Blogs

Titanium Powders in 3D Printing: The Future of Manufacturing

In the world of advanced manufacturing, 3D printing with titanium powders has emerged as a game-changer. From aerospace rockets to medical implants, titanium is no longer just a high-performance material—it’s the future of design freedom, precision, and sustainable production.

At DOMADIA™, we believe titanium powders are shaping tomorrow’s industries today. But what makes titanium so unique in additive manufacturing? Let’s dive in.

What is Titanium Powder for 3D Printing?

Titanium powder is a fine metallic powder created specifically for additive manufacturing (AM) processes like Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Direct Metal Laser Sintering (DMLS). Its high strength-to-weight ratio, biocompatibility, and corrosion resistance make it one of the most sought-after materials for high-tech industries.

Chemical Composition of Titanium Powders

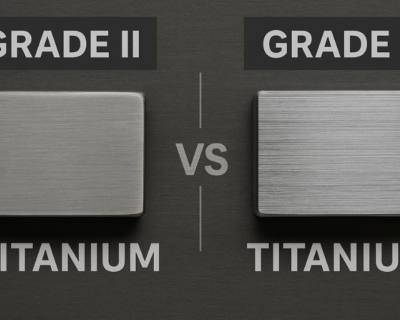

Most titanium powders used in 3D printing are based on UNS R50250 (Grade 2 Titanium) or UNS R56400 (Ti-6Al-4V alloy).

- Pure Titanium (Grade 2):

Ti: ≥ 99%

Fe: ≤ 0.3%

O: ≤ 0.25%

C, N, H: Trace amounts - Ti-6Al-4V (Grade 5):

Titanium (Ti): Balance

Aluminum (Al): 5.5–6.75%

Vanadium (V): 3.5–4.5%

Oxygen: ≤ 0.2%

Iron: ≤ 0.25%

These controlled compositions ensure uniform particle size, purity, and flowability, which are critical for reliable 3D printing.

Properties of Titanium Powder

✔ High Strength-to-Weight Ratio – Stronger than steel, yet 45% lighter.

✔ Biocompatible – Safe for medical implants and prosthetics.

✔ Corrosion Resistant – Withstands harsh environments like seawater and aerospace conditions.

✔ Thermal Stability – Performs well at extreme temperatures.

✔ Excellent Fatigue Resistance – Ensures long-lasting durability.

Technical Specifications

- Particle Size Range: 15–45 μm (for SLM/DMLS), 45–100 μm (for EBM)

- Density: ~4.43 g/cm³

- Sphericity: ≥ 95% (improves powder flowability)

- Purity: ≥ 99.5%

- Standards: ASTM F2924 (for Ti-6Al-4V), ASTM F67 (for CP Titanium)

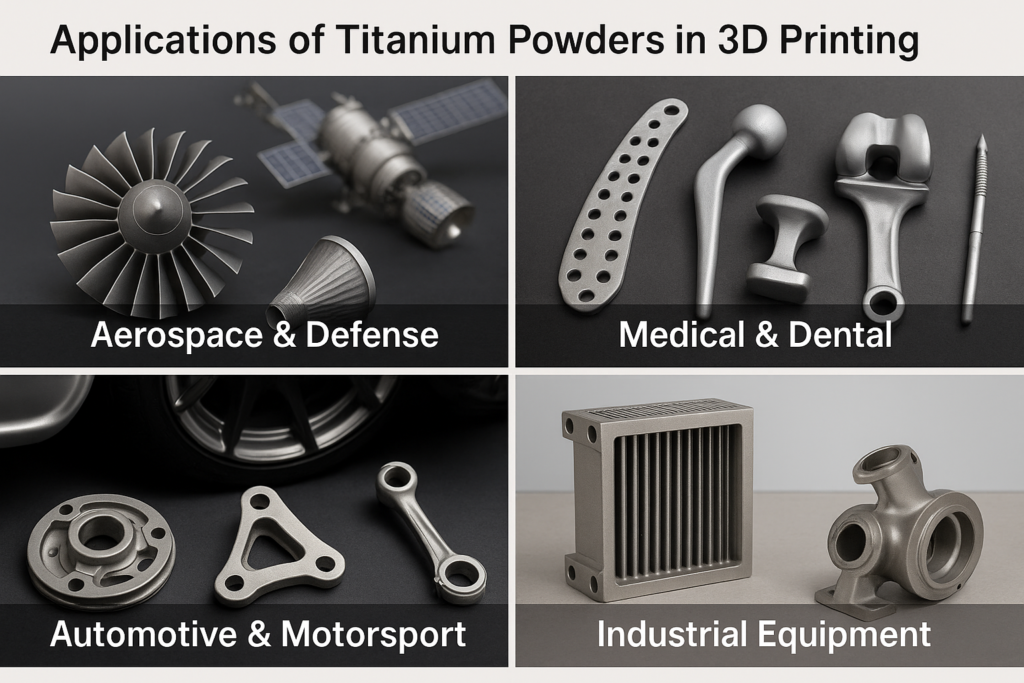

Applications of Titanium Powders in 3D Printing

1. Aerospace & Defense

Titanium powders enable the production of lightweight yet ultra-strong turbine blades, rocket nozzles, and satellite structures. Their high strength-to-weight ratio and heat resistance make them ideal for mission-critical aerospace components where performance and reliability are non-negotiable.

2. Medical & Dental

Thanks to their biocompatibility, titanium powders are used to 3D print custom implants, orthopedic devices, prosthetics, and surgical tools. This ensures patient-specific solutions that are lightweight, durable, and completely safe for long-term use inside the human body.

3. Automotive & Motorsport

In the automotive and racing industry, titanium powders create lightweight engine components, brackets, and performance parts that deliver both strength and speed. They help reduce vehicle weight, improve fuel efficiency, and boost overall performance on the track.

4. Industrial Equipment

3D-printed titanium parts are widely used in heat exchangers, pumps, and chemical processing systems, thanks to their corrosion resistance and durability. They withstand harsh industrial environments, reducing downtime and extending equipment life.

5. Energy Sector

Titanium powders are key in producing offshore drilling tools, turbine components, and nuclear power equipment. Their ability to resist corrosive seawater, radiation, and extreme heat makes them indispensable in energy applications where safety and longevity matter most.

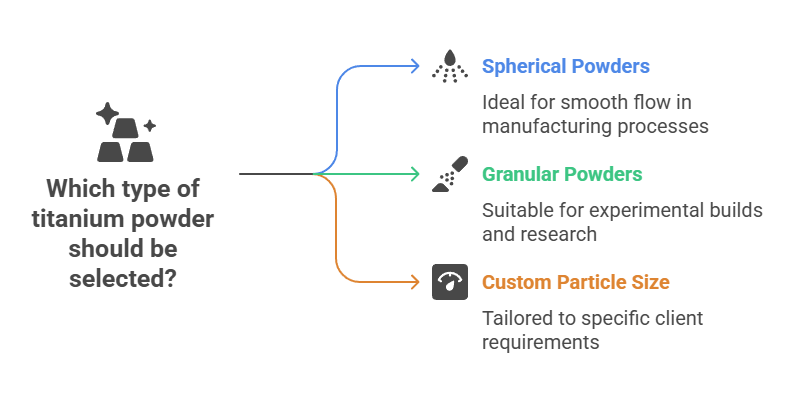

Shapes and Forms Available

DOMADIA™ supplies titanium powders in:

Why Titanium Powders are the Future of Manufacturing

Traditional manufacturing wastes a significant portion of titanium during machining. 3D printing with titanium powders reduces waste by up to 90%, lowers production costs, and enables complex geometries that are impossible with conventional methods.

On top of that, fewer replacements and higher product life cycles mean reduced environmental impact—aligning with global sustainability goals.

At DOMADIA™, we see titanium powders not just as a material but as the key to unlocking smarter, faster, and greener manufacturing.

Conclusion

The future of additive manufacturing is titanium. Its unmatched properties—strength, lightweight, biocompatibility, and sustainability—make it the cornerstone of next-generation industries.

If your business is ready to step into the future of 3D printing, DOMADIA™ titanium powders are your trusted partner in innovation.

📩 Have questions? Talk to us—we’re here to help with expert support and fast responses!

Contact Us– https://domadia.net/contact/

#TitaniumPowder #3DPrinting #AdditiveManufacturing #Aerospace #MedicalInnovation #DOMADIA #FutureOfManufacturing