Blogs

Polyimide vs Aramid Yarn: Which One Performs Better Under Extreme Heat? | DOMADIA™

Introduction — A Sudden Shutdown That Cost Millions

The production line was running smoothly… until the temperature spiked.

Within minutes, the high-heat insulation sleeve began to smoke. The aramid-coated section failed first, forcing an unexpected shutdown that cost the company a full day — and several lakhs in downtime.

Later, their engineering team discovered a crucial detail:

Polyimide vs Aramid Yarn Performance plays a far bigger role under extreme temperatures than most industries realize.

Not all high-performance fibers behave the same when heat pushes them to their limits.

This single failure sparked the question many industries ask today:

Which heat-resistant fiber performs better — Polyimide or Aramid Yarn?

In this blog, we break down the real-world performance, comparing both materials across chemical composition, thermal endurance, applications, standards, properties, and lifespan — all with DOMADIA™ technical expertise.

What Are These Fibers Made Of? (Chemical Composition)

Polyimide Yarn

A high-performance polymer made of:

- Aromatic polyimide backbone

- Imide rings (highly thermally stable)

- No melting point — it carbonizes instead of melting

This molecular structure is what gives DOMADIA™ Polyimide Yarn its legendary heat resistance.

Aramid Yarn

An aromatic polyamide consisting of:

- Para-oriented benzene rings

- Amide linkages

- Highly rigid molecular chains

Aramid fibers like Kevlar® and Nomex® are strong, flexible, and heat resistant — but have defined degradation points.

Thermal Performance Comparison: Who Survives the Heat?

| Feature / Fiber | Polyimide Yarn | Aramid Yarn |

| Continuous Temperature Rating | 260–300°C | 160–220°C |

| Short-Term Peak | ~500°C | ~370°C |

| Melting Point | No melting — carbonizes | No melting — degrades |

| Thermal Aging | Outstanding | Moderate |

| Oxidation Resistance | Excellent | Good |

| Flame Resistance | Inherent | Inherent |

Mechanical & Electrical Properties

| Property | Polyimide Yarn | Aramid Yarn |

| Tensile Strength | High | Very High |

| Dielectric Strength | Excellent | Good |

| Chemical Resistance | Superior to solvents & oils | Good |

| Moisture Absorption | <2% | ~5% (can weaken fiber) |

| Flexibility | Good | Excellent |

| Durability in Cyclic Heat | Exceptional | Moderate |

Standards & Grades

Polyimide Yarn Standards

- ASTM D5213

- IEC 60819

- ISO 10082

- MIL-grade forms available

Aramid Yarn Standards

- ASTM D7269

- NFPA 1971 (for protective clothing)

- ISO 11612 (heat & flame protection)

- MIL-spec varieties available

Applications: Where Do They Work Best?

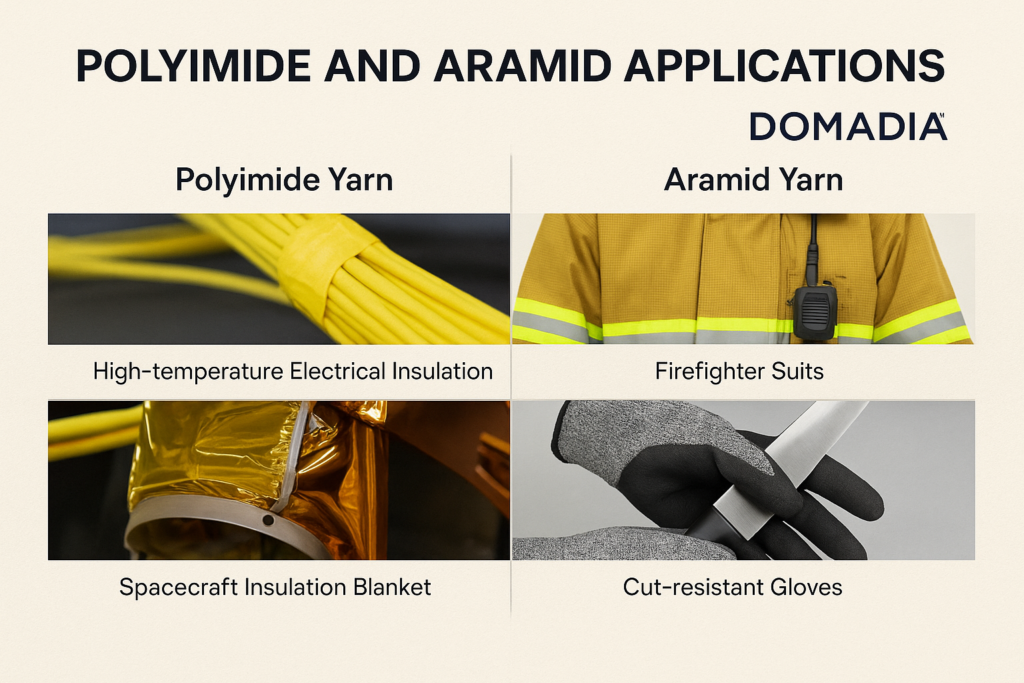

Polyimide Yarn Applications

DOMADIA™ Polyimide Yarn is widely used in:

- High-temperature electrical insulation

- Spacecraft insulation blankets

- Motor & transformer winding

- High-heat sensor wire wrapping

- Fire-safe cabling

- Aviation electronics

Ideal for continuous high-heat environments.

Aramid Yarn Applications

Aramid yarns are popular in:

- Firefighter suits

- Cut-resistant gloves

- Protective textiles

- Ropes & cables

- Automotive reinforcement parts

- FRP composites

Ideal where strength + impact resistance matter more than temperature.

Shapes & Forms Available (DOMADIA™)

We supply both materials in:

- Yarn

- Roving

- Braided sleeves

- Webbing straps

- Tapes

- Threads

- Custom dimensions available on request

So… Which One Is Better? The Honest Answer

It depends on the application — but under extreme heat, there is a clear leader:

DOMADIA™ Polyimide Yarn is the superior choice for 260°C+ conditions.

Aramid Yarn shines in:

- Strength

- Flexibility

- Mechanical toughness

Polyimide Yarn shines in:

- Temperature resistance

- Electrical insulation

- Chemical durability

- Long-term thermal aging

Environmental Impact — A Hidden Advantage

Materials that fail early need:

- More replacement

- More manufacturing

- More scrap

- More transport

- More recycling emissions

With longer lifespan & fewer replacements,

DOMADIA™ Polyimide Yarn contributes to lower carbon impact over its operational life.

A smart engineering choice — and a responsible environmental one.

Conclusion — Polyimide vs Aramid Yarn

Focus Phrase: DOMADIA Polyimide vs Aramid Yarn Performance

In high-intensity industrial environments, the right fiber can save:

- Downtime costs

- Maintenance budgets

- Safety risks

- Environmental impact

If your priority is extreme heat, high dielectric strength, and long service life —

DOMADIA™ Polyimide Yarn wins the heat battle.

If your priority is strength, cut resistance, and protection gear —

Aramid Yarn performs exceptionally well. No more guesswork — choose based on the thermal load, mechanical needs, and lifespan expectations.

Boost Your High-Temperature Performance.

Upgrade to DOMADIA™ Polyimide & Aramid Yarns Today

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#PolyimideYarn #AramidYarn #DOMADIA #HeatResistantMaterials #HighTemperatureFibers #TechnicalTextiles #IndustrialInsulation #EngineeringMaterials

Directly whatsapp us for an Enquiry: https://wa.link/kairav