Blogs

Crucible Alloy Performance: The Real Cost Difference Between Crucible and Furnace Alloys

Crucible Alloy Performance is not a “materials spec”—it’s a business decision.

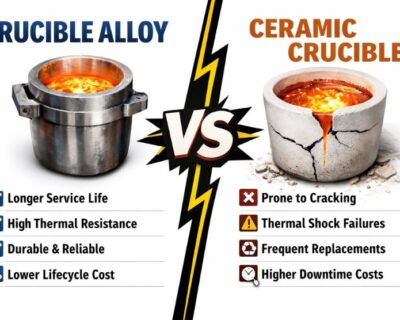

A melting shop in India upgraded its burner, optimized airflow, and repaired the refractory lining. Yet failures continued—early crucible cracking, oxidation scaling along the inner wall, and unplanned changeouts that cost more than the alloy itself through lost heat time, re-melting, labor, and production delays. This is where Crucible Alloy Performance becomes the deciding factor, not furnace settings alone.

That’s the hidden truth: conventional furnace alloys appear economical only at the purchase order stage. When Crucible Alloy Performance is compared against lifecycle cost, downtime, scrap generation, and energy loss, the “cheaper” option frequently turns into the more expensive mistake.

At DOMADIA™, we see this pattern repeatedly in non-ferrous melting, precious metal refining, heat treatment support hardware, and high-temperature chemical processing—where Crucible Alloy Performance directly impacts uptime, reliability, and operating cost.

The real comparison: what are we comparing?

Crucible Alloys

High-temperature alloys engineered for thermal cycling, oxidation resistance, hot strength, and chemical compatibility with molten metals / aggressive atmospheres.

Typical examples:

- Nickel-Chromium-Iron alloy (example grade family: UNS N06601 / N06600 type)

- Heat-resistant stainless and Ni-resist castings depending on application, temperature, and melt chemistry.

Conventional Furnace Alloys

More “standard” heat-resistant steels or stainless commonly used in furnace hardware:

- 309/310 stainless family, basic heat-resistant cast steels, or lower-cost steels used where temperature swings and chemical attack are moderate.

This blog compares them the way operations teams feel it:

Performance → Lifecycle → Total Cost → Environmental impact.

Crucible Alloy Performance: what changes in the furnace (and why it matters)

1) Hot strength and creep resistance

- Crucible alloys maintain usable strength at high temperatures and resist deformation.

- Conventional furnace alloys may soften sooner, leading to distortion, warping, or thinning—especially under repeated cycles.

Result: Crucible alloys hold shape longer, keeping wall integrity and reducing catastrophic failures.

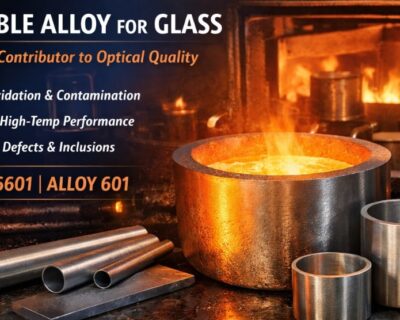

2) Oxidation + scale behavior

- Higher-end crucible alloys form stable oxide layers and resist rapid scale spallation.

- Conventional alloys can form scale that flakes off, exposing fresh metal → accelerated loss.

Result: Less metal loss per cycle, fewer weak points, longer service.

3) Thermal shock and fatigue life

Thermal cycling is the silent killer.

- Crucible alloys are selected for thermal fatigue resistance.

- Conventional alloys often fail earlier when frequent heat-up/cool-down cycles occur.

Result: Longer life in real production schedules, not just lab conditions.

4) Chemical compatibility with melts and atmospheres

Molten aluminum, copper, brass/bronze fluxes, and refining atmospheres can be unforgiving.

- Crucible alloys can be matched to chemistry and atmosphere.

- Conventional alloys may suffer accelerated attack, contamination, or embrittlement.

Result: Reduced melt contamination risk and more stable process output.

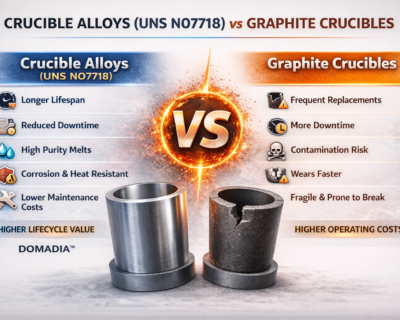

Chemical composition (typical) — Crucible vs Conventional

Below are typical composition ranges used in industry to represent each category (actual selection depends on temperature, melt type, and atmosphere).

A) Crucible Alloy Family Example: UNS N06601 (Ni–Cr–Fe)

Typical chemistry (approx. %):

- Ni: 58–63

- Cr: 21–25

- Fe: balance

- Al: ~1.0–1.7 (oxidation resistance at high temp)

- Minor: C, Mn, Si, Cu (trace-controlled)

Why it’s used: Excellent oxidation resistance and hot strength for high-temperature service.

B) Conventional Furnace Alloy Example: 310-type Heat Resistant Stainless (Fe–Cr–Ni)

Typical chemistry (approx. %):

- Cr: 24–26

- Ni: 19–22

- Fe: balance

- Minor: C, Mn, Si

Why it’s used: Economical heat resistance in many furnace fixtures and moderate-to-high temperature components—often good, but not always ideal for severe thermal cycling or aggressive atmospheres.

DOMADIA™ supports material selection based on temperature band + cycle severity + melt chemistry + atmosphere, not just a generic grade name.

Properties: what buyers should compare (not just “grade”)

Key properties that decide life in production

- Maximum service temperature (oxidizing / reducing)

- Thermal fatigue resistance (cycle life)

- Oxidation & scaling rate

- Creep rupture strength

- Thermal conductivity & heat distribution

- Resistance to carburization / sulfidation (if applicable)

- Contamination risk to melt (critical for refining & quality melts)

Technical specifications

When you buy crucibles or high-temp alloy components, your RFQ should specify measurable requirements—this is where performance becomes predictable.

Technical specification checklist (DOMADIA™ style)

- Alloy grade / UNS (example: UNS N06601)

- Product form: cast / wrought / fabricated

- Wall thickness tolerance (critical for lifecycle predictability)

- Density / soundness (casting quality)

- Surface finish (scale initiation points matter)

- Operating temperature range + cycling profile

- Atmosphere: oxidizing, reducing, inert, vacuum (if applicable)

- Melt type: Aluminum / Copper / Brass / Bronze / Precious metals

- Acceptance tests: dimensional checks, visual, NDT (if required)

Standards (commonly referenced)

Depending on whether the part is wrought, cast, plate, pipe, or fabricated, standards can vary. Commonly referenced frameworks include:

- UNS identification (e.g., UNS N06601)

- ASTM/ASME material standards for nickel alloys and heat-resistant steels (grade-specific)

- Quality documentation: heat/lot traceability, MTC, inspection plans

If you tell DOMADIA™ your temperature + cycles/day + melt chemistry, we guide the most relevant standard route for your product form.

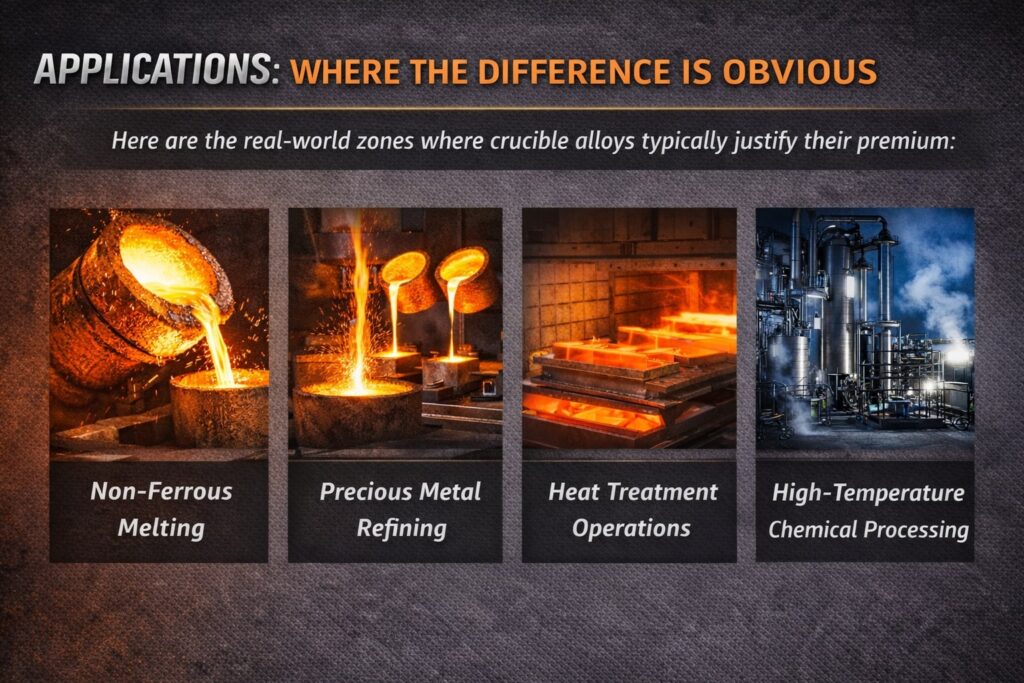

Applications: where the difference is obvious

Here are the real-world zones where crucible alloys typically justify their premium:

Non-ferrous metal melting (Aluminum, Copper, Brass, Bronze)

Consistent Crucible Alloy Performance ensures dimensional stability, minimizes contamination risk, and withstands repeated thermal cycling in continuous melting operations.

• Precious metal refining (gold, silver, platinum)

In refining environments, Crucible Alloy Performance is critical for purity control, oxidation resistance, and preventing chemical interaction with high-value melts.

• Heat treatment operations (fixtures, supports, and furnace hardware)

Repeated heating and cooling cycles place severe thermal fatigue stress on components. Superior Crucible Alloy Performance extends fixture life and reduces distortion-driven downtime.

• High-temperature chemical processing (aggressive atmospheres)

Processes involving oxidizing, carburizing, or sulfidizing atmospheres rely on Crucible Alloy Performance to maintain structural integrity and chemical stability over long service periods.

• Vacuum and controlled-atmosphere furnaces

Here, Crucible Alloy Performance supports low contamination risk and dimensional stability under extreme temperature gradients and reduced oxygen environments.

• Laboratory and R&D melting furnaces

Experimental accuracy depends on repeatable thermal behavior. Consistent Crucible Alloy Performance ensures reliable results and extended component life.

• Continuous foundry operations

In high-throughput foundries, Crucible Alloy Performance directly impacts uptime, replacement scheduling, and overall process reliability.

Shapes available (DOMADIA™ supply formats)

DOMADIA™ can support crucible alloy requirements in multiple forms depending on your build:

- Crucibles (application-specific geometry)

- Rods / bars

- Plates / sheets

- Pipes / tubes

- Wire / mesh

- Rings / forged blanks

- Custom fabricated & machined components

Performance vs Lifecycle vs Cost: the comparison that matters

1) Performance comparison (practical)

Crucible alloys (e.g., UNS N06601 family):

- Better resistance to severe thermal cycling

- Strong oxidation resistance at higher temperatures

- Better shape stability (less creep deformation)

- Lower failure surprises when properly specified

Conventional furnace alloys (e.g., 310-type family):

- Cost-effective for many general furnace components

- Can suffer earlier life reduction under harsh cycling/aggressive chemistry

- Higher chance of scaling/spallation driven thinning in certain regimes

2) Lifecycle comparison (the “how many heats?” question)

A buyer asks: “How many heats will it last?”

Better question:

How many heats will it last without unplanned failure?

Crucible alloy users often report:

- More consistent end-of-life behavior (predictable replacement planning)

- Fewer emergency shutdowns

Conventional alloy users often experience:

- Greater variance (some parts survive, others crack early under the same schedule)

Predictability is money.

3) Cost comparison: purchase price vs total cost of ownership

Let’s be blunt: crucible alloys can cost more upfront.

But the hidden costs of “cheap” are brutal:

Hidden costs conventional buyers pay repeatedly

- Unplanned downtime and heat loss

- Production schedule disruption

- Melt contamination or rework

- Labor for emergency replacement

- Higher scrap + recycling frequency

- Safety risk during unexpected failures

The lifecycle math (simple model)

Total Cost = Purchase + Downtime + Labor + Scrap/Rework + Energy Loss + Risk

Crucible alloys often win because they reduce:

- Downtime events

- Replacement frequency

- Process variability

So even if crucible alloy is, say, 30–80% higher in upfront cost, it can still be the cheaper solution when:

- The furnace runs continuously

- Cycles/day are high

- Quality melts matter

- Changeouts are disruptive

Environmental effect (your operations footprint)

Here’s the part most companies underestimate: Crucible Alloy Performance directly influences environmental impact. The more frequently metal components are scrapped and recycled, the higher the hidden burden—from collection and transport to remelting energy consumption and associated emissions.

Because superior Crucible Alloy Performance delivers longer service life, operations:

- Scrap components less often

- Reduce energy consumed in replacement cycles

- Lower the frequency of disposal and remanufacture

This isn’t marketing language—it’s operational sustainability driven by material performance. At DOMADIA™, long-life alloy selection through optimized Crucible Alloy Performance is treated as a practical step toward reducing waste and unnecessary recycling cycles across high-temperature operations.

The mindset shift: stop buying “alloy”—start buying “uptime”

If your operation is sensitive to:

- downtime cost/hour

- melt quality and contamination

- high cycles/day

- high operating temperatures

…then Crucible Alloy Performance should be treated like a reliability strategy, not a commodity purchase.

Quick selection guide

Choose crucible alloys (UNS N06601-type family) when:

- Thermal cycling is intense

- Oxidation resistance at higher temperature is critical

- Unplanned shutdowns are expensive

- Process consistency and melt integrity matter

Choose conventional furnace alloys when:

- Temperatures and cycling are moderate

- Replacement is easy and planned

- Atmosphere is less aggressive

- Cost pressure is primary and risk is acceptable

Conclusion

Crucible Alloy Performance is the clear difference between simply buying metal and truly buying reliability. When evaluated across performance, lifecycle expectancy, downtime risk, replacement labor, scrap generation, and environmental impact, crucible alloys consistently outperform conventional furnace alloys—delivering value not only technically, but financially as well.

To assess Crucible Alloy Performance accurately for your operation, share these four critical inputs and DOMADIA™ will recommend the most suitable alloy family:

• Operating temperature band

• Cycles per day

• Melt type (Al / Cu / Brass / Precious metals)

• Furnace atmosphere (oxidizing / reducing / inert)

This approach ensures material selection is driven by operating reality, not just initial cost.

Ready to Reduce Furnace Downtime & Replacement Costs?

Choosing between crucible alloys and conventional furnace alloys isn’t about price—it’s about performance, lifecycle, and uptime.

At DOMADIA™, we help you select the right alloy based on temperature, thermal cycles, melt chemistry, and operating environment.

Evaluate your furnace temperature, thermal cycles, melt chemistry, and operating atmosphere – Contact Us to identify the most reliable crucible alloy solution for your application.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#CrucibleAlloyComposition #HighTemperatureAlloys #Metallurgy #IndustrialFurnaces #DOMADIA #ExtremeHeatMaterials

Directly whatsapp us for an Enquiry: https://wa.link/kairav

We’ve supplied to Mumbai, Pune, Indore, Jaipur, and Surat—serving industries across Maharashtra, Madhya Pradesh, Rajasthan, Gujarat, and Goa, with exports to Germany, USA, Japan, South Korea, and Italy.