Blogs

Single Core Wires in Power Distribution, Control Panels, and Industrial Systems

Introduction: When One Cable Decision Shut Down an Entire Plant

Single Core Wires are often selected without a second thought—until something goes wrong.

A large manufacturing plant faced repeated overheating issues in its main power panels. Motors tripped, insulation degraded faster than expected, and maintenance costs spiraled. The root cause wasn’t the load or the equipment—it was the wrong wire construction choice.

This is where the debate begins: Single Core vs Multi Core Wires.

For industrial power systems, this choice directly affects heat dissipation, reliability, safety, lifecycle cost, and downtime. Let’s break it down clearly, practically, and without guesswork.

Single Core Wires: Definition & Industrial Role

Single Core Wires consist of one solid or stranded conductor insulated individually. In industrial environments, they are widely used for high-current transmission, switchgear, bus duct connections, and heavy-duty power panels.

Single Core Wires dominate applications where thermal stability and current handling are non-negotiable.

Multi Core Wires: Definition & Industrial Role

Multi Core Wires combine two or more insulated conductors within a single outer sheath. They simplify routing, reduce clutter, and are commonly used for control circuits, instrumentation, and low-to-medium power distribution.

In automation-heavy industries, Multi Core Wires offer flexibility and organization—but not always raw power performance.

Chemical Composition: What’s Inside Matters

Both Single Core and Multi Core Wires rely on similar conductor materials, but usage intensity differs.

Conductors

- High-purity Electrolytic Tough Pitch (ETP) Copper

- Oxygen-Free Copper (for critical systems)

- Aluminum conductors (weight-sensitive installations)

Insulation Materials

- PVC (General industrial)

- XLPE (High-temperature, high-load systems)

- EPR & Silicone Rubber (Extreme environments)

At DOMADIA™, conductor purity and insulation chemistry are tightly controlled to ensure consistent electrical and thermal behavior.

Key Properties: Single Core vs Multi Core Wires

Electrical Properties

| Property | Single Core Wires | Multi Core Wires |

| Current Carrying Capacity | Very High | Moderate |

| Voltage Drop | Lower | Slightly Higher |

| Heat Dissipation | Excellent | Limited by sheath |

Mechanical Properties

| Property | Single Core Wires | Multi Core Wires |

| Flexibility | Low to Medium | High |

| Installation Ease | Requires planning | Easy routing |

| Stress Resistance | High | Moderate |

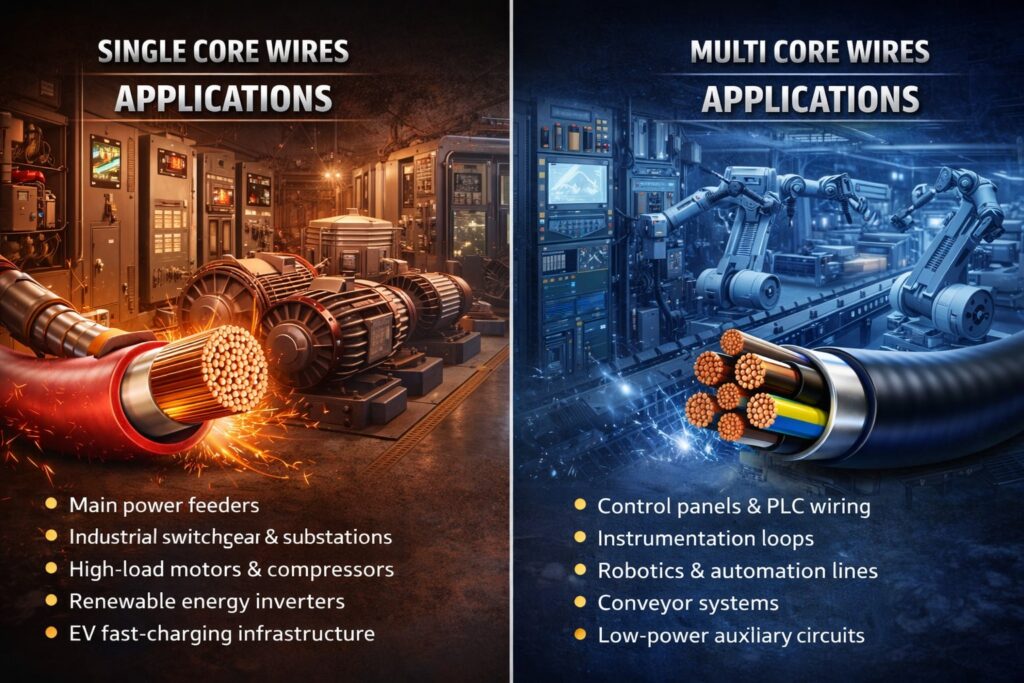

Industrial Applications: Where Each Wins

Single Core Wires Applications

- Main power feeders

- Industrial switchgear & substations

- High-load motors & compressors

- Renewable energy inverters

- EV fast-charging infrastructure

Multi Core Wires Applications

- Control panels & PLC wiring

- Instrumentation loops

- Robotics & automation lines

- Conveyor systems

- Low-power auxiliary circuits

Mindset Shift:

Using Multi Core Wires where Single Core Wires are required may reduce upfront cost—but increases heat stress, failure risk, and downtime over time.

Technical Specifications (Typical Industrial Range)

Single Core Wires

- Conductor Size: 1.5 sq mm to 1000 sq mm

- Voltage Rating: Up to 1.1 kV (higher on request)

- Temperature Rating: Up to 90°C (XLPE)

- Standards: IEC 60227, IEC 60502, IS 694

Multi Core Wires

- Cores: 2 to 61 cores

- Voltage Rating: 300/500 V to 1.1 kV

- Temperature Rating: 70°C–90°C

- Standards: IEC 60228, IS 694, UL standards

Standards & Compliance: Non-Negotiable in Industry

Industrial power systems demand compliance with:

- IEC / IS / UL standards

- Flame retardancy

- Low smoke & zero halogen (LSZH) where required

- Voltage drop and short-circuit withstand ratings

DOMADIA™ supplies industrial-grade wire materials aligned with global compliance expectations.

Shapes & Forms Available

Single Core Wires

- Solid round

- Stranded round

- Flexible rope-lay conductors

Multi Core Wires

- Round sheathed

- Flat cables

- Armored & unarmored variants

Lifecycle Cost Reality: The Hidden Equation

Here’s the part most engineers don’t calculate:

- Overheating causes insulation breakdown

- Failures trigger shutdowns

- Downtime costs exceed wire cost by multiples

Single Core Wires, though sometimes perceived as “less flexible,” often outlast Multi Core Wires in high-load systems, reducing replacement frequency and operational interruptions

Environmental Impact: Performance Is Sustainability

Every cable replacement involves:

- Copper extraction

- Energy-intensive manufacturing

- Transport & recycling emissions

Because Single Core Wires last longer under high loads, they reduce:

- Scrap generation

- Recycling cycles

- Environmental footprint

This longevity-driven sustainability aligns with DOMADIA™’s responsible material philosophy.

Conclusion: The Right Wire Is a Strategic Decision

Single Core Wires are not “basic”—they are strategic components in industrial power systems.

If your application involves:

- High current

- Continuous load

- Heat-intensive environments

- Zero tolerance for downtime

Then Single Core Wires are the safer, smarter, long-term choice.

At DOMADIA™, we don’t just supply materials—we help industries choose performance that lasts.

One wrong wire choice can cost months of downtime and repeated replacements.

Work with DOMADIA™ to select the right industrial wire solution—Contact Us and protect your power systems from avoidable failures.

Choose performance-driven materials with DOMADIA™-Contact Us to power your systems responsibly.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#SingleCoreWires #MultiCoreWires #IndustrialPower #ElectricalWires #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.