Blogs

DOMADIA™ NiMn2Cr (NiMn2CrSiTiZr) – The High-Performance Alloy Powering Every Spark

A Spark That Never Fails

From Formula 1 racetracks to freezing Himalayan mornings, engines around the world rely on one consistent miracle — a spark. That spark starts with DOMADIA™ NiMn2Cr, a scientifically engineered alloy built to resist extreme conditions while delivering reliable performance in ignition systems.

Whether it’s a gasoline spark plug or a diesel glow plug, NiMn2CrSiTiZr is the go-to solution for manufacturers who want performance without compromise.

What is DOMADIA™ NiMn2Cr?

DOMADIA™ NiMn2Cr is a Nickel-Manganese based alloy enriched with Chromium (Cr), Silicon (Si), Titanium (Ti), and Zirconium (Zr). Its advanced composition gives it excellent resistance to oxidation, rapid thermal cycling, and mechanical fatigue. Perfectly suited for spark plug and glow plug manufacturing, it is part of a select class of electrical-grade ignition alloys.

Chemical Composition: NiMn2CrSiTiZr

| Element | Percentage |

| Nickel (Ni) | 95% |

| Manganese (Mn) | 2% |

| Chromium (Cr) | 2% |

| Silicon (Si) | 0.5% |

| Titanium (Ti) | 0.3% |

| Zirconium (Zr) | 0.15% |

This combination results in a fine-tuned alloy ideal for high-energy ignition environments.

Applications of NiMn2CrSiTiZr

DOMADIA™ NiMn2Cr thrives in applications demanding extreme reliability:

- Automotive Engines: Spark plugs are essential in gasoline-powered vehicles to ignite the air-fuel mixture.

- Motorcycles: Spark plugs are vital for efficient combustion in motorcycle engines.

- Small Engines: From lawnmowers to generators, small engines rely on spark plugs.

- Aircraft Engines: Spark plugs are used in some aircraft engines for ignition.

- Marine Engines: Spark plugs are used in outboard motors and other marine engines.

- Furnaces and Other Applications: In certain industrial and domestic applications, spark plugs are used to ignite combustible mixtures.

- Spark Plugs – Ensures reliable ignition in gasoline engines

- Glow Plugs – Assists in diesel engine starting under low temperatures

- Heater Elements – Where fast heating and durability are needed

- Electrical Resistors – Due to stable resistance over temperature

Related Alloys & Standards

- Material-No.: Proprietary Grade

- Alloy Designation: NiMn2CrSiTiZr

- Related Alloys:

- Ferrochronin 600

- NiMn4Si

- BR-Ni 99.9

These alloys belong to the spark plug and glow plug material family, engineered for heat and electrical load endurance.

Key Properties

| Property | Value |

| Electrical Conductivity | Medium, optimized for ignition use |

| Thermal Resistance | Extremely high (~1000°C) |

| Oxidation Resistance | Excellent |

| Mechanical Strength | High at both room and elevated temperatures |

| Thermal Expansion | Balanced – perfect for ceramic-metal bonding |

| Corrosion Resistance | Excellent in engine environments |

Technical Specifications

- Working Temp Range: Up to 1000°C

- Density: ~8.4 g/cm³

- Melting Point: ~1425–1450°C

- Resistivity: Stable under rapid temperature cycles

- Hardness: Moderate (engineered for easy machining and forming)

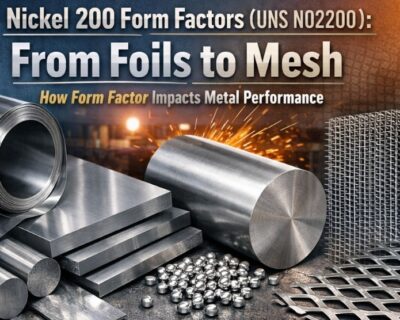

Shapes & Forms Available

We deliver DOMADIA™ NiMn2Cr in the following precision forms:

- Foils – Thin and flexible

- Strips – For automatic plug assembly

- Plates – For machining and design

- Bars & Rods – For customized plug production

- Sheets – Flat stock for multi-use machining

Each form is manufactured under tight tolerance control for consistent behavior during ignition.

Why Choose DOMADIA™ NiMn2Cr?

This isn’t just metal — it’s metallurgy engineered for ignition-grade excellence. With DOMADIA™ NiMn2Cr, you’re investing in:

✅ High spark reliability

✅ Long operational life

✅ Thermal and mechanical resilience

✅ Precision bonding to ceramics and insulators

Fun Fact

The addition of Titanium and Zirconium in this alloy isn’t random. It mimics the micro-alloying technique used in aerospace to prevent crack formation during rapid heating cycles — a perfect hack for extending plug life!

Conclusion

When performance meets metallurgy, you get DOMADIA™ NiMn2Cr. Trusted by top-tier manufacturers and designed for the highest stakes — this is the alloy that sparks the future. Whether it’s a frosty mountain start or a racing lap at full throttle, NiMn2Cr never lets you down.

Connect with DOMADIA Metals to bring the magnetic force of the future into your designs.

Explore our full range ofprecision alloys and engineering materials at https://domadia.net/

Need help choosing the right form factor? Contact our experts today!

Talk to: Kairav Domadia | Aadil Domadia | Er.Pankaj Domadia | Pragati Sanap | Pooja N N | Shivani Kanojia