Blogs

Top Trends in Metal Powder Manufacturing in 2026 and Beyond

Metal Powder Trends 2026 are no longer “nice-to-have upgrades.” They’re quickly becoming the difference between (1) powders that print, sinter, spray, and perform reliably—and (2) powders that look fine on a datasheet but fail on the shop floor.

A real 2026-ish scenario (that’s happening more often)

A production team qualifies a new powder lot for laser powder bed fusion. Chemistry is “within range.” Particle size distribution (PSD) is “close enough.” They start building parts.

Then the build starts coughing:

- flow becomes inconsistent

- spatter increases

- density fluctuates

- post-processing scrap rises

- and suddenly, the “cheaper” powder lot becomes the most expensive decision of the quarter

That pain is exactly why powder manufacturing is shifting fast—toward tighter control, deeper traceability, better morphology engineering, and cleaner supply chains.

Below are the biggest technology trends reshaping metal powder manufacturing for 2026 and beyond—and what buyers should demand.

1) Ultra-tight PSD engineering (narrow bands become the norm)

Powder users are pushing for narrower and more application-specific PSD windows:

- LPBF commonly targets ranges like 15–45 μm (application dependent)

- binder jetting often needs different distributions (and different flow/packing behavior)

- thermal spray may prefer coarser, controlled cuts (again, process dependent)

What’s changing in 2026 is the expectation that PSD control isn’t a “screening step” at the end—it’s engineered throughout production, supported by smarter classification and quality gates.

Why it matters: PSD directly affects flow, packing density, layer uniformity, energy absorption, and defect rates—so tighter PSD equals more repeatable manufacturing.

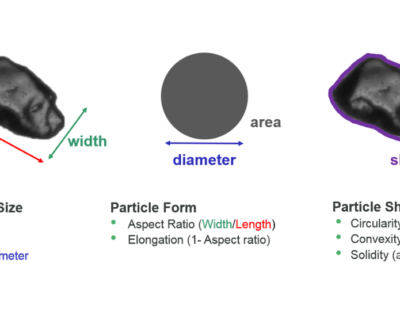

2) Morphology as a design feature (not a byproduct)

In 2026, powder morphology is being treated like a product design parameter:

- spherical powders for consistent flow and uniform spreading

- controlled satellite reduction to avoid poor flow and recoater issues

- engineered surface texture for better packing or controlled sintering

Standards increasingly formalize morphology expectations as part of powder qualification.

3) Plasma, advanced atomization, and “clean melt” pathways keep gaining share

Gas atomization remains dominant, but the direction is clear: cleaner, more controlled atomization routes are expanding, especially for high-performance alloys.

Atomization technology advancements continue to improve uniformity and reduce contamination risk, which is critical for aerospace/medical-grade requirements.

Buyer mindset shift: Stop asking only “Is it spherical?” Start asking “How stable is the melt chemistry? How controlled is oxygen pickup? What’s the traceability depth?”

4) Traceability becomes non-negotiable (powder “passport” thinking)

The powder world is moving toward full documentation and traceability, including:

- sampling plans

- packaging/storage controls

- contamination control

- tracking of reused powder (where applicable)

- chemical + physical characterization linked to lot/batch identifiers

This is strongly aligned with what ISO/ASTM standards emphasize for AM feedstock materials.

For many OEMs, “no traceability” increasingly equals “no purchase order.”

5) Quality control gets more standardized, measurable, and audited

In 2026, powder QC is moving away from vague claims and toward standard test methods and audit-friendly reporting.

One example: apparent density testing for free-flowing powders using the Hall Flowmeter funnel is defined in ASTM standards (commonly referenced by labs and buyers).

Alongside density, buyers are expecting consistent reporting for:

- flowability

- characteristic densities

- contamination limits

- chemical composition windows

- packaging integrity and storage conditions

6) “Green powder” pressure rises: hydrogen metallurgy and low-carbon feedstocks

A major macro trend: decarbonization is pushing innovation upstream—especially in iron/steel pathways that ultimately influence powder feedstock and cost structures.

Hydrogen-based routes (and related low-emission metallurgical innovations) are accelerating globally, backed by large industrial projects and policy pressure.

What it means for powder buyers: “Sustainability” is becoming a procurement requirement, not a marketing line—especially for export-facing manufacturers.

7) Powder reuse optimization becomes scientific (not casual)

In additive manufacturing, powder reuse is under the microscope. The industry is shifting to:

- clearer rules for used powder acceptance

- better contamination monitoring

- controlled blending strategies

- documented lifecycle limits

This aligns with standards that explicitly include guidance/requirements related to used powders in AM contexts.

Chemical composition (what’s changing, practically?)

Powder chemistry isn’t new—but chemistry control is getting stricter because performance windows are getting tighter.

For high-performance alloys (example spotlight: UNS N07718), buyers increasingly demand:

- tighter oxygen/nitrogen limits (process-dependent)

- low tramp elements

- consistent alloying recovery from melt to powder

- documented analysis method + sampling plan

This is exactly where a supplier’s melt practice + atomization environment + handling discipline matters as much as the nominal UNS chemistry.

Properties that are becoming “must-specify” in 2026

Under Metal Powder Trends 2026, powder buyers are no longer accepting generic claims. Specifications are now built around measurable, repeatable properties that directly impact production stability and lifecycle performance.

🔹 Morphology

Powder shape is a critical requirement under Metal Powder Trends 2026, with defined expectations for sphericity, controlled satellite content, and minimal internal porosity to avoid defects and uneven packing.

🔹 Flowability

Hall flow and Carney flow measurements are increasingly specified to match application needs, reflecting how Metal Powder Trends 2026 prioritize predictable powder behavior over broad performance claims.

🔹 Apparent Density / Tapped Density

To achieve consistent packing and densification, Metal Powder Trends 2026 emphasize apparent and tapped density values as essential quality metrics for repeatable builds and sintering outcomes.

🔹 Contamination Control

Oxygen pickup, moisture levels, and foreign particle limits are tightly controlled under Metal Powder Trends 2026, especially for high-performance and safety-critical applications.

🔹 Traceability + Storage

Full lot traceability, controlled packaging, shelf-life documentation, and defined handling procedures are now standard expectations driven by Metal Powder Trends 2026 and ISO/ASTM-aligned procurement practices.

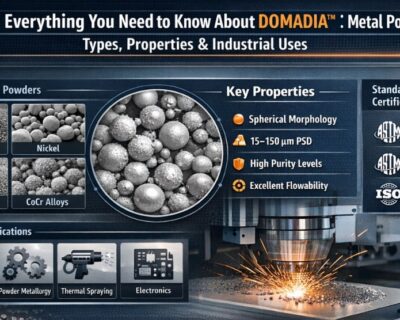

Technical specifications (buyer-ready template)

Here’s a practical spec structure you can copy into RFQs (tailor per process):

- Alloy / Grade: e.g., UNS N07718 / UNS R56400 / UNS S31603

- Process: LPBF / EBM / Binder Jetting / PM Sintering / Thermal Spray

- PSD range: e.g., 15–45 µm (or process-appropriate)

- Chemistry: target composition + max impurities + O/N limits

- Flowability: method + acceptance window

- Density metrics: apparent density method + target range

- Morphology: qualitative + quantitative limits

- Traceability: lot coding, CoA, sampling plan, packaging and storage controls ISO

- Cleanliness: foreign particle control, handling environment expectations

Standards to reference (2026 procurement-ready)

If you want your powder supply to be audit-friendly, these are key anchors:

- ISO/ASTM 52907 (AM metallic powder characterization & technical specs: traceability, sampling, PSD, chemistry, morphology, flow, contamination, packaging/storage)

- ASTM B212 (apparent density of free-flowing metal powders using Hall Flowmeter funnel)

(There are many other ASTM/ISO methods used in powder labs; the point is: write your purchasing specs around recognized methods so “quality” is measurable.)

Shapes available (powder morphologies buyers should know)

In 2026, “shape” isn’t cosmetic—it dictates behavior in printing, pressing, spraying, and mixing.

Common powder morphologies:

- Spherical (often gas/plasma atomized): best flow/spreadability

- Irregular (often water atomized): cost-effective, good for PM applications (process dependent)

- Flake: useful for certain functional/conductive filler applications (geometry-driven)

- Dendritic: high surface area; used in specific functional/thermal/electrical applications

DOMADIA™ supplies metal powders across industrial categories—so the right morphology can be matched to the right process, instead of forcing one powder to do every job.

Applications: where these trends hit first

These innovations show up fastest in:

🔹 Additive Manufacturing (3D Printing)

Metal powder trends impact Additive Manufacturing first because layer-by-layer builds demand exceptional powder consistency. Narrow particle size distribution, stable flow, and disciplined powder reuse directly influence part resolution, density, and build repeatability.

🔹 Powder Metallurgy + Sintering

In powder metallurgy, packing behavior and green strength depend heavily on particle morphology and size control. Advanced powder manufacturing enables uniform densification during sintering, reducing distortion, rejects, and post-processing effort.

🔹 Thermal Spray Coatings

Thermal spray applications rely on precisely classified powder cuts for consistent feed rates and deposition efficiency. Improved flow characteristics and controlled particle size ensure uniform coatings with predictable thickness and adhesion.

🔹 Electronics & Functional Builds Electronics and functional components demand powders with engineered morphology to achieve controlled conductivity and packing behavior. As devices shrink and performance requirements rise, powder consistency becomes critical to electrical and thermal reliability.

The tangible fix: what to do differently in 2026 buying

If you’re sourcing powders in 2026 and beyond, here’s the practical playbook:

1) Ask for the method, not just the number

“Flowability = good” is useless. Ask: which test method, what conditions, what acceptance range?

2) Demand traceability like it’s a critical component

Because it is. ISO/ASTM-aligned documentation reduces firefighting later.

3) Match powder to process—don’t generalize

LPBF powder ≠ thermal spray powder ≠ PM pressing powder. PSD + morphology must fit the use-case.

4) Treat sustainability as operational risk management

Low-carbon metallurgy trends are accelerating; procurement expectations will follow.

Final takeaway

Metal Powder Trends 2026 point to one clear direction: powders are becoming more engineered, more documented, more process-specific, and more sustainability-conscious.

The winners won’t be the teams who buy powder “by price per kg.”

They’ll be the teams who buy powder by performance per lifecycle—and who lock in repeatability through standards, traceability, and fit-for-process specifications.

If your next project involves AM, PM, thermal spray, or functional powder builds, DOMADIA™ can help you shortlist powder grades, morphology, PSD windows, and standards-aligned documentation—so your production doesn’t learn the hard way.Metal Powder Trends 2026 aren’t coming. They’re already here.

Stay Ahead of Metal Powder Manufacturing Trends

Discover how DOMADIA™ supports advanced metal powders aligned with 2026 manufacturing requirements.

👉 Explore DOMADIA™ Metal Powder Solutions

Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#MetalPowders #AdditiveManufacturing #PowderMetallurgy #ThermalSpray #GasAtomization #PlasmaAtomization #ISOASTM52907 #ASTMB212 #Manufacturing2026

Directly whatsapp us for an Enquiry: https://wa.link/kairav