Blogs

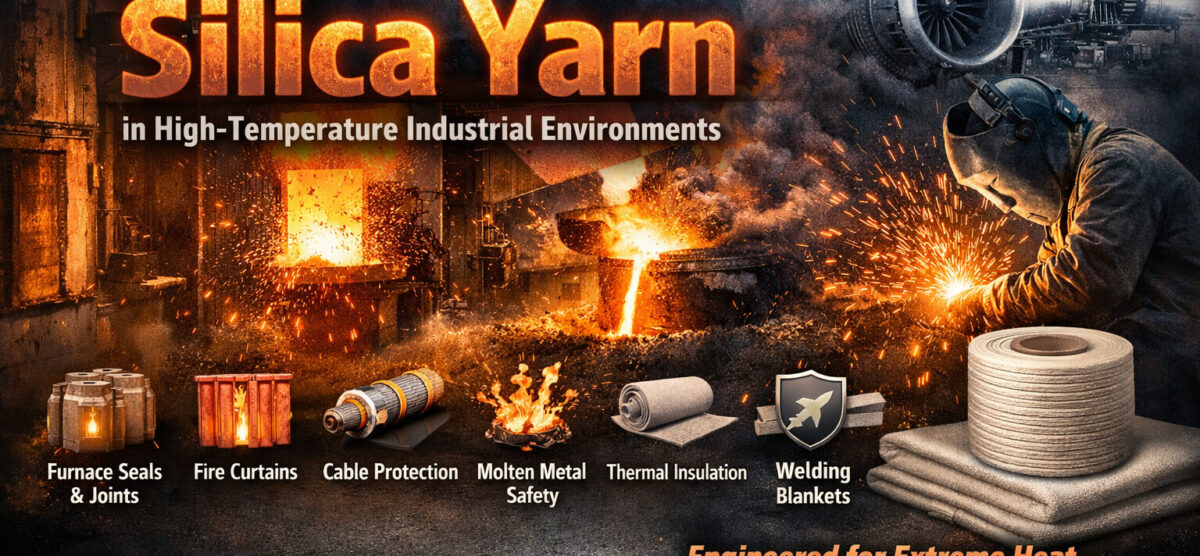

Silica Yarn Applications in High-Temperature Industries: 7 Critical Use Cases | DOMADIA™

Introduction: When Heat Becomes the Real Enemy

Silica Yarn Applications are rarely discussed until something fails.

A furnace seal leaks. A fire curtain degrades. An insulation wrap turns brittle. Production halts—not because of poor engineering, but because the chosen material could not survive sustained heat.

In high-temperature industrial environments, heat is not variable. It is a constant threat. And this is where Silica Yarn Applications quietly protect uptime, safety, and performance.

At DOMADIA™, silica yarn is supplied not as a commodity textile—but as a thermal risk-control material designed for industries where temperatures routinely exceed 1000°C.

What Is Silica Yarn?

Silica yarn is a high-temperature textile made from continuous amorphous silica fibers, typically containing ≥96% SiO₂. It is engineered to retain structural integrity, flexibility, and insulation performance under extreme thermal exposure.

Unlike fiberglass, silica yarn withstands higher temperatures with minimal shrinkage, low thermal conductivity, and exceptional chemical stability—making Silica Yarn Applications essential in critical zones.

Chemical Composition of Silica Yarn

- Silicon Dioxide (SiO₂): ≥96%

- Al₂O₃, CaO, MgO: Trace elements

- Organic Content: Minimal or heat-cleaned

- Melting Point: ~1650°C

This high-purity composition enables Silica Yarn Applications in direct flame contact and continuous high-heat operations.

Key Properties That Enable Silica Yarn Applications

- Continuous temperature resistance up to 1000°C

- Short-term exposure up to 1200°C

- Low thermal conductivity

- Excellent thermal shock resistance

- Non-combustible and low smoke emission

- High tensile strength even at elevated temperatures

These properties explain why Silica Yarn Applications outperform conventional glass-based textiles.

7 Critical Silica Yarn Applications in High-Temperature Industrial Environments

1. Furnace Door Seals & Expansion Joints

Silica Yarn Applications are vital in furnace doors, inspection ports, and expansion joints where repeated opening, closing, and thermal cycling occur. The yarn maintains sealing integrity without hardening or cracking.

Result: Reduced heat loss, safer operations, longer seal life.

2. Fire Curtains & Passive Fire Protection Systems

In steel plants, power stations, and chemical facilities, silica yarn is woven into fire curtains and barriers that must withstand sudden flame exposure.

Silica Yarn Applications here are about time—delaying fire spread and protecting assets long enough for control measures.

3. High-Temperature Cable Wrapping & Protection

Electrical cables routed near furnaces, kilns, or exhaust zones are wrapped with silica yarn braids and sleeves.

Silica Yarn Applications protect insulation from radiant heat, preventing electrical failure and unplanned shutdowns.

4. Molten Metal Splash & Foundry Protection

Foundries use silica yarn in protective fabrics, gloves, and covers exposed to molten aluminum, copper, and steel splashes.

Because silica does not melt or drip easily, Silica Yarn Applications significantly improve operator safety.

5. Thermal Insulation in Glass & Ceramic Manufacturing

Glass furnaces and ceramic kilns rely on silica yarn tapes and fabrics for insulation in extreme hot zones.

Here, Silica Yarn Applications prevent heat migration, stabilize temperatures, and improve energy efficiency.

6. Welding Blankets & Heat Shields

Welding operations near sensitive machinery require shielding that resists sparks, slag, and radiant heat.

Silica Yarn Applications in welding blankets provide higher temperature margins compared to fiberglass-based products.

7. Aerospace & Defense Thermal Barriers

In aerospace ground equipment, defense testing rigs, and thermal research setups, silica yarn fabrics serve as insulation layers and fire-resistant barriers.

These Silica Yarn Applications demand reliability—not replacement.

Technical Specifications (Typical)

- Filament Diameter: 6–9 microns

- Linear Density: Customizable

- Weave Compatibility: Braided, twisted, woven

- Thermal Shrinkage: <3% at 1000°C

- Electrical Conductivity: Non-conductive

Shapes & Forms Available

DOMADIA™ supplies silica yarn in multiple engineered formats to match specific Silica Yarn Applications:

- Twisted yarn

- Braided cords

- Woven tapes

- Sleeves & ropes

- Fabric-ready yarns

Standards & Compliance

- ASTM E84 (fire behavior testing – when fabricated)

- ISO fire resistance norms (application dependent)

- RoHS compliant

The Mindset Shift: Heat Is Not Occasional—It’s Permanent

Most failures occur because materials are chosen for average conditions, not worst-case exposure.

The smartest engineers specify Silica Yarn Applications not as upgrades—but as baseline protection in hot zones.

The Tangible Fix: Specify for Lifecycle, Not Just Cost

Silica yarn lasts longer, degrades slower, and requires fewer replacements. That means:

- Less downtime

- Fewer shutdowns

- Lower recycling frequency

- Reduced Environmental impact

This is not marketing—it’s operational math.

Conclusion: Why Silica Yarn Applications Matter

Silica Yarn Applications sit quietly inside furnaces, behind panels, and around cables—doing the work no one notices until it’s missing.

At DOMADIA™, silica yarn is positioned as thermal insurance for industries where heat is relentless and failure is expensive.

When extreme heat is non-negotiable, material choice decides uptime.

DOMADIA™ Silica Yarn solutions are engineered for continuous high-temperature reliability.

Contact Us to discuss the right silica yarn format for your application.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#SilicaYarnApplications #HighTemperatureMaterials #IndustrialSafety #ThermalInsulation #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.