Blogs

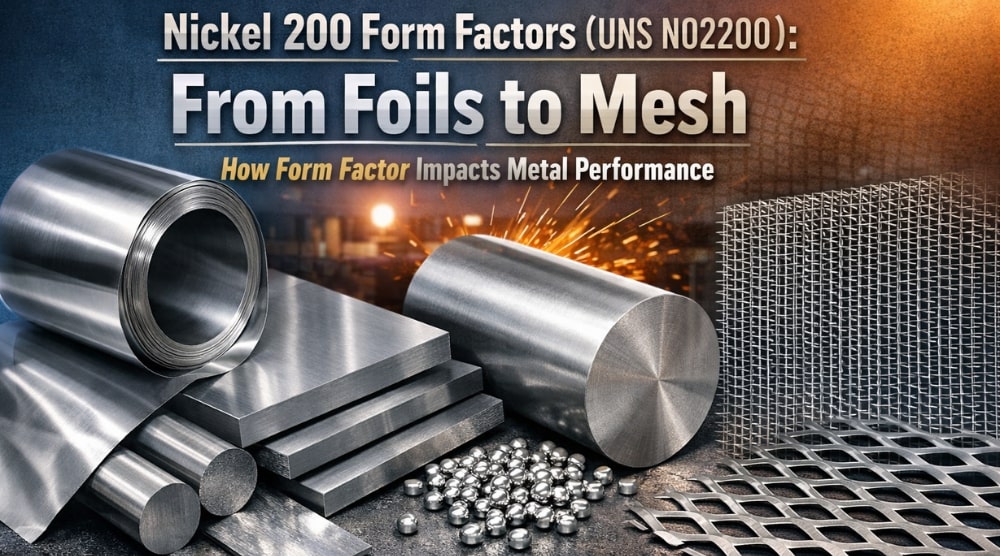

Nickel 200 Form Factors (UNS N02200): From Foils to Mesh — How Form Factor Impacts Metal Performance

Nickel 200 Form Factors: Why Shape Matters More Than You Think

Nickel 200 Form Factors are often overlooked in metal selection, where most conversations stop at chemical composition.

But in real industrial environments, Nickel 200 Form Factors decide performance. The same alloy can behave like a precision instrument—or a liability—depending on whether Nickel 200 is supplied as foil, sheet, strip, mesh, or plate. For engineers, procurement teams, and plant managers, Nickel 200 Form Factors quietly control efficiency, durability, and total lifecycle cost.

At DOMADIA™, we see this daily: the alloy is right, but the Nickel 200 Form Factor is wrong.

This blog breaks down how Nickel 200 Form Factors (UNS N02200) transform metal behavior from ultra-thin foils to structural mesh, and why understanding Nickel 200 Form Factors is no longer optional for reliable industrial performance.

Understanding Nickel 200 (UNS N02200)

Nickel 200 is commercially pure nickel, known for its excellent electrical conductivity, corrosion resistance, and thermal stability.

Chemical Composition (Typical %)

- Nickel (Ni): 99.0 min

- Iron (Fe): ≤ 0.40

- Carbon (C): ≤ 0.15

- Manganese (Mn): ≤ 0.35

- Sulfur (S): ≤ 0.01

- Silicon (Si): ≤ 0.35

High purity gives Nickel 200 its signature behavior—but geometry controls how that behavior is expressed.

From Foils to Mesh: How Form Factor Changes Performance

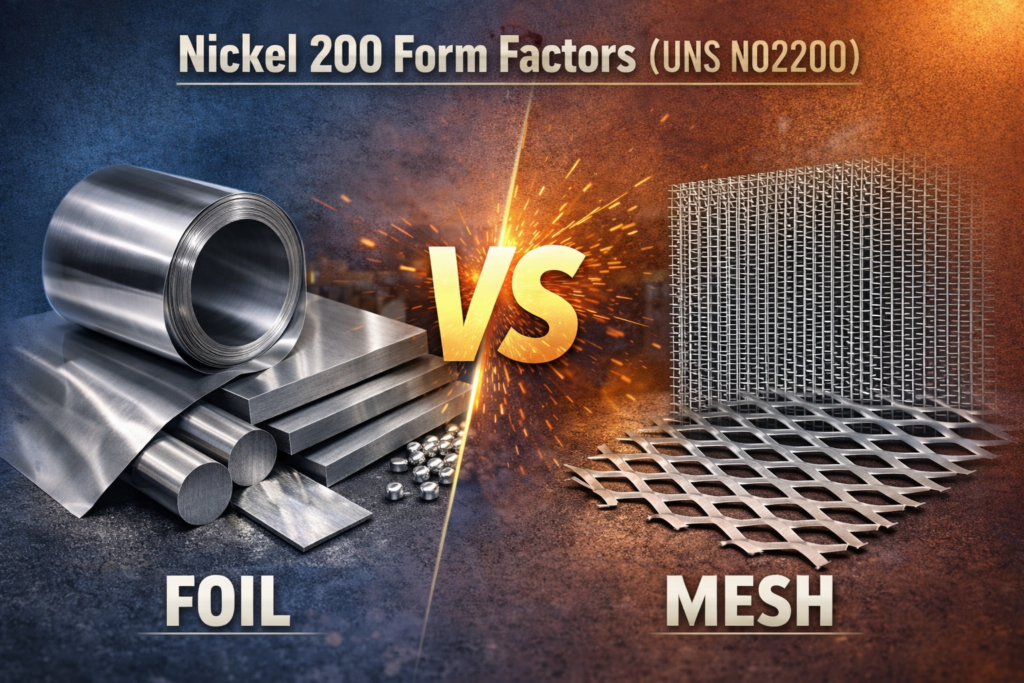

1. Nickel 200 Foils – Precision Under Pressure

Nickel 200 foils are ultra-thin, typically below 0.1 mm.

Performance impact:

- Exceptional electrical & thermal conductivity

- Rapid heat transfer

- High surface-area-to-volume ratio

- Minimal thermal mass

Where they win:

- Battery components

- Fuel cell layers

- EMI shielding

- Precision electronics

Trade-off:

Foils sacrifice mechanical rigidity. Use them where responsiveness matters more than strength.

2. Nickel 200 Sheets & Strips – The Balanced Workhorse

Sheets and strips are where Nickel 200 becomes versatile.

Performance impact:

- Balanced strength and ductility

- Excellent formability

- Consistent corrosion resistance

- Stable mechanical properties

Where they win:

- Chemical processing equipment

- Heat exchangers

- Electrical bus bars

- Aerospace sub-components

This is the form factor engineers default to when performance must be predictable and repeatable.

3. Nickel 200 Plates – Structural Confidence

As thickness increases, Nickel 200 shifts roles.

Performance impact:

- Higher load-bearing capacity

- Reduced deformation under stress

- Slower thermal response

- Increased service life in static environments

Where they win:

- Pressure vessels

- Structural chemical equipment

- Heavy-duty processing systems

Plates aren’t about speed—they’re about stability and longevity.

4. Nickel 200 Mesh – Performance Through Surface Engineering

Mesh is where Nickel 200 becomes strategic.

Performance impact:

- Massive surface area

- Controlled permeability

- Efficient heat and mass transfer

- Reduced material weight

Where they win:

- Filtration systems

- Catalyst supports

- Electrochemical applications

- Gas diffusion layers

Mesh proves that removing material can improve performance—when engineered correctly.

Mechanical & Physical Properties (Typical)

- Density: 8.89 g/cm³

- Melting Range: 1435–1446°C

- Electrical Conductivity: ~14.3 MS/m

- Thermal Conductivity: ~67 W/m·K

- Tensile Strength: 380–550 MPa

- Elongation: 40% min

Same alloy.

Dramatically different behavior—purely due to form factor.

Standards & Specifications

Nickel 200 form factors supplied by DOMADIA™ conform to:

- ASTM B162 – Plate, Sheet & Strip

- ASTM B160 – Rod & Bar

- ASTM B161 – Seamless Pipe & Tube

- ASTM B552 – Foil

- ASME SB standards (where applicable)

Every form factor meets tight dimensional and metallurgical control.

Shapes & Forms Available at DOMADIA™

- Foils

- Sheets

- Strips

- Plates

- Mesh (woven / expanded)

- Wire

- Rods & Bars

- Custom-cut precision formats

Because performance shouldn’t be compromised by availability.

The Real-World Mindset Shift

Most failures don’t happen because the alloy was wrong.

They happen because Nickel 200 Form Factors were assumed.

Choosing Nickel 200 without defining the correct Nickel 200 Form Factor is like choosing an engine without knowing the vehicle it must power.

At DOMADIA™, we help customers select both the alloy and the right Nickel 200 Form Factors, ensuring real-world performance aligns with operating conditions—not just theoretical specifications.

Final Takeaway

Nickel 200 Form Factors don’t just change dimensions—they redefine performance, lifespan, and reliability.

From ultra-responsive foils to high-surface-area mesh, form factor is the silent performance multiplier in modern engineering.

If your application demands consistency, efficiency, and long-term value, the question is no longer which alloy?

It’s which form?

Nickel 200 performance isn’t just about chemistry—it’s about form factor.

👉 Talk to DOMADIA™ today for expert guidance on Nickel 200 form factors that match real operating conditions—not assumptions.

Selecting the right Nickel 200 form factor defines performance and lifecycle—Contact Us to get the exact UNS N02200 solution your application demands.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#Nickel200FormFactors #UNSN02200 #NickelAlloys #MetalFoils #MetalMesh #IndustrialNickel #SpecialtyMetals #DOMADIA™

Directly whatsapp us for an Enquiry: https://wa.link/kairav

Our reach includes Surat, Vapi, Ankleshwar, Bharuch, and Silvassa across Gujarat, Maharashtra, Dadra & Nagar Haveli, Rajasthan, and MP, with exports to China, Taiwan, Hong Kong, Macau, and Mongolia.