Blogs

Hastelloy C22 vs Hastelloy C276 : Choosing the Best Alloy for Corrosive Environments

A Suspenseful Start…

A major chemical plant contacted DOMADIA™ with an urgent problem: every alloy they had tested for their new chloride-heavy line failed—some within weeks, some within months.

Only two alloys remained in contention: Hastelloy C22 and Hastelloy C276.

The stakes?

A wrong choice could mean corrosion, shutdown, contamination… and millions lost.

This is where the real comparison begins.

Introduction

When industries operate in aggressive chemical environments, the comparison Hastelloy C22 vs Hastelloy C276 becomes mission-critical. Both alloys belong to the elite family of nickel-chromium-molybdenum superalloys—renowned for resistance to pitting, crevice corrosion, and stress corrosion cracking.

But performance differences matter.

Choosing the right alloy ensures longevity, reduces downtime, and safeguards your operations.

DOMADIA™ helps industries make this decision daily.

Chemical Composition Comparison

| Element | Hastelloy C22 (UNS N06022) | Hastelloy C276 (UNS N10276) |

| Nickel (Ni) | Balance | Balance |

| Chromium (Cr) | 20–22.5% | 14.5–16.5% |

| Molybdenum (Mo) | 12.5–14.5% | 15–17% |

| Tungsten (W) | Up to 3.5% | 3–4.5% |

| Iron (Fe) | 2–6% | 4–7% |

| Cobalt (Co) | Up to 2.5% | Up to 2.5% |

What This Means

- C22 has higher chromium → better resistance to oxidizing and mixed acid environments.

- C276 has higher molybdenum & tungsten → superior resistance to reducing environments.

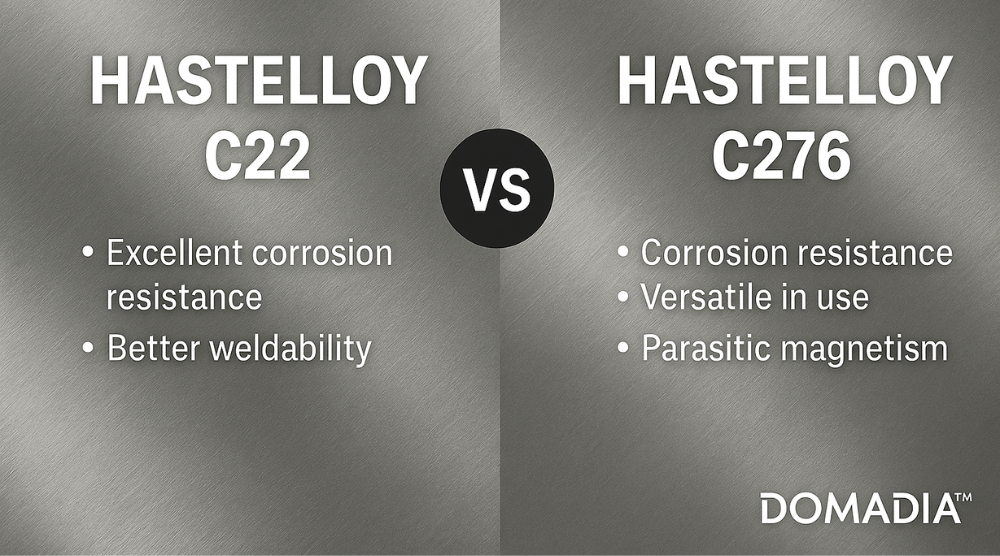

Corrosion Resistance: The Real Difference

Hastelloy C22

- Exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking

- Excellent for wet chlorine, oxidizing acids, and mixed chemical streams

- Better performance than C276 in environments containing:

✔ Ferric ions

✔ Cupric ions

✔ Chlorine dioxide

Hastelloy C276

- Performs remarkably in strong reducing conditions

- Resistant to chlorine-containing and sulfur-rich media

- A trusted choice in high-temperature corrosive streams

Verdict:

C22 wins in oxidizing environments.

C276 wins in reducing environments.

Mechanical Properties & Standards

| Property | C22 | C276 |

| Tensile Strength | ~690 MPa | ~690 MPa |

| Yield Strength | ~310 MPa | ~283 MPa |

| Elongation | 45% | 40–45% |

| Hardness | Similar | Similar |

Standards

Both alloys comply with:

- ASTM B575 (Plate, Sheet, Strip)

- ASTM B622 (Seamless Pipe)

- ASTM B574 (Bar)

- ASTM B619/B626 (Welded Pipe/Tubes)

DOMADIA™ supplies all forms with mill test certificates.

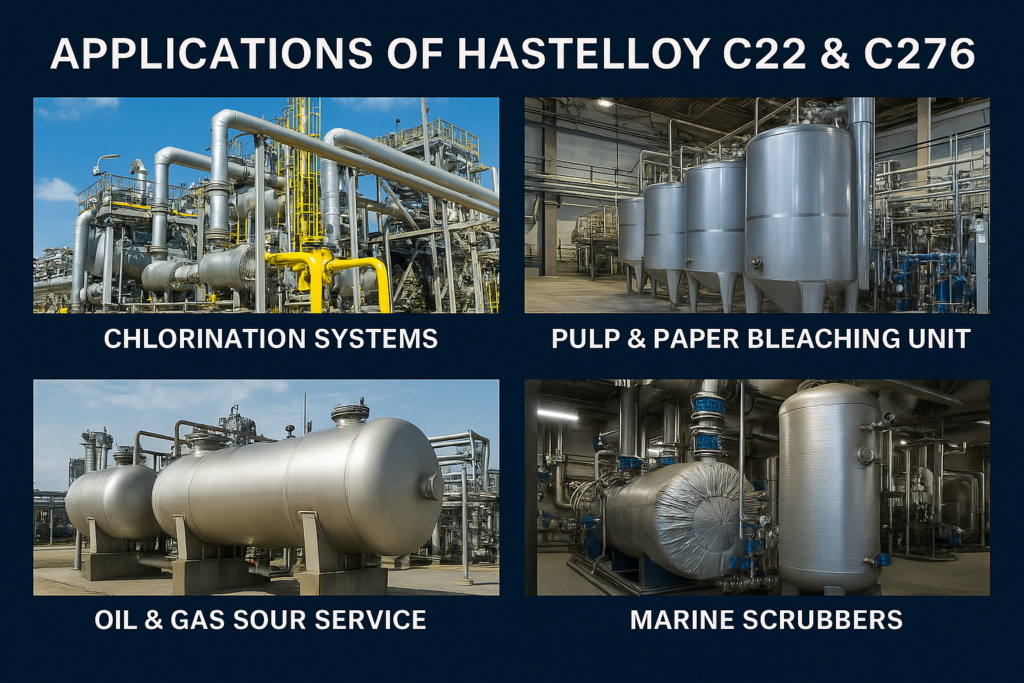

Applications: Where Each Alloy Excels

Hastelloy C22 Applications

- Chlorination systems

- Pulp & paper bleaching plants

- Flue gas desulfurization units

- Chemical reactors handling mixed acids

- Pollution control equipment

Hastelloy C276 Applications

- Oil & gas sour service components

- Pharmaceutical reactors

- Waste treatment involving strong reducing acids

- Heat exchangers in aggressive chemical lines

- Marine scrubbers

Shapes & Forms Available at DOMADIA™

- Pipes & Tubes (Seamless & Welded)

- Sheets & Plates

- Bars & Rods

- Wire & Wire Mesh

- Flanges & Fittings

- Custom-machined components

DOMADIA™ ensures precision manufacturing with strict quality controls.

Technical Specifications Overview

| Specification | C22 | C276 |

| Density | 8.69 g/cm³ | 8.89 g/cm³ |

| Melting Range | 1325–1370°C | 1325–1370°C |

| Thermal Conductivity | Slightly Higher | Slightly Lower |

| Max Continuous Service | Up to 1250°C | Up to 1100°C |

Life Cycle, Cost & Environmental Impact

Life Cycle Advantage

While both alloys are premium-priced, C22’s superior resistance in mixed corrosive media often results in:

- Longer service life

- Lower replacement frequency

- Reduced shutdown losses

Cost of Downtime

Industries have seen up to 40% cost savings over 5 years by choosing the correct alloy, as replacement costs and plant halts exceed alloy price differences.

Environmental Impact

A longer-lasting alloy means:

✔ Less scrap

✔ Lower recycling load

✔ Reduced carbon footprint

Choosing performance materials from DOMADIA™ supports sustainability initiatives.

Conclusion: Which Alloy Should You Choose?

The Hastelloy C22 vs Hastelloy C276 decision depends on the nature of your chemical environment.

| Choose C22 when | Choose C276 when |

| Oxidizing or mixed acid media | Strong reducing media |

| Highly variable process streams | High-temperature corrosive flows |

| Maximum pitting & crevice resistance is needed | Proven performance in sour gas & chemical reactors |

Both alloys are exceptional.

Choosing the correct one ensures reliability, longevity, and environmental responsibility—something DOMADIA™ proudly supports.

Choose the Right Alloy—Talk to DOMADIA™ Experts Today.

👉 Visit DOMADIA™ to learn more or request a custom quote.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#HastelloyC22 #HastelloyC276 #NickelAlloys #CorrosionResistance #DOMADIA #ChemicalIndustry #Superalloys

Your quick connection to us — message now! – https://wa.link/kairav