Blogs

Thermocouple Cable Insulation: The Most Ignored Cause of Temperature Measurement Failure

Thermocouples are widely used for industrial temperature measurement in furnaces, reactors, turbines, kilns, and processing plants.

However, when thermocouple readings become inaccurate or fail, the problem is often blamed on the thermocouple type itself.

That assumption is wrong.

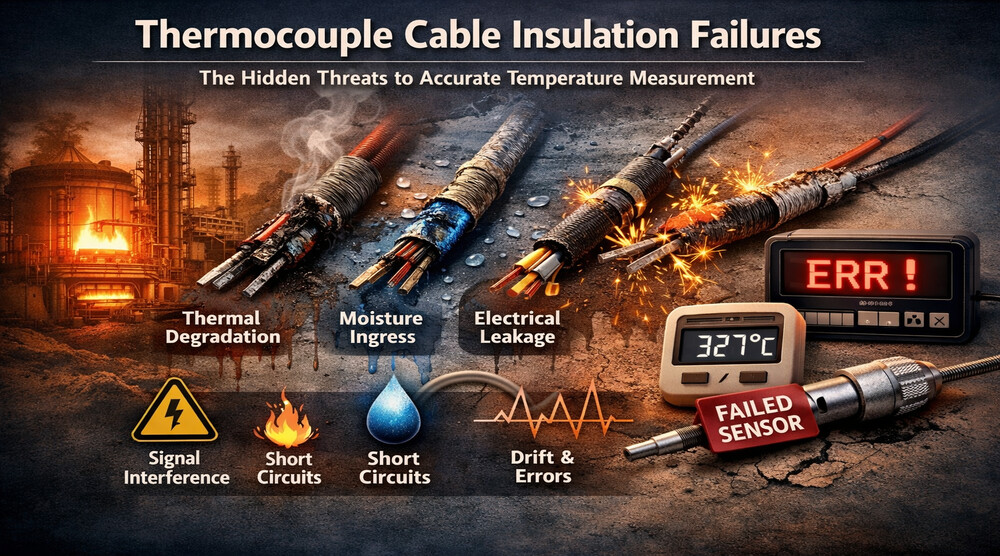

In real industrial operating conditions, thermocouple cable insulation failure occurs long before the thermoelement degrades. Choosing the wrong insulation material is one of the most common—and costly—mistakes in temperature sensing systems.

Why Thermocouple Insulation Matters More Than You Think

A thermocouple works by generating microvolt-level signals. Because the signal strength is extremely low, the system is highly sensitive to Thermocouple Cable Insulation quality.

Even minor issues such as:

- Leakage current

- Moisture ingress

- Thermal degradation of insulation

can directly cause signal distortion, drift, or total measurement failure — clearly demonstrating why Thermocouple Cable Insulation is critical for accurate temperature measurement.

For example, a Type K thermocouple rated up to 1260 °C becomes useless if the cable insulation starts to carbonize at 400 °C. In such cases, the limitation is not the thermocouple—but the Thermocouple Cable Insulation material itself.

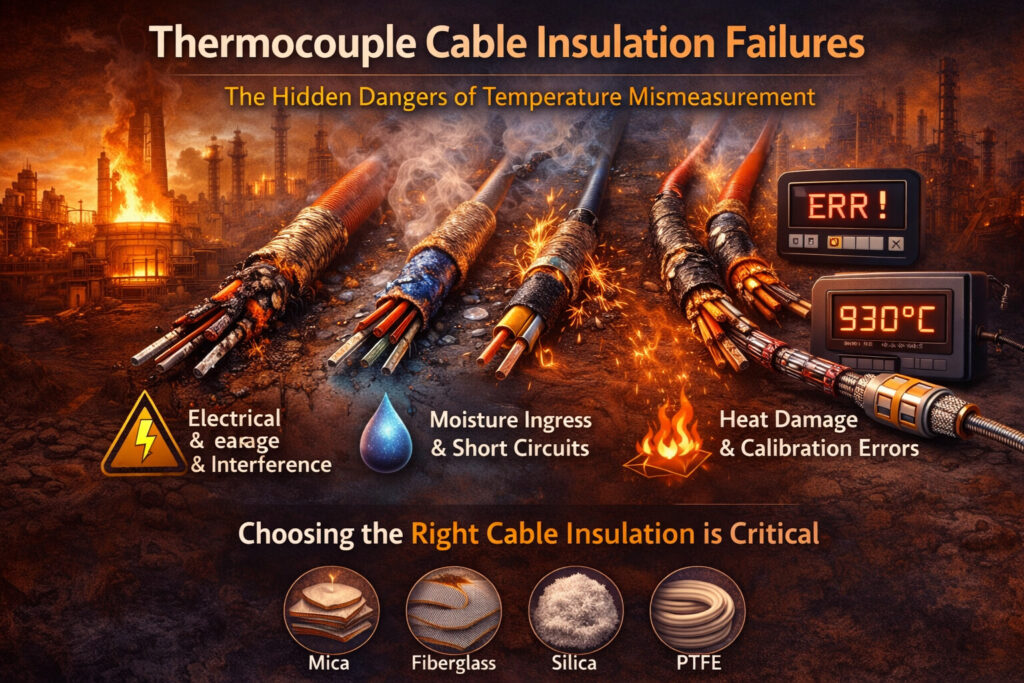

Common Thermocouple Cable Insulation Materials Explained

Polyimide (Kapton®) Insulation

Polyimide insulation is used where space constraints and electrical integrity are critical. It offers excellent dielectric strength and chemical resistance, making it suitable for aerospace, electronics, and vacuum applications. However, it is not recommended for sustained high-temperature furnace environments.

Fiberglass / E-Glass Insulation

Fiberglass (E-glass) insulation is the most widely used thermocouple cable insulation in industrial applications. It provides good thermal resistance and mechanical strength but can absorb moisture unless properly treated, which may affect long-term accuracy.

Mica Tape Insulation

Mica tape insulation is commonly used in steel plants, cement kilns, and glass manufacturing. It offers excellent high-temperature stability, flame resistance, and electrical insulation, but it is relatively stiff and mechanically fragile.

Silica Yarn Insulation

Silica insulation is essential for very high-temperature applications above 900 °C. It provides low thermal conductivity and excellent heat resistance, making it ideal for glass furnaces and ceramic kilns. The main drawback is brittleness and handling difficulty.

PTFE (Teflon®) Insulation

PTFE insulation is selected primarily for its chemical resistance and moisture immunity, not for extreme heat. It is widely used in chemical processing, pharmaceutical, and food industries where corrosive environments or hygiene standards are critical.

Mineral Insulated (MI) Thermocouple Cables

Mineral insulated thermocouple cables represent the highest reliability solution for critical temperature measurement, especially when Thermocouple Cable Insulation performance determines system stability. Using magnesium oxide (MgO) inside a metal sheath, this advanced Thermocouple Cable Insulation design provides superior resistance to extreme heat, vibration, pressure, and chemically aggressive environments.

As a result, Thermocouple Cable Insulation in MI cables ensures long-term measurement accuracy, electrical integrity, and durability even in the most demanding industrial conditions.

| Thermocouple Type | Common Insulation Choices | Why |

| J (Iron/Constantan) | Fiberglass, PTFE | Limited temp → insulation not the bottleneck |

| K (Chromel/Alumel) | Fiberglass, Mica, MgO | Oxidation + wide temp range |

| T (Copper/Constantan) | PTFE, FEP | Moisture resistance critical |

| E (Chromel/Constantan) | Fiberglass, Polyimide | High EMF → good dielectric needed |

| N (Nicrosil/Nisil) | Mica, MgO | Designed for high-temp stability |

| R / S / B (Platinum-based) | Silica, Ceramic, MgO | Extreme temps, zero contamination tolerance |

| Insulation Material | Continuous Temp Range | Short-Term Peak | Key Properties | Typical Applications |

| PVC (baseline reference) | –40 to 105 °C | ~120 °C | Cheap, flexible, poor heat resistance | Control panels, low-temp instrumentation |

| Polyimide Tape (Kapton®) | –200 to 260 °C | ~300 °C | Thin, excellent dielectric strength, chemical resistant | Aerospace, compact sensors, vacuum environments |

| Fiberglass / E-Glass Yarn | –50 to 400 °C | ~480 °C | Good mechanical strength, abrasion resistant | General industrial furnaces, heaters |

| Mica Tape | –50 to 700 °C | ~800 °C | Excellent thermal stability, flame resistant | Steel plants, kilns, high-heat zones |

| Silica Yarn (High-Purity) | –50 to 1000 °C | ~1200 °C | Very low thermal conductivity, brittle | Glass furnaces, ceramic kilns |

| PTFE (Teflon®) | –200 to 260 °C | ~280 °C | Chemically inert, moisture proof, flexible | Chemical plants, pharma, food |

| PFA / FEP (Fluoropolymers) | –200 to 260 °C | ~300 °C | Better flex life than PTFE | Cleanrooms, corrosive atmospheres |

| Ceramic Fiber Braid | 0 to 1200 °C | ~1300 °C | Extreme heat resistance, zero flexibility | Furnace hot zones, R&D labs |

| Mineral Insulated (MgO) | –200 to 1100 °C | ~1300 °C | Hermetically sealed, vibration resistant | Nuclear, turbines, critical processes |

When selecting a thermocouple for industrial temperature measurement, insulation choice is just as important as thermocouple type. Ignoring insulation properties can lead to inaccurate readings, premature sensor failure, and costly downtime.

For expert guidance on selecting the right thermocouple cable insulation for your application, please do not hesitate to contact us.

Temperature accuracy is not optional — it’s operational survival. Don’t let insulation failure quietly damage your process control, product quality, and equipment life.

Upgrade to precision-engineered thermocouple cable solutions designed for extreme heat, electrical stability, and long-term reliability with DOMADIA™.

Protect your temperature accuracy before insulation failure costs you production, precision, and performance — Connect With Us today.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

Directly whatsapp us for an Enquiry: https://wa.link/kairav

#ThermocoupleCableInsulation #TemperatureMeasurement #IndustrialSensors #ProcessInstrumentation #HighTemperatureApplications #FurnaceMonitoring #SensorReliability #ThermalInsulation

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.