Blogs

Rare Earth Magnet Lifecycle: 9 Proven Reasons Higher Cost Saves Millions | DOMADIA™

Rare Earth Magnet Lifecycle Is Not About Price — It’s About Survival

A global EV motor manufacturer once faced an uncomfortable truth.

Their motors were failing—not catastrophically, but quietly. Efficiency dropped. Heat increased. Maintenance crews were called more often. Downtime crept into quarterly reports.

The magnets were cheaper alternatives.

The losses were not.

This is where the Rare Earth Magnet Lifecycle conversation begins—not at procurement desks, but on factory floors where every minute of downtime costs more than the magnet itself.

At DOMADIA™, we don’t sell magnets based on sticker price.

We engineer decisions based on Rare Earth Magnet Lifecycle performance.

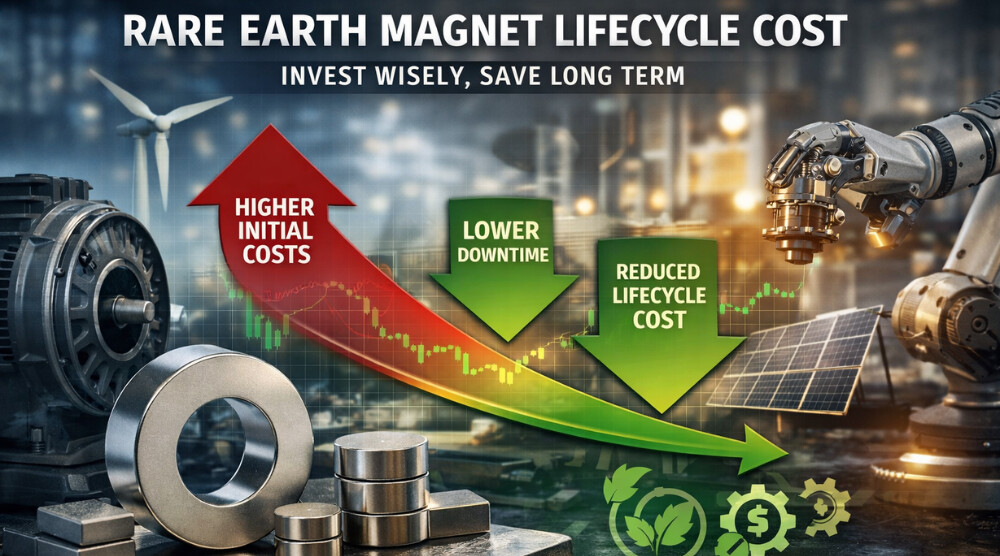

The Mindset Shift: From Purchase Cost to Rare Earth Magnet Lifecycle Cost

Traditional sourcing asks:

“What does this magnet cost today?”

Advanced engineering teams ask:

“What will this magnet cost us over 5–15 years?”

That single mindset shift changes everything.

The Rare Earth Magnet Lifecycle includes:

- Initial procurement

- Energy efficiency over time

- Maintenance frequency

- Replacement cycles

- Downtime losses

- Environmental impact

When viewed through this lens, Rare Earth Magnets stop being “expensive” and start becoming financial risk reducers.

Why Rare Earth Magnet Lifecycle Outperforms Conventional Magnets

1. Higher Magnetic Energy Density = Smaller, Lighter Systems

Rare Earth Magnets deliver exceptional magnetic strength per unit volume.

This allows designers to reduce motor size, weight, and material usage—directly improving system efficiency.

Over the Rare Earth Magnet Lifecycle, this means:

- Lower energy consumption

- Compact designs

- Reduced mechanical stress on components

Smaller systems fail less. That’s physics—not marketing.

2. Stable Performance Across the Entire Rare Earth Magnet Lifecycle

Ferrite and Alnico magnets degrade faster under heat, vibration, and cyclic loads.

Rare Earth Magnets maintain predictable performance for years.

That stability across the Rare Earth Magnet Lifecycle ensures:

- Consistent torque output

- Predictable thermal behavior

- No mid-life efficiency surprises

Predictability is priceless in automation-heavy industries.

3. Downtime Is the Real Cost Driver

Replacing a magnet is cheap.

Stopping a production line is not.

Every unplanned shutdown triggers:

- Labor costs

- Lost production

- Missed delivery timelines

- Reputation damage

A longer Rare Earth Magnet Lifecycle dramatically reduces replacement frequency—cutting downtime risk at the source.

Lifecycle Cost Comparison: Cheap Magnet vs Rare Earth Magnet Lifecycle

| Cost Element | Conventional Magnet | Rare Earth Magnet Lifecycle |

| Initial Cost | Low | Higher |

| Energy Losses | High | Minimal |

| Replacement Frequency | Frequent | Rare |

| Downtime Risk | High | Low |

| Long-Term Cost | Unpredictable | Controlled |

This is why engineers don’t optimize for purchase price—they optimize for Rare Earth Magnet Lifecycle cost.

Environmental Impact: Rare Earth Magnet Lifecycle as a Sustainability Strategy

Here’s the uncomfortable truth:

The more often you replace a component,

the more often you scrap it,

the more often you recycle it,

the higher the environmental damage.

Because the Rare Earth Magnet Lifecycle is significantly longer:

- Fewer magnets are scrapped

- Recycling cycles reduce

- Energy and emissions drop

This is not branding.

This is engineering-led sustainability.

At DOMADIA™, supplying longer-life magnets is part of how we reduce industrial waste—quietly, consistently, and measurably.

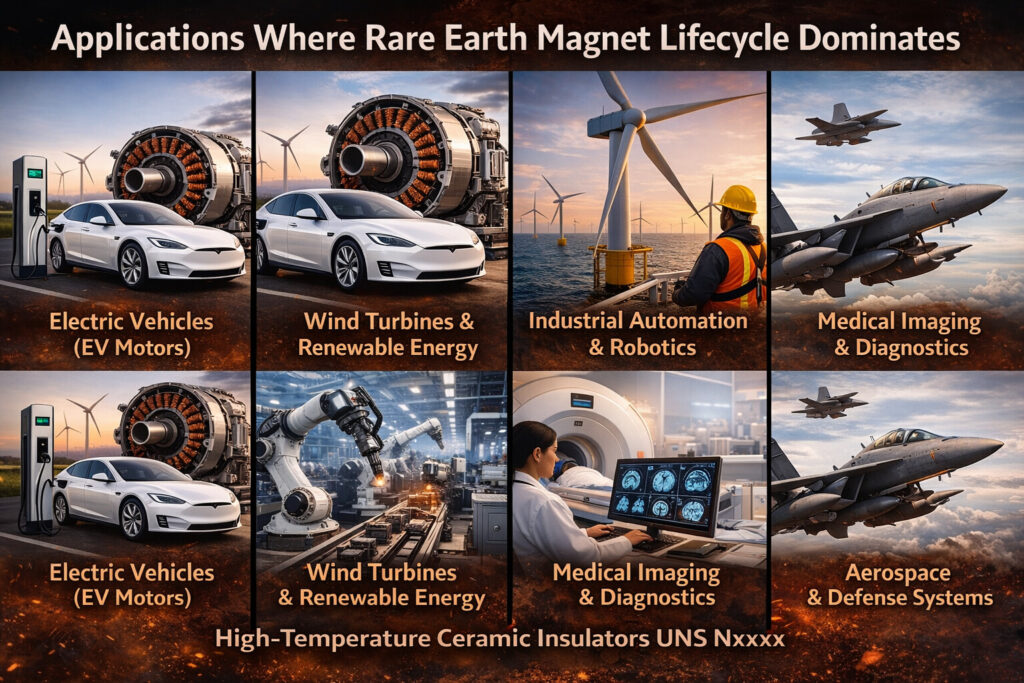

Applications Where Magnet Lifecycle Dominates

Electric Vehicles (EV Motors)

Longer magnet life ensures consistent torque, higher efficiency, and reduced warranty risk.

Wind Turbines & Renewable Energy

Extended Rare Earth Magnet Lifecycle minimizes offshore maintenance and service disruptions.

Industrial Automation & Robotics

Precision systems depend on magnetic stability over millions of cycles.

Medical Imaging & Diagnostics

Stable magnetic fields protect accuracy, safety, and compliance.

Aerospace & Defense Systems

Failure is not tolerated—long lifecycle performance is mandatory.

Technical Properties Supporting Magnet Lifecycle

- High coercivity (demagnetization resistance)

- Superior thermal stability

- High corrosion resistance with proper coatings

- Excellent fatigue behavior

These properties are why the Rare Earth Magnet Lifecycle consistently outperforms alternatives in real-world conditions.

Why DOMADIA™ Engineers for Long-Term Magnet Performance

At DOMADIA™, Rare Earth Magnets are positioned as system reliability components, not consumables.

We support:

- Application-specific magnet selection

- Lifecycle-focused material recommendations

- Long-term supply consistency

- Engineering-backed risk reduction

Because in modern industry, failure is always more expensive than prevention.

Conclusion: Rare Earth Magnet Lifecycle Is an Investment, Not a Cost

Rare Earth Magnets are not chosen because they are premium.

They are chosen because downtime, inefficiency, and replacement cycles are far more expensive.

When evaluated correctly, the Rare Earth Magnet Lifecycle delivers:

- Lower total cost of ownership

- Reduced environmental impact

- Higher operational confidence

That is not a purchasing argument.

That is an engineering truth—delivered by DOMADIA™.

Downtime is expensive. Prevention is engineered.

Design systems that last longer—discover how DOMADIA™ delivers Rare Earth Magnets engineered for lifecycle reliability or Contact Us to reduce downtime and total ownership cost.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#RareEarthMagnetLifecycle #RareEarthMagnets #IndustrialEfficiency #LifecycleCost #SustainableEngineering #EVMotors #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.