Blogs

Rare Earth Magnets Efficiency: 7 Powerful Reasons They Are Critical for High-Efficiency Industrial Motors | DOMADIA™

Introduction: When Motors Don’t Fail Loudly—They Fail Expensively

Rare Earth Magnets Efficiency is no longer a design luxury—it is a survival requirement for modern industry.

In a real factory scenario, a motor doesn’t stop suddenly.

It starts running hotter.

Consumes more power.

Loses torque under load.

By the time alarms trigger, energy bills are already inflated, production speed is compromised, and maintenance teams are under pressure.

This silent loss of performance is why Rare Earth Magnets Efficiency has become central to high-efficiency industrial motor design—across automation, EV manufacturing, HVAC systems, robotics, and heavy-duty processing lines.

At DOMADIA™, Rare Earth Magnets are treated not as components, but as performance enablers.

The Mindset Shift: Motors Are Energy Systems, Not Just Machines

For decades, industries optimized motors around copper windings and mechanical tolerances. Magnet choice was secondary.

That mindset is outdated.

Today’s engineers ask a sharper question:

“How do we convert every unit of electrical energy into controlled mechanical output—with minimum loss?”

The answer consistently points to Rare Earth Magnets Efficiency.

Rare Earth Magnets fundamentally change how motors behave:

- Higher magnetic flux density

- Lower current demand

- Reduced resistive losses

- Smaller, lighter motor geometries

Efficiency is no longer about running, it’s about running cooler, longer, and predictably.

What Makes Rare Earth Magnets Different? (Technical Overview)

Rare Earth Magnets—primarily Neodymium-Iron-Boron (NdFeB) and Samarium Cobalt (SmCo)—deliver magnetic strength far beyond conventional ferrite or AlNiCo magnets.

Chemical Composition (Typical NdFeB Magnet)

- Neodymium (Nd): ~30–32%

- Iron (Fe): ~64–68%

- Boron (B): ~1%

- Minor alloying elements (Dy, Tb) for thermal stability

This composition is the foundation of Rare Earth Magnets Efficiency, enabling extreme energy density in compact volumes.

7 Critical Reasons Rare Earth Magnets Drive Motor Efficiency

1. Higher Torque Density

Rare Earth Magnets produce stronger magnetic fields in smaller sizes.

This allows motors to generate higher torque without increasing frame size—a direct win for Rare Earth Magnets Efficiency.

2. Lower Energy Consumption

Stronger magnets reduce the current required to achieve the same output.

Less current = lower copper losses = better Rare Earth Magnets Efficiency.

3. Reduced Heat Generation

Heat is wasted energy.

Rare Earth Magnets allow motors to operate at lower temperatures, improving insulation life and bearing reliability.

4. Compact & Lightweight Motor Designs

Smaller motors reduce material usage, structural load, and installation complexity—key advantages driven by Rare Earth Magnets Efficiency.

5. Superior Performance at Variable Speeds

Modern VFD-driven motors rely on stable magnetic fields. Rare Earth Magnets maintain predictable performance across wide speed ranges.

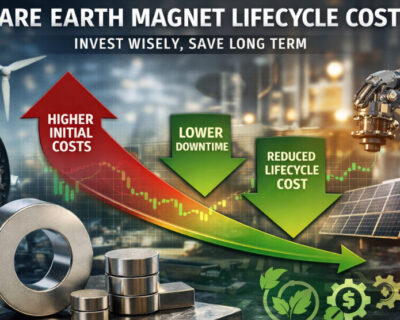

6. Longer Service Life & Reduced Downtime

Stable magnetic properties mean fewer performance drifts over time.

Longer operational life directly supports Rare Earth Magnets Efficiency from a lifecycle cost perspective.

7. Sustainability & Environmental Impact

Frequent motor replacements increase scrap, recycling energy, and emissions.

Because Rare Earth Magnet-based motors last longer, they are recycled less often—a quiet but meaningful environmental contribution supported by DOMADIA™.

Applications Where Rare Earth Magnets Efficiency Is Non-Negotiable

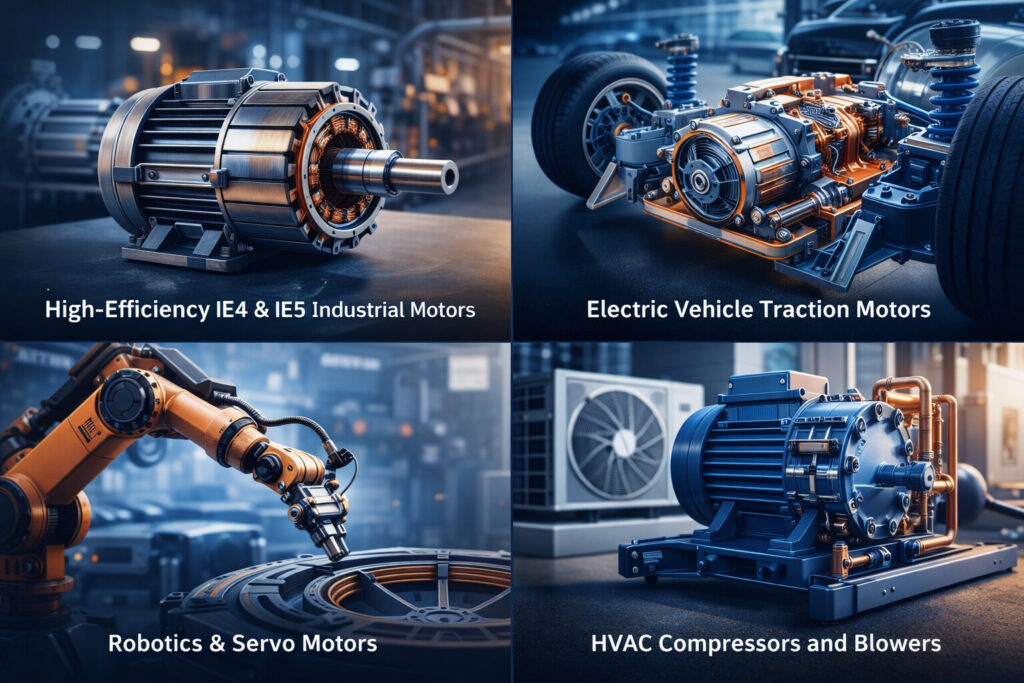

High-Efficiency IE4 & IE5 Industrial Motors

Rare Earth Magnets Efficiency enables IE4 and IE5 motors to achieve higher torque density, lower electrical losses, and reduced operating temperatures—meeting global efficiency standards with ease.

Electric Vehicle Traction Motors

In EV traction motors, Rare Earth Magnets Efficiency delivers compact design, high power-to-weight ratio, and extended driving range by minimizing energy losses under variable load conditions.

Robotics & Servo Motors

Precision robotics depend on Rare Earth Magnets Efficiency for fast response, accurate positioning, and stable torque output, even during continuous start-stop and high-speed operations.

HVAC Compressors and Blowers

Rare Earth Magnets Efficiency improves airflow control and reduces power consumption in HVAC systems, ensuring quieter operation, lower heat generation, and long-term reliability.

Pumps, Conveyors, and Automation Lines

For continuous-duty systems, Rare Earth Magnets Efficiency ensures consistent torque, reduced downtime, and lower lifecycle energy costs across pumps, conveyors, and automated production lines.

CNC Spindle Motors

CNC spindle motors rely on Rare Earth Magnets Efficiency to maintain high-speed stability, superior machining accuracy, and reduced thermal distortion during prolonged machining cycles.

Renewable Energy Generators

In wind and renewable energy generators, Rare Earth Magnets Efficiency supports higher power output, compact generator design, and improved performance under fluctuating environmental conditions.

Standards & Compliance

Rare Earth Magnets used in industrial motors align with:

- IEC 60034 efficiency classes

- ISO quality standards

- Automotive-grade magnet specifications

- RoHS & REACH compliance (application dependent)

DOMADIA™ supplies magnets engineered to meet global industrial standards with consistent batch control.

Technical Properties Snapshot

- Magnetic Energy Product (BHmax): Extremely high

- Coercivity: Excellent resistance to demagnetization

- Operating Temperature: Application-specific grades available

- Corrosion Protection: Coated or alloy-enhanced options

- Dimensional Precision: Tight tolerances for motor assemblies

Each property reinforces Rare Earth Magnets Efficiency at both design and operational levels.

Shapes Available

DOMADIA™ Rare Earth Magnets are supplied in:

- Arc segments (motor rotors)

- Blocks & plates

- Rings & discs

- Custom engineered geometries

Shape optimization plays a direct role in maximizing Rare Earth Magnets Efficiency.

The Tangible Fix: What Engineers Should Do Now

If efficiency targets are tightening and energy costs are rising:

- Upgrade from ferrite to Rare Earth Magnet motor designs

- Evaluating total lifecycle cost—not just upfront price

- Design motors around torque density, not motor size

- Choose suppliers who understand application-specific magnet behavior

At DOMADIA™, Rare Earth Magnets are positioned as risk-control materials, not commodity parts.

Conclusion: Efficiency Is Not About Cheaper Motors—It’s About Smarter Ones

Rare Earth Magnets Efficiency defines the future of industrial motors.

They are not chosen because they are expensive.

They are chosen because inefficiency is far more expensive—in power loss, downtime, replacements, and environmental impact.

High-efficiency motors are no longer optional.

And Rare Earth Magnets are no longer negotiable.

That’s where DOMADIA™ delivers value.

High-efficiency motors start with the right magnetic foundation.

Talk to DOMADIA™ experts to select the right Rare Earth Magnet solution for your high-efficiency industrial motor.

Contact Us to discuss Rare Earth Magnet solutions from DOMADIA™ that improve efficiency, reduce losses, and extend motor life.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#RareEarthMagnetsEfficiency #IndustrialMotors #HighEfficiencyMotors #EnergyEfficientDesign #PermanentMagnets #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.