Blogs

Special Alloys: The Backbone of Modern Aerospace Engineering | DOMADIA™

Introduction: From Sky Dreams to Supersonic Realities

Every great leap in aerospace history — from the Wright Brothers’ wooden flyer to hypersonic jets — has been built not just on design innovation, but on the metals that made it possible. Behind every roaring jet engine, every heat-defying spacecraft, and every lightweight fuselage lies a family of unsung heroes: special alloys. At DOMADIA™, we understand that the future of flight isn’t just about aerodynamics; it’s about the materials that can survive extremes of pressure, heat, and stress. And that’s where special alloys in aerospace engineering truly take center stage.

The Science Behind Strength: What Are Special Alloys?

Special alloys are engineered metallic compounds designed to perform under extreme conditions — from cryogenic temperatures to blazing turbine cores. Unlike conventional metals, these alloys combine multiple elements to deliver unmatched performance.

Common Alloy Families in Aerospace

| Alloy Type | Key Elements | Primary Characteristics |

| Nickel-Based Superalloys | Ni, Cr, Co, Al, Ti | Exceptional heat & corrosion resistance (used in turbine blades) |

| Titanium Alloys (UNS R50400, R56400) | Ti, Al, V | Lightweight, strong, and oxidation-resistant (used in airframes & engines) |

| Aluminum-Lithium Alloys | Al, Li, Cu, Mg | Ultra-light, high fatigue resistance (used in fuselage panels) |

| Cobalt-Based Alloys | Co, Cr, W, Ni | Wear & temperature-resistant (used in afterburners, exhausts) |

Key Properties That Make Them Indispensable

| Property | Why It Matters |

| High Strength-to-Weight Ratio | Enables lighter aircraft without compromising safety. |

| Thermal Stability | Withstands turbine temperatures beyond 1,000°C. |

| Corrosion Resistance | Essential for long-term performance in varying atmospheres. |

| Fatigue & Creep Resistance | Maintains integrity under repeated stress cycles. |

| Machinability & Weldability | Allows for precise manufacturing and maintenance. |

Chemical Composition & Standards

Nickel-Based Superalloys (e.g., Inconel 718 – UNS N07718)

- Composition: Ni (50–55%), Cr (17–21%), Fe (Balance), Nb, Mo, Ti, Al

- Standards: ASTM B637 / AMS 5662 / ISO 6208

- Temperature Limit: Up to 700°C

Titanium Alloy (Ti-6Al-4V – UNS R56400)

- Composition: Ti (Balance), Al (6%), V (4%)

- Standards: ASTM B348 / AMS 4928 / ISO 5832-3

- Temperature Limit: Up to 400°C

Cobalt Superalloy (Haynes 188 – UNS R30188)

- Composition: Co (Balance), Cr (22%), Ni (22%), W (14%), Fe (3%)

- Standards: AMS 5608 / ASTM B435

- Temperature Limit: Up to 1,090°C

Applications Across Aerospace Engineering

1. Jet Engine Components

- Turbine blades, combustors, and nozzles use nickel and cobalt superalloys for unmatched heat resistance.

- DOMADIA™ supplies precision-grade alloys that withstand the harshest thermal cycles.

2. Airframe & Structural Parts

- Titanium alloys offer strength comparable to steel but 45% lighter, enhancing flight efficiency.

- Used in landing gear, fuselage, and wing structures.

3. Spacecraft & Rocket Systems

- Nickel-titanium (NiTi) shape memory alloys are used in deployable satellite structures.

- High-purity titanium alloys resist corrosion from rocket fuels and cryogenic conditions.

4. Defense & Hypersonic Vehicles

- Cobalt-based alloys endure extreme temperatures during re-entry or supersonic flight.

- DOMADIA™ supports defense projects where reliability is mission-critical.

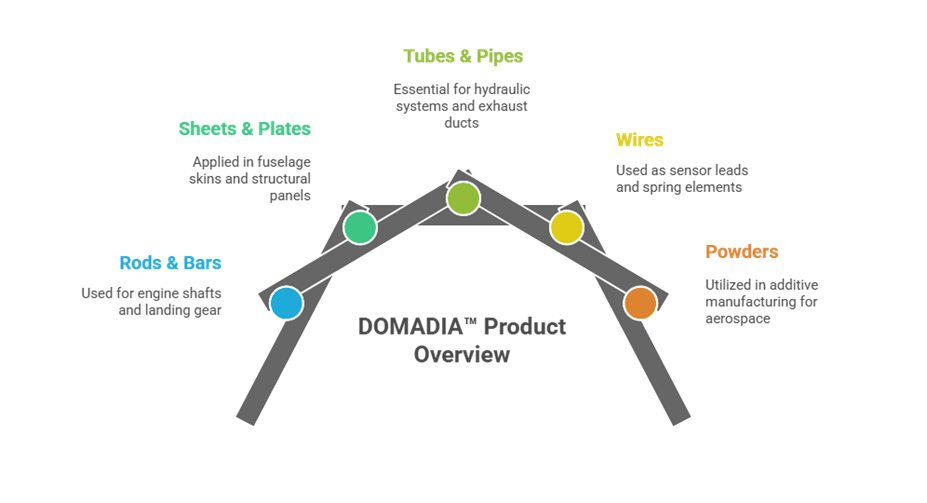

Shapes & Forms Available from DOMADIA™

The Environmental Edge

Using long-life special alloys reduces material wastage, maintenance frequency, and fuel consumption — all of which lower the carbon footprint of modern aircraft.

At DOMADIA™, sustainability meets innovation — every high-performance alloy we deliver is a step toward a cleaner, more efficient aviation future.

Conclusion: The Future of Flight is Alloyed with Innovation

From the quiet hum of electric aircraft to the thunder of reusable rockets, one truth remains constant — special alloys in aerospace engineering form the backbone of progress.

At DOMADIA™, we don’t just supply alloys — we engineer possibilities that help humankind fly higher, faster, and cleaner.

Looking for aerospace-grade alloys that redefine performance?

🔗 Visit DOMADIA™ — where every metal is engineered for the skies.

🔗 Visit domadia.net to explore our sustainability initiatives and e-waste recovery solutions.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#AerospaceEngineering #SpecialAlloys #NickelAlloys #TitaniumAlloys #DOMADIA #AviationMaterials #DefenseTechnology #InnovationInFlight