Blogs

Monel 400 vs Monel K500: The High-Performance Nickel Alloy Showdown | DOMADIA™

Introduction — A Failure That Sparked a Big Question

The offshore platform was just 18 months into its operation when a critical fastener began showing signs of stress corrosion. Engineers were confused — the material used was Monel 400, known for its legendary corrosion resistance.

But the repeated loading, high-velocity seawater, and abrasive impact were slowly eating away at it.

After inspection, the lead metallurgist concluded:

“This application needed something stronger. This needed Monel K500.”

That moment sparked a debate many industries still face today:

When should you choose Monel 400, and when is Monel K500 the smarter choice?

DOMADIA™ breaks it down with science, applications, properties, and industry experience — all in one definitive comparison.

What Are These Alloys?

Monel alloys are nickel-copper alloys known for extreme corrosion resistance, especially in marine and chemical environments.

But Monel 400 and Monel K500 are NOT interchangeable — their mechanical strength, behavior under stress, and long-term durability differ significantly.

Chemical Composition

Monel 400 (UNS N04400)

- Nickel: 63% min

- Copper: 28–34%

- Iron: 2.5% max

- Manganese: 2.0% max

- Sulfur, Silicon: Trace

Monel K500 (UNS N05500)

(Aged-hardenable version of Monel 400)

- Nickel: 63% min

- Copper: 27–33%

- Aluminum: 2.3–3.15%

- Titanium: 0.35–0.85%

- Iron: 2.0% max

- Manganese: 1.5% max

Key Difference:

K500 adds Al + Ti, enabling precipitation hardening, which makes it dramatically stronger than Monel 400.

Mechanical & Physical Properties

Monel 400

- Tensile Strength: 480 MPa

- Yield Strength: 170 MPa

- Hardness: ~65 Rockwell B

- Melting Range: 1300–1350°C

- Density: 8.80 g/cm³

Monel K500

- Tensile Strength: 960–1100 MPa

- Yield Strength: 690–760 MPa

- Hardness: 20–35 Rockwell C

- Melting Range: 1310–1350°C

- Density: 8.44 g/cm³

Key Takeaway:

K500 can be twice as strong as 400, with far greater abrasion and fatigue resistance.

Corrosion Resistance Comparison

Monel 400

- Exceptional resistance to seawater corrosion

- Excellent resistance to hydrofluoric acid, alkalis, neutral salts

- Self-passivating surface

Monel K500

- Same base-level corrosion resistance as Monel 400**

- PLUS improved resistance to:

- Cavitation

- Erosion

- High-velocity seawater

- Stress corrosion cracking

Warning:

In certain conditions, K500 may undergo trace hydrogen embrittlement — proper heat treatment avoids this.

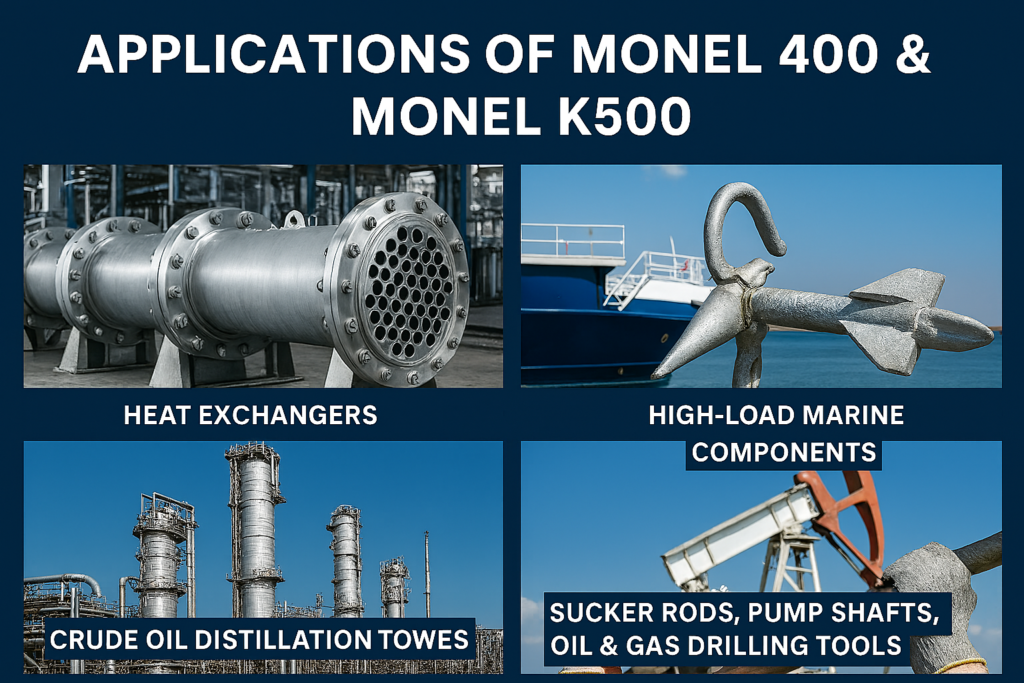

Applications

Where Monel 400 Is Ideal

- Heat exchangers

- Marine fasteners

- Pump and valve components

- Chemical processing equipment

- Crude oil distillation towers

- Freshwater & seawater tanks

- Fuel & water lines

Where Monel K500 Dominates

- High-load marine components

- Sucker rods, pump shafts

- Oil & gas drilling tools

- High-strength springs

- Non-magnetic components in instrumentation

- Fasteners needing strength + corrosion resistance

- Propeller shafts

- Downhole tools

DOMADIA™ supplies both grades in bars, sheets, plates, strips, wires, and custom CNC-machined parts.

Monel 400 vs Monel K500 — Side-by-Side Comparison

| Property / Feature | Monel 400 | Monel K500 |

| Strength | Medium | Extremely High |

| Hardening Ability | Non-hardenable | Precipitation Hardenable |

| Corrosion Resistance | Excellent | Excellent + Better in high-velocity seawater |

| Machinability | Good | Harder to machine |

| Wear Resistance | Moderate | Superior |

| Cost | Lower | Higher |

| Ideal Use | General corrosion | High load, extreme marine, heavy-duty |

Why Monel K500 Costs More — and Why It’s Worth It

Many buyers see the price difference and pause. But engineers know the truth:

✔ Higher mechanical strength

✔ Less downtime

✔ Higher fatigue resistance

✔ Longer product lifecycle

✔ Lower maintenance costs

✔ Less environmental waste due to fewer replacements

In harsh marine & offshore environments, K500 pays for itself by lasting 2–3× longer than Monel 400.

Environmental Impact — A Responsible Choice

Choosing stronger alloys like Monel K500 reduces how often parts need replacement.

This means:

🌍 Less metal waste

🌍 Fewer recycling cycles

🌍 Lower CO₂ output over lifecycle

By selecting the right alloy, industries indirectly support cleaner oceans and greener engineering — a commitment DOMADIA™ strongly prioritizes.

Standards

Monel 400

- ASTM B127, B164

- ASME SB-127, SB-164

Monel K500

- ASTM B865

- ASME SB-865

Shapes Available at DOMADIA™

- Sheets

- Plates

- Coils

- Bars / Rods

- Forgings

- Pipes

- Tubes

- Strips

- Wires

- CNC custom parts

Conclusion — Monel 400 vs Monel K500: Which Should You Choose?

The answer depends on your application — and the Focused Phrase: Monel 400 vs Monel K500 summarizes it best:

- Choose Monel 400 when corrosion resistance is needed without extreme loads.

- Choose Monel K500 when both strength and corrosion resistance are critical for long-term performance.

For industries that value reliability, longevity, and sustainability, Monel K500 becomes the clear long-term winner.

DOMADIA™ is here to supply it with precision, global quality, and engineer-backed support.

Need Custom Mesh Sizes or Weave Patterns? Talk to Our Experts →

📩 Contact DOMADIA™ for OEM, bulk, and customized solutions.

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#Monel400 #MonelK500 #NickelAlloys #DOMADIA #MarineEngineering #OilAndGasMaterials #MetalComparison #HighPerformanceAlloys

Directly whatsapp us for an Enquiry: https://wa.link/kairav