Blogs

The Future of Metal Recycling: Innovations Driving Sustainability

Introduction — A Turning Point for Waste & Metals

A decade ago, scrapyards were places where discarded metal had little future beyond melting down to basic grade. Today, we stand at a crossroads: soaring demand for critical metals, dwindling ore grades, and climate urgency have turned scrap into a strategic asset. The future of metal recycling is not just about waste disposal — it’s about closing the loop, unlocking value, and rethinking how metals serve humanity.

Consider this scenario: your smartphone, long discarded, contains traces of gold, palladium, copper, and rare earths. With the right process, those metals can be refined and fed back into new devices—reducing mining, emissions, and dependence on geopolitically constrained sources. That possibility is no longer hypothetical — it’s becoming operational in labs and plants around the world.

In this blog, we dive into the chemical principles, emerging technologies, standards & norms, applications, and technical properties that define how metal recycling is evolving — with a nod to how DOMADIA™ envisions playing a role in this transformation.

Why Metal Recycling Matters — the Big Picture

Finite Resources, Rising Demand

- Many ores are now of lower grade than before, meaning more waste per ton of metal extracted.

- Demand for metals like copper, lithium, cobalt, nickel — key to electrification, batteries, renewable energy — is skyrocketing.

- Recycling metal typically consumes far less energy than primary production: e.g. recycled aluminum can save ~95 % energy versus mining and refining bauxite.

Environmental & Climate Impact

- Avoided mining reduces land disruption, habitat loss, and tailings risk.

- Lower carbon footprints: recycling emits far less CO₂ than primary production.

- Reduces landfill burden, toxic leachates, and secondary pollution.

Circular Economy & Closed-Loop Systems

- In a circular economy, materials are kept in use as long as possible, then reclaimed and reprocessed.

- Closed-loop recycling means that a metal can be reused repeatedly without quality loss (or with minimal processing).

Thus, the future of metal recycling is central to achieving resource security, climate goals, and sustainable industry.

Chemical & Metallurgical Underpinnings

To appreciate the innovations, it’s useful to recall key chemical and metallurgical concepts in metal recovery.

Key Chemical Principles

- Redox reactions: Many recovery processes rely on oxidation or reduction steps to liberate metal ions or reduce metal salts to elemental metal.

- Leaching & solvent extraction: For more complex wastes (like e-waste), acids or other reagents dissolve metals selectively, followed by separation.

- Electrowinning / electrodeposition: After leaching, metals can be plated out back to pure metallic form.

- Smelting & refining: High-temperature processes melt scrap and adjust composition (e.g. removing impurities through slagging).

- Bioleaching / biometallurgy: Use of bacteria or microorganisms to mobilize or strip metals under milder conditions — especially for low-grade or complex waste.

Alloy Behavior, Impurities & Tolerance

- Recycled metals often include impurity elements (e.g. iron in aluminum scrap). Controlling microstructure and refining methods is essential to ensure mechanical integrity.

- Example: recent research on direct strip casting of recycled aluminum demonstrated an improved tolerance to iron impurities, avoiding coarse intermetallic phases, thus preserving alloy properties. a

Understanding these principles helps us see where innovation can break trade-offs (e.g. purity vs cost, energy vs yield).

Innovations & Technologies Shaping the Future

Here is where the real transformation is happening.

1. Smart Sorting & AI / Automation

- Spectroscopic sorting (XRF, LIBS, NIR, hyperspectral imaging): Enables fast, non-contact identification of metal types and alloy grades.

- Robotics + Computer Vision + AI: Automated pickers, sorting robots reduce contamination, improve throughput, and lower labor cost.

- Digital Twins & Predictive Maintenance: Modeling and real-time optimization help reduce downtime and energy waste.

2. Advanced Recycling Processes

- Hydrometallurgy / Low-temperature processing: Shifting away from high-temperature smelting, using milder chemical extraction to reduce emissions and energy.

- Electrochemical / Electrowinning enhancements: More efficient plating, lower overpotentials, better electrodes.

- Bioleaching / Microbial recovery: Using microbes to dissolve metals from complex waste streams (e.g. e-waste, mining tailings) in a gentler, more sustainable manner.

- Induction furnace & smart melting: Improved furnace design, better heat control, and waste-heat recovery.

3. Urban Mining & Decentralized Recovery

- Urban mining: Treating cities as mines — extracting metals from e-waste, aging infrastructure, demolished buildings.

- Localized / micro recycling hubs: Smaller, modular units can process scrap near the source, reducing transport, improving flexibility.

- Example: Taiwan is leveraging urban mining to reclaim metals like zinc from city infrastructure and waste streams.

4. Traceability, Blockchain & Supply Chain Transparency

- Blockchain and distributed ledgers can track metal batches from scrap to reuse, ensuring provenance, preventing fraud, and enabling responsible sourcing.

- Digital labeling / IoT sensors help monitor purity, lifecycle, and end-of-life recovery pathways.

5. Integrating Renewable Energy & Decarbonization

- Running recycling plants on solar, wind, or low-carbon grids reduces the carbon footprint.

- Technologies like PeroCycle (carbon recycling for steelmaking) aim to integrate recycled inputs with reduced emissions.

- Some companies are investing to dramatically expand recycled feedstock processing, e.g. Japan’s JX Advanced Metals will raise its pre-treatment capacity by 50 % to increase recycled material use.

6. Precious Metal Recovery & E-Waste Focus

- E-waste contains high-value metals (gold, palladium, platinum, rare earths). Advanced methods aim to extract them efficiently.

- Royal Mint’s new plant in the UK is recovering gold, silver, copper, palladium from printed circuit boards using low-temperature, low-contamination processes.

Standards, Certifications & Regulatory Frameworks

For recycling to scale reliably, consistent standards and policies are essential.

- ISO and material standards: Standards for recycled metal quality, allowable impurity levels, traceability protocols.

- Extended Producer Responsibility (EPR) mandates: requiring manufacturers to take back products end of life.

- Certifications & audits: Certification schemes for “responsible recyclers” help buyers trust recycled-grade metals.

- Government incentives & subsidies: Tax credits or carbon offsets for using recycled content.

- Global trade & regulation: Controls to prevent “greenwashing” in recycled claims and to regulate cross-border scrap movement.

Properties, Specs & Performance of Recycled Metals

One concern: will recycled metals match the performance of virgin ones?

- Mechanical & chemical integrity: With proper refinement and control, recycled metals can match virgin metal properties.

- Alloy retention: Preserving exact alloy chemistry (e.g. in specialty steels, aluminum alloys) requires careful blending and purification steps.

- Fatigue, corrosion resistance: Microstructural control is key — impurities, inclusions, or segregation must be minimized.

- Purity & trace element limits: For high-tech uses (electronics, aerospace), extremely low impurity tolerances are required.

Technical specs might look like:

| Parameter | Virgin Metal | High-Quality Recycled Metal (target) |

| Purity (wt %) | 99.90+ | ≥ 99.80 (or better depending on application) |

| Impurity (e.g. Fe in Al) | ≤ 0.1% | ≤ 0.1% (or matched to spec) |

| Mechanical properties | Specified (Yield, UTS, elongation) | Within ±5% of virgin |

| Residual inclusions | Minimal | Tight control via filtration, degassing |

| Acceptable trace ppm (rare earths, heavy metals) | ≤ specified | Meet same thresholds |

As technologies like strip casting (for aluminum) evolve, the gap narrows — even recycled alloys can be almost indistinguishable from primary ones.

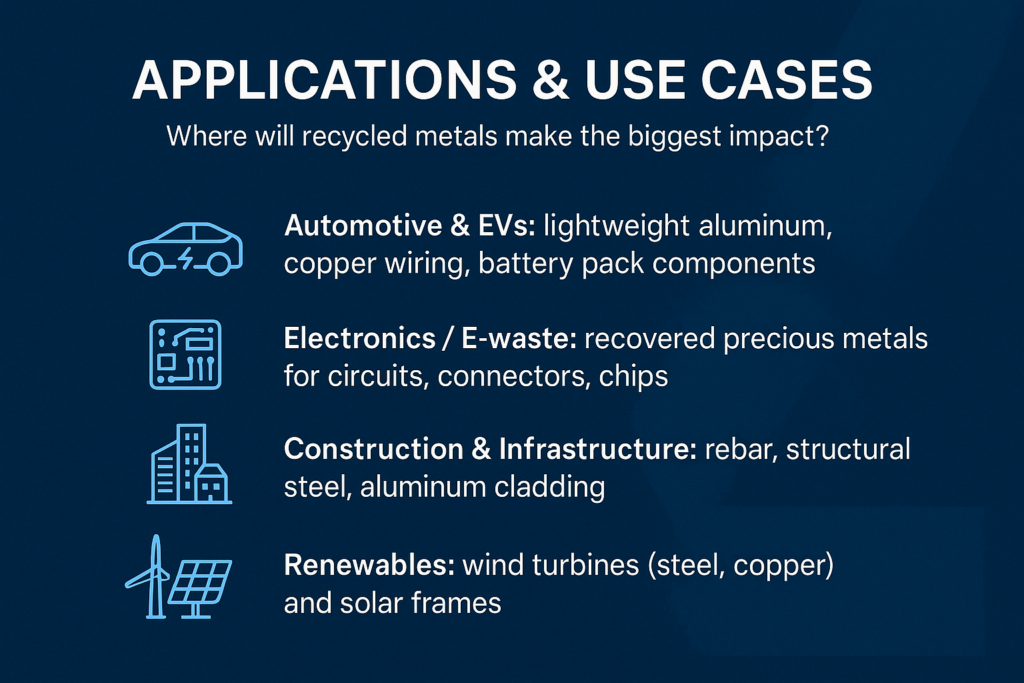

Applications & Use Cases

Where will recycled metals make the biggest impact?

- Automotive & EVs: lightweight aluminum, copper wiring, battery pack components.

- Electronics / E-waste: recovered precious metals for circuits, connectors, chips.

- Construction & Infrastructure: rebar, structural steel, aluminum cladding.

- Aerospace & Defense (where purity is critical) — only top-tier recycled metal may qualify.

- Renewables: wind turbines (steel, copper) and solar frames.

- New domains: 3D-printed metal parts, advanced electronics where recycled feedstock becomes feedstock for additive manufacturing.

Challenges & Barriers (and How Innovation Addresses Them)

No transformation is without friction. Some challenges, and innovation responses:

| Challenge | Impact | Mitigation / Innovation |

| Mixed, contaminated scrap | Low yield, high cost for purification | Better sorting, AI, robotics, pre-treatment steps |

| Impurity buildup in closed loops | Degraded alloy properties over cycles | Purification, dilution with fresh feed, periodic “reboot” |

| High capital cost of advanced plants | Barrier to adoption | Modular / scalable units, shared infrastructure, co-investment |

| Regulatory fragmentation | Inconsistent practices, trading issues | Standardization, certification, policy alignment |

| Energy & carbon footprint | Undermines sustainability goal | Power recycling plants with renewables, integrate waste heat use |

| Traceability & trust | Buyers may distrust recycled quality | Blockchain, chain-of-custody systems, certified recyclers |

Role & Vision for DOMADIA™ in the Future of Metal Recycling

As DOMADIA™ charts its path in this evolving landscape, here’s how the brand can play a role:

- R&D & Pilot Projects: Invest in pilot plants for bioleaching, modular recycling units, AI-based sorting — to build hands-on expertise.

- Circular Design Services: Offer product design consultancy so that products are easier to disassemble, demanufacture, and reclaim.

- Traceability Platform: Develop or partner for a blockchain-based metal provenance system under the DOMADIA™ brand.

- Partnerships & Collaborations: With governments, research institutes, recyclers, and OEMs to scale infrastructure.

- Marketing & Brand Trust: Label products with certified “recycled-metal content by DOMADIA™” — giving customers confidence in green sourcing.

- Education & Advocacy: Host webinars, workshops, and publications to raise awareness of best practices, standards, and investment in recycling.

By doing so, DOMADIA™ becomes more than a metals provider — it becomes a catalyst for sustainable materials ecosystems.

Looking Ahead: What Will the Future Look Like?

Here are some likely trajectories for the future of metal recycling:

- Near-100 % recovery of high-value metals from e-waste and complex wastes.

- Distributed recycling micro-plants in urban zones — “recycling at source” becomes commonplace.

- Integration with Industry 4.0 / circular digital platforms — smart factories, automated feedback loops, AI optimization.

- Hybrid supply chains mixing recycled and primary metal depending on demand cycles.

- Standards-mandated recycled content in many new metal products (e.g. “≥ 30 % recycled copper” requirements).

- Decarbonized recycling — powering operations with renewables and coupling with carbon capture.

- Global recycling networks — arbitrage across regions depending on scrap availability, regulation, and tech deployment.

Conclusion & Call to Action

The future of metal recycling is not a distant dream — it’s in motion today. Through innovations in sorting, metallurgy, bioleaching, urban mining, and digital traceability, we are closing the loop on metals and redefining sustainability in the industrial age.

For brands like DOMADIA™, this presents a unique opportunity: to lead the charge, differentiate with certified recycled content, and build ecosystems around resource circularity.

Takeaway / Actionable Thought:

Start small — pilot a local recycling cell, adopt traceability on one product line, or partner with a research lab. But begin. The shift from linear to circular is not optional — it defines competitiveness, reputation, and legitimacy in tomorrow’s world.

Connect with our sustainability team today.

Partner with DOMADIA™ to build smarter, cleaner, and circular metal ecosystems.

Let’s innovate sustainability together — from concept to certified recycled metal supply.

Explore Now on DOMADIA.net.

Follow us on LinkedIn: https://www.linkedin.com/in/kairav

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#DOMADIA #RecyclingInnovation #SustainableFuture #CircularEconomy #CleanManufacturing #MetalRecycling #EcoFriendlyTech #UrbanMining #EwasteRecycling #GreenIndustry