Blogs

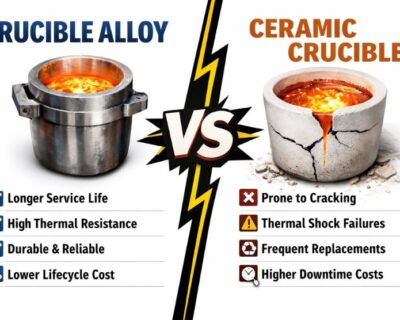

Crucible Alloy vs Ceramic Crucible (UNS N07718): Which Truly Survives Real Heat?

Crucible Alloy vs Ceramic Crucible — the debate starts where theory ends

Crucible Alloy vs Ceramic Crucible is not a lab discussion. It begins on the furnace floor—when temperatures spike, production schedules tighten, and failure costs real money.

A metallurgical plant running continuous induction melting shared a familiar story: ceramic crucibles worked “fine” on paper, but cracked unexpectedly during thermal cycling. The replacement was quick. The downtime was not. What followed was metal loss, production delays, and a rethink of material strategy.

This is where the Crucible Alloy vs Ceramic Crucible conversation becomes serious.

The mindset shift: heat resistance is not heat survival

Many buyers assume that if a material can withstand high temperatures, it will survive real heat. That assumption is costly.

Crucible Alloy vs Ceramic Crucible is not about maximum temperature rating alone—it’s about:

- Repeated thermal shock

- Mechanical stress under molten metal load

- Chemical attack from aggressive melts

- Predictable lifecycle performance

Ceramic crucibles are brittle by nature. Crucible alloys—especially nickel-based grades like UNS N07718—are engineered to deform slightly, absorb stress, and recover.

That difference defines survival.

Material fundamentals: Crucible Alloy vs Ceramic Crucible

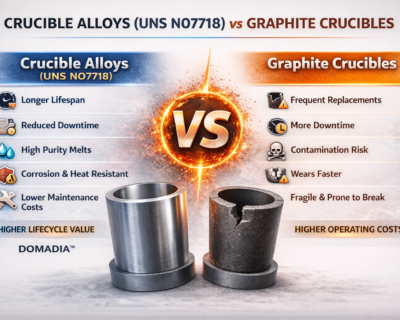

Crucible Alloys (UNS N07718)

Crucible alloys are metallic systems designed for extreme thermal and mechanical environments.

Key characteristics:

- Nickel-based composition with chromium, iron, and strengthening elements

- High creep resistance at elevated temperatures

- Excellent thermal shock tolerance

- Structural integrity under electromagnetic stirring

DOMADIA™ supplies crucible alloys with controlled metallurgy to ensure consistent grain structure and performance.

Ceramic Crucibles

Ceramic crucibles are typically alumina, zirconia, or silica-based.

Key characteristics:

- High melting point

- Chemical inertness to specific melts

- Low thermal conductivity

- Brittle fracture behavior

In the Crucible Alloy vs Ceramic Crucible comparison, ceramics resist heat—but struggle with shock.

Thermal shock reality: where ceramic crucibles fail first

Rapid heating and cooling cycles are routine in modern melting operations. This is where Crucible Alloy vs Ceramic Crucible shows a clear divergence.

Ceramic crucibles:

- Develop microcracks during fast temperature ramps

- Fail suddenly without warning

- Cannot redistribute stress

Crucible alloys:

- Absorb expansion stress elastically

- Maintain shape during repeated cycles

- Show predictable wear instead of sudden fracture

This predictability alone makes crucible alloys operationally safer.

Mechanical stress & molten metal dynamics

Induction melting doesn’t just heat metal—it moves it.

Electromagnetic forces create constant stirring, exerting pressure on crucible walls.

In Crucible Alloy vs Ceramic Crucible performance under load:

- Ceramic crucibles resist compression but fail under tensile stress

- Crucible alloys withstand both tensile and compressive forces

Metallic crucibles survive where brittle materials fracture.

Lifecycle cost: the hidden math buyers ignore

Ceramic crucibles are cheaper upfront. That’s where the advantage ends.

Crucible Alloy vs Ceramic Crucible lifecycle comparison tells a different story:

| Factor | Ceramic Crucible | Crucible Alloy |

| Initial cost | Lower | Higher |

| Service life | Short | Long |

| Failure mode | Sudden | Gradual |

| Downtime risk | High | Low |

| Metal loss | Frequent | Minimal |

Downtime, emergency replacement, lost batches, and labor costs quickly outweigh the initial savings of ceramics.

This is why high-temperature industries increasingly choose crucible alloys despite the higher purchase price.

Environmental impact: durability is sustainability

Here’s the overlooked truth:

The more often you scrap and recycle a material, the greater the environmental burden.

In the Crucible Alloy vs Ceramic Crucible debate:

- Ceramic crucibles require frequent disposal

- Recycling ceramics consumes energy with limited recovery value

- Replacements increase transport and remanufacturing emissions

Crucible alloys last significantly longer. Fewer replacements mean:

- Lower scrap frequency

- Reduced remelting energy

- Lower overall environmental impact

At DOMADIA™, this longevity is positioned as practical environmental responsibility, not marketing.

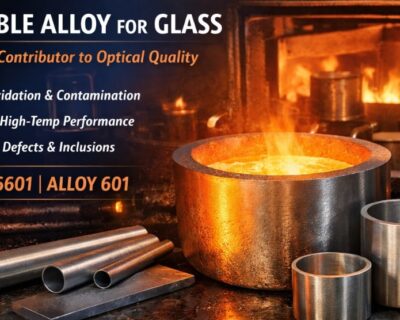

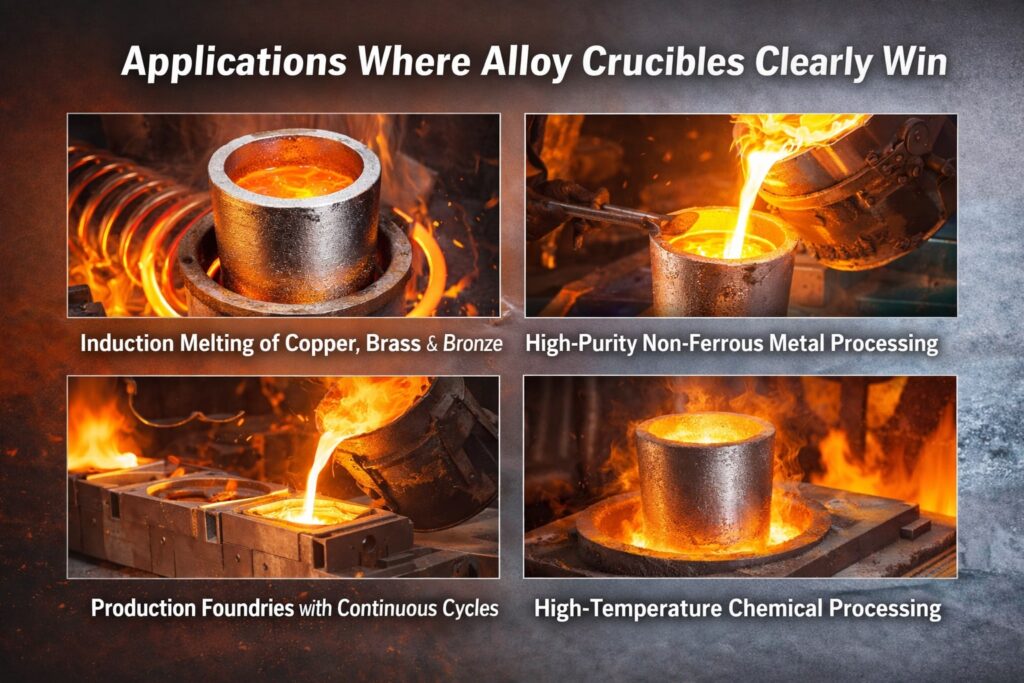

Applications where Crucible Alloy vs Ceramic Crucible matters most

Crucible alloy superiority becomes obvious in high-risk environments:

- Induction melting of copper, nickel, and superalloys

- Precious metal refining, where contamination and cracking are unacceptable

- Heat treatment furnaces with frequent start-stop cycles

- Aerospace alloy development, requiring precise thermal control

- Chemical processing, where reactive melts attack brittle ceramics

In these sectors, crucible failure is not an inconvenience—it’s a financial and safety risk.

Standards & quality control

Crucible alloys supplied by DOMADIA™ align with:

- UNS material specifications (including UNS N07718)

- Controlled chemistry and grain structure

- Traceable batches for industrial accountability

Ceramic crucibles vary widely in quality depending on manufacturing consistency—introducing variability into critical processes.

Shapes & technical availability

DOMADIA™ crucible alloys are available in:

- Cylindrical crucibles

- Custom profiles for induction systems

- Thick-wall designs for extended service life

Ceramic crucibles offer limited shape customization and are sensitive to dimensional stress.

Final verdict: which survives real heat?

Crucible Alloy vs Ceramic Crucible is no longer a theoretical comparison.

Ceramics resist heat.

Crucible alloys survive it.

For industries that value uptime, predictability, safety, and sustainability, crucible alloys—especially UNS N07718—are not a premium choice. They are a risk-control strategy.

DOMADIA™ supplies crucible alloys as long-term performance solutions, not consumables.

Ready to Stop Crucible Failures Before They Start?

If repeated cracking, downtime, and unpredictable crucible life are costing you more than you realize, it’s time to switch from heat resistance to heat survival. DOMADIA™ crucible alloys are engineered for longer life, safer operation, and lower total lifecycle cost in real industrial conditions.

Talk to DOMADIA™ experts today to evaluate the right crucible alloy for your melting, refining, or heat-treatment application.

Contact Us to reduce failures, downtime, and replacement cycles—permanently.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CrucibleAlloyVsCeramic #UNSN06600 #NickelAlloyCrucible #CeramicCrucible #HighTemperatureMaterials #FoundryTechnology #InductionMelting #MetalProcessing

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.