

Applications Where Crucible Alloy Performance Is Non-Negotiable

Crucible alloys are trusted where failure is expensive and downtime is unacceptable.

Primary Applications

- Non-ferrous metal melting (Aluminum, Copper, Brass, Bronze)

- Precious metal refining

- Glass manufacturing

- Laboratory and R&D furnaces

- Heat treatment operations

- High-temperature chemical processing

In each application, Crucible Alloy Composition determines not just performance—but process reliability.

Industry Standards Followed

Crucible alloys supplied by DOMADIA™ align with globally accepted material and furnace standards:

- ASTM standards for high-temperature alloys

- DIN and EN material guidelines

- Foundry and furnace OEM specifications

- Custom compositions for proprietary furnace designs

Standards ensure repeatability—but composition optimization ensures superiority.

Technical Specifications (Typical Range)

| Property | Typical Value |

| Service Temperature | Up to 1400°C |

| Density | 7.5 – 8.4 g/cm³ |

| Thermal Expansion | Low & controlled |

| Oxidation Resistance | Excellent |

| Thermal Shock Resistance | High |

| Creep Strength | Superior at elevated temperatures |

Exact specifications vary based on crucible size, furnace type, and molten material, all of which DOMADIA™ supports with application-specific guidance.

Shapes & Forms Available

DOMADIA™ crucible alloys are available in:

- Cylindrical crucibles

- Conical crucibles

- Custom geometry crucibles

- Furnace liners and inserts

- Crucible shells and supports

Each shape is engineered with uniform alloy distribution to avoid weak thermal zones.

Crucible Alloy Composition & Sustainability

Every crucible replacement involves:

- Scrap generation

- Energy-intensive recycling

- Furnace downtime

Longer-lasting crucible alloys reduce material waste and energy consumption.

By optimizing Crucible Alloy Composition, DOMADIA™ actively reduces environmental impact—fewer failures, fewer replacements, lower carbon footprint.

Crucible Alloy Composition: The DOMADIA™ Advantage

Crucible Alloy Composition is not a datasheet number.

It is the difference between stable production and unexpected shutdowns.

At DOMADIA™, composition is engineered with:

- Metallurgical precision

- Application-driven design

- Long-term performance mindset

Because in extreme heat, performance is not optional—it is engineered.

Ready to Upgrade Your Crucible Performance?

Connect with DOMADIA™ today to select the right crucible alloy composition for your process.

Talk to our materials experts to select the right crucible alloy for your exact application.

Contact Us for Technical Support.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CrucibleAlloyComposition #HighTemperatureAlloys #Metallurgy #IndustrialFurnaces #DOMADIA #ExtremeHeatMaterials

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.