Blogs

Molybdenum vs Tungsten: The Power Duo of Vacuum Furnaces | DOMADIA™ Guide

Introduction – The Hidden Heroes Behind Extreme Heat

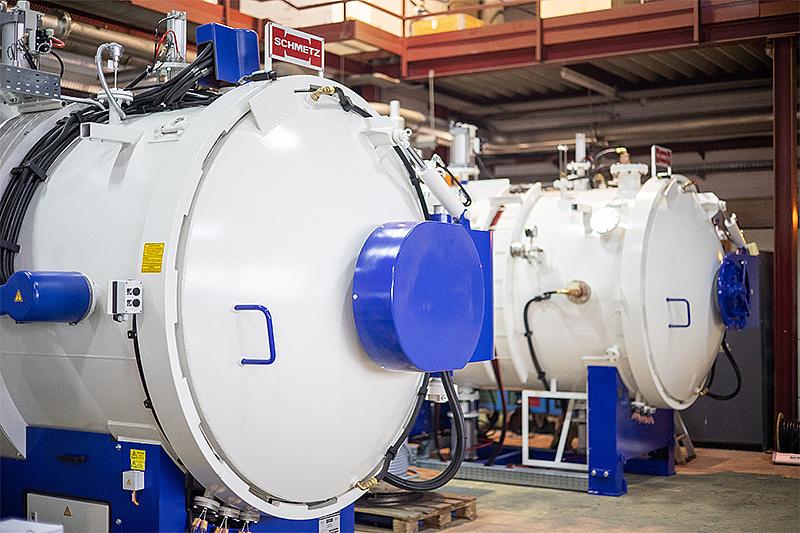

Step inside a vacuum furnace, and you’ll enter a world where temperatures soar beyond imagination — high enough to melt most metals. Yet, amid this furnace inferno, two champions stand tall: Molybdenum and Tungsten. These refractory metals are the backbone of industries that rely on heat treatment, sintering, brazing, and vacuum deposition, where precision and durability are non-negotiable.

At DOMADIA™, we know that choosing the right material can make the difference between flawless operation and costly downtime. That’s why understanding the strengths of molybdenum and tungsten is key for anyone working with high-performance vacuum furnaces.

Molybdenum in Vacuum Furnaces – The Cost-Effective High Performer

Melting Point: 2,623°C

Specialty: High temperature strength, thermal uniformity, and cost efficiency.

- Heating Elements – With outstanding thermal stability, molybdenum resists degradation through countless heating cycles in vacuum or inert gas.

- Thermal Shields – Reflects heat efficiently back into the work zone, reducing power consumption while ensuring uniform temperatures.

- Molybdenum Boats & Trays – Perfect for holding materials during sintering and evaporation processes.

- Corrosion Resistance – Excels in reducing or inert atmospheres, providing long service life with minimal maintenance.

Tungsten in Vacuum Furnaces – The Ultra-High Temperature Titan

Melting Point: 3,422°C

Specialty: Extreme heat endurance, high density, and unmatched strength.

- Heating Elements for Extreme Heat – Performs flawlessly in operations exceeding 2,500°C, such as sapphire crystal growth or superalloy processing.

- Thermal Shields Beyond Mo’s Limit – Maintains shape and function in the most demanding furnace conditions.

- Structural Components – Supports heavy loads inside hot zones thanks to its high density and strength retention at elevated temperatures.

- Evaporation Sources – Offers unmatched stability for thin-film deposition in electronics and semiconductors.

Side-by-Side Comparison – Mo vs W

| Property | Molybdenum (Mo) | Tungsten (W) |

| Melting Point | 2,623°C | 3,422°C |

| Cost | Lower | Higher |

| Max Operating Temp | ~2,500°C | 3,000°C+ |

| Oxidation Resistance | Excellent in vacuum/inert gas | Excellent in vacuum/inert gas |

| Density | Moderate | Very High |

Applications in Vacuum Furnaces – DOMADIA™ Precision at Work

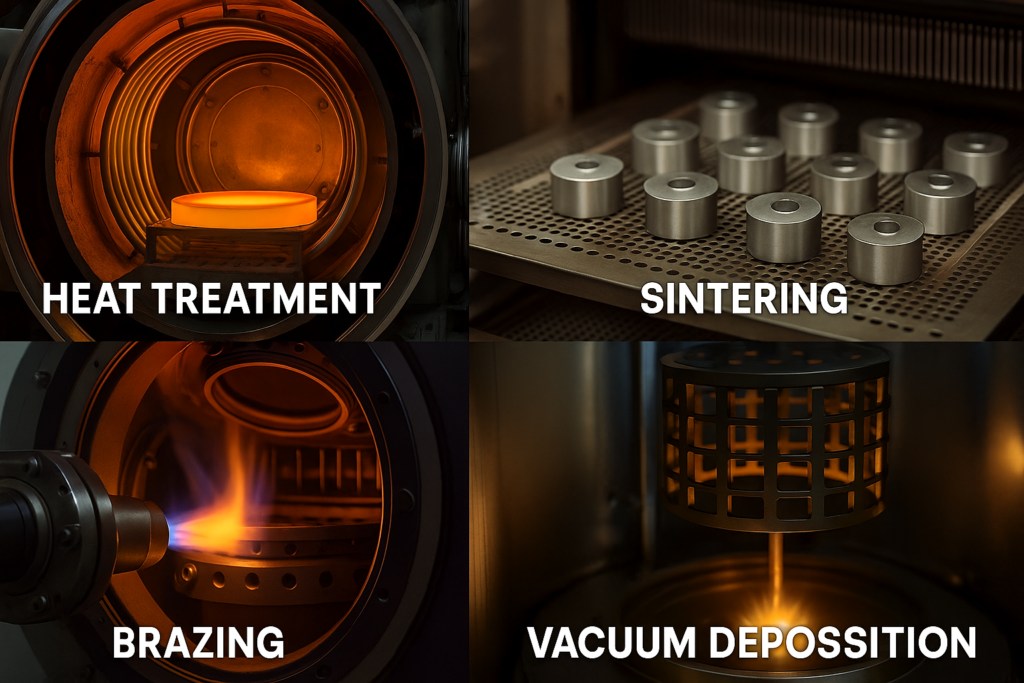

Heat Treatment – For hardening, tempering, and annealing metals with flawless temperature control and oxidation-free results.

Sintering – Converts powders into dense, high-performance solids for superalloys, ceramics, and wear-resistant parts.

Brazing – Delivers clean, strong joints for aerospace, electronics, and complex assemblies without contamination.

Vacuum Deposition – Enables precision thin-film coatings for electronics, optics, and semiconductors with high-purity results.

Mo or W? DOMADIA™ Helps You Heat Smarter, Last Longer

If your processes demand cost-effective, high-performance heat handling, Molybdenum is your go-to. For extreme temperature endurance and unmatched durability, Tungsten is the champion.

By choosing the right metal for your furnace hot zone, you’re not just boosting efficiency—you’re cutting downtime, reducing replacements, and contributing to a more sustainable industrial process. At DOMADIA™, we supply precision-engineered molybdenum and tungsten products designed to deliver unmatched performance in the world’s toughest environments.

Conclusion – Harness the Power of Mo & W with DOMADIA™

In the extreme world of vacuum furnaces, every degree, every cycle, and every component matters. Molybdenum and Tungsten aren’t just materials—they’re the foundation of reliability, efficiency, and long-term performance. Where Molybdenum delivers cost-effective versatility, Tungsten brings unshakable strength at the highest temperatures.

The real advantage lies in choosing wisely for your application—and that’s where DOMADIA™ becomes your trusted partner. With our expertise in precision-engineered refractory metals, we ensure your furnace operates longer, consumes less, and delivers the results your industry demands.

Ready to heat smarter, cut downtime, and achieve unmatched results?

Connect with DOMADIA™ today and explore our tailored solutions in molybdenum and tungsten for your next vacuum furnace challenge.

Contact our experts today!

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#Molybdenum #Tungsten #VacuumFurnace #DOMADIA #HeatTreatment #Sintering #Brazing #ThinFilmDeposition #HighTemperatureMetals