Blogs

Crucible Alloys Lifecycle Cost vs Graphite Crucibles: Lifecycle Cost Tells a Different Story

Crucible Alloys Lifecycle Cost is rarely discussed during procurement meetings—but it dominates the real financial outcome on the shop floor.

The scenario is familiar. A melt schedule is tight. Operators are ready. The furnace is at temperature. Then a crucible shows premature wear. The decision is made to “push one more cycle.” Minutes later, the operation stops, quality is questioned, and a full reset becomes unavoidable.

That’s when purchasing savings disappear.

This is where Crucible Alloys Lifecycle Cost becomes more important than crucible purchase price—and where the comparison between UNS N07718 Crucible Alloys and Graphite Crucibles changes completely.

The Mindset Shift: From Purchase Price to Crucible Alloys Lifecycle Cost

Graphite crucibles are widely used and respected. They offer good thermal shock resistance, reliable performance for non-ferrous melting, and an attractive upfront cost.

But Crucible Alloys Lifecycle Cost asks a different question:

- How long does the crucible last?

- How predictable is its performance?

- What happens to production when it fails?

When these questions are answered honestly, lifecycle economics—not unit price—start driving smarter decisions.

Material Overview: What Are You Really Comparing?

Graphite Crucibles

Graphite crucibles are commonly used for:

- Aluminum, copper, brass, and bronze melting

- Precious metal refining

- Foundry and laboratory furnaces

They are valued for thermal conductivity and resistance to thermal shock, but they are typically treated as consumables with defined service limits.

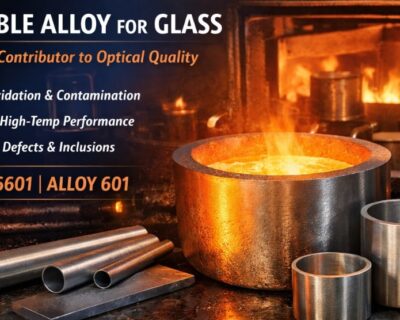

Crucible Alloys – UNS N07718

UNS N07718 is a precipitation-hardened nickel-chromium alloy designed for strength, corrosion resistance, and dimensional stability under repeated thermal cycling.

In crucible applications, UNS N07718 is selected when Crucible Alloys Lifecycle Cost must be controlled through durability, consistency, and reduced intervention.

Chemical Composition: Why UNS N07718 Lasts Longer

The chemical design of UNS N07718 explains its lifecycle advantage:

- High nickel content ensures strength retention

- Chromium improves oxidation and corrosion resistance

- Niobium, titanium, and aluminum enable precipitation hardening

- Controlled carbon limits embrittlement

This composition allows the alloy to maintain mechanical integrity over repeated heating and cooling cycles—directly lowering Crucible Alloys Lifecycle Cost by extending usable service life.

Standards That Support Long-Term Reliability

UNS N07718 crucible alloys are manufactured in compliance with globally recognized alloy standards used across aerospace, energy, and high-temperature industries.

These standards ensure:

- Consistent chemistry

- Predictable mechanical properties

- Repeatable performance batch after batch

Graphite crucibles, while available in many grades and shapes, rely more heavily on manufacturer-specific formulations and operating discipline.

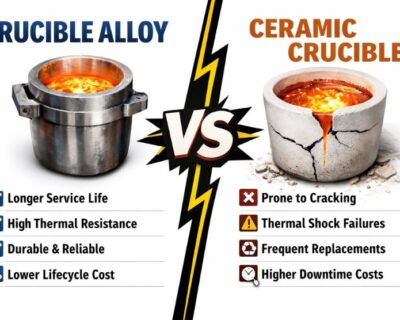

Properties That Define Crucible Alloys Lifecycle Cost

UNS N07718 Crucible Alloy Properties

- High strength retention under thermal cycling

- Excellent resistance to oxidation and corrosion

- Dimensional stability under mechanical load

- Reduced deformation during extended service

These properties reduce unexpected failures—one of the largest hidden drivers of Crucible Alloys Lifecycle Cost.

Graphite Crucible Properties

- High thermal conductivity

- Strong thermal shock resistance

- Good chemical compatibility with many molten metals

However, graphite gradually oxidizes and wears, making replacement frequency a predictable—but recurring—expense.

Lifecycle Cost Comparison: Where the Numbers Shift

1. Replacement Frequency

Graphite crucibles typically require regular replacement. UNS N07718 crucible alloys are selected specifically to extend service intervals.

Fewer replacements directly lower Crucible Alloys Lifecycle Cost.

2. Downtime Impact

Every crucible change involves:

- Furnace cooling

- Removal and installation

- Reheating and stabilization

Downtime often costs far more than the crucible itself. Longer-lasting alloy solutions reduce this loss.

3. Scrap and Quality Risk

Each crucible change introduces variability. In high-value melts, even minor contamination or instability increases scrap risk—another hidden contributor to Crucible Alloys Lifecycle Cost.

4. Maintenance and Handling

Graphite crucibles are more susceptible to handling damage. Alloy crucibles offer greater robustness in busy industrial environments.

Environmental Impact: Lifecycle Cost Meets Sustainability

Every replacement cycle consumes energy, generates emissions, and adds to recycling volume.

Because UNS N07718 crucible alloys operate for longer periods:

- Fewer crucibles are scrapped

- Recycling frequency is reduced

- Environmental impact per ton of metal processed decreases

At DOMADIA™, extending service life is not only an economic decision—it’s part of responsible material stewardship.

Applications Where Crucible Alloys Lifecycle Cost Clearly Wins

1. High-Value Non-Ferrous Metal Melting

In melting operations involving copper alloys, nickel alloys, or precious non-ferrous metals, crucible failure leads to metal loss, contamination, and safety risks. Crucible alloys made from UNS N07718 offer superior thermal fatigue resistance, ensuring longer service life and consistent melt quality.

2. Continuous Foundry Operations

In 24/7 foundries, every unplanned shutdown multiplies costs across labor, energy, and production schedules. The extended durability of crucible alloys minimizes replacement frequency, making lifecycle cost significantly lower despite higher upfront pricing.

3. Precision Alloy Development & R&D Melting

When developing new alloys, repeatability and chemical stability are critical. UNS N07718-based crucible alloys resist oxidation and chemical interaction with molten metals, protecting composition accuracy and reducing costly rework or rejected trials.

4. Aerospace & Defense Material Processing

Aerospace-grade alloys demand zero compromise on purity and consistency. Crucible alloys outperform graphite in high-temperature stability and crack resistance, reducing the risk of batch failure in mission-critical material production.

5. Processes Where Downtime Is Unacceptable

In operations where furnace downtime halts entire production lines—such as specialty alloy casting or investment casting—crucible alloy reliability translates directly into cost savings by avoiding emergency replacements and lost throughput.

6. Operations with Strict Quality & Repeatability Requirements

Industries with tight quality audits benefit from crucible alloys’ predictable wear behavior and long-term stability. Fewer crucible changes mean stable process parameters, improved repeatability, and lower scrap generation over time.

Shapes Available Through DOMADIA™

DOMADIA™ supports UNS N07718 in multiple forms used for crucible fabrication and high-temperature assemblies, including:

- Plates and sheets

- Bars and billets

- Rings and custom-machined components

Correct geometry plays a direct role in wear distribution and service life—another factor influencing Crucible Alloys Lifecycle Cost.

Conclusion: Lifecycle Cost Is the Only Honest Metric

Crucible Alloys Lifecycle Cost reveals what purchasing spreadsheets often hide: downtime, instability, scrap risk, and operational stress.

Graphite crucibles remain a reliable choice for many melting applications. But when performance must be consistent, uptime must be protected, and replacements must be minimized, UNS N07718 Crucible Alloys deliver value that extends far beyond initial cost.

DOMADIA™ helps engineers and procurement teams move from short-term savings to long-term performance.

Stop crucible failures before they disrupt production.

Connect with DOMADIA™ to choose the right crucible material—UNS N07718 alloy or graphite—based on lifecycle cost, uptime, and thermal reliability.

Contact Us to choose the right crucible material—UNS N07718 alloy or graphite—based on lifecycle cost, uptime, and thermal reliability.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CrucibleAlloysLifecycleCost #UNSN07718 #CrucibleAlloys #GraphiteCrucible #FoundryIndustry #MetalProcessing #HighTemperatureAlloys #DOMADIA™

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.