Blogs

MuMetal Annealing Process Guide | UNS N14080 | DOMADIA™

MuMetal Annealing Process: Why Permeability Depends on It

A precision electronics lab once faced repeated EMI failures—even after installing MuMetal shields. The alloy composition was correct. The design was sound. Yet performance remained inconsistent.

The root cause wasn’t design.

It was improper annealing.

The MuMetal Annealing Process is not an optional step—it is the defining factor that determines whether UNS N14080 delivers world-class magnetic permeability or behaves like an ordinary nickel alloy.

At DOMADIA™, we treat annealing as a performance science, not a routine heat cycle.

What Happens to MuMetal Before Annealing?

MuMetal (UNS N14080) is extremely sensitive to:

- Cold working

- Bending and forming

- Cutting, stamping, and welding

These processes introduce mechanical stress and lattice distortion, locking magnetic domains in random orientations. The result?

❌ Drastically reduced permeability

❌ Poor shielding effectiveness

❌ Unpredictable EMI leakage

The MuMetal Annealing Process exists to reverse this damage completely.

What Is the MuMetal Annealing Process?

Annealing is a controlled heat treatment performed in a hydrogen atmosphere that restores the alloy’s crystal structure and aligns magnetic domains for effortless magnetization.

When done correctly, annealing can increase permeability by hundreds of times compared to the as-fabricated condition.

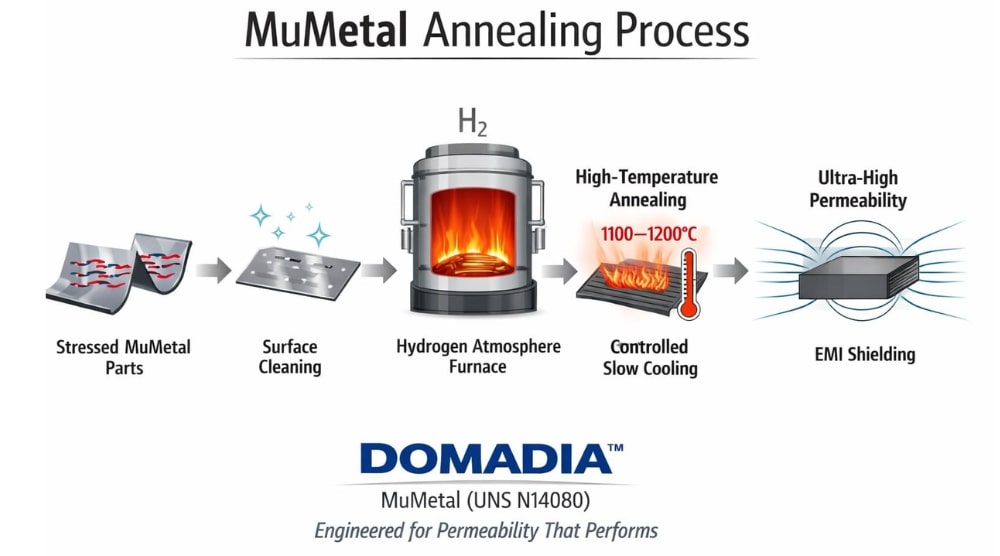

Step-by-Step MuMetal Annealing Process (Industry-Proven)

1. Pre-Annealing Cleaning

Before heating, MuMetal must be:

- Free from oil, grease, fingerprints

- Free from oxides or contaminants

Even minor surface contamination can degrade permeability during annealing.

2. Controlled Hydrogen Atmosphere

Annealing must be carried out in:

- Dry hydrogen or vacuum environment

- Oxygen content kept near zero

Why hydrogen?

- Prevents oxidation

- Reduces existing oxides

- Promotes clean grain boundaries

This step is critical for achieving ultra-high permeability.

3. Precise Temperature Control

Typical annealing temperature for MuMetal:

- 1100°C to 1200°C

This range allows:

- Stress relief

- Grain growth

- Magnetic domain realignment

Exceeding or undershooting this range can permanently reduce performance.

4. Soaking Time

The material is held at peak temperature long enough to:

- Fully relax internal stresses

- Achieve uniform grain structure

Thickness, shape, and geometry determine soak duration.

5. Controlled Cooling (Non-Negotiable)

Cooling must be:

- Slow

- Uniform

- Hydrogen-protected

Rapid cooling reintroduces stress and negates the entire process.

Why Improper Annealing Ruins MuMetal Performance

Many shielding failures occur because:

- Annealing is skipped entirely

- Atmosphere control is poor

- Cooling rates are rushed

- Post-annealing handling is careless

Even a perfectly annealed MuMetal sheet can lose permeability if bent or drilled afterward.

That’s why DOMADIA™ provides annealing guidance matched to real-world fabrication needs.

Key Properties Achieved After Proper MuMetal Annealing

| Property | Result |

| Magnetic Permeability | Extremely High |

| Coercivity | Ultra-Low |

| Shielding Effectiveness | Maximum |

| Magnetic Loss | Minimal |

| Stability | Long-Term |

The MuMetal Annealing Process transforms UNS N14080 from a sensitive alloy into a reliable shielding solution.

Standards Engineers Trust

Proper annealing aligns MuMetal performance with:

- ASTM material practices

- Aerospace EMI shielding norms

- Medical and metrology compliance requirements

DOMADIA™ ensures materials are supplied annealing-ready, with composition consistency critical for repeatable results.

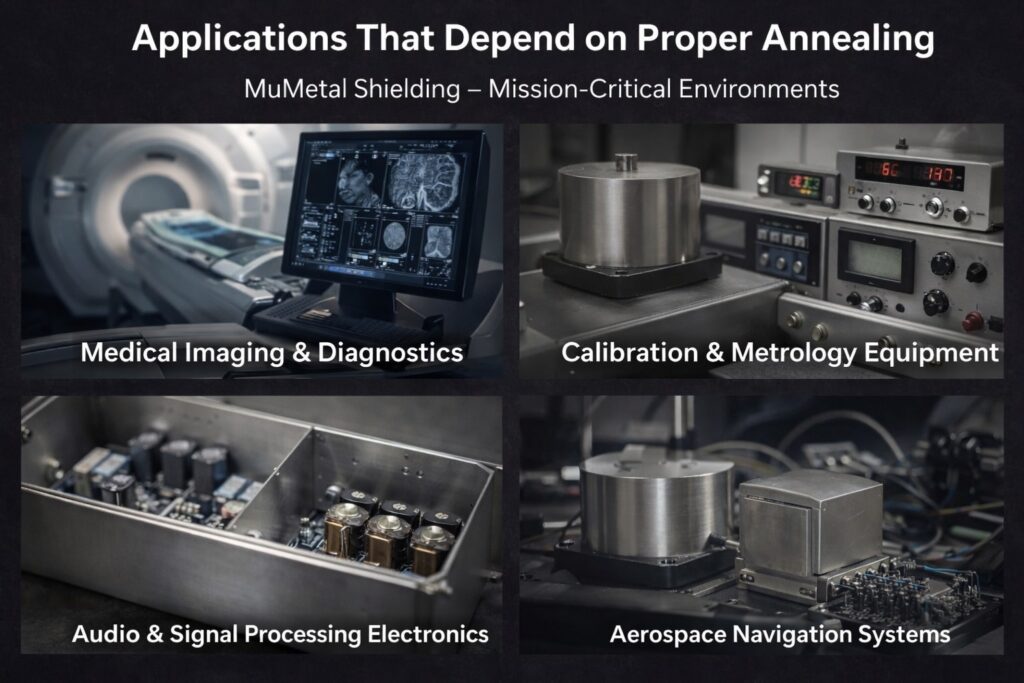

Applications That Depend on Proper Annealing

Without correct annealing, these applications fail:

- Medical imaging and diagnostics

- Calibration and metrology equipment

- Audio and signal processing electronics

- Aerospace navigation systems

- Quantum and research instruments

In these environments, shielding is not optional—it is signal insurance

Shapes Available for Annealing | DOMADIA™

DOMADIA™ supplies MuMetal in forms suitable for post-fabrication annealing:

- Sheets and plates

- Foils

- Strips

- Cylinders

- Custom-formed enclosures

Each geometry requires tailored annealing parameters for optimal permeability.

Environmental Perspective: Annealing Done Right Lasts Longer

Improperly annealed MuMetal:

- Fails sooner

- Requires replacement

- Increases scrap and recycling cycles

High-performance annealing extends service life—reducing material waste and environmental impact.

At DOMADIA™, longevity is part of sustainability.

Final Takeaway: MuMetal Annealing Process Defines Performance

The MuMetal Annealing Process is the decisive factor that separates theoretical material properties from real-world magnetic shielding success. It is not a routine heat treatment or a box to be checked during fabrication. Proper annealing is a precision-controlled operation that directly determines magnetic permeability, shielding effectiveness, regulatory compliance, and long-term reliability in critical applications.

Choosing MuMetal without understanding its annealing requirements risks compromised performance and costly failures. Selecting materials that are compositionally correct, annealing-ready, and supported by technical expertise ensures consistent results in demanding environments. Choose materials prepared for success. Choose standards trusted by engineers. Choose DOMADIA™ MuMetal (UNS N14080)—engineered for permeability that performs where precision matters most.

Shielding performance doesn’t come from alloy names—it comes from how the material is prepared.

Choose DOMADIA™ MuMetal.

📩 Contact us today to get custom sizes and specifications for your project.

Talk to: Er.Pankaj Domadia | Kairav Domadia | Aadil Domadia | Pragati Sanap | Pooja N N

#MuMetalAnnealingProcess #MuMetalUNSN14080 #MagneticShielding #EMIShielding #DOMADIA #HighPermeabilityAlloy

Directly whatsapp us for an Enquiry: https://wa.link/kairav