Blogs

Thermal Shock Resistant Alloys That Stop Cracks, Downtime & Chemical Attack

Introduction: When One Crack Shuts Down Everything

Thermal Shock Resistant Alloys are rarely discussed—until a crucible cracks mid-cycle.

In a real foundry scenario, a production manager once traced three consecutive shutdowns to the same root cause: rapid temperature swings combined with chemical slag attack. The alloy didn’t fail dramatically—it failed quietly, with microcracks that grew with every heat cycle. Downtime multiplied. Scrap increased. Confidence dropped.

This is where the mindset must change.

The Mindset Shift: Heat Resistance Is Not Enough

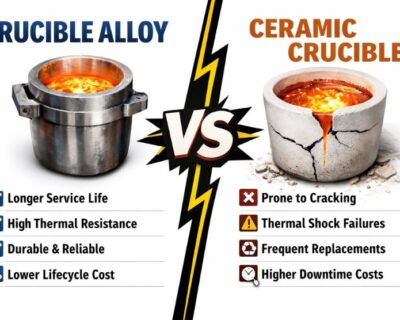

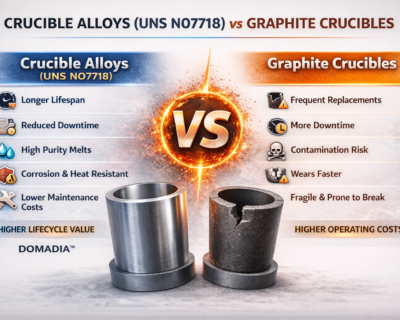

Many engineers still select crucibles based only on maximum temperature ratings. That approach is outdated. Thermal Shock Resistant Alloys are not defined by how hot they can get, but by how well they survive repeated heating and cooling without cracking. True performance lies in controlled expansion, chemical stability, and microstructural integrity.

At DOMADIA™, these advanced materials are positioned as risk-control solutions—engineered to protect operations from unexpected failure, not treated as routine consumables.

What Makes Thermal Shock Resistant Alloys Different?

1. Controlled Thermal Expansion

Thermal Shock Resistant Alloys are engineered to handle steep temperature gradients. Low and predictable coefficients of thermal expansion reduce internal stress during rapid heat-up and quenching cycles.

2. Microstructural Stability

Grain structure matters. Fine, stable grains prevent crack initiation. DOMADIA™ supplies Thermal Shock Resistant Alloys with tightly controlled metallurgical consistency to prevent weak zones.

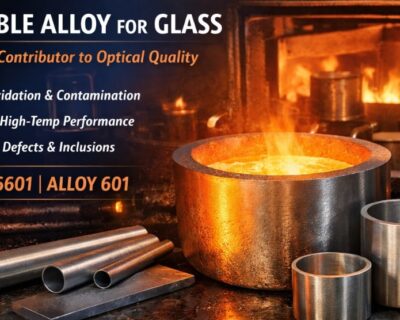

3. Chemical Inertness at High Temperature

Molten metals, fluxes, and slags aggressively attack inferior materials. Thermal Shock Resistant Alloys resist oxidation, carburization, and corrosive penetration—preserving wall thickness and strength.

Chemical Composition: Designed for Survival

The chemistry behind Thermal Shock Resistant Alloys is not accidental.

Typical alloying elements include:

- Nickel (Ni): Maintains strength at elevated temperatures

- Chromium (Cr): Forms protective oxide layers against chemical attack

- Iron (Fe): Structural balance and toughness

- Molybdenum (Mo): Enhances resistance to localized corrosion

- Controlled carbon levels: Prevents brittleness during thermal cycling

DOMADIA™ ensures each batch of Thermal Shock Resistant Alloys meets strict composition tolerances to guarantee repeatable performance.

Properties That Prevent Cracks and Failure

Key Mechanical & Thermal Properties

- High thermal shock resistance

- Excellent hot strength retention

- Low crack propagation tendency

- Superior oxidation resistance

- Stability under cyclic thermal stress

These properties allow Thermal Shock Resistant Alloys to outperform conventional crucible materials where temperature fluctuation is unavoidable.

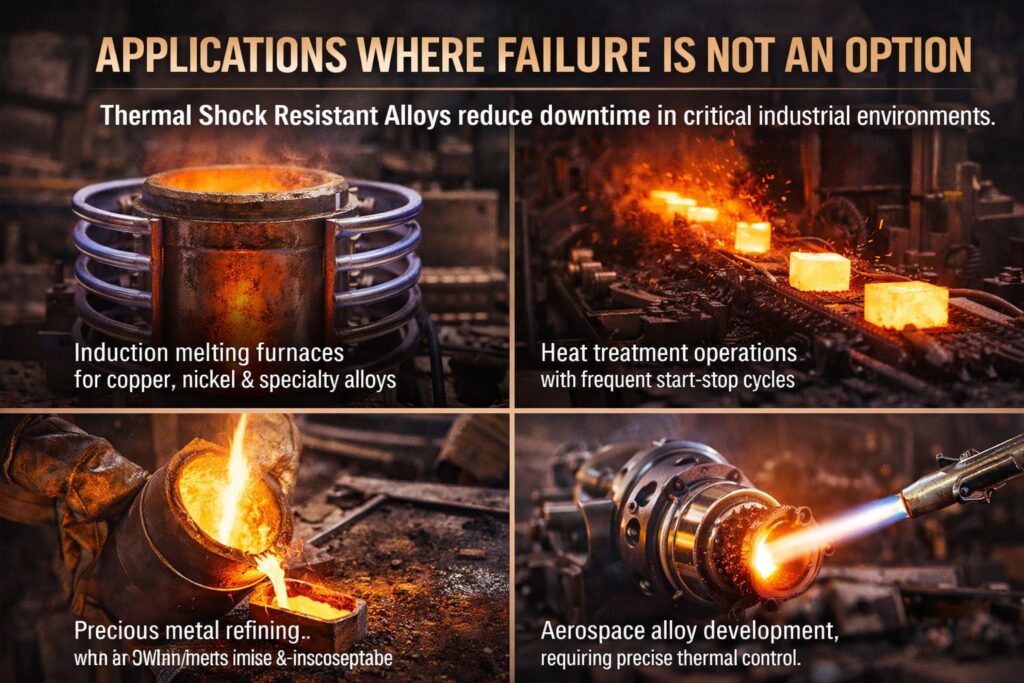

Applications Where Failure Is Not an Option

Thermal Shock Resistant Alloys are essential in environments where downtime is expensive:

- Induction melting furnaces for copper, nickel, and specialty alloys

- Heat treatment operations with frequent start-stop cycles

- Precious metal refining, where contamination risk is unacceptable

- Aerospace alloy development, requiring precise thermal control

- Chemical processing furnaces exposed to reactive atmospheres

Across these sectors, Thermal Shock Resistant Alloys reduce unplanned shutdowns and extend service life.

Standards & Quality Benchmarks

DOMADIA™ supplies Thermal Shock Resistant Alloys aligned with global expectations, including:

- ASTM material standards (where applicable)

- UNS-grade traceability

- Internal metallurgical validation for thermal cycling performance

Each lot of Thermal Shock Resistant Alloys is evaluated not just for chemistry—but for real-world durability.

Technical Specifications (Typical Range)

- Operating temperature capability: Up to 1,200°C+ (grade dependent)

- Thermal expansion: Optimized for cyclic heating

- Density: Engineered for structural balance

- Oxidation resistance: High at elevated temperatures

Exact specifications vary by grade, and DOMADIA™ supports customers in selecting the right Thermal Shock Resistant Alloys for their process.

Shapes Available

DOMADIA™ supplies Thermal Shock Resistant Alloys in multiple forms to suit furnace and crucible designs:

- Cylindrical crucibles

- Custom-fabricated crucible shapes

- Plates and liners

- Rings and sleeves

- Precision-machined components

This flexibility ensures Thermal Shock Resistant Alloys integrate seamlessly into existing systems.

The Tangible Fix: How to Reduce Downtime Today

If cracks, erosion, or unpredictable failures are recurring, the fix is not maintenance—it is material selection. Switching to Thermal Shock Resistant Alloys reduces replacement frequency, stabilizes production schedules, and lowers long-term cost of ownership.

Environmental Impact: Strength That Reduces Scrap

Frequent failure means frequent recycling—and recycling consumes energy. Because Thermal Shock Resistant Alloys last longer, they reduce scrap generation and remelting cycles. This longevity is DOMADIA™’s quiet contribution to industrial sustainability.

Conclusion: Performance You Don’t Notice—Until It’s Gone

The best Thermal Shock Resistant Alloys are the ones you never have to think about. They don’t crack. They don’t contaminate. They don’t fail under pressure. They simply work—cycle after cycle. For operations where reliability defines profitability, Thermal Shock Resistant Alloys are not an upgrade; they are insurance.

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.

Stop Cracks Before They Start

Unplanned furnace shutdowns begin with the wrong material choice.

Thermal Shock Resistant Alloys from DOMADIA™ are engineered to survive extreme cycling, chemical attack, and real-world abuse.

Explore proven alloy solutions with DOMADIA™ Contact Us to secure crucible performance that lasts.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#ThermalShockResistantAlloys #CrucibleAlloys #HighTemperatureMaterials #FurnaceReliability #IndustrialMetallurgy #ChemicalResistance #HeatTreatment #FoundrySolutions #DOMADIA

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.