Blogs

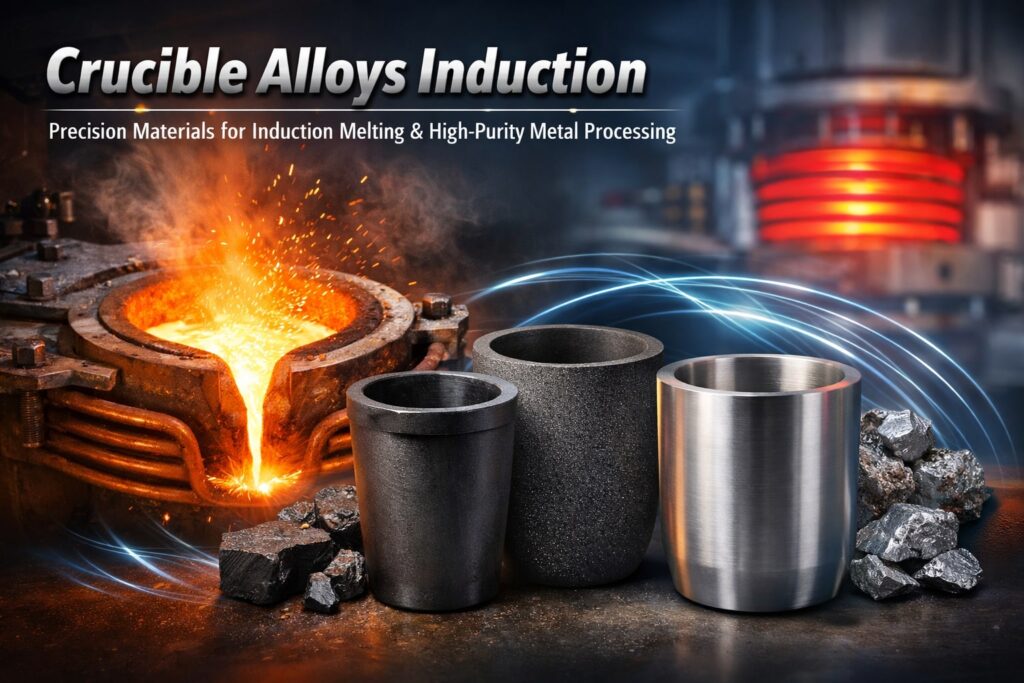

Crucible Alloys Induction: The Role of Crucible Alloys in Induction Melting & High-Purity Metal Processing

In modern metallurgy, precision is no longer a luxury—it is a requirement. As industries demand cleaner metals, tighter tolerances, and repeatable performance, Crucible Alloys Induction has emerged as a defining factor in achieving reliable induction melting outcomes. While induction melting is one of the most efficient and controllable melting technologies available today, there is a critical component that quietly determines the success or failure of this process: crucible alloys.

Crucible alloys are not just containers for molten metal. Within Crucible Alloys Induction systems, they are active participants in heat transfer, purity control, operational efficiency, and overall metallurgical quality. In induction melting and high-purity metal processing, their role becomes even more decisive—shaping consistency, performance, and lifecycle reliability with every melt.

Why Induction Melting Demands Advanced Crucible Alloys

Induction melting relies on electromagnetic fields to heat metal rapidly and uniformly. Unlike fuel-fired furnaces, there is no direct flame contact, which already reduces contamination risk. However, in Crucible Alloys Induction systems, this advantage can be completely lost if the crucible material reacts with the melt, introduces impurities, or fails under thermal stress.

Crucible alloys used in induction systems must withstand:

- Extremely high temperatures

- Rapid heating and cooling cycles

- Electromagnetic forces

- Chemically aggressive molten metals

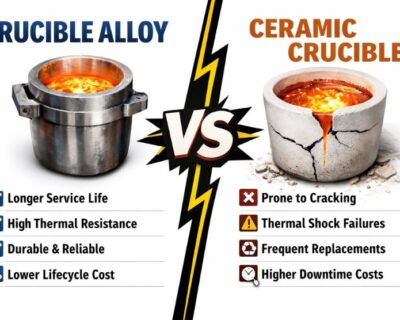

This is why conventional refractory materials often fall short, and engineered crucible alloys become essential for maintaining stability, purity, and process reliability in induction melting environments.

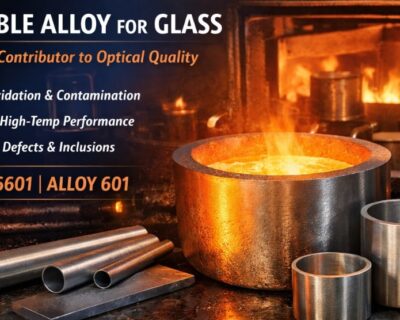

Purity Control: The First Quality Gate

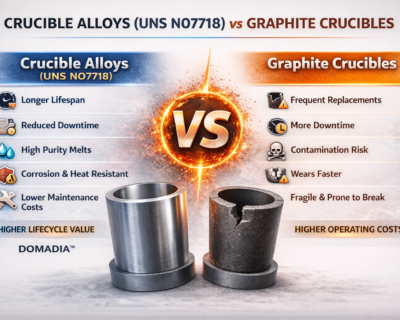

In high-purity metal processing, the crucible is the first quality checkpoint. Within Crucible Alloys Induction systems, any interaction between the crucible wall and molten metal can lead to contamination—often invisible but costly.

Advanced crucible alloys used in Crucible Alloys Induction melting environments are engineered to be:

- Chemically inert to molten aluminum, copper, nickel, precious metals, and specialty alloys

- Low in impurity content, preventing unwanted element pickup

- Structurally dense, minimizing porosity where chemical reactions can occur

For industries such as electronics, aerospace, medical devices, and precision casting, even trace contamination can compromise conductivity, mechanical properties, or corrosion resistance. High-performance crucible alloys ensure that the metal composition leaving the furnace is exactly what was intended.

Crucible Alloys Induction Thermal Performance in High-Energy Melting Systems

Induction melting subjects crucibles to some of the most demanding operating conditions in modern metallurgy. In Crucible Alloys Induction environments, heat is generated rapidly within the metal itself, creating steep thermal gradients, while electromagnetic stirring applies continuous mechanical stress to the crucible walls.

To perform reliably under these extremes, crucible materials in Crucible Alloys Induction systems must deliver a rare balance of properties:

- Exceptional thermal shock resistance to withstand repeated heating and cooling cycles

- Precisely controlled thermal conductivity to enable fast, uniform energy transfer

- High mechanical strength at elevated temperatures to resist cracking, erosion, and deformation

Advanced Crucible Alloys Induction designs—often incorporating graphite, silicon carbide, or engineered composite structures—excel where conventional materials fail. They support faster melting cycles, lower energy consumption, and stable process control, making them indispensable in high-volume production lines and precision-driven metallurgical operations where consistency is non-negotiable.

Extended Service Life = Process Stability

In induction melting, an unexpected crucible failure does far more than halt production. Within Crucible Alloys Induction operations, it can lead to equipment damage, molten metal loss, and serious safety hazards—all of which carry high operational and financial risks.

High-quality crucible alloys engineered for Crucible Alloys Induction environments are designed to deliver:

- Predictable wear patterns that support planned maintenance

- Strong resistance to erosion caused by continuous electromagnetic stirring

- Reduced oxidation and structural fatigue under extreme thermal cycling

This performance stability is a defining advantage of advanced Crucible Alloys Induction systems. It allows operators to maintain consistent melt conditions, schedule maintenance with confidence, and eliminate costly emergency shutdowns that disrupt productivity and compromise safety.

Enabling High-Purity Specialty Metals

High-purity metal processing is not limited to base metals. It includes:

- Copper and copper alloys for electrical applications

- Aluminum alloys for aerospace and automotive

- Nickel-based and cobalt-based alloys for extreme environments

- Precious metals for electronics and refining

Each of these materials interacts differently with crucible surfaces. Advanced crucible alloys can be tailored to specific metals, ensuring minimal reaction and maximum yield. This customization is particularly important in R&D labs, pilot plants, and specialty alloy production where flexibility and precision are key.

Energy Efficiency and Cost Optimization

While crucible alloys may appear as a consumable cost, their influence on total operational cost is significant.

Efficient crucible alloys contribute to:

- Faster melting cycles

- Lower energy consumption

- Reduced metal loss from contamination or oxidation

- Fewer crucible replacements

In induction melting, where energy efficiency is a major advantage, the right crucible alloy amplifies these benefits rather than limiting them.

Environmental and Sustainability Considerations

Modern metallurgy is increasingly focused on sustainability. Frequent crucible failure leads to higher material waste, increased recycling loads, and additional energy consumption.

Long-life crucible alloys reduce:

- Scrap generation

- Reprocessing frequency

- Environmental impact associated with recycling

By lasting longer and performing more consistently, advanced crucible alloys indirectly support cleaner, more sustainable metal production.

The DOMADIA™ Approach to Crucible Alloy Performance

At DOMADIA™, crucible alloys are approached as engineered solutions—not off-the-shelf consumables. Every alloy is selected or designed with a clear understanding of:

- Induction furnace dynamics

- Metal chemistry and purity requirements

- Thermal and mechanical stress profiles

- Lifecycle cost implications

This application-driven mindset ensures that crucible alloys do not limit performance but actively enhance it.

Conclusion: The Silent Enabler of Precision Metallurgy

In induction melting and high-purity metal processing, success is defined by control—control over chemistry, temperature, energy, and outcomes. Crucible alloys play a silent yet decisive role in delivering that control.

From purity preservation and thermal efficiency to service life stability and sustainability, the right crucible alloy transforms induction melting from a heating method into a precision metallurgical process.

As metal processing continues to evolve toward higher performance and tighter specifications, crucible alloys will remain at the core—quietly shaping quality, efficiency, and reliability with every melt.

Take Control of Purity in Induction Melting

For induction melting and high-purity metal processing, crucible alloy selection directly impacts metal quality, furnace efficiency, and lifecycle cost.

DOMADIA™ – Explore our crucible alloy expertise and material solutions built for precision induction melting.

Contact Us – Speak with our technical team to select the right crucible alloy for your metal, furnace, and operating conditions.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CrucibleAlloys #InductionMelting #HighPurityMetals #MetalProcessing #FoundryTechnology #SpecialtyAlloys #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

Our reach includes Surat, Vapi, Ankleshwar, Bharuch, and Silvassa across Gujarat, Maharashtra, Dadra & Nagar Haveli, Rajasthan, and MP, with exports to China, Taiwan, Hong Kong, Macau, and Mongolia.