Blogs

Meta Aramid vs Para Aramid Yarn: Which High-Performance Fiber Wins the Race? | DOMADIA™

Introduction

There’s a silent battle happening inside every fire suit, aerospace panel, high-temperature cable, and industrial protective gear. A battle between meta aramid vs para aramid yarn, two super-fibers trusted when failure is NOT an option.

But here’s the twist—most people think both aramids are “almost the same.”

DOMADIA™ specializes in advanced technical textiles, and we see this confusion every day. The truth is: they are engineered for completely different missions, and choosing the wrong one can cost performance, money, and even safety.

Today, let’s decode the entire story—from molecular structure to real-world use—so you select the right fiber for your application.

The Science Behind the Difference

Aramid fibers are aromatic polyamides, but their chemical structure changes everything.

Chemical Composition & Structure

Meta Aramid (m-Aramid)

- Polymer chain link at meta-position (1,3)

- Example: Poly(m-phenylene isophthalamide)

- Molecular structure gives:

✔ High thermal stability

✔ Flame resistance

✔ Good insulation

✔ Moderate tensile strength

Para Aramid (p-Aramid)

- Polymer chain link at para-position (1,4)

- Example: Poly(p-phenylene terephthalamide)

- Molecular structure gives:

✔ Extremely high tensile strength

✔ High modulus

✔ Superior impact & cut resistance

✔ Good chemical resistance

Key Properties (Side-by-Side)

| Property | Meta Aramid | Para Aramid |

| Heat Resistance | Up to 400°C | Up to 500°C |

| Flame Resistance | Excellent | Good |

| Tensile Strength | Moderate | Very High |

| Cut Resistance | Low | Very High |

| Melting Point | Does not melt | Does not melt |

| Dielectric Strength | High | Moderate |

| UV Resistance | Good | Low |

| Flexibility | High | Moderate |

| Density | ~1.38 g/cm³ | ~1.44 g/cm³ |

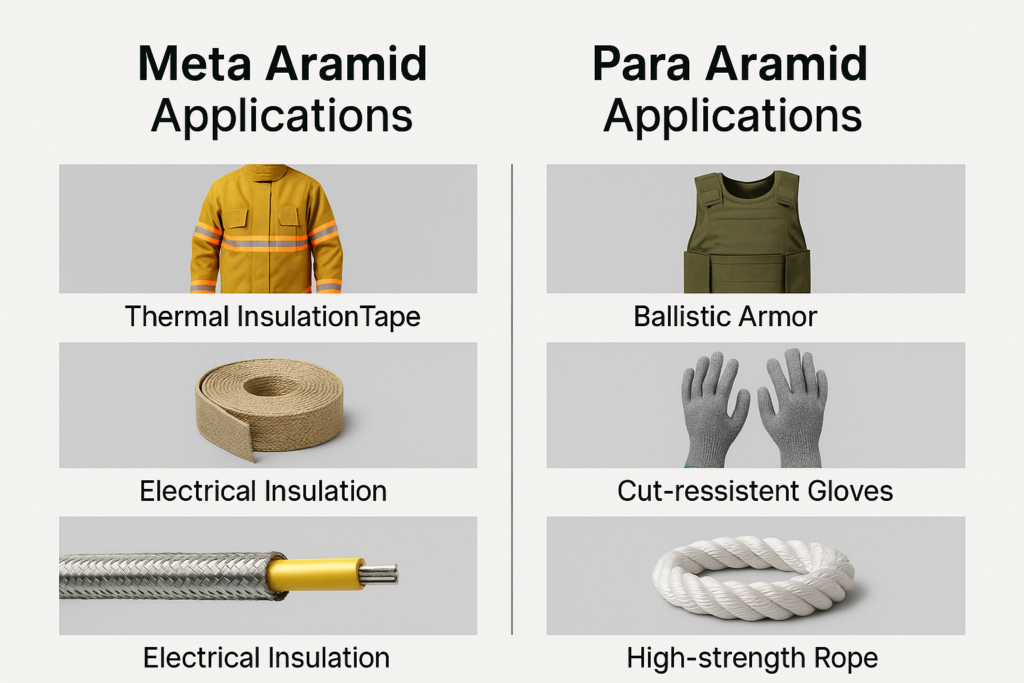

Applications: Built for Different Battles

Meta Aramid Applications

Perfect for heat-intensive and flame-exposed environments:

- Firefighter suits

- Thermal insulation tapes & sleeves

- Electrical insulation

- Cables & wiring protection

- Heat-resistant filters

- Industrial protective clothing

- Hot gas filtration

Para Aramid Applications

Designed for high strength and impact resistance:

- Ballistic armor & helmets

- Cut-resistant gloves

- High-strength ropes

- Composite reinforcement

- Aerospace structural components

- Tires & automotive belts

- Industrial conveyor belts

International Standards Supported by DOMADIA™

Meta Aramid Standards

- ASTM D6040

- NFPA 1971

- ISO 11612

- EN 388

- UL94 V-0 flame rating

Para Aramid Standards

- ASTM D7269

- ISO 13934

- NIJ 0101.06 (Ballistics)

- EN 15630

- ISO 527 (Tensile)

Technical Specifications

Meta Aramid Yarn (Typical DOMADIA™ Specs)

- Denier: 150D – 3000D

- Tenacity: 3.0–5.0 g/d

- Elongation: 20–30%

- Thermal Decomposition: ~400°C

- Conductivity: Low (excellent insulation)

Para Aramid Yarn (Typical DOMADIA™ Specs)

- Denier: 200D – 3000D

- Tenacity: 18–23 g/d

- Elongation: 3–4%

- Thermal Decomposition: ~500°C

- Modulus: Very high

Shapes & Forms Available at DOMADIA™

- Continuous filament yarn

- Spun yarn

- Twisted yarn

- Roving

- Chopped fiber

- Fabrics (woven / non-woven)

- Needle-punched fabrics

- Sewing threads

- Braided sleeves

So… Which One Should You Choose?

The answer lies in your application:

Choose Meta Aramid if you need:

✔ High heat resistance

✔ Flame protection

✔ Electrical insulation

✔ Long-term thermal stability

Choose Para Aramid if you need:

✔ Maximum strength

✔ Ballistic or cut resistance

✔ Impact protection

✔ Structural reinforcement

Both are champions—just in different arenas.

Conclusion

In the debate of meta aramid vs para aramid yarn, there is no “winner”—only the right fiber for the right job. DOMADIA™ provides both engineered to global standards, ensuring performance, reliability, and durability where it matters most.

Whether it’s shielding firefighters or strengthening aerospace structures, DOMADIA™ aramid fibers deliver uncompromised strength and safety.

Still Unsure Which Aramid Yarn Fits Your Application?

Let DOMADIA™ guide you with the perfect material selection for your electrical, thermal or mechanical needs.

Request Samples & Specifications Now

Upgrade to DOMADIA™ Polyimide & Aramid Yarns Today

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#DOMADIA #AramidYarn #MetaAramid #ParaAramid #HighTemperatureFibers #BallisticMaterials #TechnicalTextiles #HeatResistance #EngineeringMaterials

Directly whatsapp us for an Enquiry: https://wa.link/kairav