Blogs

Global Rare Earth Supply Chain in 2025: Why Neodymium & Dysprosium Are More Important Than Ever

Introduction

The year 2025 marks a turning point for the Global Rare Earth Supply Chain in 2025. Industries that once took the reliability of rare earth elements for granted are now re-evaluating their sourcing strategies. Why? Because two elements—Neodymium (Nd) and Dysprosium (Dy)—have quietly become the backbone of next-gen technology.

From EV motors to AI-driven robotics, from wind turbines to military systems, the entire world is racing to secure stable access to these critical metals. Their demand is rising faster than current mining, refining, and geopolitical systems can adapt—making them more important than ever.

Let’s break down what’s happening, why these elements matter, and how companies like DOMADIA™ are helping industries stay ahead.

The Rare Earth Bottleneck: What’s Really Happening in 2025?

The global rare earth market is going through a massive shift, driven by:

🔥 Exploding EV Adoption

Electric vehicle production is consuming unprecedented volumes of NdFeB magnets, which require high-purity neodymium and dysprosium.

🌬 Renewable Energy Demand

Direct-drive wind turbines use up to 600 kg of NdFeB magnets per megawatt.

⚠ Geopolitical Tensions

Recent efforts by the U.S., EU, Japan, and India to reduce dependency on China are reshaping the supply network. China still controls:

- 60–70% of mining

- 85–90% of refining capacity

📈 Market Growth Insights

According to IDTechEx and Precedence Research:

- Demand for high-performance magnets is projected to grow 7–10% annually.

- Technologies like grain boundary diffusion are reducing heavy rare earth usage by up to 70%, lowering overall costs.

But even with innovation, demand is rising faster than global production.

Why Neodymium Matters More Than Ever

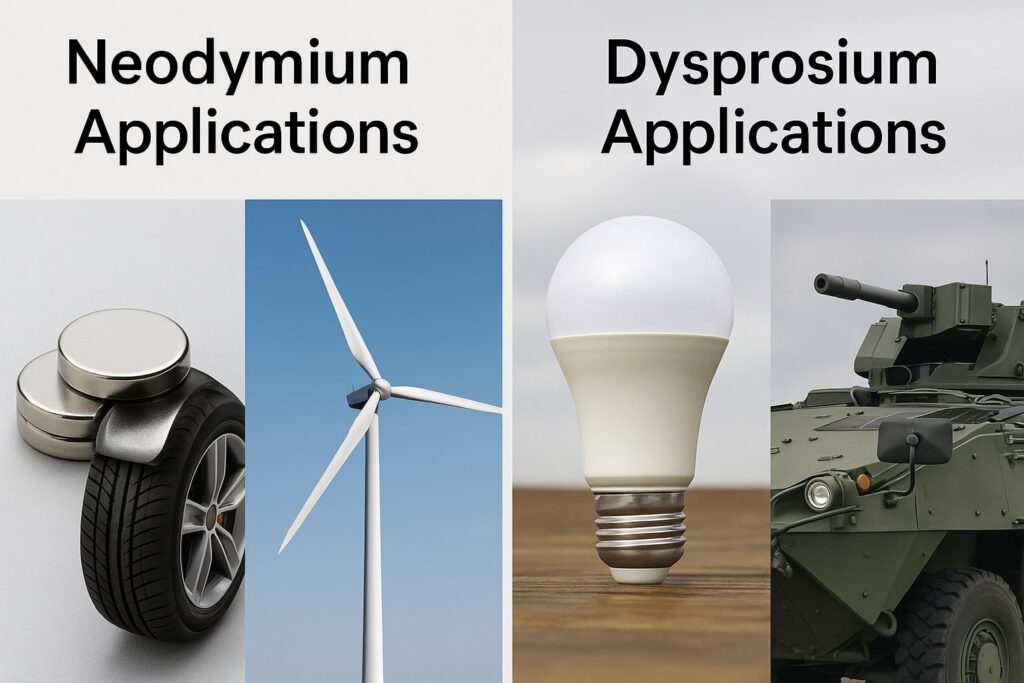

What is Neodymium used for?

Neodymium is essential for making NdFeB permanent magnets, the strongest commercial magnets available.

Key Applications

- EV traction motors

- Wind turbine generators

- Smartphones & laptops

- Drones

- Robotics & automation

- Hard disk drives

- MRI systems

Why It’s Critical in 2025

- Helps reduce motor size by 40%

- Increases energy efficiency by 20–30%

- Enables compact, lightweight next-gen devices

Without neodymium, the global EV and renewable energy industries would slow dramatically.

Why Dysprosium Is Even More Strategic

While neodymium provides strength, dysprosium gives high-temperature stability.

Where It’s Used

- High-heat EV motors

- Aerospace magnetics

- Military-grade systems

- Deep-sea and space applications

Why It’s Irreplaceable

Dysprosium prevents demagnetization at high temperatures. EV motors that run at 150–200°C rely on Dy for durability and safety.

The Supply Problem

Dysprosium comes mainly from ion-absorbed clays, found almost entirely in China and Myanmar. Limited sources mean:

- High price volatility

- Supply insecurity

- Strategic stockpiling by multiple nations

The 2025 Supply Chain Reality: What Industries Must Prepare For

1️⃣ A Shift from Mining to Recycling

Recycling rates for rare earths are still below 5%, but rising demand is making reclamation essential.

2️⃣ Manufacturing Localization

Countries are building refining plants to reduce dependency on China, including:

- U.S. (Texas, California)

- Australia

- India

- Canada

3️⃣ Rising Competition Between EV & Wind Sectors

Wind turbines may compete directly with EV makers for the same magnet raw materials.

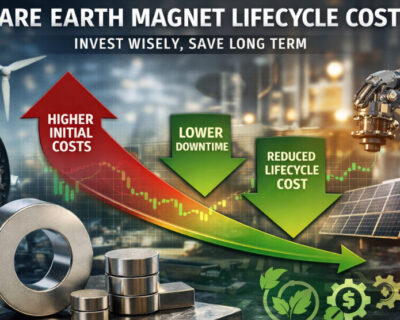

4️⃣ Premium Pricing is Becoming Normal

High-purity Nd and Dy products are expected to command a 15–25% premium due to scarcity and processing complexity.

How DOMADIA™ Supports Global Magnet & Alloy Supply Chains

As demand rises, manufacturers need:

- High-purity rare earth metals

- Reliable sourcing beyond single countries

- Custom magnet-grade material options

- Stable long-term supply contracts

DOMADIA™ provides:

- Sourcing from multi-country pipelines

- Industrial-grade Neodymium & Dysprosium metals/oxides

- Custom specifications for magnet manufacturing

- Logistics support for high-volume industrial applications

This ensures uninterrupted production for EV, aerospace, robotics, and defense industries.

What the Future Looks Like (2025–2035)

🌍 Demand Will Double by 2030

Driven by EVs and wind power, demand for Nd and Dy could reach 2x current levels.

🔬 New Tech Will Change the Game

Grain boundary diffusion and low-Dy motors will reduce reliance, but not eliminate it.

♻ Recycling Will Become a Core Supply Chain Pillar

Expect large-scale magnet recycling plants globally.

🔄 Countries Will Fight for Supply Security

Expect more government funding, incentives, and strategic stockpiles.

Conclusion: The Global Rare Earth Supply Chain in 2025 Has One Clear Message

The Global Rare Earth Supply Chain in 2025 is entering a new era—one driven by surging demand, complex geopolitics, and breakthrough technologies. Neodymium and Dysprosium are no longer niche metals… they are now strategic resources powering the world’s biggest technological transformations.

And with partners like DOMADIA™, industries gain access to consistent supply, reliable quality, and future-ready materials that keep their innovations moving forward.

Secure High-Purity Rare Earth Materials with DOMADIA™

DOMADIA™ ensures purity, consistency, and long-term availability.

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#GlobalRareEarthSupplyChain #RareEarth #Neodymium #Dysprosium #CriticalMinerals #EVMaterials #MagnetTechnology #DOMADIA #SupplyChain2025 #AdvancedMaterials

Directly whatsapp us for an Enquiry: https://wa.link/kairav