Blogs

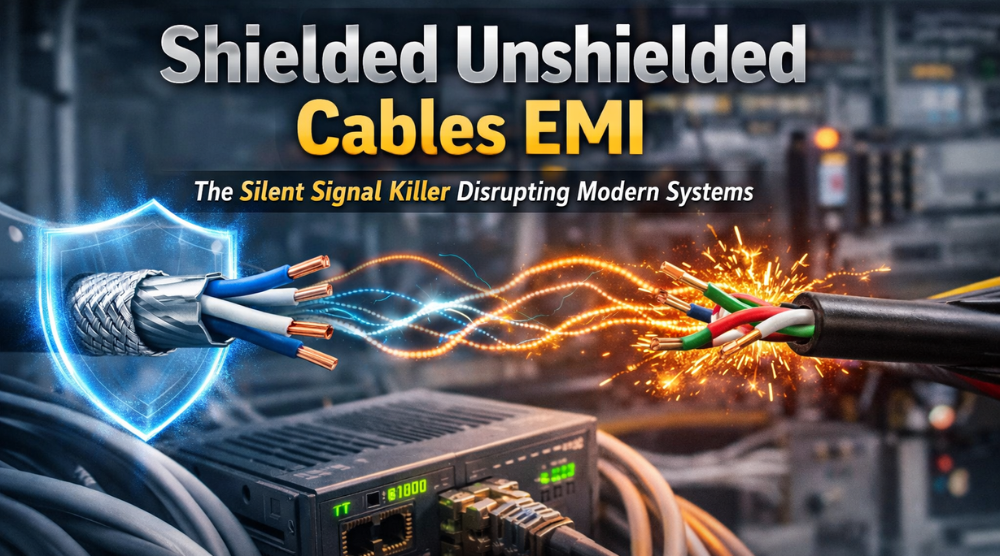

Shielded Unshielded Cables EMI: The Silent Signal Killer Disrupting Modern Systems

Shielded Unshielded Cables EMI — The Problem Nobody Mentions

Production was flawless on paper. PLC logic checked out. Drives were calibrated.

Yet the line kept stopping—random faults, ghost signals, unexplained data drops.

The post-mortem blamed software. Then hardware. Then “operator error.”

The real culprit? Shielded Unshielded Cables EMI—a silent disruptor most teams never investigate deeply enough.

The Real-World Scenario Engineers Face

In modern factories, cables don’t operate in clean lab environments. They run beside:

- Variable frequency drives

- Motors and transformers

- High-current busbars

- Switching power supplies

- Wireless and RF systems

Here, Shielded Unshielded Cables EMI isn’t theoretical—it’s daily reality. And the wrong cable choice quietly erodes reliability long before failure becomes visible.

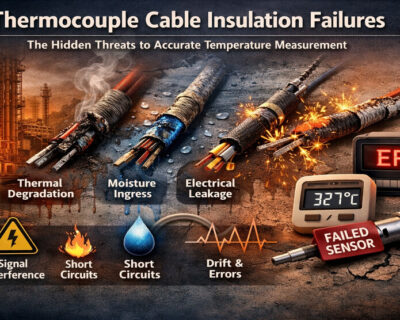

What EMI Actually Does to Cables (Beyond Textbook Definitions)

Electromagnetic interference doesn’t always cause total failure. More often, it creates:

- Intermittent signal distortion

- Data packet loss without alarms

- Sensor drift and false triggering

- Communication retries that slow systems

- Accelerated wear of connected electronics

This is why Shielded Unshielded Cables EMI issues are so dangerous—they hide in plain sight.

Unshielded Cables: Where Problems Begin

Unshielded cables rely only on insulation and conductor geometry. They work well when:

- Cable runs are short

- EMI sources are minimal

- Data speeds are low

- Environments are electrically “quiet”

But in industrial settings, Shielded Unshielded Cables EMI exposure quickly overwhelms unshielded designs.

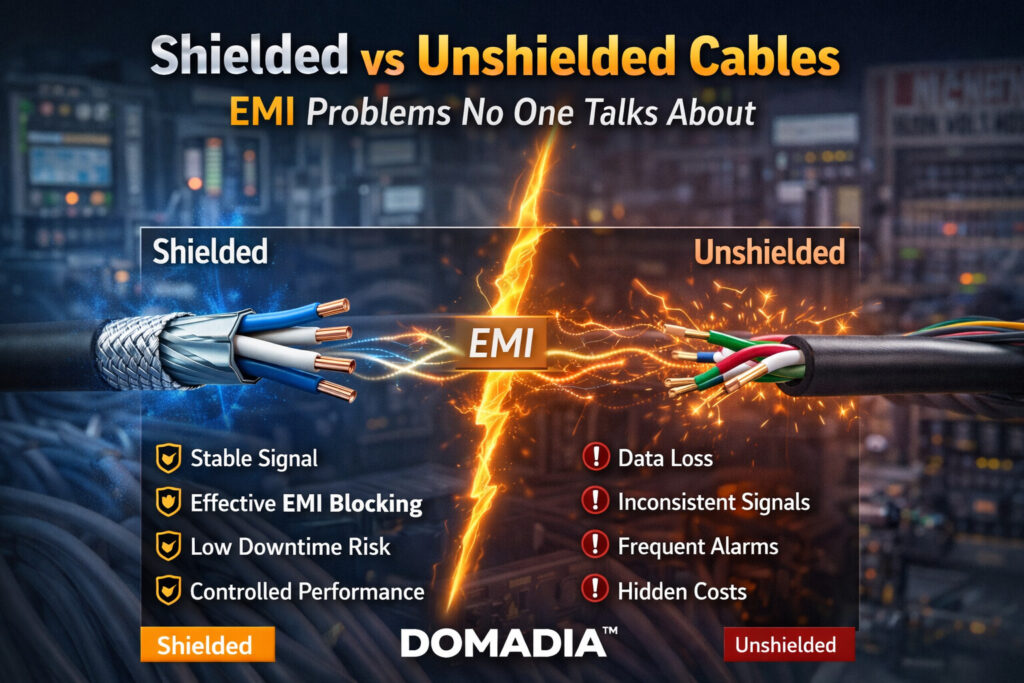

Hidden Risks of Unshielded Cables

- Act as unintended antennas

- Pick up noise from nearby power lines

- Cause cross-talk between adjacent cables

- Increase troubleshooting time

The cost savings upfront often disappear in downtime, scrap, and diagnostics.

Shielded Cables: More Than Just “Extra Protection”

Shielded cables incorporate metallic layers—foil, braid, or combinations—designed to block EMI before it reaches conductors.

But here’s the nuance most blogs skip: shielding only works when engineered and terminated correctly.

When done right, Shielded Unshielded Cables EMI exposure is dramatically reduced.

Benefits of Shielded Cables

- Stable signal transmission

- Reduced noise-induced errors

- Improved system repeatability

- Longer equipment life

DOMADIA™ supplies shielded cable solutions with controlled construction—not cosmetic shielding.

The Comparison That Actually Matters

| Aspect | Unshielded Cables | Shielded Cables |

| EMI Resistance | Low | High |

| Installation Sensitivity | Low | Medium |

| Signal Integrity | Variable | Consistent |

| Downtime Risk | Higher | Lower |

| Lifecycle Cost | Hidden & rising | Predictable |

This table explains why Shielded Unshielded Cables EMI decisions should never be made on price alone.

A Smarter Perspective: EMI Is an Engineering Design Issue

Most teams treat cables as accessories.

High-performing plants treat them as signal infrastructure.

Once this mindset shifts, Shielded Unshielded Cables EMI becomes a design parameter—not a troubleshooting surprise.

Engineering the Right Choice: Cable Selection That Stops EMI

Actionable steps that actually work:

- Map EMI sources before routing cables

- Use shielded cables near drives, motors, and RF zones

- Ensure 360° shield termination—not pigtails

- Separate power and signal routing physically

- Choose cable geometry matched to data speed

DOMADIA™ supports customers at the application level, not just the part number level.

Standards That Govern Shielded vs Unshielded Cables

When dealing with Shielded Unshielded Cables EMI, compliance matters:

- IEC 61156 / IEC 60228

- ISO/IEC 11801

- TIA/EIA standards

- RoHS & REACH compliance

DOMADIA™ aligns cable supply with relevant global and industrial standards.

Key Electrical & Mechanical Properties

Shielded Cable Properties

- Controlled impedance

- High noise attenuation

- Stable dielectric performance

- Superior grounding capability

Unshielded Cable Properties

- Flexible routing

- Lower cost

- Simpler termination

Understanding these differences keeps Shielded Unshielded Cables EMI under control across lifecycle use.

Technical Specifications (Typical Range)

- Conductor: Copper / Tinned Copper

- Shield Types: Foil, Braid, Foil + Braid

- Voltage Rating: 300–600V

- Temperature Range: -20°C to +105°C

- Jacket Materials: PVC, XLPE, LSZH

Specifications vary by application—DOMADIA™ customizes accordingly.

Shapes & Constructions Available

- Round shielded cables

- Flat signal cables

- Twisted pair constructions

- Multi-core shielded assemblies

- Custom harness-ready lengths

Every construction choice influences Shielded Unshielded Cables EMI behavior.

Environmental Impact: The Angle Nobody Talks About

Every cable replacement means:

- Scrapping material

- Recycling energy

- Downtime emissions

Because shielded cables last longer and reduce failures, Shielded Unshielded Cables EMI mitigation also becomes an environmental contribution. Fewer replacements mean less recycling—and less environmental load.

That’s responsible engineering, not marketing.

Soft Takeaway from DOMADIA™

Cables don’t fail loudly.

They fail quietly—through EMI, noise, and inconsistency.

DOMADIA™ treats Shielded Unshielded Cables EMI as a performance risk, not an afterthought—supporting industries where uptime, safety, and signal integrity matter.

Conclusion: Shielded Unshielded Cables EMI Is a Choice, Not Fate

The difference between stable operations and chronic troubleshooting often comes down to one decision.

Shielded Unshielded Cables EMI isn’t just about interference—it’s about control, predictability, and long-term cost. Choose accordingly.

EMI issues don’t announce themselves—they quietly drain performance, accuracy, and uptime.

If Shielded vs Unshielded cable decisions are impacting reliability, DOMADIA™ helps you eliminate signal risk at the source.

Signal failures don’t start at the controller—they start in the cable, Contact Us to eliminate EMI risks with engineered solutions from DOMADIA™.

#ShieldedUnshieldedCablesEMI #EMIProblems #IndustrialCables #SignalIntegrity #DOMADIA #CableEngineering #AutomationWiring #ReliableConnectivity

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.