Blogs

Samarium Cobalt vs Neodymium Magnets: Which One Offers Longer Lifecycle? | DOMADIA™

Introduction — A Little Suspense To Start

A major EV manufacturer contacted DOMADIA™ recently with a strange problem:

Their motors were powerful… but failing far earlier than expected. After months of testing, the culprit wasn’t the copper windings or the bearings.

The real villain?

The magnets.

This sparked the million-dollar question seen across aerospace labs, EV plants, defense suppliers and industrial design rooms:

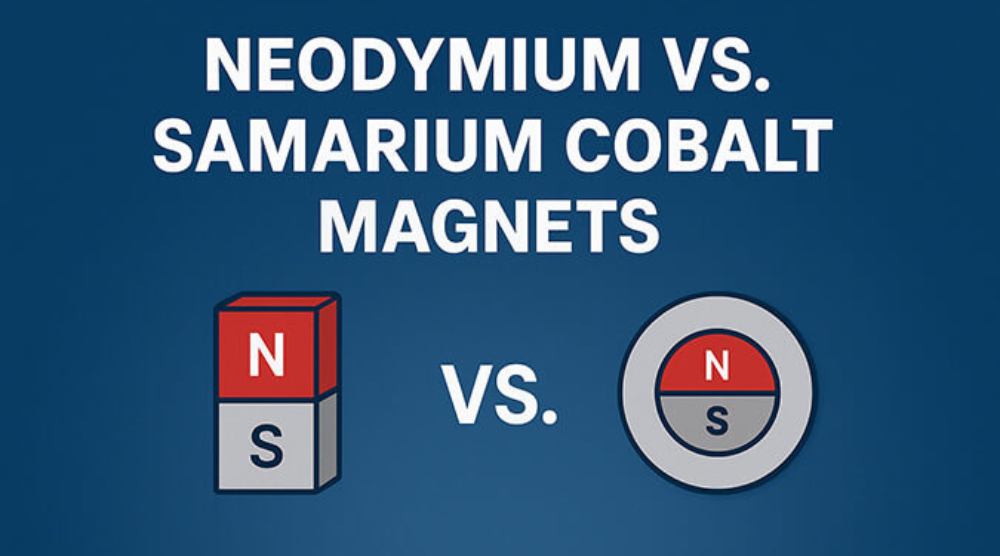

Between Samarium Cobalt vs Neodymium Magnets — which one actually delivers a longer lifecycle?

Let’s settle this with data, science, and real-world performance.

Understanding the Magnet Chemistry

1. Neodymium (NdFeB) Magnets — UNS R05400 Series

- Composition: Nd + Fe + B, often doped with Dy (Dysprosium) or Tb (Terbium) for heat resistance.

- Strongest commercially available permanent magnets.

- Highly sensitive to heat, corrosion, and oxidation.

2. Samarium Cobalt (SmCo) Magnets — UNS R30000 Series

- Composition: Sm + Co, often with Fe, Cu, Zr.

- Second strongest rare earth magnets.

- Exceptional thermal stability and corrosion resistance.

- Naturally resistant to oxidation — unlike NdFeB.

Lifecycle Comparison: The Real Winner

1. High-Temperature Stability

- SmCo retains magnetic strength up to 350–550°C.

- NdFeB rapidly loses magnetism above 80–180°C, unless heavily doped with expensive Dysprosium.

Winner: Samarium Cobalt

2. Corrosion & Environmental Durability

- NdFeB must have coatings (Ni-Cu-Ni, epoxy) or it corrodes aggressively.

- SmCo requires no coating, survives salt spray, humidity, chemicals.

Winner: Samarium Cobalt

3. Mechanical Strength

- NdFeB: Stronger, but brittle.

- SmCo: More brittle, but more dimensionally stable at extreme temperatures.

Winner: Depends on application — but for lifecycle, SmCo remains more stable.

4. Magnetic Strength Over Time (Demagnetization Resistance)

- SmCo has ultra-low temperature coefficient.

- NdFeB demagnetizes faster in heat cycles and vibration-heavy environments.

Winner: Samarium Cobalt

Total Lifecycle Scorecard

| Property | Neodymium | Samarium Cobalt | Lifecycle Winner |

| Max Operating Temp | 80–250°C | 350–550°C | SmCo |

| Corrosion Resistance | Low | Very High | SmCo |

| Oxidation Resistance | Poor | Excellent | SmCo |

| Magnetic Strength | Very High | High | NdFeB |

| Long-Term Stability | Medium | Very High | SmCo |

| Cost | Lower | Higher | — |

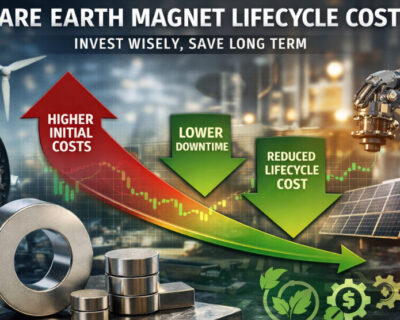

Is Samarium Cobalt Worth the Higher Cost? — YES

Most companies compare magnet cost per piece.

DOMADIA™ recommends comparing Total Lifecycle Value instead:

Hidden Costs of Cheaper NdFeB:

- Frequent replacements

- Downtime in motors

- Heat degradation in high-performance systems

- Coating failures

- Corrosion-related breakdowns

Benefits of SmCo:

- Works for decades without performance loss

- Zero coating failures

- Designed for aerospace-level reliability

- Lower downtimes

- Lower environmental impact

- Less scrapping

- Fewer replacements

- Lower recycling energy consumption

In the long run, Samarium Cobalt often costs less.

Applications Comparison

Where Samarium Cobalt Dominates

- Aerospace actuators

- Defense & missile systems

- High-temperature pumps

- High-speed motors

- Oil & gas sensors

- Space-grade equipment

Where Neodymium Excels

- Consumer electronics

- EV traction motors

- Headphones & speakers

- Robotics

- Wind turbines

If reliability and lifecycle matter → SmCo wins.

If maximum strength at lowest cost matters → NdFeB wins.

Technical Specifications Overview

| Feature | SmCo Magnets | NdFeB Magnets |

| Residual Flux Density (Br) | 0.9–1.1 T | 1.0–1.4 T |

| Coercivity (Hc) | Very High | High |

| Curie Temp | 700–850°C | 310–370°C |

| Density | ~8.4 g/cm³ | ~7.4 g/cm³ |

| Coating | Not needed | Essential |

Shapes Available at DOMADIA™

- Rings

- Blocks

- Discs

- Segments (arc magnets)

- Custom CNC shapes

Conclusion — Final Verdict

When comparing Samarium Cobalt vs Neodymium Magnets, one truth stands out:

👉 If you want the longest lifecycle with zero compromise under extreme temperatures — choose Samarium Cobalt.

👉 If you want highest magnetic strength at a budget — choose Neodymium. DOMADIA™ supplies both, engineered to meet aerospace, EV, industrial, and defense standards.

Get Expert Magnet Guidance Today” Understand which magnet—SmCo or NdFeB—fits your application perfectly.

📩 Contact DOMADIA™ for custom recommendations.

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#SamariumCobalt #NeodymiumMagnets #RareEarthMagnets #MagnetTechnology #AerospaceMaterials #EVMotors #DOMADIA #IndustrialMagnets

Directly whatsapp us for an Enquiry: https://wa.link/kairav