Blogs

From Molecules to Masterpieces: The Journey of Polyimide Yarn | DOMADIA™

There’s a moment in every industry—electronics, aerospace, automotive or insulation—when a silent hero steps in and transforms an entire product’s destiny. That hero is often Polyimide Yarn. And the journey it takes—from molecular engineering to becoming a high-performance marvel—is nothing short of extraordinary.

Today, let’s unfold the fascinating world of DOMADIA™ Polyimide Yarn, a material born from chemistry but celebrated across industries as a masterpiece of engineering.

Focus Phrase: Journey of Polyimide Yarn

A Suspenseful Start: What Happens When Heat Meets Ordinary Insulation?

A high-voltage motor is running at peak load… temperatures surge… insulation begins to degrade… performance drops… and failure creeps in silently.

But in systems protected by DOMADIA™ Polyimide Yarn, something different happens—nothing fails.

Because before this yarn becomes a masterpiece, it is built molecule by molecule to survive the extremes that no ordinary fiber could tolerate.

The Molecular Beginning: Chemical Composition of Polyimide Yarn

Polyimide yarn’s strength and heat resistance come from its unique aromatic heterocyclic polymer structure.

Typical Chemical Backbone

- Aromatic Dianhydrides (e.g., PMDA, BPDA)

- Aromatic Diamines (e.g., ODA, PDA)

- Imide Rings providing thermal stability

- High Carbon Content for strength

- No halogens making it eco-safe

This powerful structure results in:

- Outstanding thermal endurance

- Inherent flame resistance

- Dimensional stability at extreme temperatures

- Superior electrical insulation performance

DOMADIA™ ensures purity, consistency, and enhanced performance by following global-quality controlled polymerization and spinning processes.

Properties: Why Polyimide Yarn Is Called a “Super Fiber”

Polyimide Yarn is not just strong—it’s engineered for environments where failure is not an option.

Key Properties

| Property | Value / Behavior |

| Heat Resistance | 400–500°C continuous, >550°C peak |

| Flame Retardant | LOI > 28% (self-extinguishing) |

| Electrical Resistance | Excellent dielectric strength |

| Mechanical Strength | High tensile strength & modulus |

| Chemical Stability | Resistant to solvents, fuels, oils |

| Aging Resistance | Retains strength long-term |

| Low Smoke & Toxicity | Ideal for enclosed spaces |

These properties make Polyimide Yarn the preferred choice for high-temperature and mission-critical environments.

Technical Specifications of DOMADIA™ Polyimide Yarn

| Parameter | Specification |

| Denier Range | 140D – 3000D |

| Tensile Strength | 3.0 – 3.5 GPa |

| Elongation | 5 – 8% |

| Thermal Shrinkage | <1% at 250°C |

| Continuous Temperature Use | 450°C |

| Dielectric Strength | > 180 kV/mm |

| Moisture Absorption | <2% |

DOMADIA™ provides customization for industries requiring special mechanical, thermal, or electrical parameters.

International Standards DOMADIA™ Polyimide Yarn Meets

- ISO 9001 & ISO 14001

- ASTM D2101 (Filament Yarn Standards)

- RoHS and REACH Compliant

- UL94-V0 Flame Retardant Rating

- Aerospace Material Standards (AMS)

- IEC 60684 (Electrical Insulation Standards)

These ensure high reliability, global acceptance, and consistent quality.

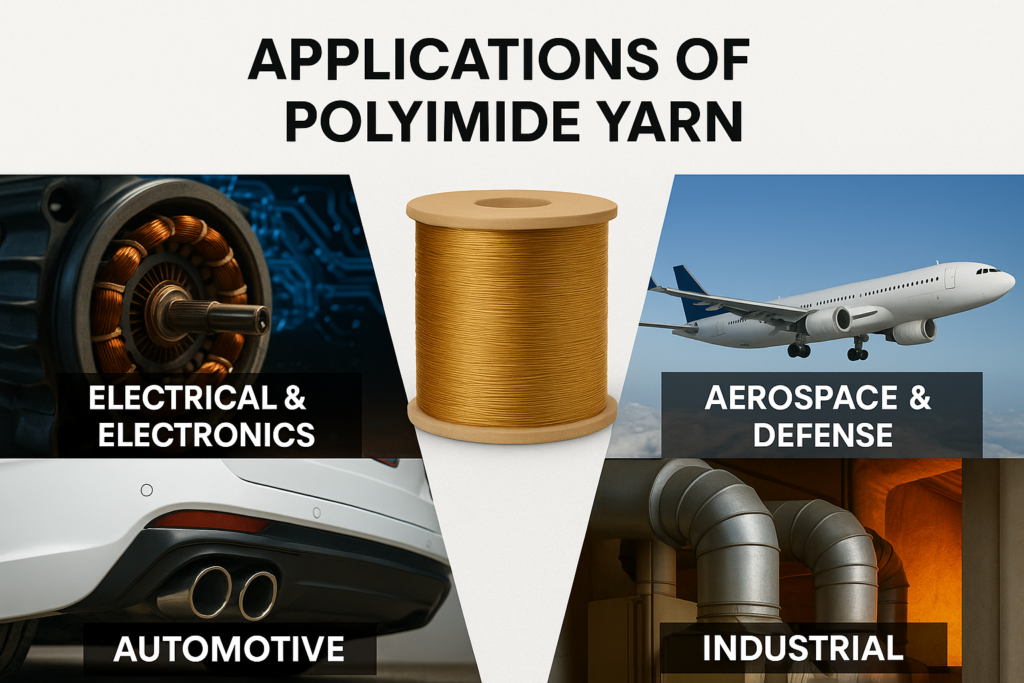

Applications: Where Polyimide Yarn Becomes a Masterpiece

Electrical & Electronics

- High-temperature motor insulation

- Transformer coil wrapping

- EMI-resistant wiring support

- High-voltage cable braiding

Aerospace & Defense

- Heat shields

- Structural composites

- Thermal protection systems

Automotive

- EV motor insulation

- Exhaust heat shielding

- High-temperature harness wrapping

Industrial

- Filter fabrics

- Fire-resistant textiles

- Industrial heating equipment insulation

Protective Clothing

- Fire-retardant garments

- Welding suits

- High-temperature gloves

3D Composites

- Aerospace-grade composite reinforcement

- High-strength molded components

From aircraft to electric vehicles to next-gen electronics—Polyimide Yarn remains the foundation of high-performance reliability.

Shapes & Forms Available

DOMADIA™ supplies Polyimide Yarn in multiple shapes to suit diverse manufacturing needs:

- Continuous Filament Yarn

- Textured Yarn

- Twisted Yarn

- Braided Yarn

- Staple Fiber

- Roving & Tows

- Plied Yarns

Each variant is optimized for tensile strength, flexibility, insulation behavior, and thermal endurance.

Why DOMADIA™ Polyimide Yarn Stands Out

- Manufactured with precision polymer engineering

- Complies with global insulation standards

- Offers superior thermal stability

- Available in custom counts and twists

- Backed by technical support for OEMs

This transforms every molecule into a masterpiece—reliable, durable, and engineered for extreme performance.

Conclusion: The Journey of Polyimide Yarn Comes Full Circle

From molecular design to engineering marvels, the Journey of Polyimide Yarn is a story of resilience, innovation, and performance.

With DOMADIA™ Polyimide Yarn, industries get a fiber that doesn’t just withstand heat—it thrives in it.

A material that doesn’t merely insulate—it elevates every application it touches.

Upgrade to High-Performance Polyimide Yarn Today

Experience the unmatched thermal stability, electrical insulation, and long-life performance of DOMADIA™ Polyimide Yarn.

Perfect for high-temperature motors, aerospace systems, EV components, and next-gen industrial applications.

Enhance reliability. Reduce failures. Power innovation.

👉 Get a Quote from DOMADIA™

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#DOMADIA #ElectricalInsulation #CrepePaper #KraftPaper #TransformerInsulation

#EngineeringMaterials #IndustrialSolutions

Directly whatsapp us for an Enquiry: https://wa.link/kairav