Blogs

Crucible Alloys 2025 Extreme Heat: Where Materials Are Truly Tested

Crucible Alloys 2025 Extreme Heat

At 1,200°C, most materials fail quietly.

They creep.

They oxidize.

They crack.

But inside furnaces, jet engines, induction heaters, and vacuum melting systems, failure is not an option. This is where Crucible Alloys 2025 Extreme Heat applications continue to prove their value—remaining indispensable despite advances in additive manufacturing and ceramic composites.

At DOMADIA™, Crucible Alloys 2025 Extreme Heat solutions are not treated as legacy materials. They are engineered systems—designed to survive repeated thermal shock, chemical attack, and mechanical stress in the world’s harshest operating environments.

Why Crucible Alloys Still Matter in 2025

The global high-temperature materials market continues to expand as industries demand more from their materials. Crucible Alloys 2025 Extreme Heat applications are growing rapidly as manufacturers push for:

- Higher operating temperatures

- Longer equipment life cycles

- Reduced downtime and replacement costs

- Lower environmental impact from frequent scrap and recycling

Crucible Alloys 2025 Extreme Heat performance remains central to critical industrial processes such as:

- Vacuum induction melting (VIM)

- Heat treatment furnaces

- Glass and crystal growth

- Superalloy and rare-metal processing

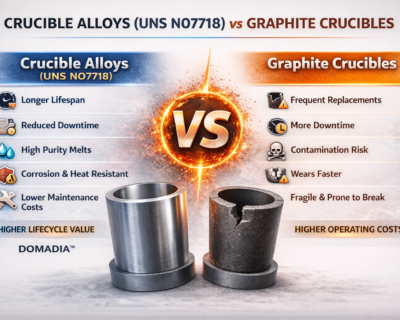

Even in 2025, nickel-based crucible alloys like UNS N07718 continue to set the benchmark for strength retention, oxidation resistance, and reliability above 700°C, where many alternative materials begin to fail.

What Are Crucible Alloys?

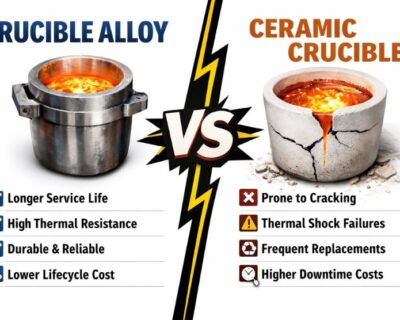

Crucible alloys are high-temperature, corrosion-resistant metallic alloys specifically designed for containment and processing of molten metals, salts, or reactive materials.

Unlike structural alloys, they must endure:

- Continuous thermal cycling

- Molten metal contact

- Oxidizing and reducing atmospheres

- Mechanical loads at elevated temperature

Chemical Composition of Crucible Alloys (Typical – UNS N07718)

| Element | Typical % |

| Nickel (Ni) | 50–55 |

| Chromium (Cr) | 17–21 |

| Iron (Fe) | Balance |

| Niobium (Nb) + Tantalum (Ta) | 4.75–5.5 |

| Molybdenum (Mo) | 2.8–3.3 |

| Titanium (Ti) | 0.65–1.15 |

| Aluminum (Al) | 0.2–0.8 |

Why this matters:

This chemistry allows precipitation hardening, oxidation resistance, and exceptional creep strength—critical for crucible longevity.

Key Properties of Crucible Alloys

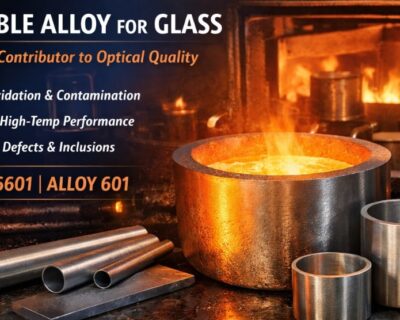

Crucible Alloys 2025 Extreme Heat performance is defined by:

- High melting point & thermal stability

- Outstanding creep resistance

- Resistance to carburization and oxidation

- Low thermal fatigue cracking

- Excellent hot strength retention

At DOMADIA™, every crucible alloy batch is verified for microstructural stability, not just room-temperature strength.

Technical Specifications (Typical – UNS N07718)

| Property | Value |

| Density | ~8.19 g/cm³ |

| Melting Range | 1260–1336°C |

| Tensile Strength (RT) | ~1,240 MPa |

| Yield Strength (RT) | ~1,035 MPa |

| Operating Temp Range | Up to 980°C (continuous) |

| Oxidation Resistance | Excellent |

Applications of Crucible Alloys in 2025

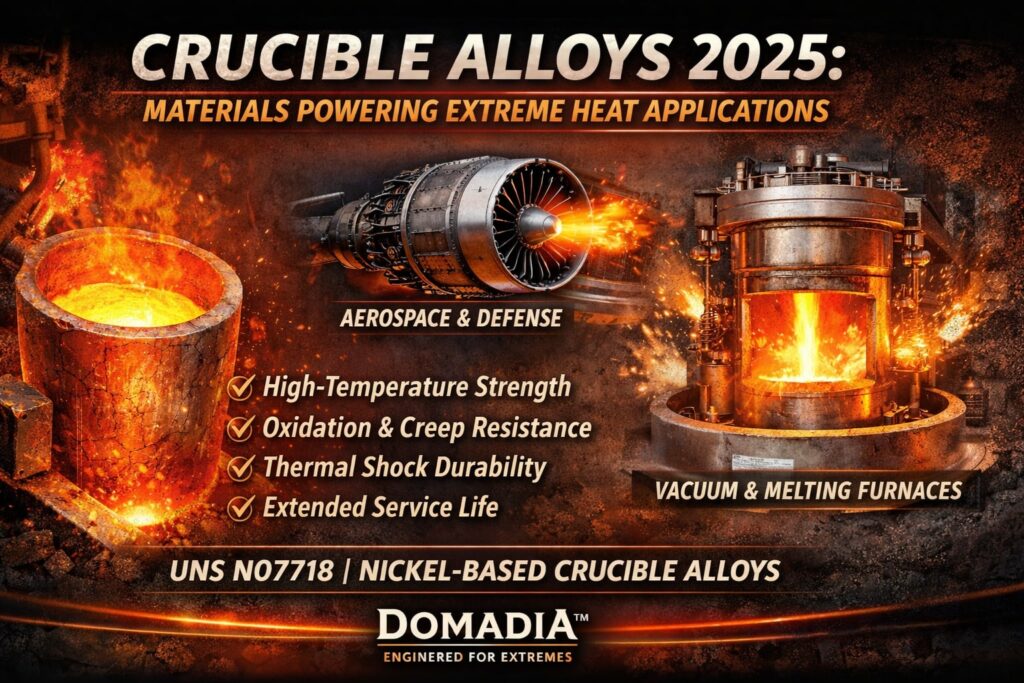

1. Vacuum & Induction Furnaces

- Superalloy melting

- Titanium and reactive metal processing

- Long service life under cyclic heat loads

2. Aerospace & Defense

- Alloy melting for turbine components

- High-purity processing environments

3. Glass, Crystal & Semiconductor Processing

- Sapphire growth

- Specialty glass melts

- Minimal contamination risk

4. Energy & Nuclear

- Molten salt handling

- Experimental high-temperature reactors

Shapes Available from DOMADIA™

DOMADIA™ supplies crucible alloys in precision-engineered forms, including:

- Solid crucibles

- Fabricated crucible assemblies

- Plates & sheets

- Rings & cylinders

- Custom machined shapes

- Bars and billets

Every shape is optimized for thermal stress distribution, not just geometry.

Standards & Compliance

Crucible alloys supplied by DOMADIA™ conform to:

- ASTM B637

- AMS 5662 / 5664

- UNS N07718

- ISO & customer-specific furnace standards

Full traceability, heat numbers, and test reports are provided.

Environmental Impact: The Hidden Advantage

Here’s the part most buyers overlook.

Every crucible replacement means:

- Energy-intensive recycling

- Transport emissions

- Production downtime

High-performance crucible alloys last longer, meaning:

- Fewer replacements

- Less scrap

- Lower environmental footprint

At DOMADIA™, material longevity is part of our sustainability contribution, not just a performance metric.

Why DOMADIA™ Crucible Alloys

- Metallurgy-first selection approach

- Extreme-heat application expertise

- Consistent quality across batches

- Long-term cost and lifecycle optimization

Crucible Alloys 2025 Extreme Heat solutions are not about lowest upfront cost—they are about surviving where failure is expensive.

Conclusion

Crucible Alloys 2025 Extreme Heat applications prove one thing clearly:

When temperatures rise, shortcuts disappear.

In an era of advanced manufacturing, crucible alloys—especially UNS N07718-grade systems—remain the quiet backbone of high-temperature industry.

At DOMADIA™, we don’t just supply crucible alloys.

We engineer confidence at extreme temperatures.

When extreme heat leaves no margin for failure, material choice matters.

Choose crucible alloys engineered for longevity and reliability.

👉 Connect with DOMADIA™ for high-temperature solutions that last.

Contact DOMADIA™ for crucible alloys engineered for extreme heat performance.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CrucibleAlloys #ExtremeHeatMaterials #UNSN07718 #NickelAlloys #HighTemperatureEngineering #DOMADIA #Metallurgy2025

Directly whatsapp us for an Enquiry: https://wa.link/kairav

Tags: Crucible alloysDOMADIA™