Blogs

Understanding Beryllium Copper Melting Point: An In-Depth Tutorial

Introduction

In the realm of materials science, the melting point serves as a critical benchmark that influences not only the behavior of materials under heat but also their suitability for various applications. For procurement managers and engineers, a profound understanding of melting points is indispensable, particularly when selecting materials like beryllium copper, renowned for its exceptional conductivity and strength. This alloy’s melting point not only dictates processing methods such as casting and machining but also plays a pivotal role in ensuring safety and performance in high-stakes environments, including aerospace and medical sectors.

As industries continue to evolve, the implications of melting points extend beyond mere technical specifications, shaping strategic procurement decisions and enhancing product reliability. This article delves into the multifaceted aspects of melting points, focusing on beryllium copper and its applications, while underscoring the importance of informed material selection in driving operational excellence and safety across diverse industries.

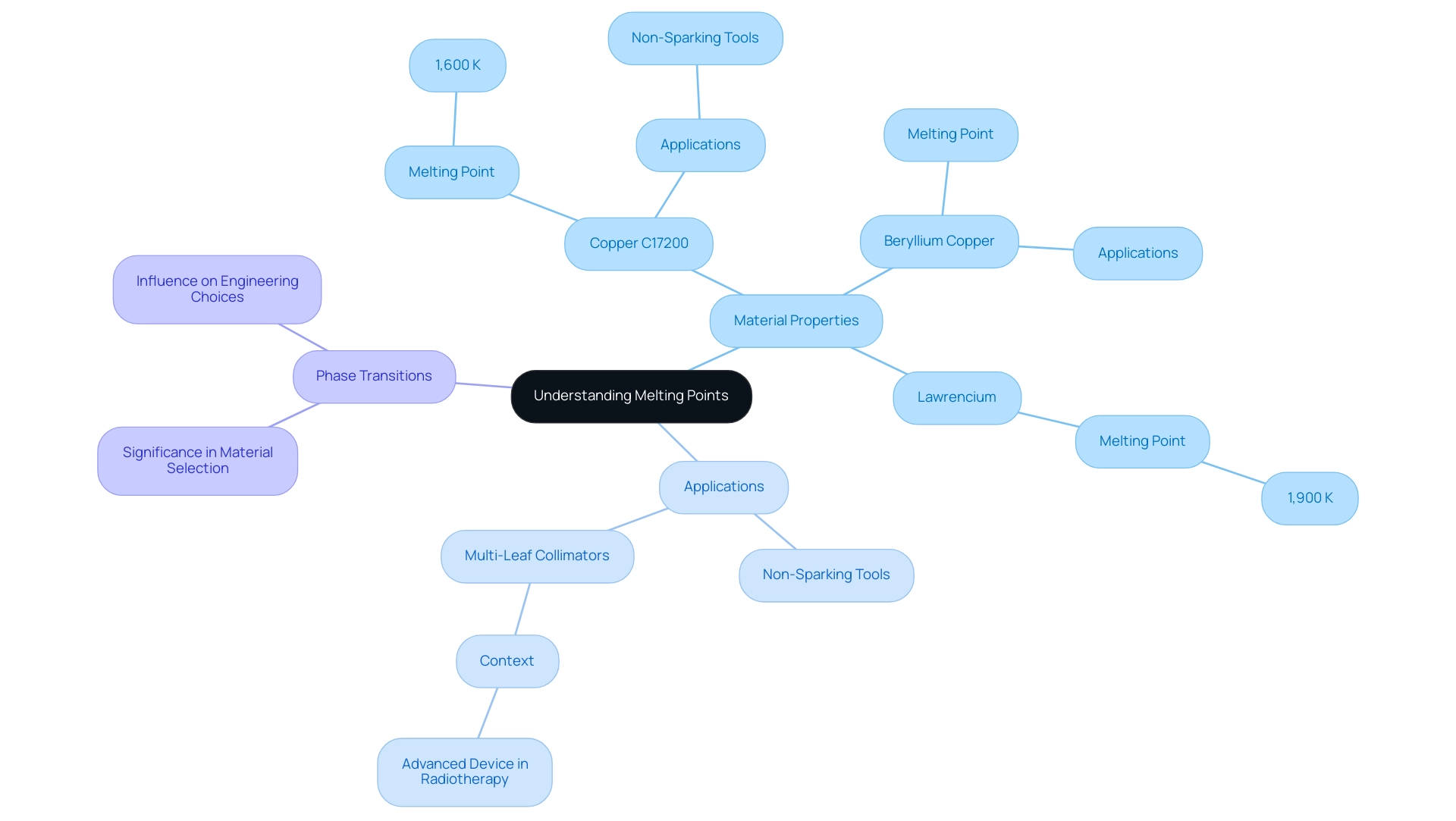

Understanding Melting Points: A Fundamental Concept

The transition temperature is described as the heat level at which a solid changes into a liquid, signifying a crucial feature in materials science. This property significantly influences material behavior under thermal conditions and determines the suitability of materials for specific applications, including Non-Sparking Tools used in explosive environments. For example, Copper C17200 is recognized for its outstanding conductivity and strength, with a fusion temperature of around 1,600 K, rendering it appropriate for uses where both electrical performance and safety are essential.

Understanding the beryllium copper melting point is vital for procurement specialists and engineers, as it plays a significant role in material selection for various manufacturing methods, thermal treatments, and overall effectiveness in end-use applications. Recent advancements in materials science have further clarified the significance of phase transitions, emphasizing their influence on engineering choices and product design. For instance, in the scenario of Multi-Leaf Collimators utilized in radiotherapy, the choice of substances with suitable temperatures ensures optimal performance and accuracy in radiation delivery.

Furthermore, Non-Sparking Tools, vital for avoiding ignition in explosive settings, should also be chosen according to their thermal characteristics, including liquefaction temperatures. Thus, understanding phase transitions not only improves material choices but also guarantees optimal functionality across various sectors, especially in uses demanding strict safety protocols.

The Melting Point of Beryllium Copper: Key Facts and Figures

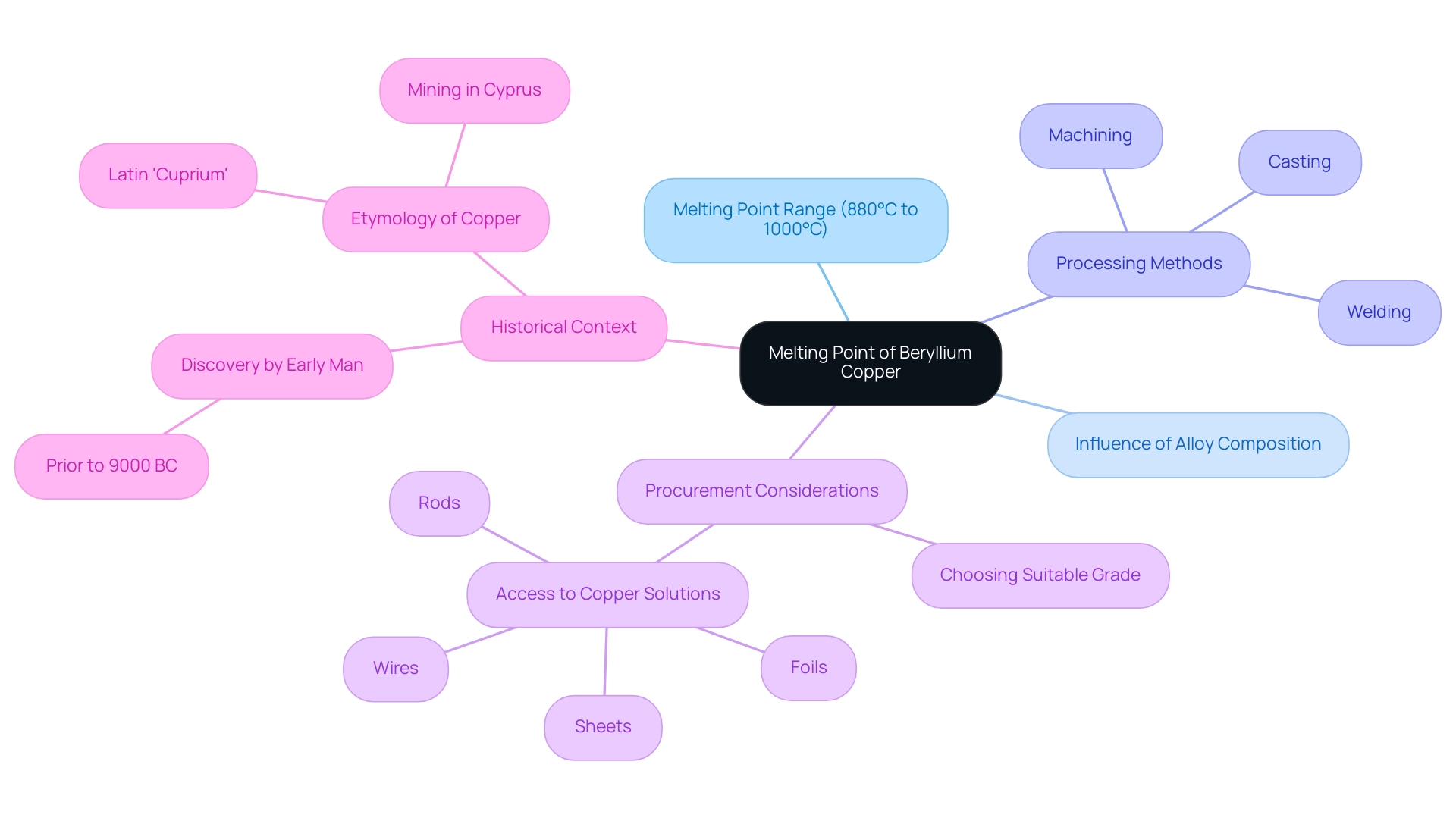

The beryllium copper melting point for alloys typically ranges from 880°C to 1000°C (1616°F to 1832°F), a variation influenced by the specific alloy composition. This fusion range is crucial as it directly impacts processing methods such as casting, machining, and welding. For procurement managers, comprehending these temperature parameters is crucial for choosing the suitable grade of copper for high-performance applications.

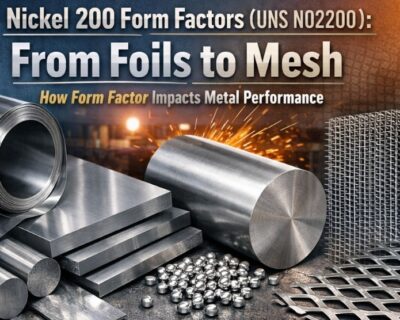

Ensuring that the selected alloy meets the required characteristics of the beryllium copper melting point is vital for achieving optimal performance in end products. Domadia, your reliable partner for copper solutions, offers a wide product range including foils, sheets, rods, and wires, complemented by custom fabrication options tailored to your specific needs. This partnership guarantees you have access to the finest copper solutions available.

Our pricing and inventory details are designed to provide you with the flexibility needed for your projects. Historically, copper has been significant since its discovery by Early Man prior to 9000 BC, as noted: ‘Copper was first discovered by Early Man prior to 9000 BC.’ The term ‘copper’ derives from the Latin ‘cuprium,’ referencing the ancient mining of this metal in Cyprus.

This context highlights the enduring significance of copper and its alloys, particularly the beryllium copper melting point, emphasizing the necessity of accurate temperature knowledge in modern procurement strategies. Furthermore, the case study titled ‘Copper Alloy Overview’ illustrates the versatility of copper alloys, showcasing their suitability for multiple applications including bearing assembly, radiation shielding, and the use of Copper Non-Sparking Wrenches, which are essential for safety in hazardous environments. Recent research on copper processing methods further highlights the importance of comprehending temperature thresholds, as they directly affect the efficiency and effectiveness of production techniques.

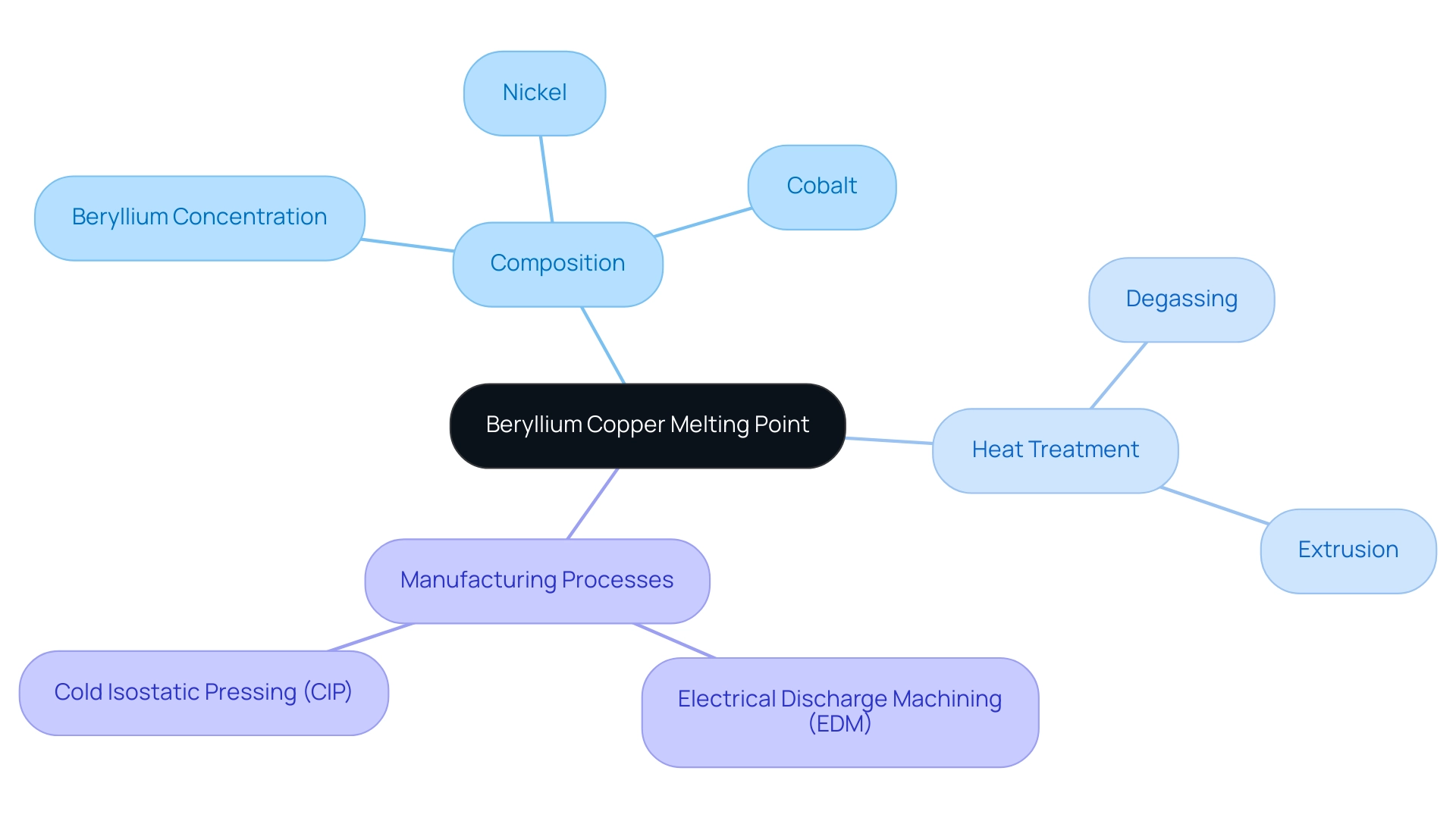

Properties of Beryllium Copper Affecting Melting Point

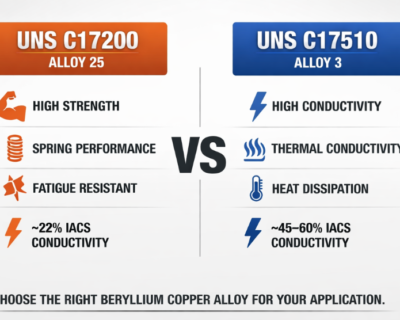

The beryllium copper melting point is greatly influenced by its composition, especially the beryllium concentration, which typically ranges from 0.5% to 2.0%. The influence of additional alloying elements, such as nickel and cobalt, cannot be overlooked, as they also alter the characteristics of the alloy during its fusion. Furthermore, the heat treatment process is essential; it not only influences the physical properties but also modifies the microstructural integrity of the alloy, which in turn affects the beryllium copper melting point.

Recent studies, including work by Lewis et al., highlight that melt spinning techniques can be employed to examine the properties of beryllium copper alloys, particularly emphasizing the beryllium copper melting point and the significance of composition in determining thermal characteristics. Furthermore, the encapsulated billet in the Cold Isostatic Pressing (CIP) process is degassed at elevated temperatures and preheated before extrusion, which plays a vital role in avoiding the melting of the copper-aluminum interface and optimizing the alloy’s performance. The distinctive blend of strength, conductivity, and corrosion resistance in Copper Plates renders them perfect for a range of industrial uses, from electrical connectors to precision components.

The precision of Electrical Discharge Machining (EDM) demonstrated in case studies reveals that this method significantly reduces microstructural strain compared to conventional machining methods, allowing for acceptable production rates while maintaining part integrity. Domadia’s commitment to high-quality Copper solutions is evident in our innovative manufacturing processes, such as advanced heat treatment and quality assurance protocols, positioning us as a leader in the industry. Procurement managers can also benefit from our extensive product offerings, including Copper Strips, available at competitive pricing to support various industrial applications.

Understanding these dynamics is imperative for procurement managers aiming to leverage the advantages of beryllium copper melting point in their projects.

Applications of Beryllium Copper: Why Melting Point Matters

Copper C17200 is increasingly favored in the automotive and electronics sectors due to its remarkable conductivity, strength, and fatigue resistance. These attributes make it an ideal choice for applications including:

- Electrical connectors

- Precision springs

- High-performance tools

Additionally, the use of Non-Sparking Tools in explosive environments adds another layer of safety, making Beryllium Copper crucial in:

- Aerospace

- Oil and gas

- Medical

- Marine

- Cryogenic industries

This showcases its versatility across critical sectors.

A crucial element of the manufacturing procedure is the beryllium copper melting point; maintaining temperatures below this melting point is vital during activities such as soldering and casting to avoid material distortion and maintain performance integrity. For procurement professionals, a thorough understanding of the beryllium copper melting point not only aids in selecting suitable materials but also ensures that the end products meet the rigorous demands of their applications. Moreover, telecommunications firms have acknowledged Copper’s durability and color retention, which enhances its desirability for critical components and contributes to superior product longevity and reliability.

Furthermore, with Domadia’s dedication to delivering high-quality, customized Copper Plates supported by expert assistance, procurement managers can rely on the success of their projects. Domadia provides competitive pricing for Copper Strips, with inventory readily available to meet project demands. It is also vital to consider the health risks linked to exposure to this element, as prolonged exposure can result in severe health problems, highlighting the necessity for safety precautions in the procurement and use of Copper products containing this material.

As one satisfied customer remarked, ‘Domadia’s Copper Plates surpassed our expectations in quality and performance, making them your preferred supplier for all your needs.

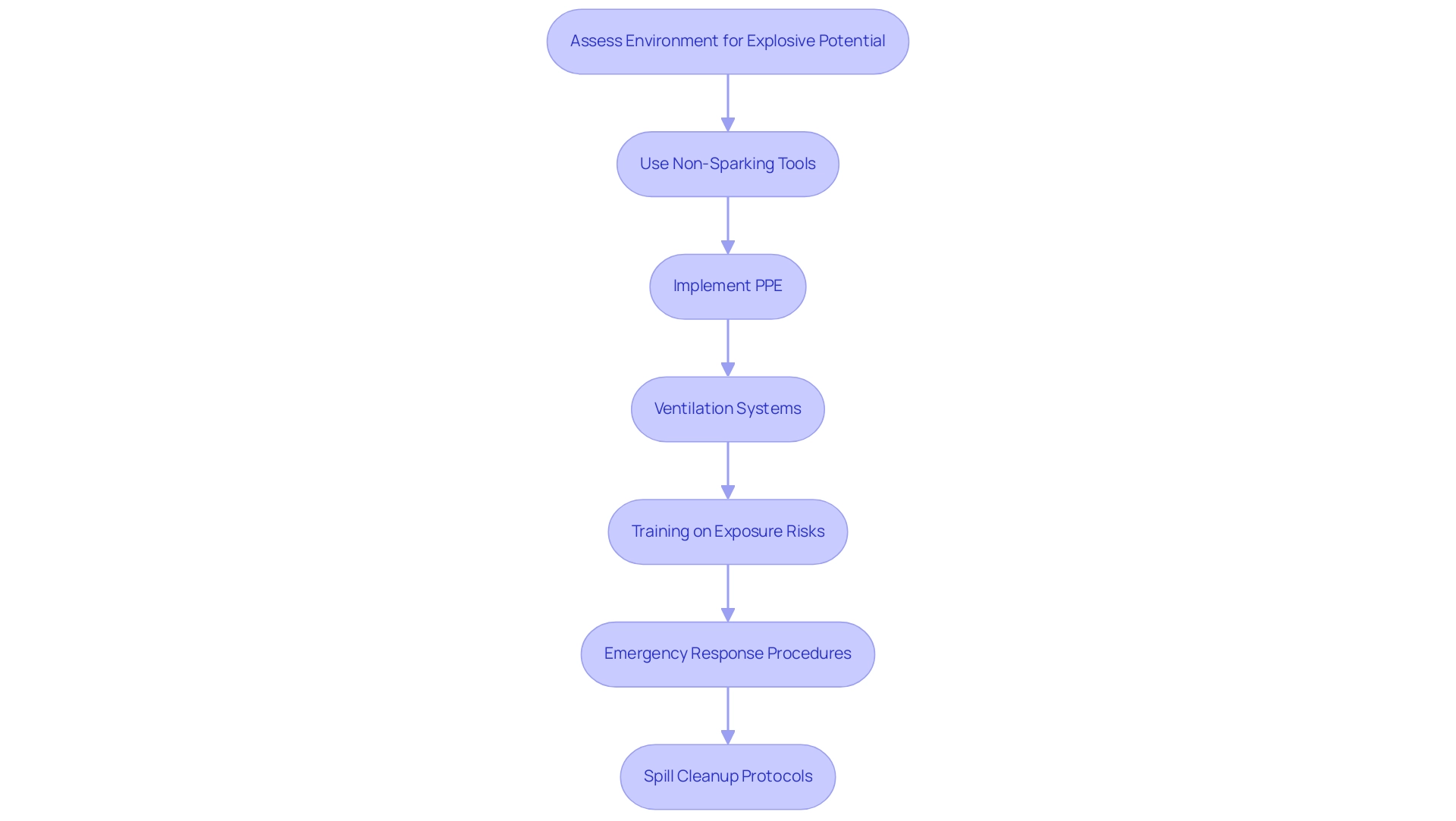

Safety and Handling of Beryllium Copper: Important Considerations

Managing copper alloy requires strict safety measures because of the dangerous characteristics of dust and fumes generated during machining and melting procedures. In explosive potential environments, the use of Non-Sparking Tools, such as Beryllium Copper Non-Sparking Wrenches, is critical due to their unique properties that prevent sparks during use, significantly reducing the risk of ignition in volatile settings. Effective safety measures should include the implementation of personal protective equipment (PPE) tailored to mitigate exposure, along with robust ventilation systems to ensure a safe working environment.

Thorough training for employees on the dangers linked to exposure to beryllium is essential. As highlighted by OSHA, ‘A BWA is a work area where the general industry rule mandates special protections for workers who may be exposed from processes that release this hazardous material.’ This definition highlights the critical need for protective measures.

Additionally, the standardized mortality ratio (SMR) for lung cancer among workers employed before 1965 in Reading is 1.15 (95% CI: 1.00–1.31), underscoring the serious health risks linked to exposure to the element. The case study on Emergency Response to Beryllium Spills illustrates the importance of prompt cleanup to prevent exposure and contamination, establishing clear definitions and procedures for managing spills. By incorporating Non-Sparking Tools into safety protocols, procurement operations not only safeguard employee health but also align with industry compliance standards, reinforcing a commitment to safety and environmental management, especially in scenarios where beryllium exposure may occur.

Conclusion

The significance of understanding melting points, particularly in relation to beryllium copper, cannot be overstated. This alloy’s melting point is a critical factor that influences material processing methods, safety protocols, and overall performance in high-demand applications. With melting points typically ranging from 880°C to 1000°C, procurement managers must ensure that the selected grade of beryllium copper aligns with the specific thermal requirements of their projects. This knowledge not only facilitates optimal manufacturing processes but also enhances the reliability of end products across various sectors.

Furthermore, the diverse applications of beryllium copper—from electronics to aerospace—highlight its versatility and importance in modern industry. The ability to select the right materials based on their melting points ensures that safety measures are upheld, particularly in environments where explosive hazards are present. By emphasizing the need for stringent safety protocols and appropriate handling practices, organizations can mitigate risks associated with beryllium exposure while maximizing the benefits of this high-performance alloy.

In conclusion, a comprehensive understanding of melting points is essential for procurement professionals and engineers alike. Armed with this knowledge, they can make informed decisions that not only enhance product performance but also ensure safety and compliance across various industrial applications. As industries continue to advance, prioritizing informed material selection will be vital in driving operational excellence and innovation.