Blogs

Top 10 Industrial Applications of Tungsten and Its Alloys | DOMADIA™

Introduction: The Metal That Doesn’t Back Down

When the world needs strength, endurance, and performance under extreme conditions — Tungsten steps in. Known for its highest melting point of all metals (3422°C) and incredible density, tungsten and its alloys are indispensable in modern industries.

At DOMADIA™, we supply high-purity tungsten and tungsten alloys that power innovation — from aerospace engines to cutting-edge medical devices. Let’s dive into the top 10 industrial applications of tungsten and its alloys and see why this “unyielding metal” continues to shape the future of engineering.

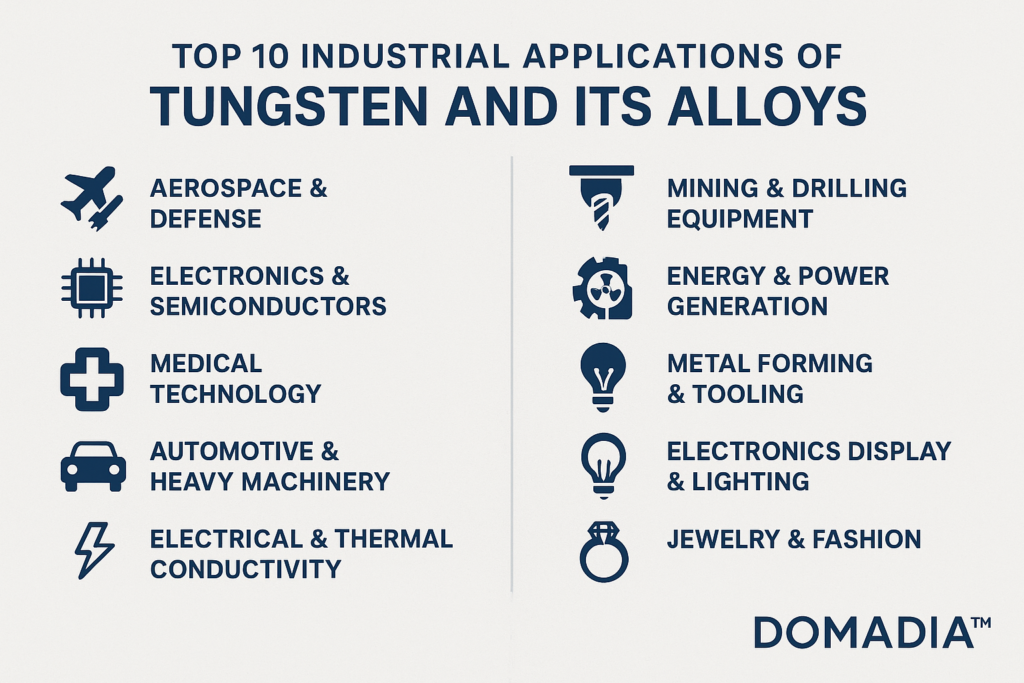

Top 10 Industrial Applications of Tungsten and Its Alloys

1. Aerospace & Defense

Tungsten’s unmatched density and strength make it ideal for aircraft counterweights, missile parts, and kinetic energy penetrators. Tungsten alloys like W-Ni-Fe and W-Ni-Cu provide high strength and resistance to high temperatures — essential for jet turbine blades and armor-piercing projectiles.

Used In:

- Jet engines

- Ballast weights

- Military projectiles

- Aerospace fasteners

2. Electronics & Semiconductors

Tungsten’s excellent electrical conductivity and thermal stability make it a go-to material for semiconductor interconnects, filaments, and contacts. Its low vapor pressure ensures reliability even in vacuum environments.

Used In:

- X-ray tubes

- Electrical contacts

- Integrated circuit chips

Lighting filaments

3. Medical Technology

From radiation shielding to medical imaging, tungsten alloys ensure safety and precision. In CT scanners and radiotherapy machines, tungsten shields protect both patients and operators from radiation.

Used In:

- X-ray shielding

- Collimators

- CT scanner components

4. Automotive & Heavy Machinery

Tungsten alloys are key players in engine valves, crankshafts, and balancing systems due to their high-density performance. They also withstand high wear and mechanical stress in racing cars and heavy trucks.

Used In:

- Engine parts

- Counterweights

- Tooling dies

5. Electrical & Thermal Conductivity

Tungsten’s high thermal conductivity makes it ideal for heating elements, electrical contacts, and thermal management systems.

Used In:

- Electrical contacts

- Heat sinks

Furnace elements

6. Mining & Drilling Equipment

Tungsten carbide — one of the hardest materials on Earth — is extensively used in drill bits, cutting tools, and mining machinery. It ensures durability and performance in the harshest geological conditions.

Used In:

- Mining drill bits

- Cutting tools

Rock crushing equipment

7. Energy & Power Generation

In nuclear reactors, tungsten serves as a plasma-facing material due to its radiation resistance and high melting point. In renewable energy, it’s used in fusion reactors and solar technologies.

Used In:

- Nuclear shields

- Fusion reactors

- Renewable energy components

8. Metal Forming & Tooling

Tungsten carbide tools dominate in cutting, grinding, and forming operations. They last longer, cut faster, and maintain precision, making them a staple in manufacturing industries.

Used In:

- Dies and punches

- Cutting tools

- Milling inserts

9. Electronics Display & Lighting

Before LEDs took over, tungsten filaments lit the world. Even today, tungsten is used in halogen lamps and display components for its stability and brightness.

Used In:

- Halogen bulbs

- CRT displays

- Vacuum tube heaters

10. Jewelry & Fashion

A surprising yet growing market — tungsten carbide jewelry. Known for its scratch resistance and shine, it’s a favorite for men’s rings and watches.

Used In:

- Rings

- Watches

Fashion accessories

Chemical Composition

Typical Tungsten Alloys (W-Ni-Fe / W-Ni-Cu):

- Tungsten (W): 90–97%

- Nickel (Ni): 1.5–5%

- Iron (Fe) or Copper (Cu): 1–4%

Key Properties

| Property | Value |

| Density | 19.3 g/cm³ |

| Melting Point | 3422°C |

| Tensile Strength | Up to 1000 MPa |

| Thermal Conductivity | 170 W/m·K |

| Electrical Resistivity | 5.3 µΩ·cm |

Technical Specifications

- UNS Number: W73000 (Pure Tungsten)

- ASTM Standards: ASTM B777, ASTM F288

- Forms Available: Rods, Plates, Bars, Sheets, Wires, and Powder

- Purity: Up to 99.95%

Shapes & Forms Available at DOMADIA™

- Tungsten Rods – For aerospace and electrical applications

- Tungsten Sheets & Plates – Ideal for shielding and tooling

- Tungsten Wires – Used in lighting and semiconductors

- Tungsten Carbide Powder – For cutting tools and coatings

Applications Across Industries

| Industry | Application |

| Aerospace | Turbine Blades, Ballast Weights |

| Defense | Armor, Ammunition |

| Electronics | Semiconductors, Contacts |

| Medical | Shielding, Imaging Equipment |

| Automotive | Counterweights, Tooling |

| Mining | Drill Bits, Wear Parts |

Conclusion: Why Tungsten Still Dominates

From powering satellites to strengthening tools, tungsten and its alloys remain the backbone of modern industry. Its exceptional density, durability, and heat resistance make it irreplaceable where other metals fail.

At DOMADIA™, we ensure every tungsten product meets global standards (ASTM, ISO) — engineered to last, perform, and protect.

Power Your Industry with Tungsten That Performs.

Get in touch with DOMADIA™ for high-purity tungsten and tungsten alloy products that meet global ASTM standards.

👉 Contact Us Today

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#DOMADIA #TungstenAlloys #IndustrialMaterials #RefractoryMetals #AerospaceEngineering

#TungstenCarbide #MetalIndustry #EngineeringMaterials #HighTemperatureMetals